Pump body assembly and compressor

A component and pump body technology, applied in the field of compressors, can solve problems such as large specific gravity, adverse effects on compressor performance, and large compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

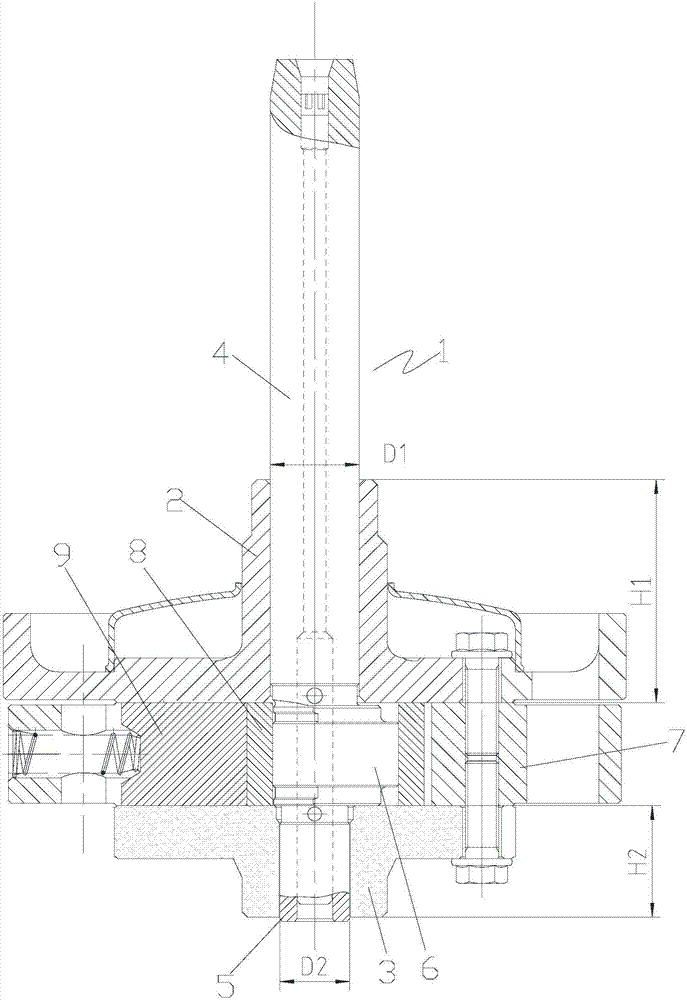

[0027] The bearing system (the system composed of the upper and lower flanges and the crankshaft) under a certain shaft diameter meets a certain flange height, and the bearing load has met the design requirements. Increasing the flange height has no effect on the load, but increases the friction The area can only increase the friction power consumption of the bearing. However, if the flange height is too low, although the friction area is small, it may not meet the bearing load and cause wear and increase mechanical friction power consumption. If the long shaft diameter is too large, the friction area will increase, and the power consumption will also increase. If the shaft diameter is too small, the crankshaft deflection will increase, which will also affect the mechanical friction power consumption. Therefore, it needs to be comprehensively evaluated in conjunction with the flange height.

