Rotary compressor, gas compression system, refrigeration system and heat pump system

A technology of rotary compressors and cylinders, which is applied in the field of compressor manufacturing, can solve the problems of needle rolling stuck failure, compressor stuck failure, contact stress increase, etc., to reduce friction power consumption, improve stress, reduce The effect of friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

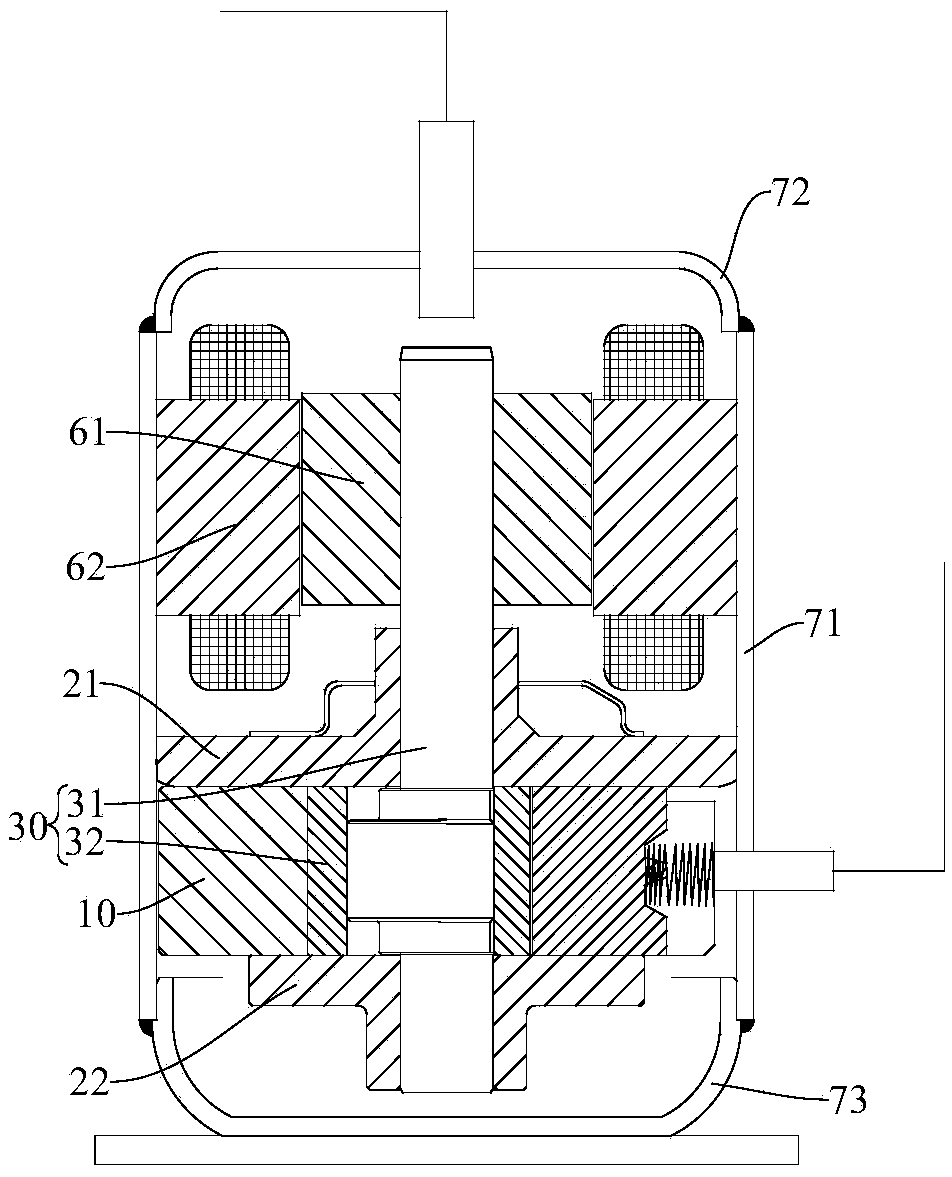

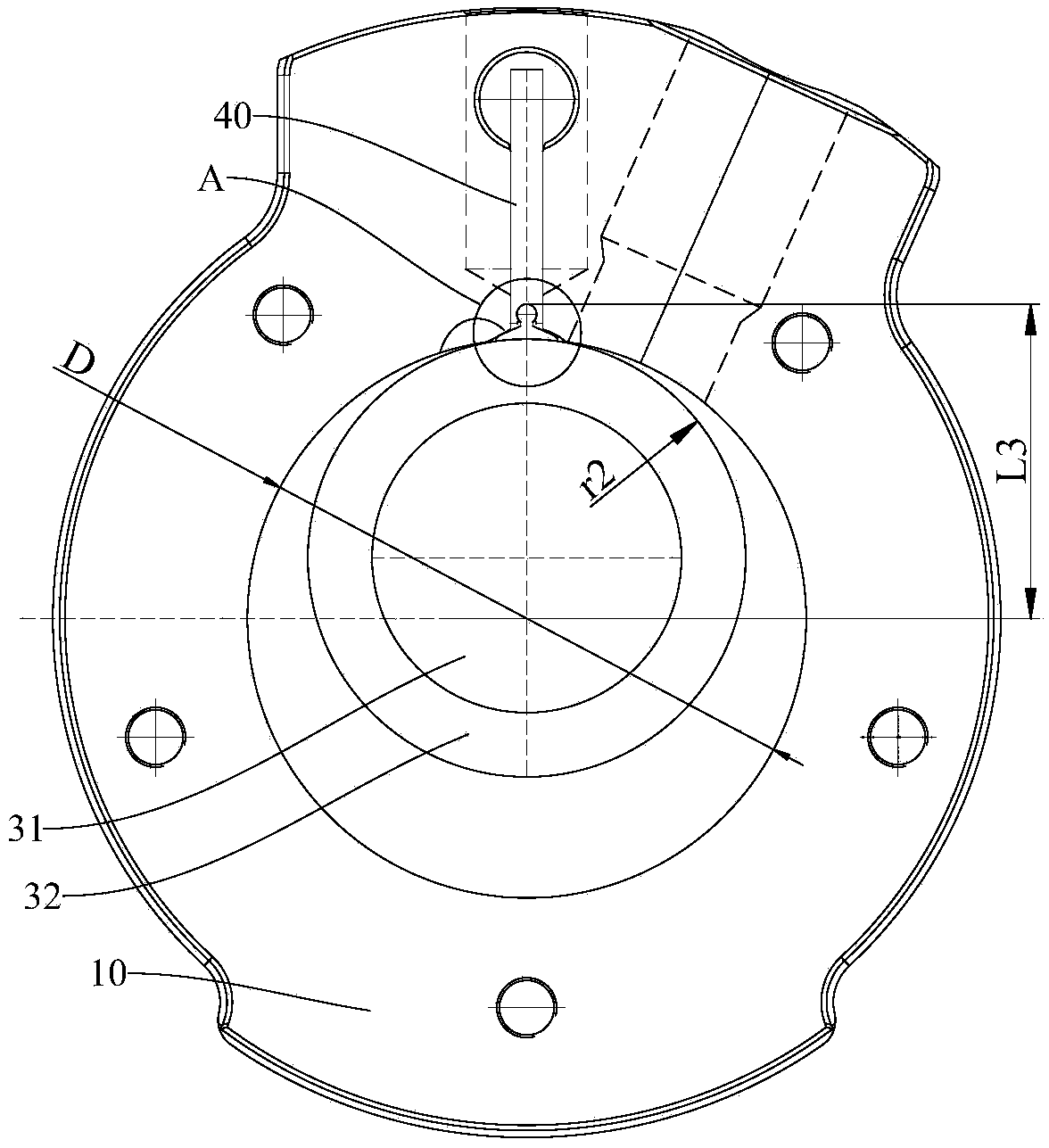

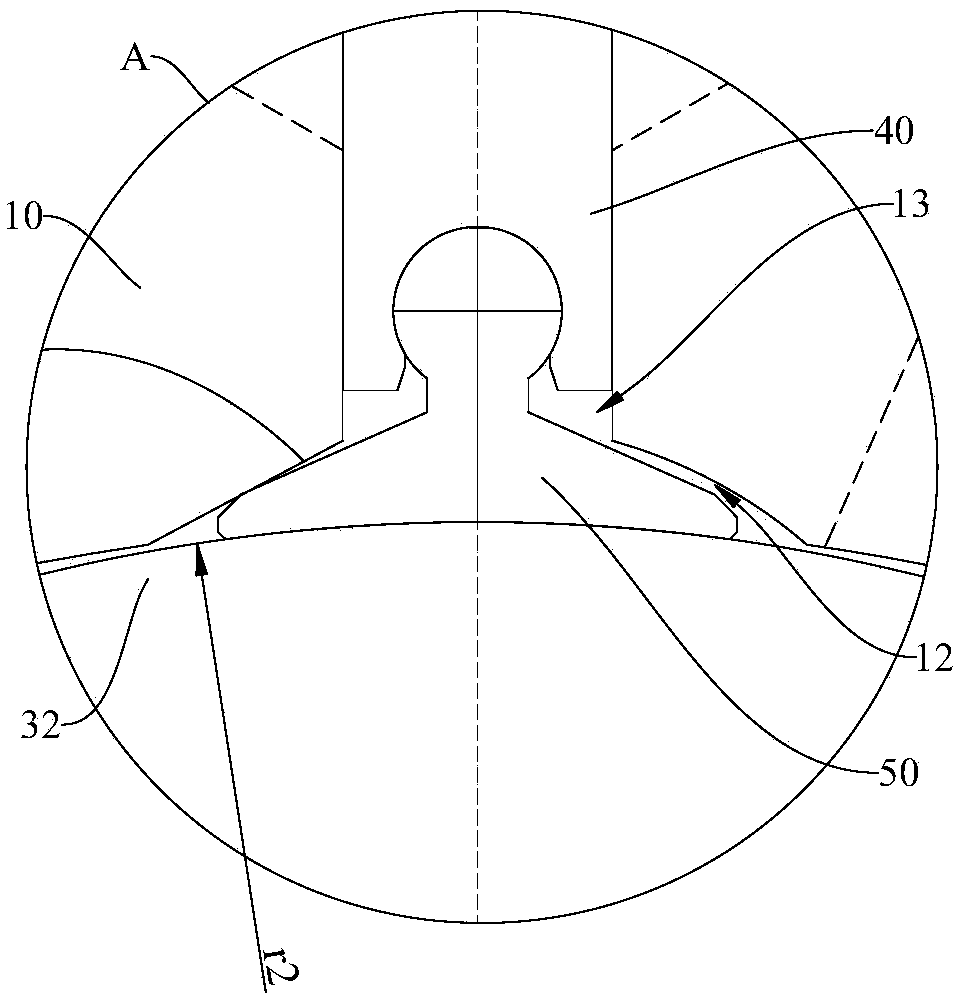

[0044] Refer below Figure 1-Figure 35 A rotary compressor according to an embodiment of the present invention is described. The rotary compressor includes: a casing, a stator 62 , a rotor 61 , a cam mechanism 30 , a cylinder 10 , a main bearing 21 , an auxiliary bearing 22 , a sliding vane 40 and a rocker 50 .

[0045] Among them, refer to figure 1 , the casing can include a casing body 71, an upper casing 72, a lower casing 73, and the stator 62, the rotor 61, the cam mechanism 30, the cylinder 10, the main bearing 21, the auxiliary bearing 22, the sliding plate 40 and the rocker 50 can be installed in the inside the case.

