Dynamic and static pressure conical bearing with wedged dovetail cavities

A tapered bearing, dynamic and static pressure technology, applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of unsuitable for the use of the main shaft system of mechanical equipment, unsuitable for the main shaft system of rotating mechanical equipment, and difficult to ensure the neutrality of the oil chamber. , to achieve the effect of easy adjustment of oil film gap, efficient throttling method, and enlarged effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

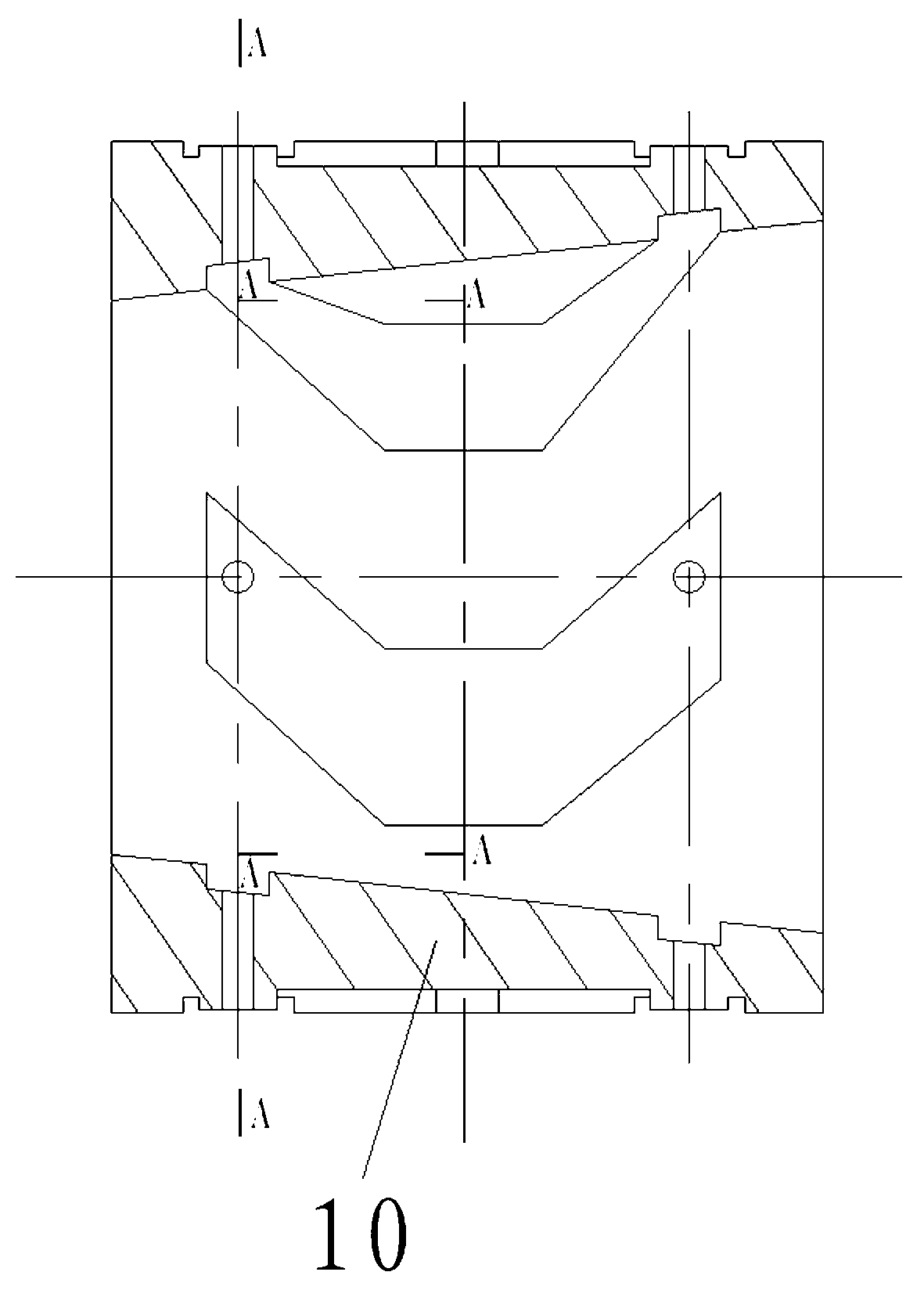

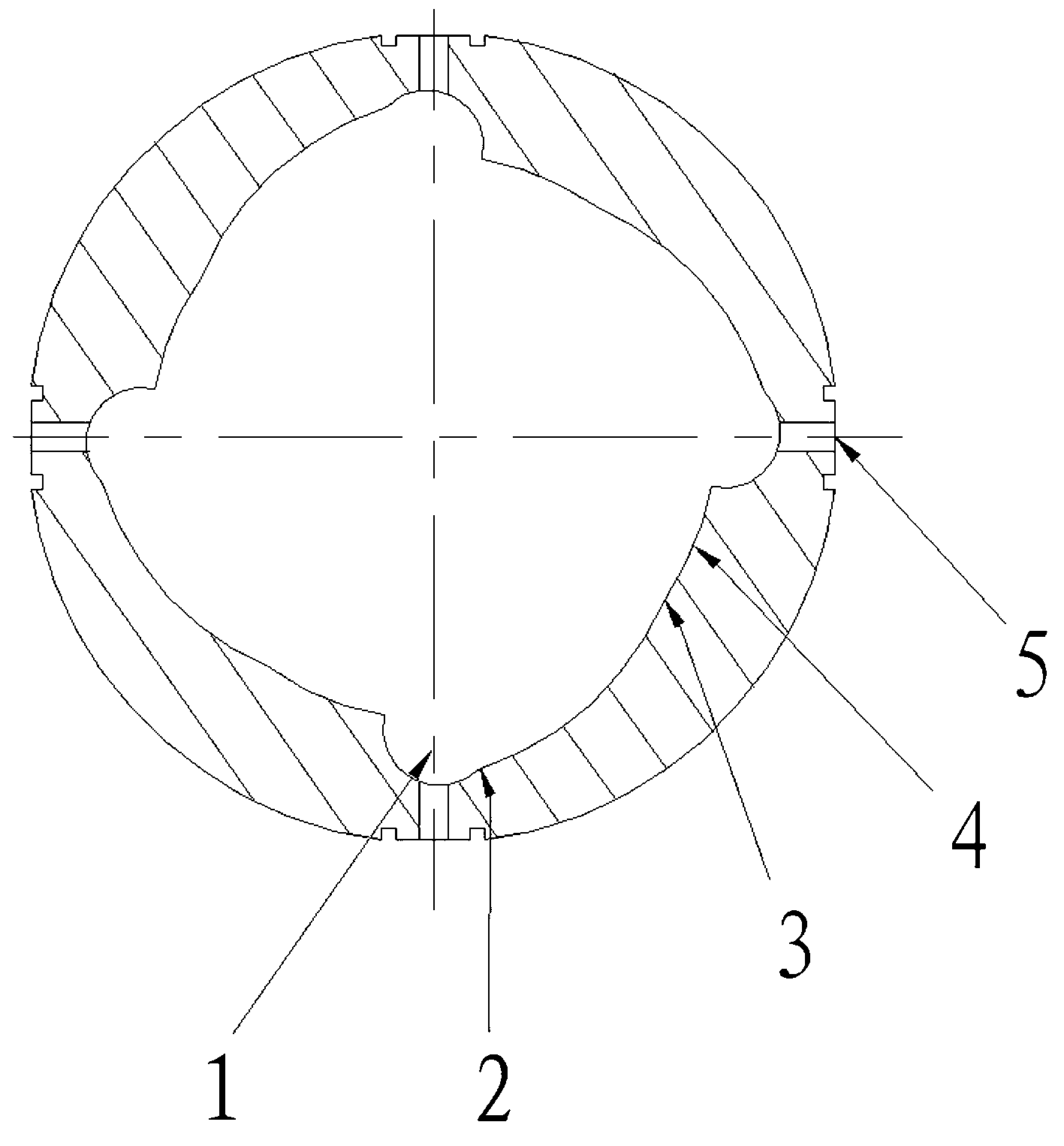

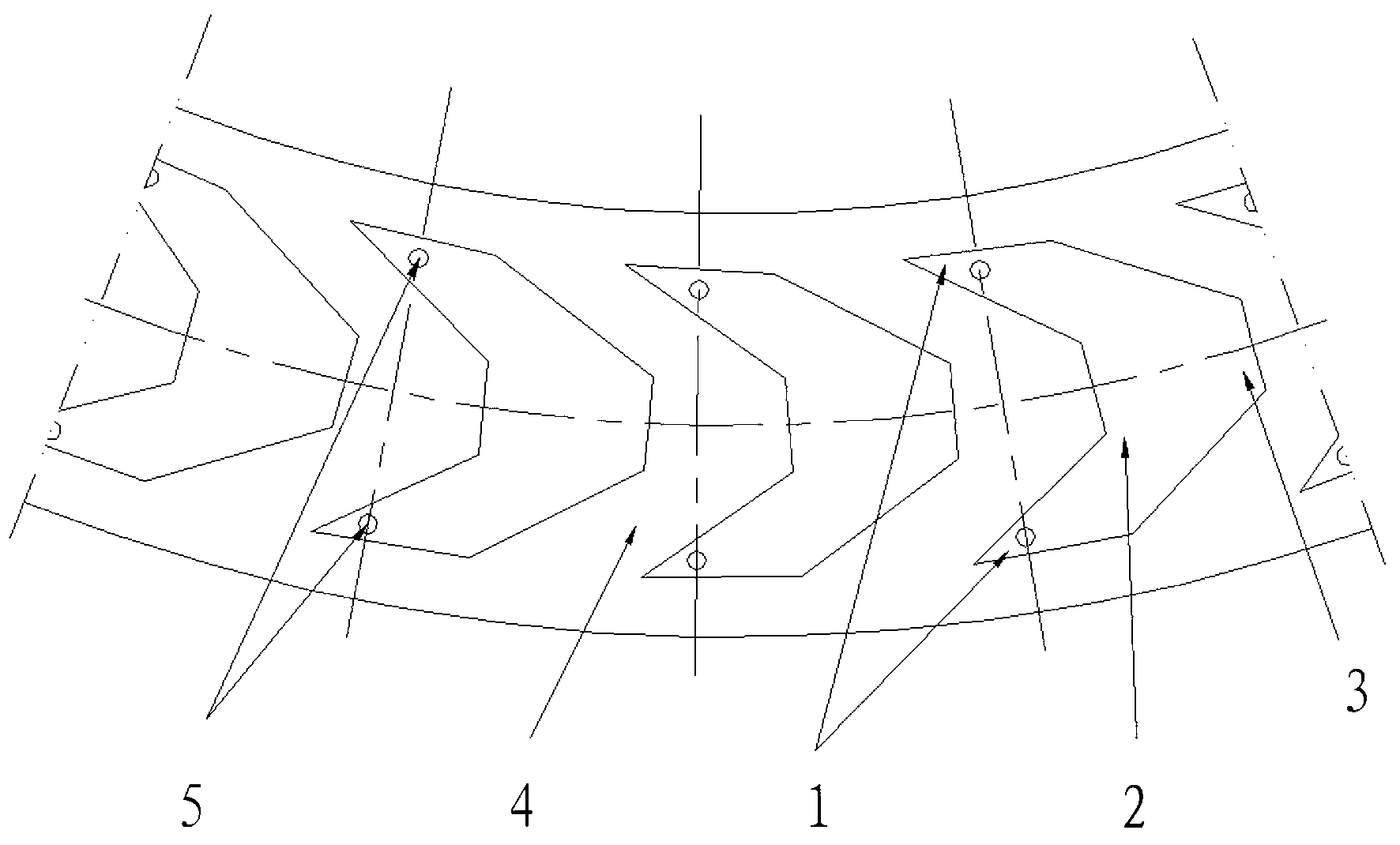

[0013] Example: such as Figure 1-4 As shown in the wedge-shaped dovetail chamber dynamic and static pressure tapered bearing, an oil film is formed between the main shaft and the bearing bush 10, the inner surface of the bearing bush 10 is an inner cone surface, and four oil chambers with a wedge-shaped dovetail cavity structure are evenly arranged on the inner cone surface along the circumferential direction, each The wedge-shaped dovetail cavity includes a deep cavity area 1, a wedge-shaped cavity large end area 2 and a wedge-shaped tip area 3. The edge of each oil cavity is an oil sealing edge 4, and each deep cavity area 1 is provided with two oil inlets connected to the oil supply groove. The hole 5; the outer surface of the bearing bush 10 is cylindrical, and there are an annular small-end oil supply groove 11 and an annular large-end oil supply groove 8, and the small-end oil supply groove 11 and the large-end oil supply groove 8 are throttled through the ring gap 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com