Valve bag sealing machine

A technology of valve bag and sealing machine, which is applied in packaging sealing/fastening, external support, transportation and packaging, etc. It can solve the problems of complex design, inability to feed materials in place at one time, and low quality of stitching, and achieves simple structure, reasonable design, The effect of uniform and stable feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

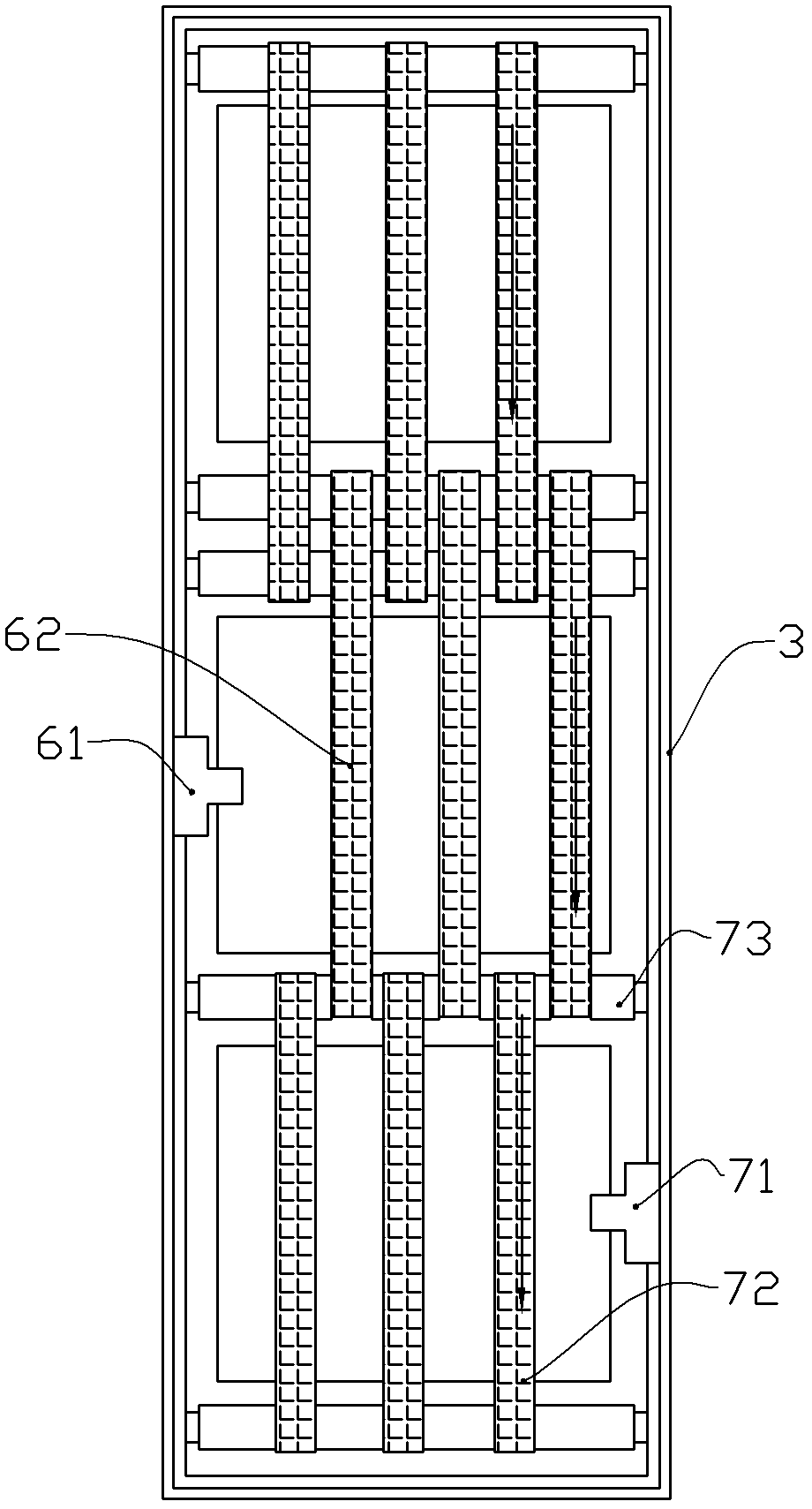

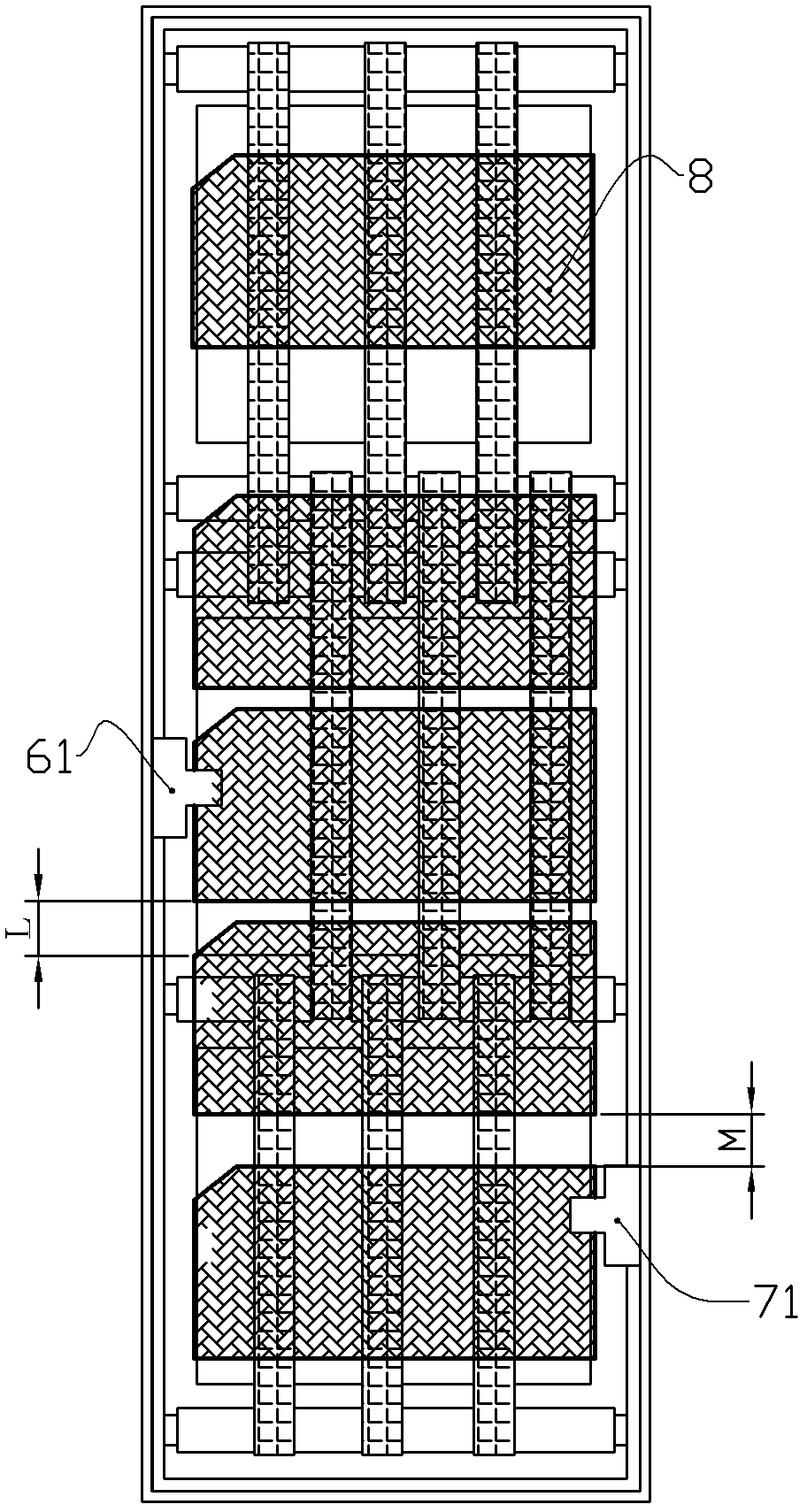

