Straight line type air compressor

An air compressor, linear technology, applied in the field of air compressors, can solve the problems of complex overall structure, low transmission efficiency, and large volume of air compressors, and achieve the effects of light weight, improved efficiency, and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

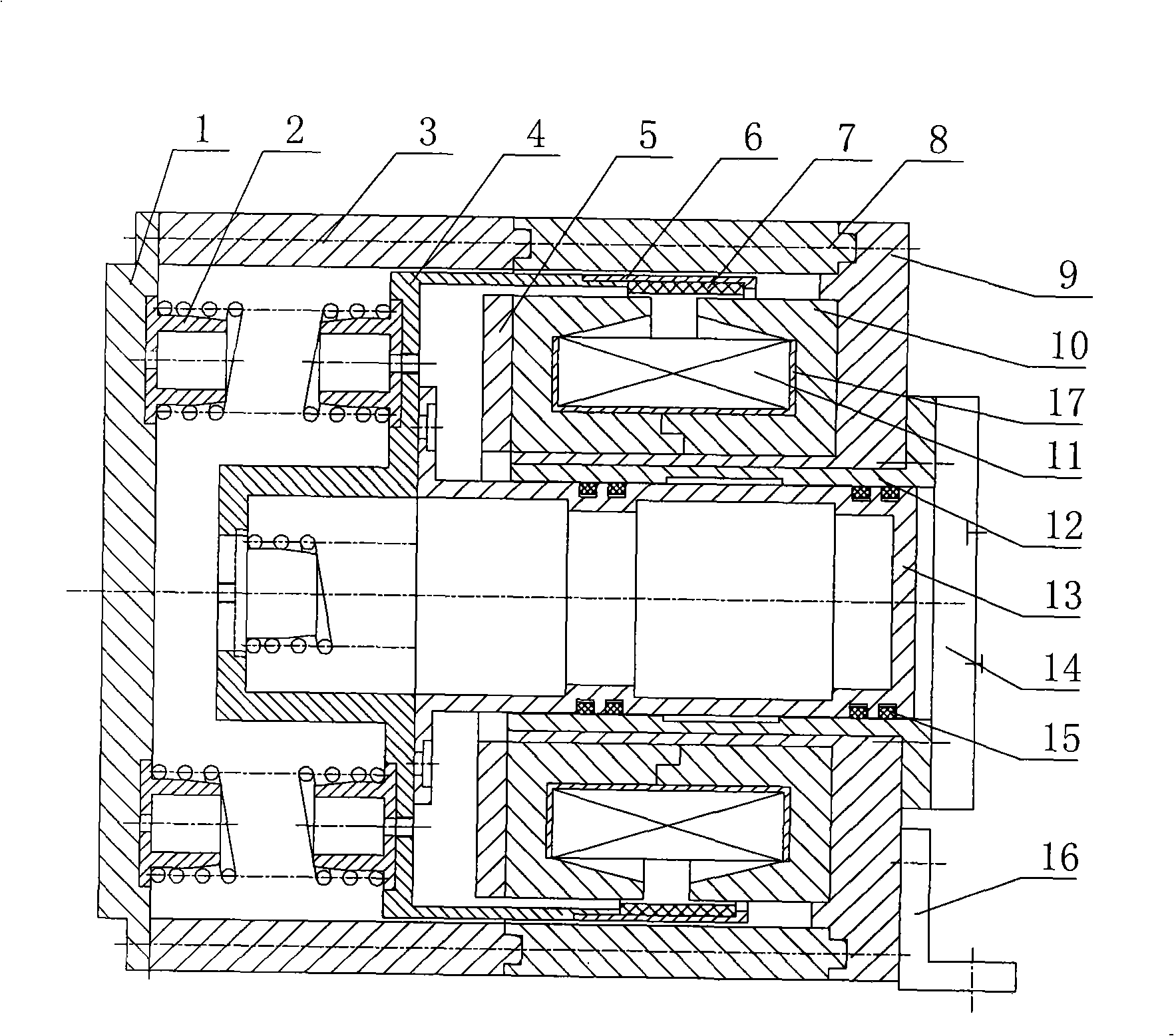

[0024] See Figure 2 ~ Figure 4 This embodiment includes the cylinder 12, the piston 13, the suction and exhaust valve assembly 14, the mover bracket 4, the outer end cover 1, the resonance spring 2, and the inner yoke part, the outer yoke part and the magnet part, the piston 13, the mover The bracket 4 and the magnet component form a motor mover. The piston 13 is located in the cylinder 12 and is fixed to the mover bracket 4. The suction and exhaust valve assembly 14 is fixed at the tail of the cylinder 12, and a piston ring 15 is provided between the piston 13 and the cylinder 12 , A pair of resonance springs 2 are fixed in the cavity between the outer end cover 1 and the mover bracket 4, and the motor mover can move linearly in the cylinder.

