Combined Bailey frame load-bearing bent frame for pouring long-span concrete beams

A concrete beam and combined technology, which is applied in construction, ship lifting devices, and machinery for lifting ships along slopes, etc., can solve the problems of high cost investment, slow construction progress, and difficulty in ensuring construction quality, and achieve strong safety and stability. Guaranteed construction quality, convenient and quick demolition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

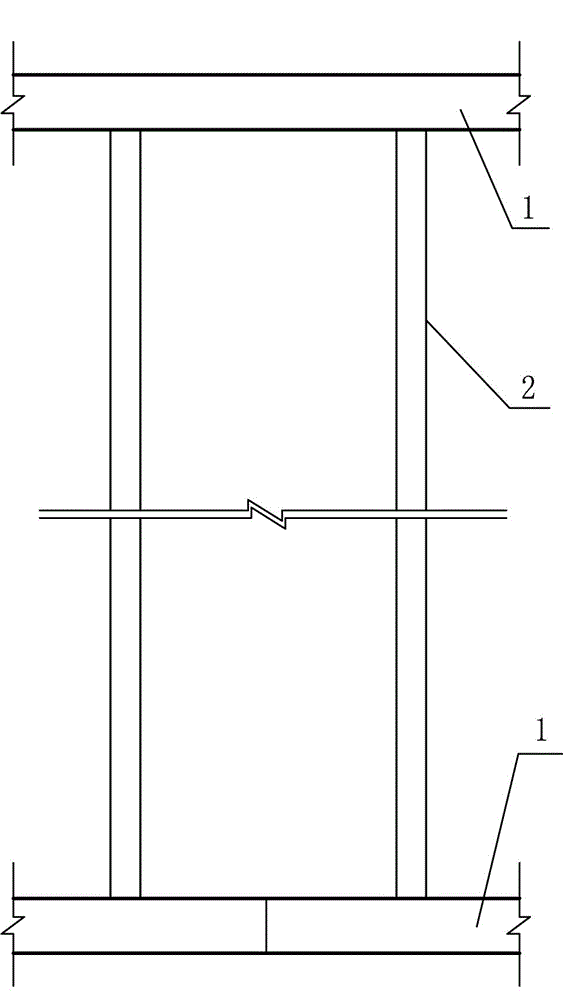

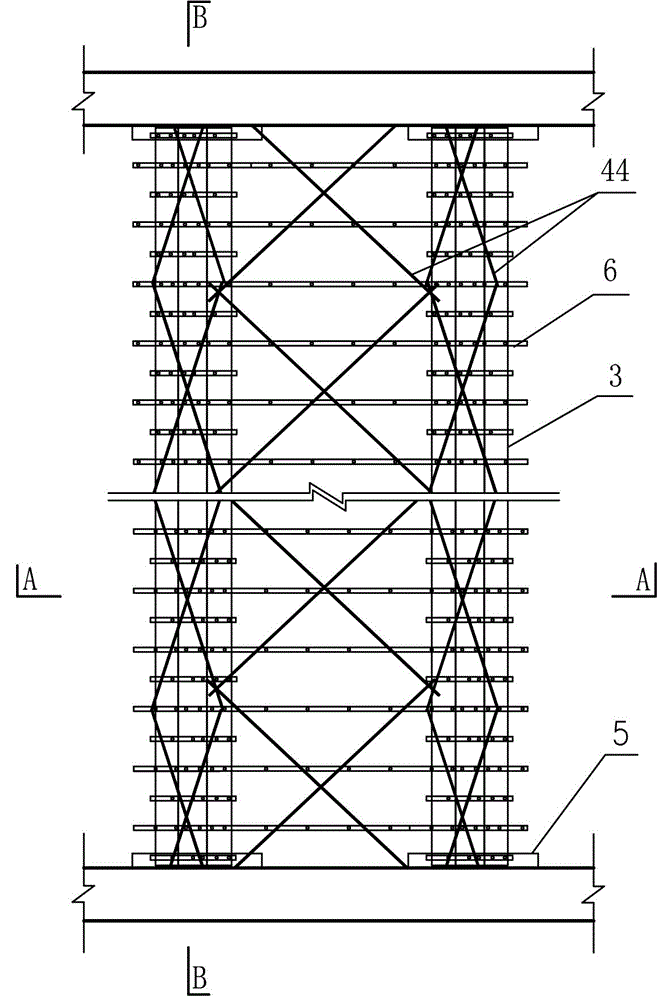

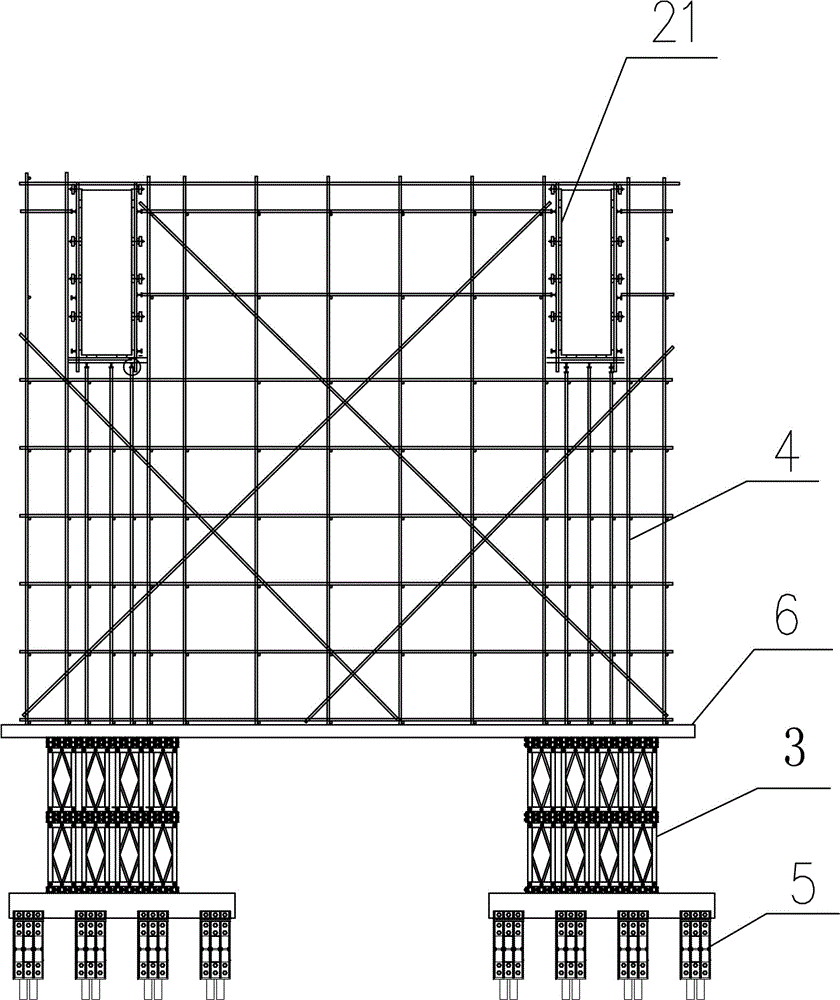

[0018] Such as Figure 2-6 As shown, a combined Bailey frame load-bearing bent frame for pouring large-span concrete beams, including a combined Bailey frame beam 3, a steel pipe bent frame 4, a support system 5, and at least two combined Bailey frames parallel to each other The two ends of the beam 3 are respectively located on the steel box girder 52 of the support system 5 fixed on two parallel concrete upright walls 1, and the combined Bailey frame beam 3 is uniformly and vertically arranged with multiple beams of different lengths. 1. I-beam bases 6 parallel to each other, steel pipe bent frames 4 are set up on the I-beam bases 6 .

[0019] The support system 5 is composed of a plurality of load-bearing steel corbels 51 and steel box girders 52, the load-bearing steel corbels 51 are fixedly connected with a plurality of pre-embedded anchor cones 53 arranged on the concrete upright wall 1, and the steel box girder 52 Erection on the top surface of load-bearing steel corbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com