Rotor supporting structure of high speed electric rotary machine and rotary machine

A technology of electric rotation and rotor support, applied in mechanical equipment, electric components, control of mechanical energy, etc., can solve the problems of low reliability, complex electric control and manufacturing, large friction loss of liquid sliding bearings, etc., to achieve stable and reliable operation of the system, The effect of reducing the relative rotational speed and improving the bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

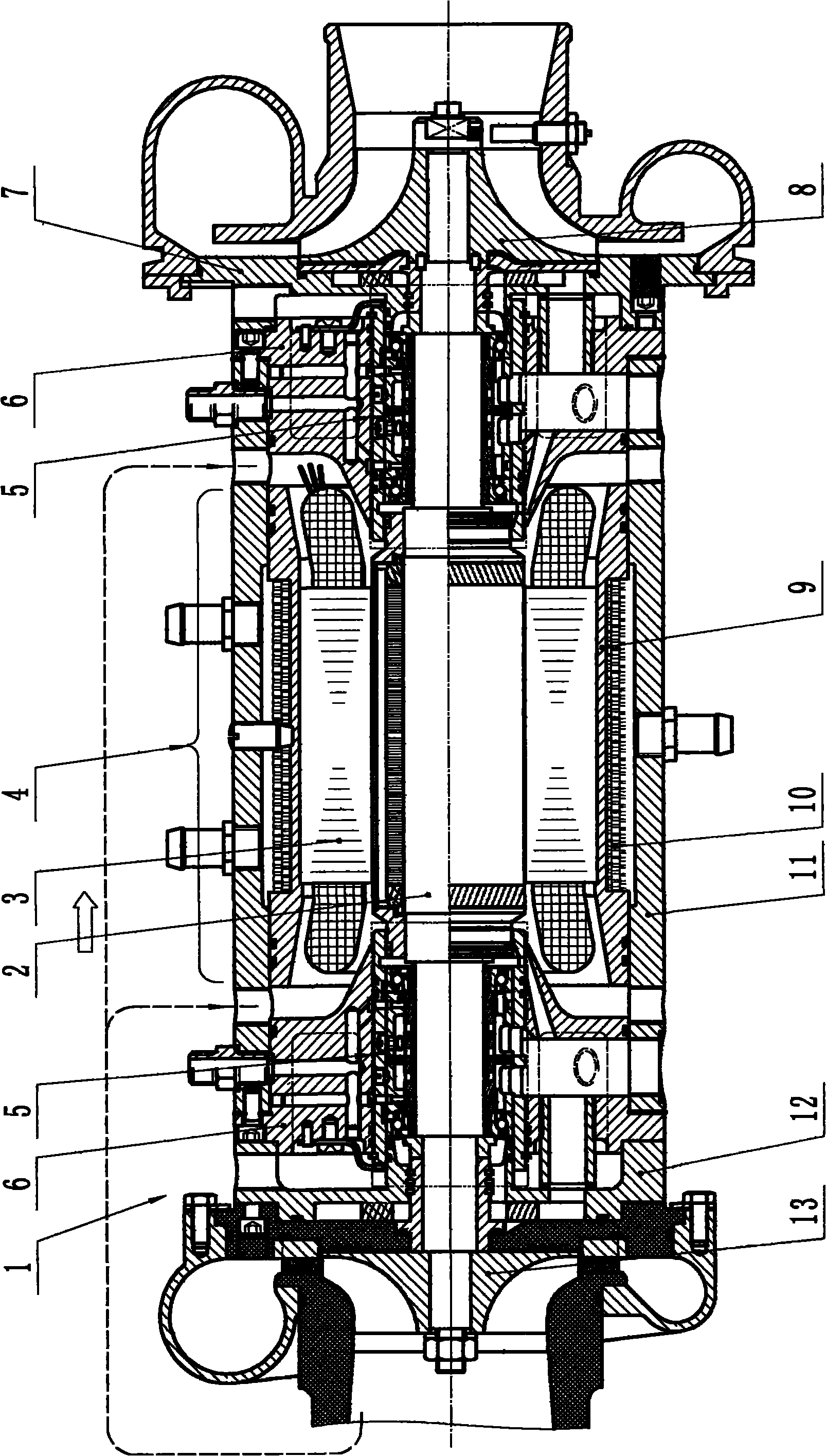

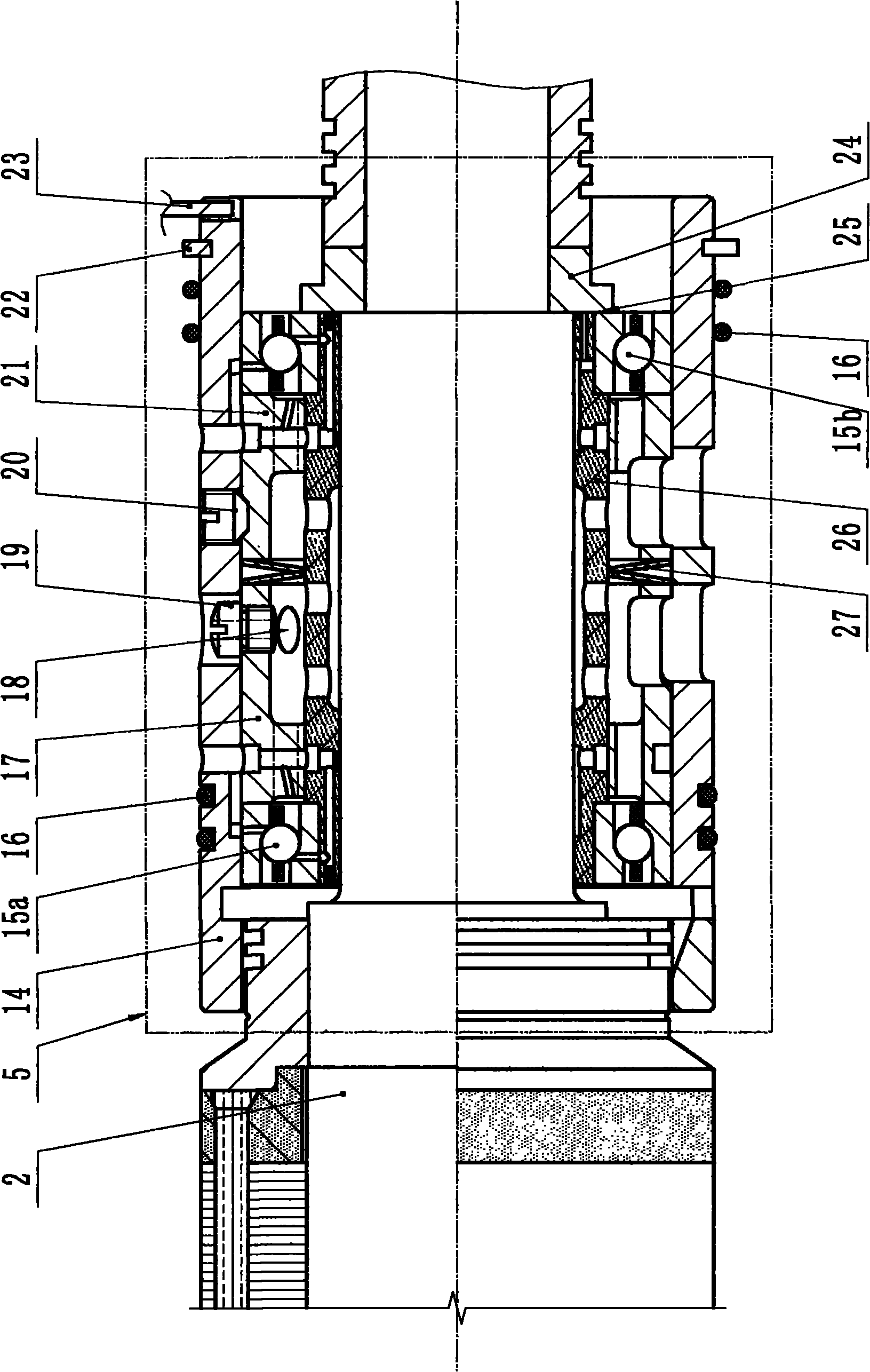

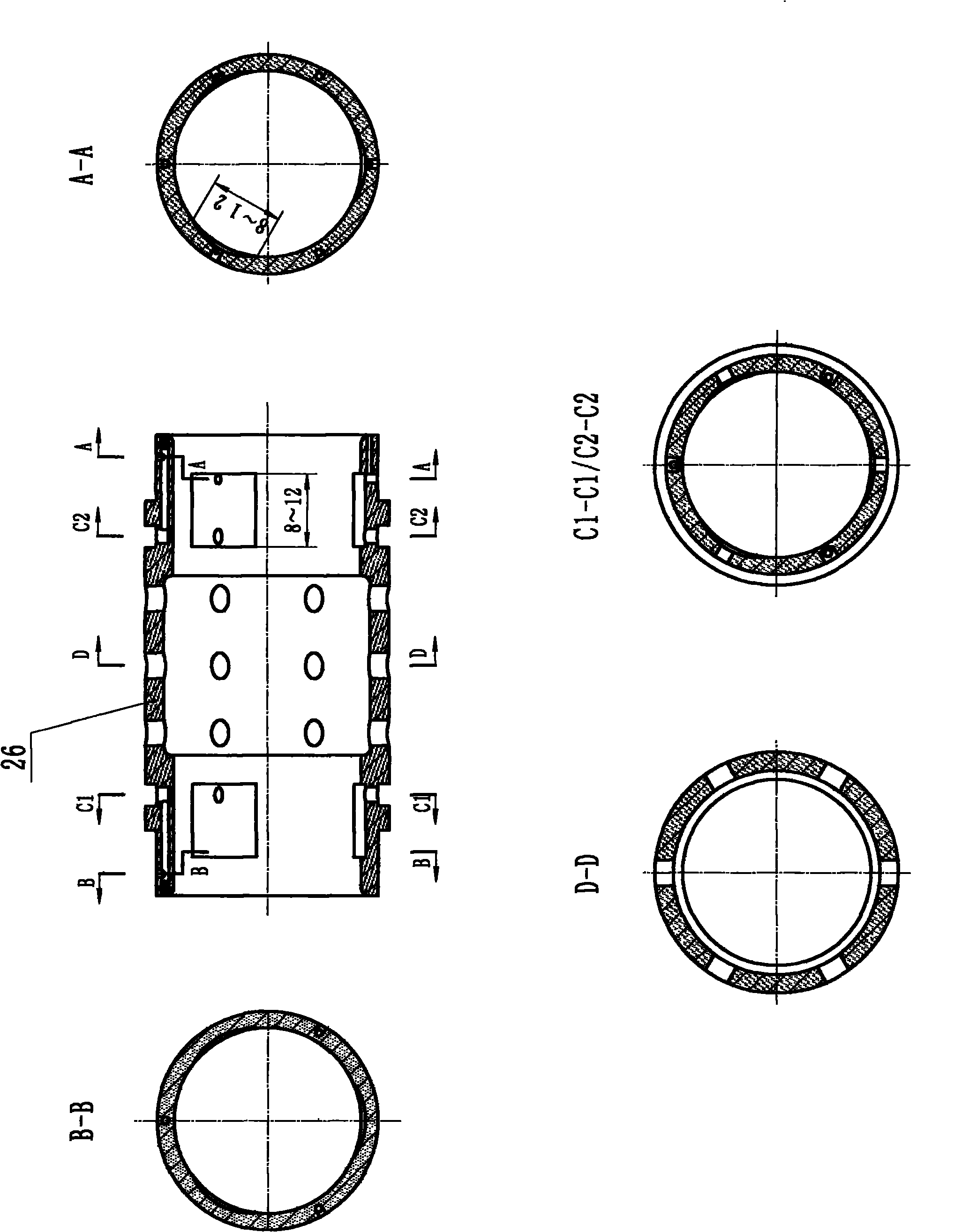

[0009] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. figure 1 Shown is a front view of an air refrigerator 1 driven directly by an electric motor 4 comprising a semi-floating roller-slide double bearing 5 of the present invention. figure 1 Among them, the air refrigerator 1 includes an electric motor 4 in the middle thereof. The motor 4 includes a rotor 2 and a stator 3 . The opposite sides of the rotor 2 are semi-floating roller-sliding double bearings 5 . The bearing seat 6 of the left end and the left water jacket cover 12 form the left cooling water jacket, and the bearing seat 6 of the right end and the right water jacket cover 7 form the right cooling water jacket. The stator casing 9 brazed with cooling fins 10 and the body 11 form the cooling water jacket of the stator 3 . The cooling impeller 13 and the compressor impeller 8 are fixed on the two shaft ends of the rotor 2 . Part of the cool ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com