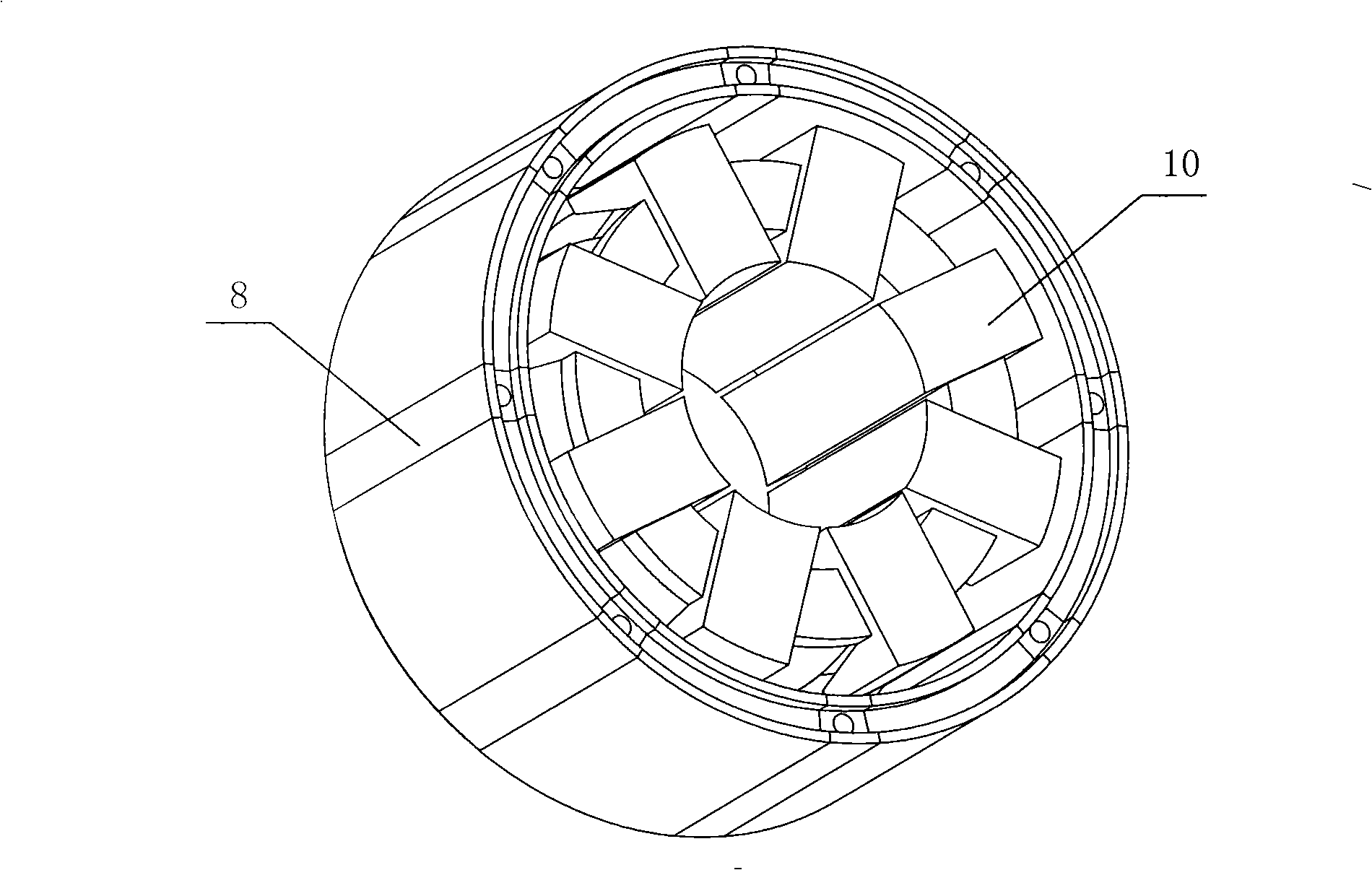

[0025] Among them, the inner yoke component includes a coil 11 and several inner silicon steel sheets 10 with cavities. The inner silicon steel sheets 10 are uniformly distributed on the outer wall of the cylinder 12 in a ring shape, and t...

