Laser micro-texturing method of piston ring

A piston ring and micro-texture technology, applied in the field of piston rings, can solve the problems of high PM2.5 content in exhaust gas, high friction power consumption of piston rings, and high peak pressure, so as to reduce PM2.5 value, reduce fuel consumption rate, Reduce the effect of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Example: A method for laser micro-texturing of national 5 emission piston rings, comprising the following steps:

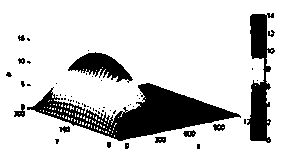

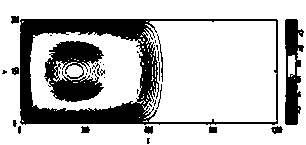

[0017] (1) Select the best friction pair contact surface parameters: cavity radius 10-60 μm, cavity depth 3-15 μm, cavity area ratio 5%-40%, establish theoretical model of piston ring-cylinder liner friction pair surface fluid lubrication ;

[0018] (2) Establish the optimal theoretical shape of the friction surface of the piston ring, substitute the boundary conditions of the national 5 discharge piston ring, and calculate the concave cavity parameters to ensure that the piston ring is in fluid lubrication: the concave cavity radius of the outer circular sealing surface is 20 μm, the depth is 8 μm, the concave cavity area Accounting for 12%; the radius of the cavity on the upper and lower end faces is 50 μm, the depth is 10 μm, and the area of the cavity accounts for 8%;

[0019] (3) Using a semiconductor-pumped YAG laser, the piston ring is clamped o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com