Scroll compressor

A scroll compressor and compressor technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problems of performance degradation, friction power consumption increase, etc., achieve contact force optimization, reduce friction work Consumption, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

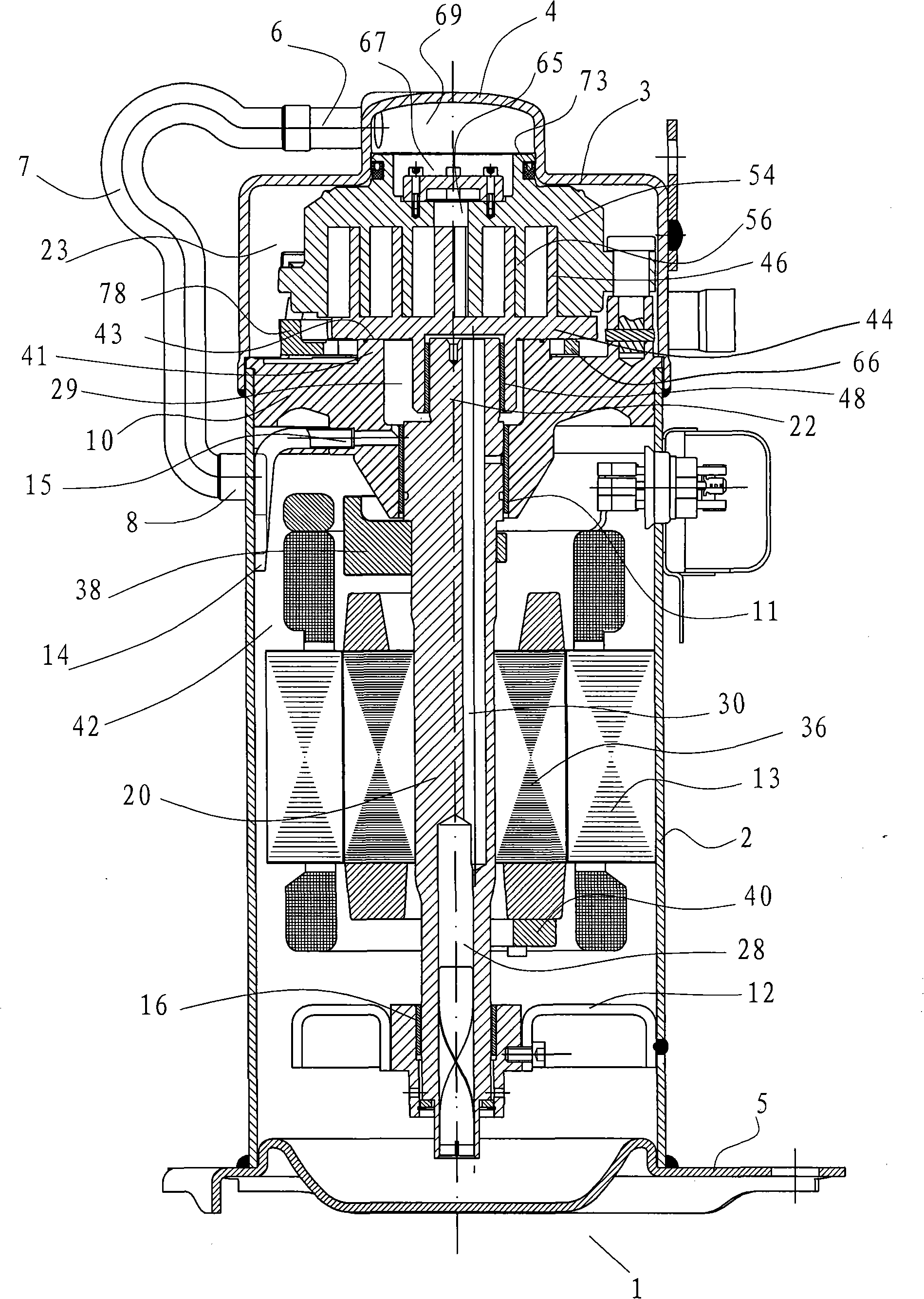

[0024] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0025] See attached image 3 , the shell of the scroll compressor 1 includes a generally cylindrical main shell 2, the upper part of the main shell is welded with an upper shell 3, and the middle of the upper shell protrudes outward to form a cup-shaped The concave part 4. A base 5 is welded to the lower part of the main housing, and a plurality of mounting feet are installed on the base, which are not shown in the figure. An upper gas guide joint 6 for refrigerant is installed on the recess 4 of the upper housing, and a lower air guide joint 8 is also installed on the main housing. One end of the exhaust pipe 7 is installed in the upper air guide joint 6, and the other end is installed in the lower guide Gas connector 8. Other main components fixed on the main housing include: frame 10, which is suitably fixed on the main housing; The leg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com