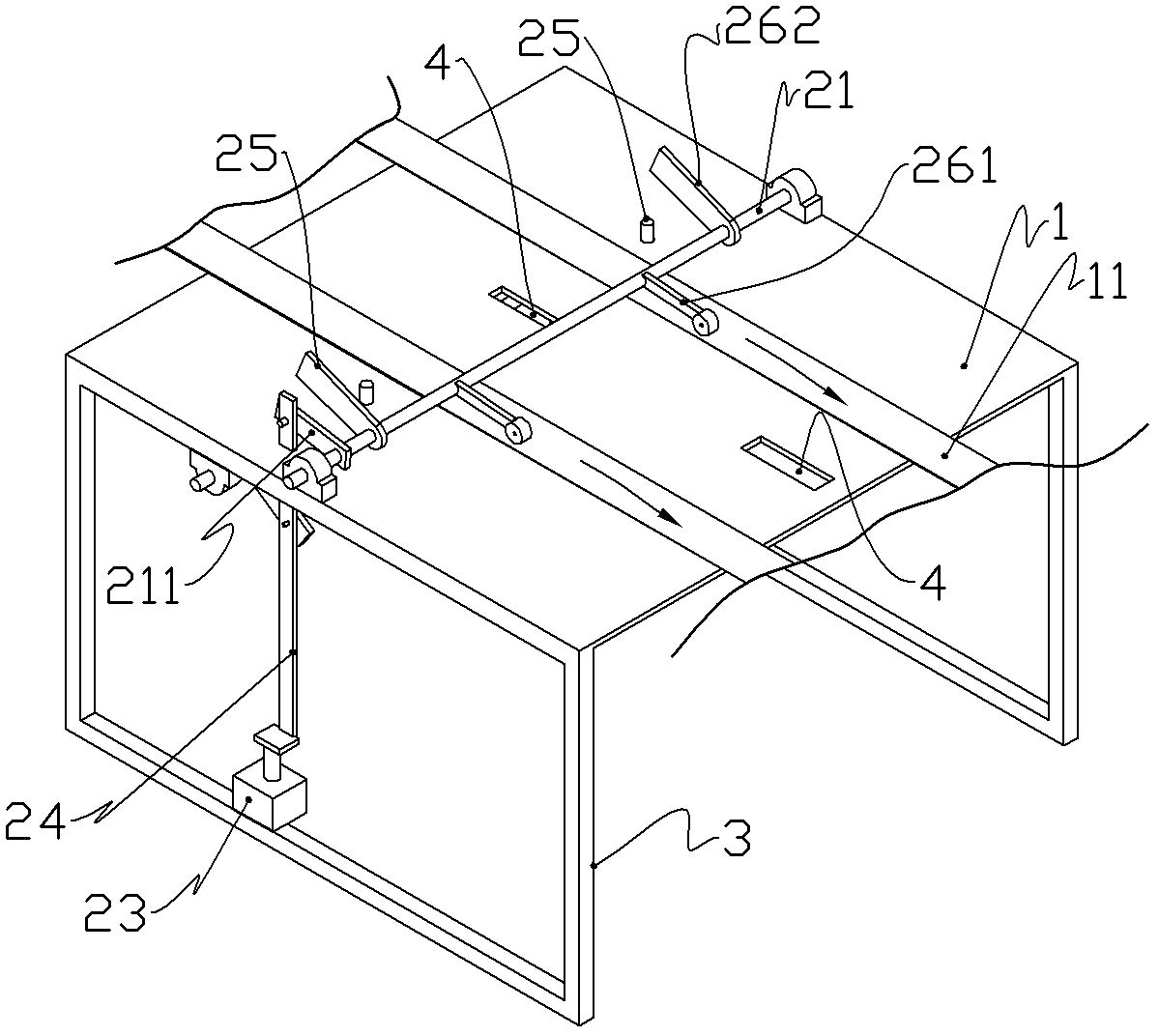

[0018] like Figure 1 ~ Figure 2 as shown, figure 1 The arrow in the figure indicates the transmission direction of the belt. A valve bag sealing machine includes a frame 3 and a feeding part, a sealing part, and a sealing bottom installed on the frame in sequence. The feeding part is used for uniform feeding, and only one piece is fed at a time The valve pocket blank is also provided with a valve pocket finishing mechanism at the end of the cover.

[0019] Feeding section comprises the first belt conveying device 11 and feeding mechanism, and the first belt conveying device is made up of front and rear rotating shaft, conveyor belt and driving motor, identical with existing belt conveying device.

[0020] like Figure 3 ~ Figure 7 As shown, the feeding mechanism is an auxiliary device of the valve bag sealing machine. It includes a stacking platform 1 and a feeding mechanism. The stacking platform 1 is a thin steel plate. The stacking platform 1 is welded on the upper side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com