Low-noise reciprocating piston compressor

A reciprocating piston, low-noise technology, used in liquid variable-capacity machinery, mechanical equipment, variable-capacity pump components, etc., can solve the problems of increased compressor power consumption, loud noise, shortened life, etc., and reduce frictional power consumption. , noise reduction, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

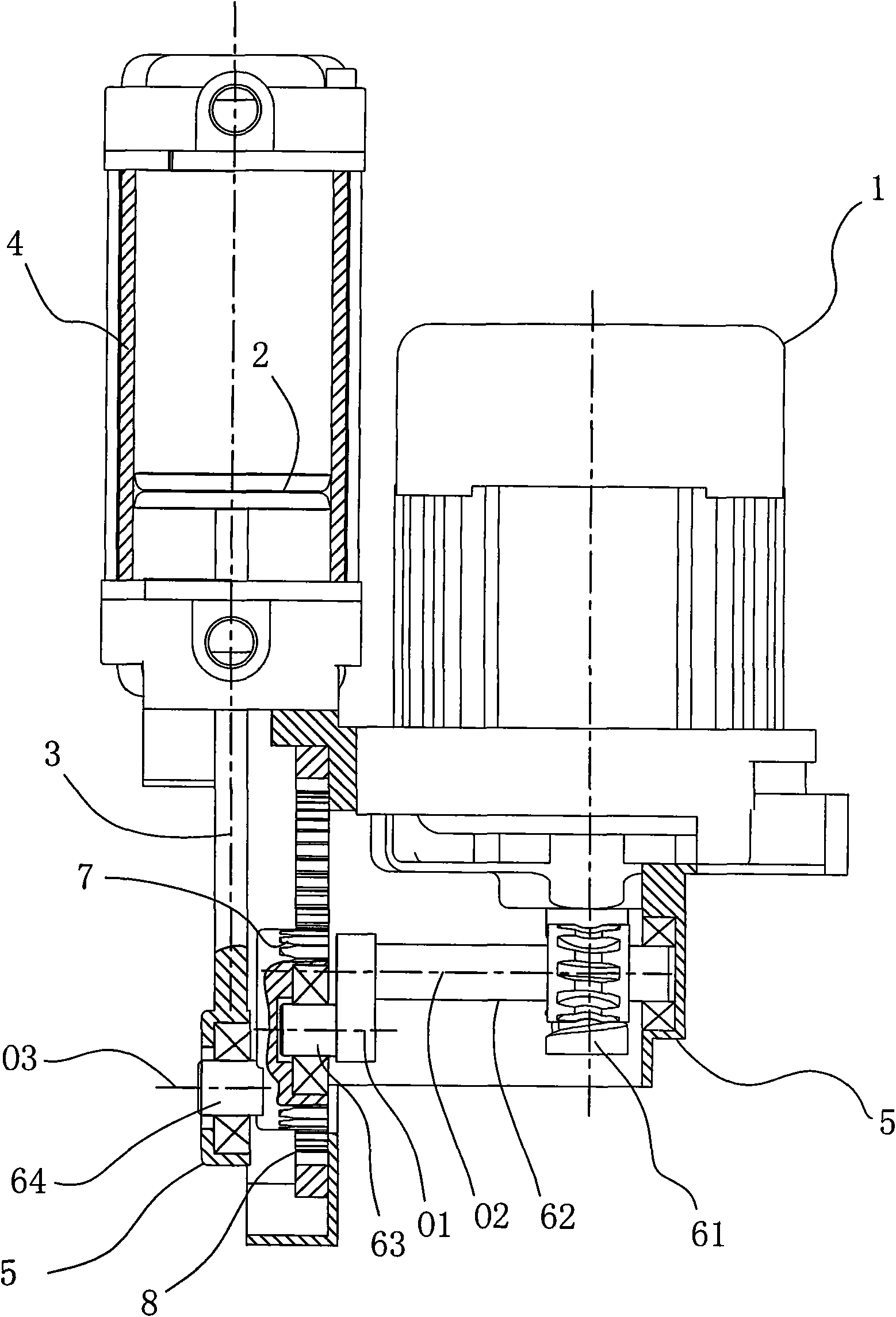

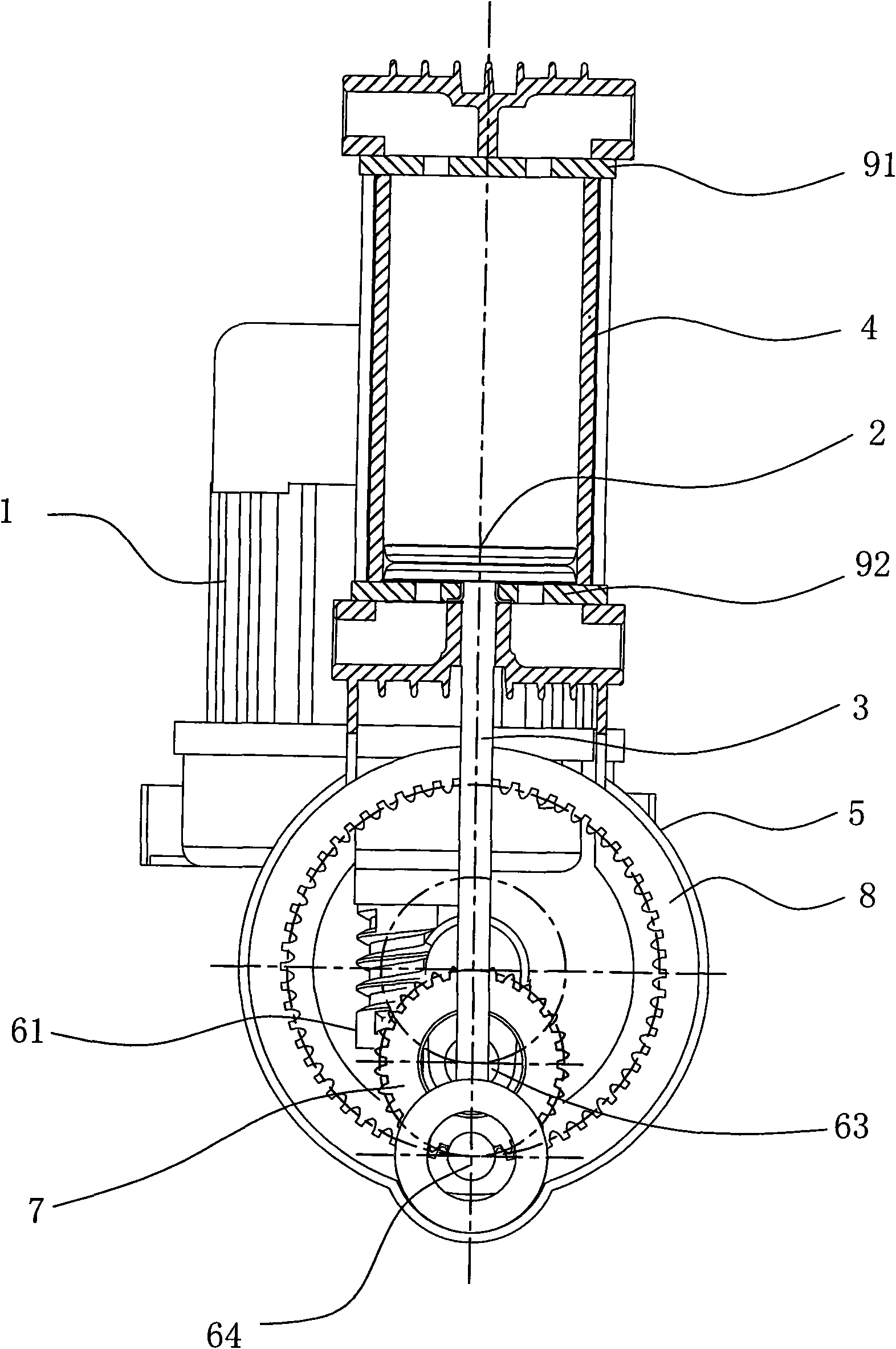

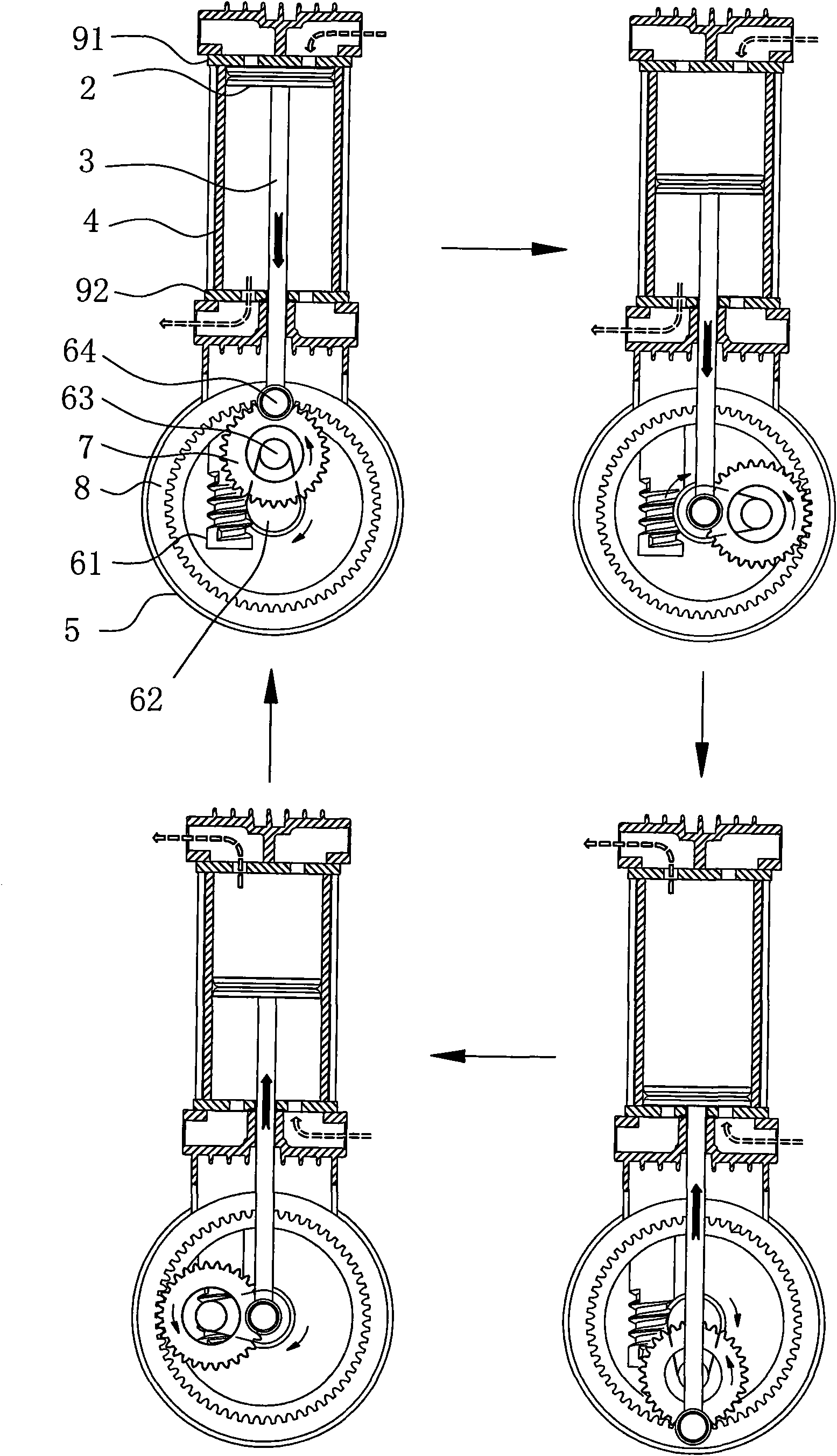

[0028] The present invention will be further described below with specific embodiment, see Figure 1-8 :

[0029] A low-noise reciprocating piston compressor, which includes a motor 1, a piston body 2, a connecting rod 3, a cylinder 4, a transmission box 5, and an intake and exhaust device. The cylinder 4 is connected to the transmission box 5, and the transmission box 5 is set There is a reduction transmission mechanism, wherein the main shaft of the motor is connected to the input shaft 61 of the reduction transmission mechanism, and after deceleration, power and motion are output from the output shaft 62 of the reduction transmission mechanism. The output shaft 62 is provided with a first eccentric shaft 63, A planetary gear 7 is rotated on the first eccentric shaft 63, and the planetary gear 7 is coaxial with the first eccentric shaft 63 O1 (certain manufacturing errors and installation errors are allowed); a fixed gear 8 is installed in the transmission case 5, The fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com