Modular pump unit used in multi-stage pump

A modular, pump unit technology, applied to the components, pump components, pumps, etc. of the pumping device for elastic fluids, which can solve the problem of limiting the working conditions of the multi-stage pump, the structure of stress concentration, and affecting the service life, etc. problems, to achieve the effect of increasing operating conditions, prolonging shaft life, and improving shaft life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

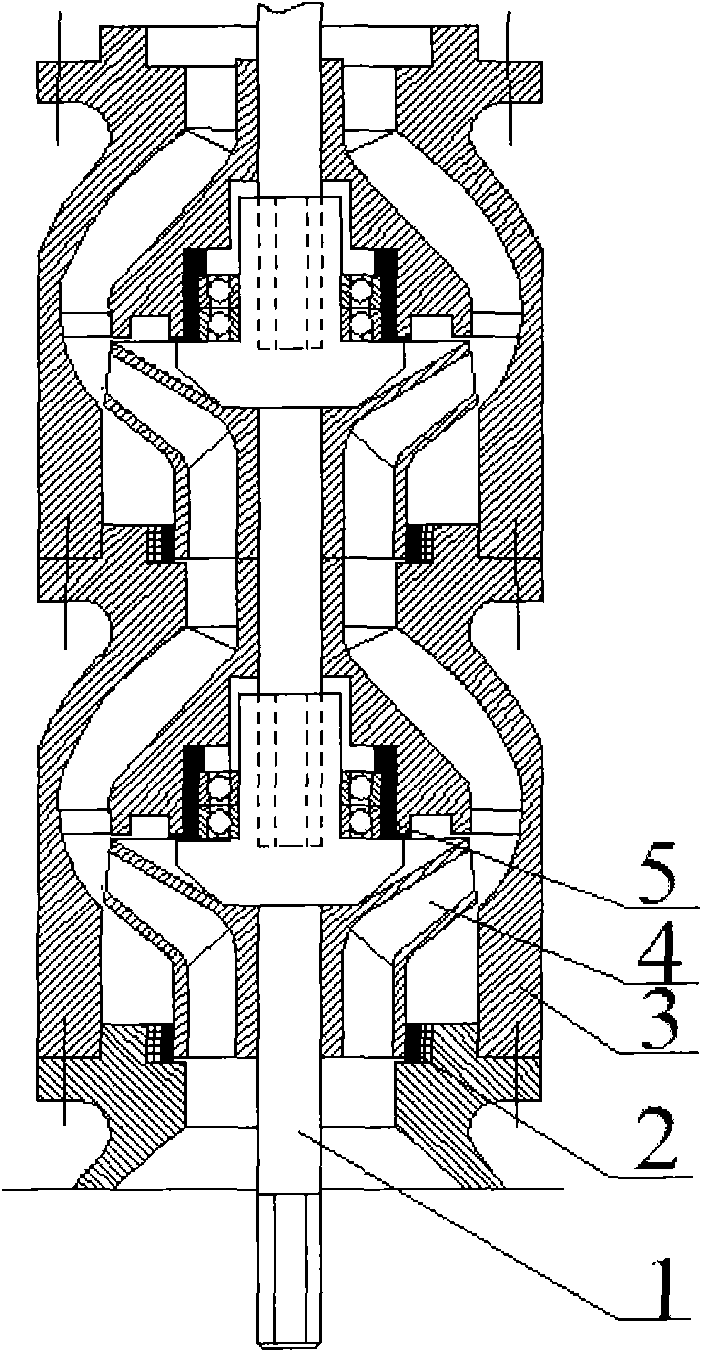

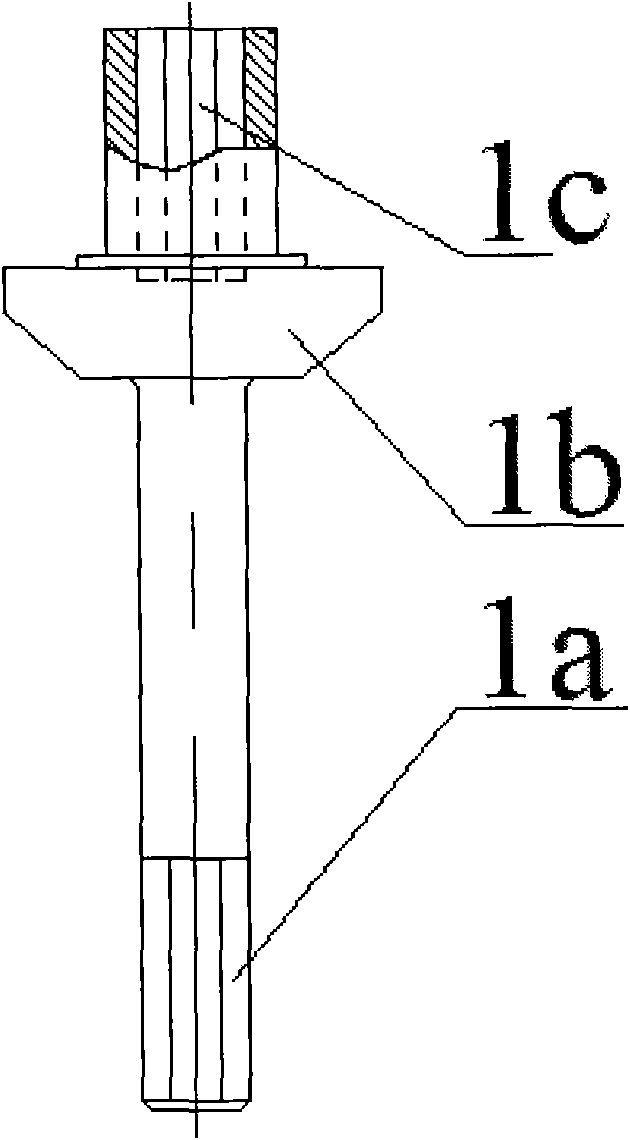

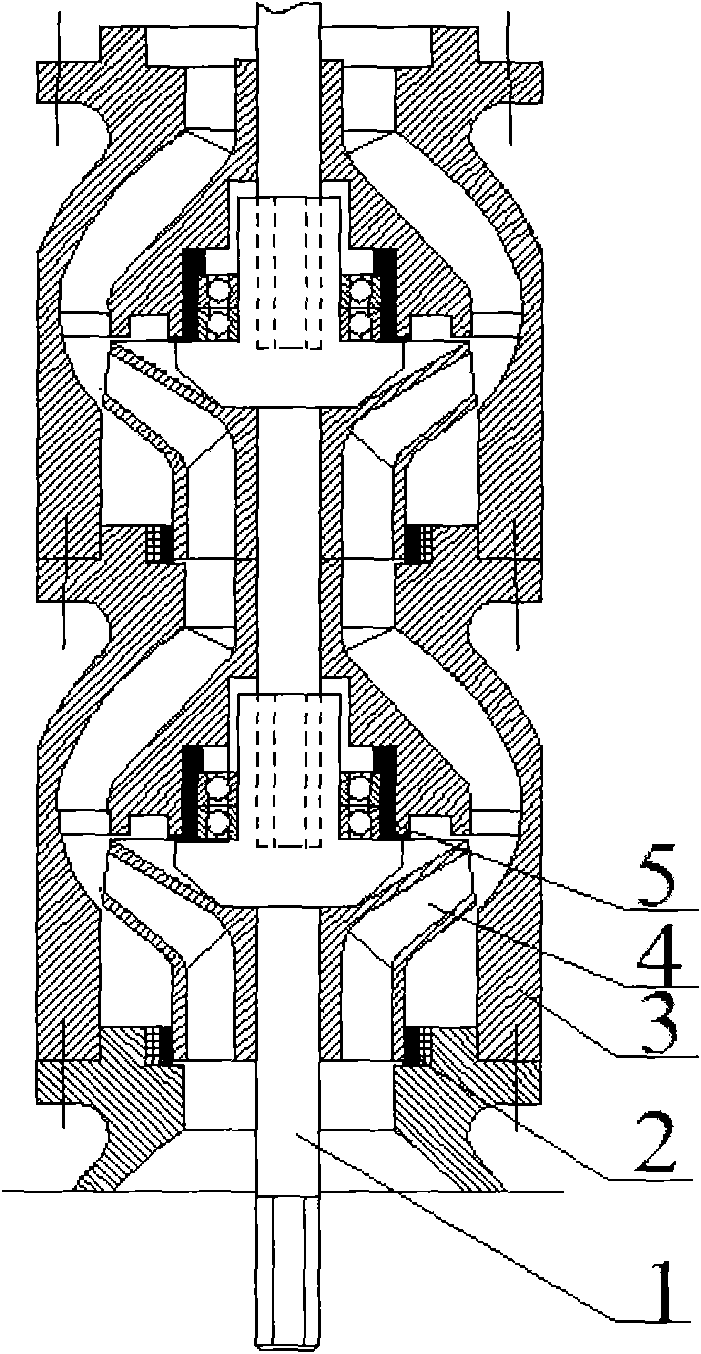

[0014] refer to figure 1 It is a structural schematic diagram of an embodiment of the present invention for a multi-stage pump. The single-stage modular pump unit is composed of a modular pump shaft unit 1, a single-stage bearing system 5, an impeller 4, a mouth ring 2 and a pump casing surrounded by the impeller. 3 components; when assembling, first assemble a single-stage pump unit, the single-stage pump shaft unit is connected to the lower-stage pump shaft through a hexagonal shaft head or thread or spline, and the pump casing is connected by bolts; the same multi-stage pump can be used according to the use The working conditions require that the number of pump stages can be increased or decreased quickly and easily to achieve the required pump head.

[0015] The shaft drives the impeller to rotate through the key, and the fluid medium is driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com