LED (light-emitting diode) support and manufacturing method thereof

A technology of an LED bracket and a manufacturing method, which is applied in the field of LED brackets, can solve the problems of easy loosening of conductive terminals, waterproof LED brackets, poor moisture-proof effect, and unsuitable use of outdoor products, etc., so as to achieve the effect of improving waterproofing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

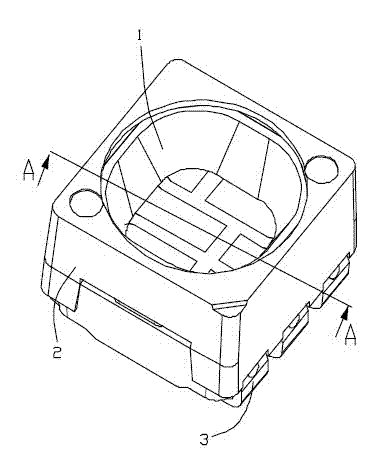

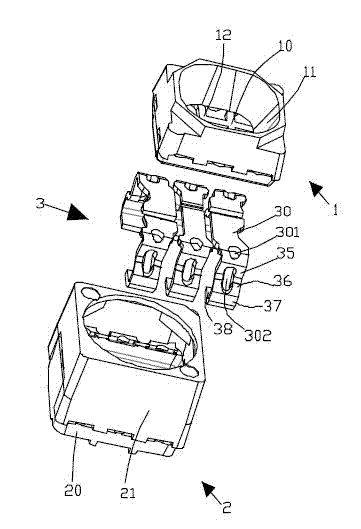

[0019] see Figure 1 to Figure 4 ,and Figure 9 As shown, the LED bracket of the present invention includes a first insulating body 1, a second insulating body 2 formed and covered outside the first insulating body 1, and at least one integrally formed in the first insulating body 1 and the second insulating body 2 A pair of conductive terminals 3 .

[0020] The first insulating body 1 includes a base plate 10 and a first peripheral wall 11 extending upward from the periphery of the base plate 10. The base plate 10 and the first peripheral wall 11 together form an open-ended enclosure for encapsulating LED chips. Accommodating cavity 12.

[0021] The second insulating body 2 includes a bottom 20 formed under the bottom plate 10 of the first insulating body 1 , and a second peripheral wall 21 extending upward from the bottom 20 and covering the first peripheral wall 11 .

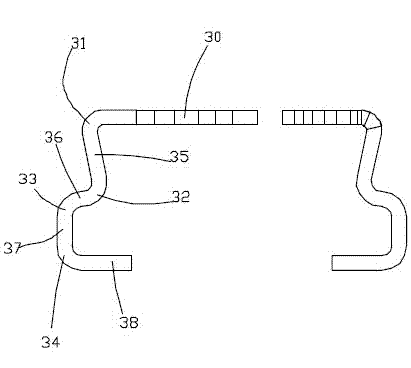

[0022] Each of the conductive terminals 3 includes a solid welding area 30, a first bent portion 31 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com