[0046] The rotor 61 is connected with the cam mechanism 30 to drive the cam mechanism 30 to rotate. The main bearing 21 and the auxiliary bearing 22 are respectively arranged on the upper and lower surfaces of the cylinder 10, and a compression chamber is defined between the cylinder 10, the main bearing 21 and the auxiliary bearing 22. , the cam porti...

Embodiment 2

[0054] Refer below Figure 1-Figure 35 A rotary compressor according to an embodiment of the present invention is described. The rotary compressor includes: a casing, a stator 62 , a rotor 61 , a cam mechanism 30 , a cylinder 10 , a main bearing 21 , an auxiliary bearing 22 , a sliding vane 40 and a rocker 50 .

[0055] Among them, refer to figure 1 , the casing can include a casing body 71, an upper casing 72, a lower casing 73, and the stator 62, the rotor 61, the cam mechanism 30, the cylinder 10, the main bearing 21, the auxiliary bearing 22, the sliding plate 40 and the rocker 50 can be installed in the inside the case.

[0056] The rotor 61 is connected with the cam mechanism 30 to drive the cam mechanism 30 to rotate. The main bearing 21 and the auxiliary bearing 22 are respectively arranged on the upper and lower surfaces of the cylinder 10, and a compression chamber is defined between the cylinder 10, the main bearing 21 and the auxiliary bearing 22. , the cam porti...

Embodiment 3

[0067] Refer below Figure 1-Figure 4 , Image 6 , Figure 8-Figure 10 , Figure 12 , Figure 14-Figure 35 A rotary compressor according to an embodiment of the present invention is described. The rotary compressor includes: a casing, a stator 62 , a rotor 61 , a cam mechanism 30 , a cylinder 10 , a main bearing 21 , an auxiliary bearing 22 , a sliding plate 40 and a rocker 50 .

[0068] Among them, refer to figure 1 , the casing can include a casing body 71, an upper casing 72, a lower casing 73, and the stator 62, the rotor 61, the cam mechanism 30, the cylinder 10, the main bearing 21, the auxiliary bearing 22, the sliding plate 40 and the rocker 50 can be installed in the inside the case.

[0069] The rotor 61 is connected with the cam mechanism 30 to drive the cam mechanism 30 to rotate. The main bearing 21 and the auxiliary bearing 22 are respectively arranged on the upper and lower surfaces of the cylinder 10, and a compression chamber is defined between the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com