Ring cylinder engine

An engine and ring-cylinder technology, which is applied in the field of annular curved surface cylinder block piston engines, can solve the problems of unsuitable high-temperature structural ceramics, etc., and achieve the effects of improving heat engine efficiency, reducing manufacturing and use costs, and simplifying engine structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

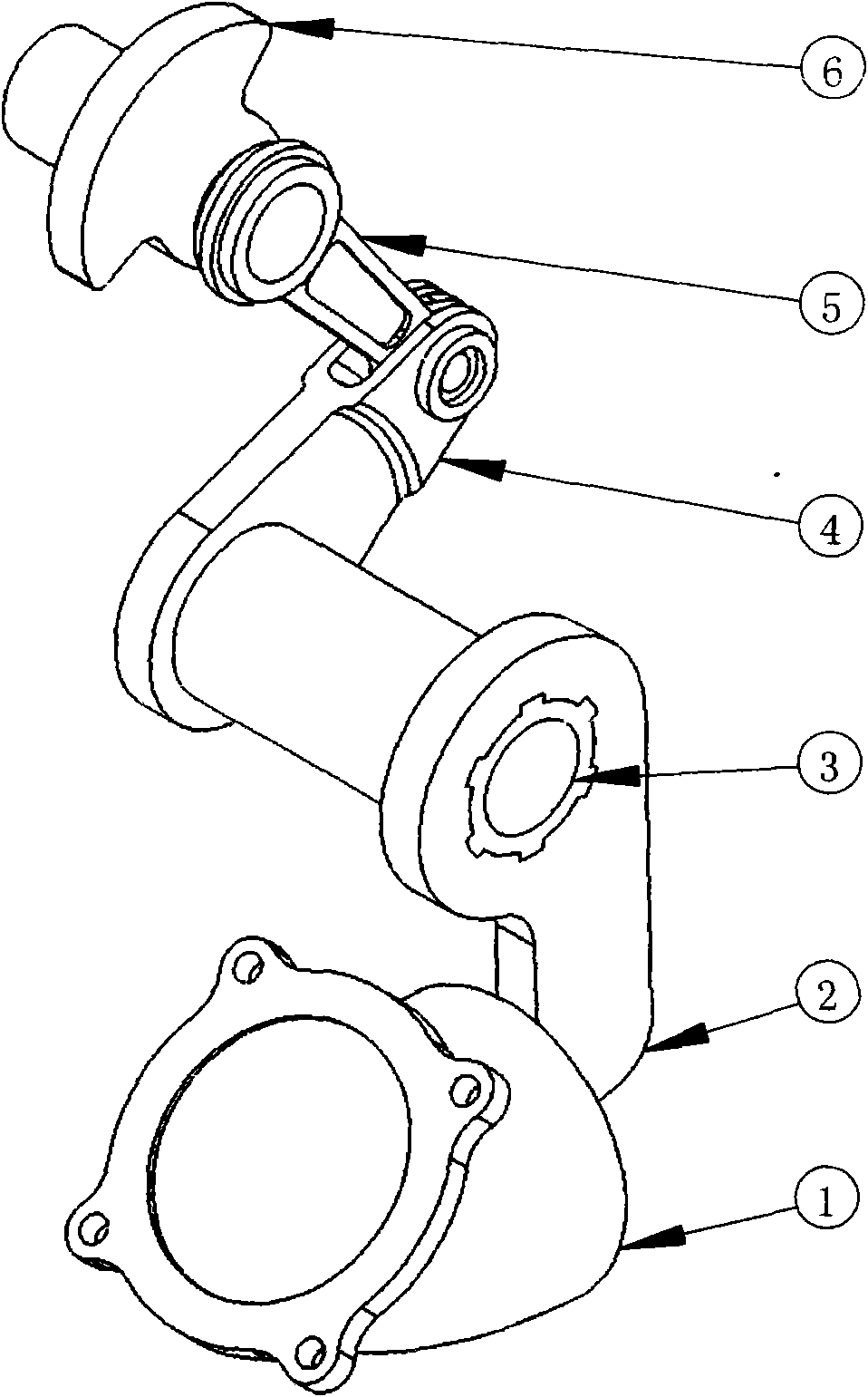

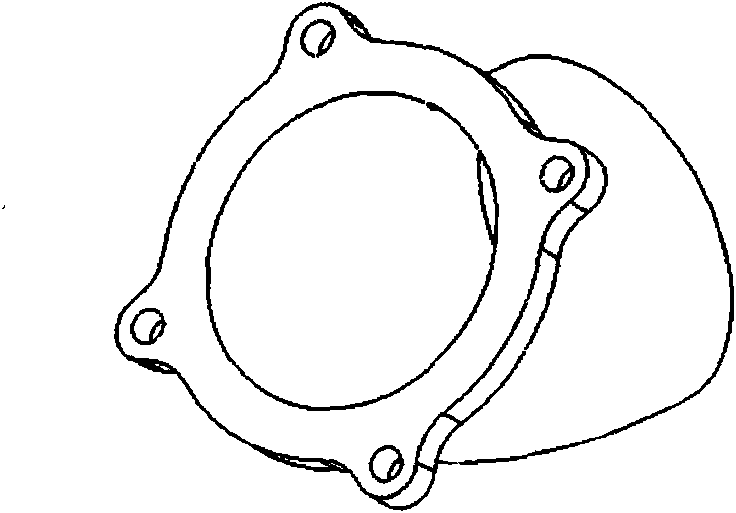

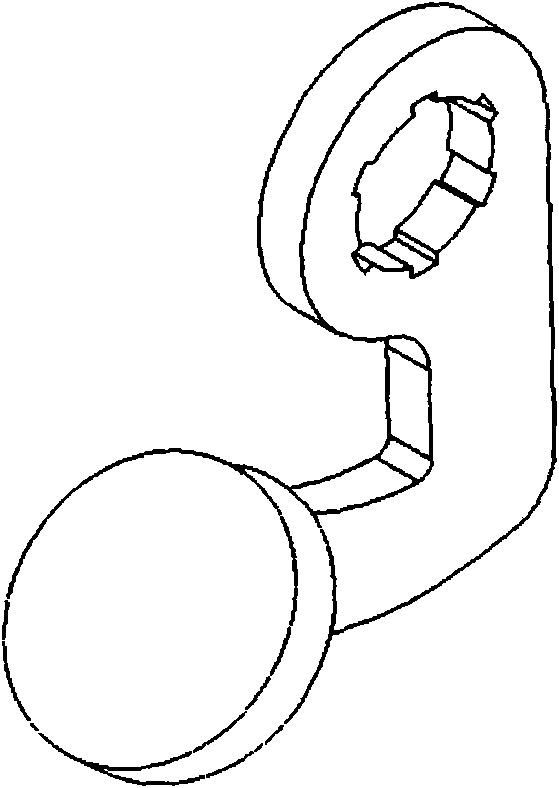

[0024] Depend on figure 1 It can be known that the assembly structure of the ring cylinder engine is: piston (2) is housed in the cylinder block (1), and piston (2) and rocking arm (4) are all fixedly connected on the rocking arm shaft (3). The rocking arm (4) is hinged with the small end of the connecting rod (5), and the big end of the connecting rod (5) is hinged with the crank pin on the crankshaft (6). The creation axis of the inner wall surface of the cylinder body (1), the creation axis of the outer surface of the piston (2), and the center line of the rocker arm shaft (3) are three coincident lines. The piston (2) can swing around its axis and relative to the cylinder (1) in the cylinder (1).

[0025] exist Figure 4 In the shown first embodiment, the cylinder body (1) is fixedly connected with the central shaft (10), the cylinder body (1) is equipped with a cylinder head (11), and the cylinder body (1) is equipped with a piston (2), Piston (2) and rocking arm (4) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com