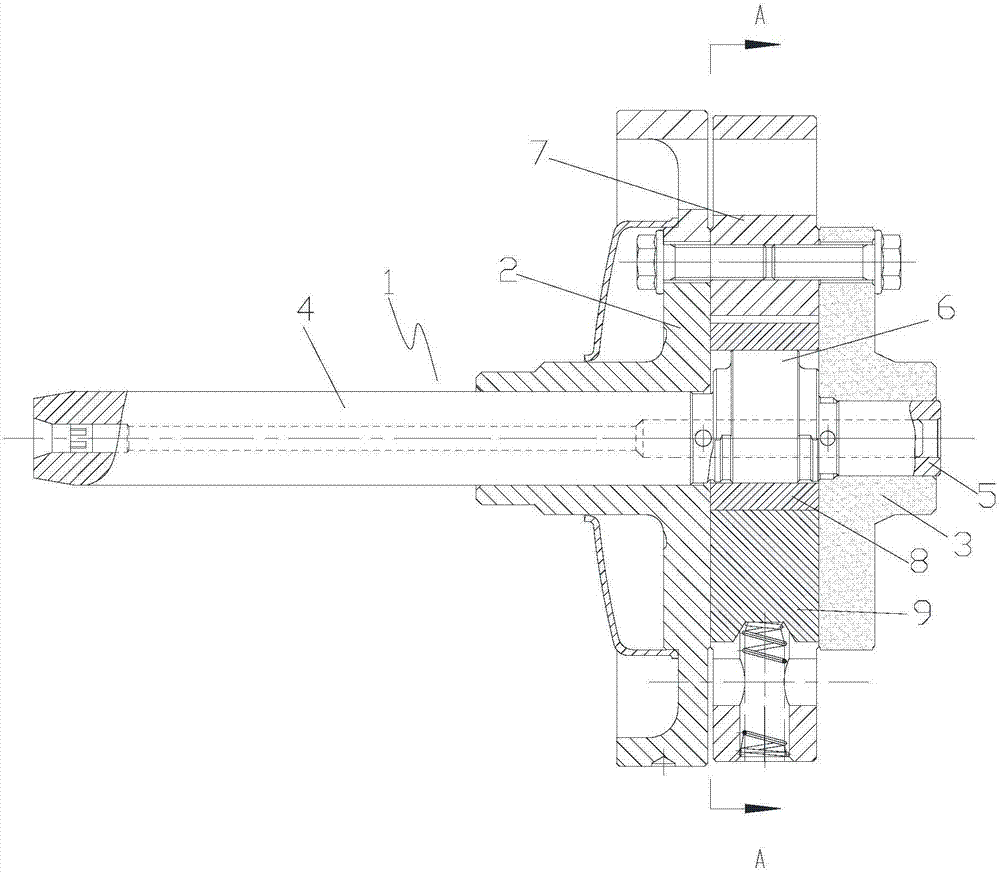

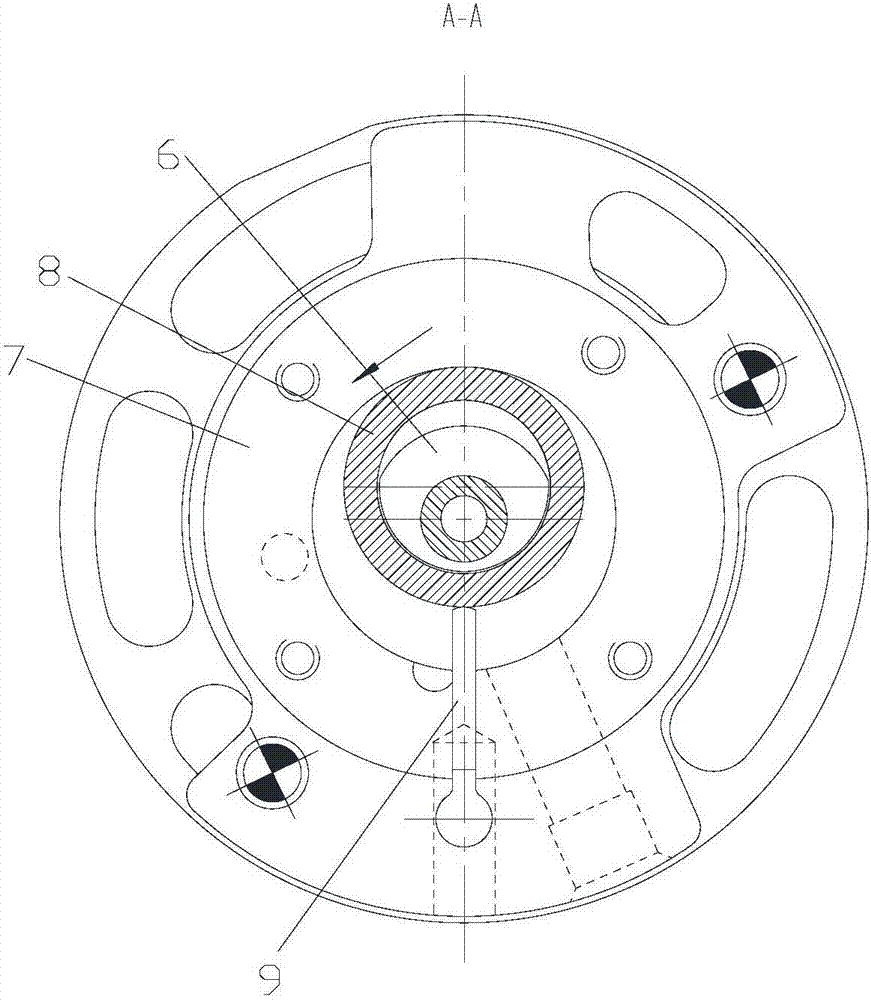

[0028] According to the above analysis, combined with Figure 1 to Figure 8 As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial height | aaaaa | aaaaa |

| Axial height | aaaaa | aaaaa |

| Axial height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com