Embodiment 2

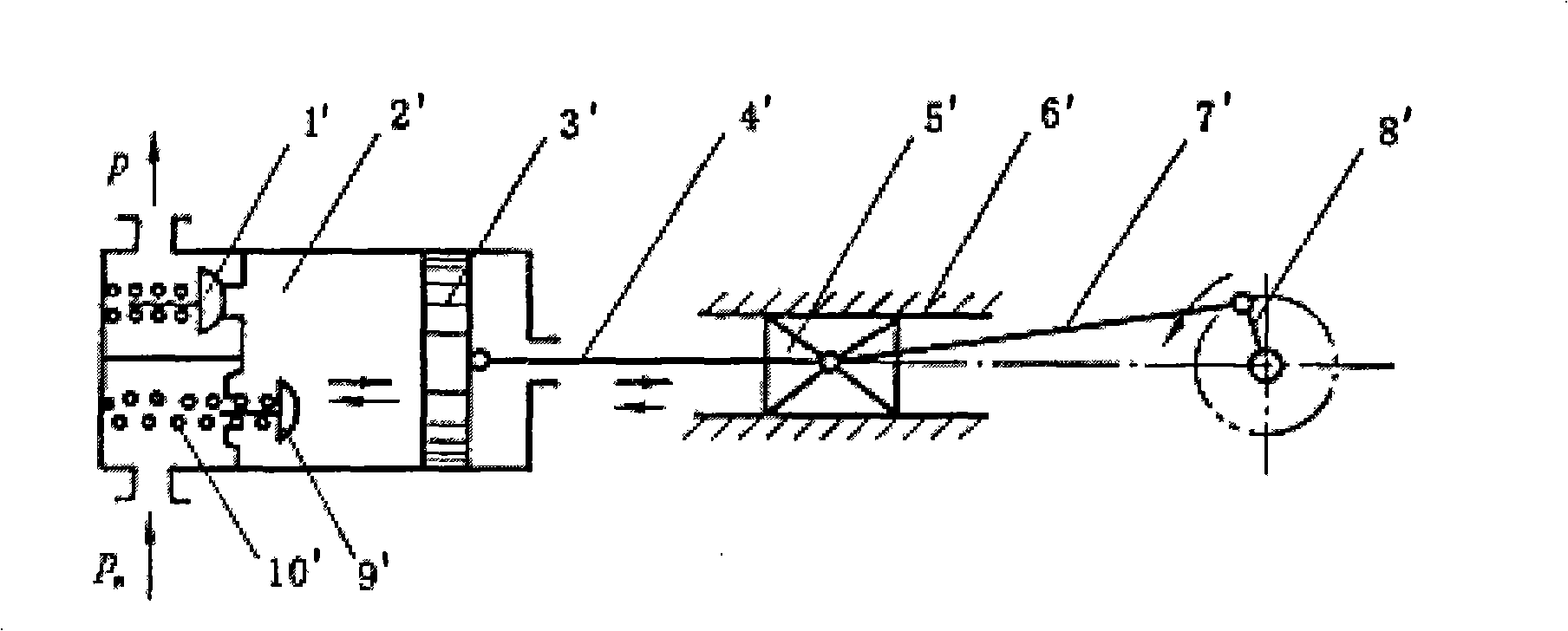

[0033] Referring to Fig. 5, this embodiment is composed of two identical linear air compressors on the left and right sides, and the two compressors are fixed together to form a counter-moving structure. The structure of each compressor is the same as in the first embodiment.

[0034] When the air compressor of the present invention is operating, the piston 13 reciprocates in the cylinder 12, which will generate reciprocating inertial force. This inertial force and the moment of inertia caused by these forces belong to free force and free moment. They will cause the foundation and compressor to vibrate, resulting in fragile mechanical parts and increased power loss. Since the movement of the piston 13 is not converted from a rotational movement, but the motor mover directly drives the piston 13 to make a linear reciprocating movement, there is no rotational inertia force.

[0035] This embodiment is a counter-acting structure. When the coil 11 receives current, the left piston 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com