Compressor pump structure and compressor

A compressor and pump body technology, applied in the field of compressors, can solve problems such as high friction power consumption of friction pairs, difficulty in processing cylinders, and reduced performance of compressors, so as to improve work performance, reduce mechanical power consumption, and reduce friction work consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

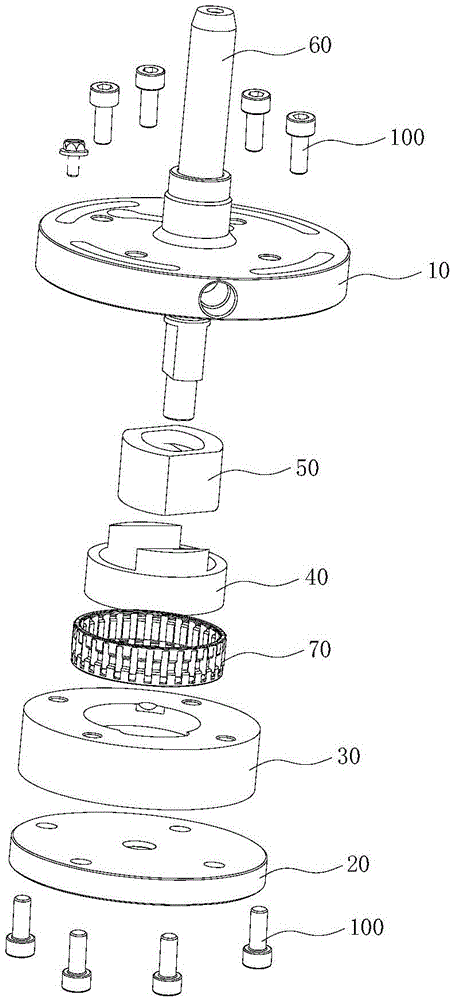

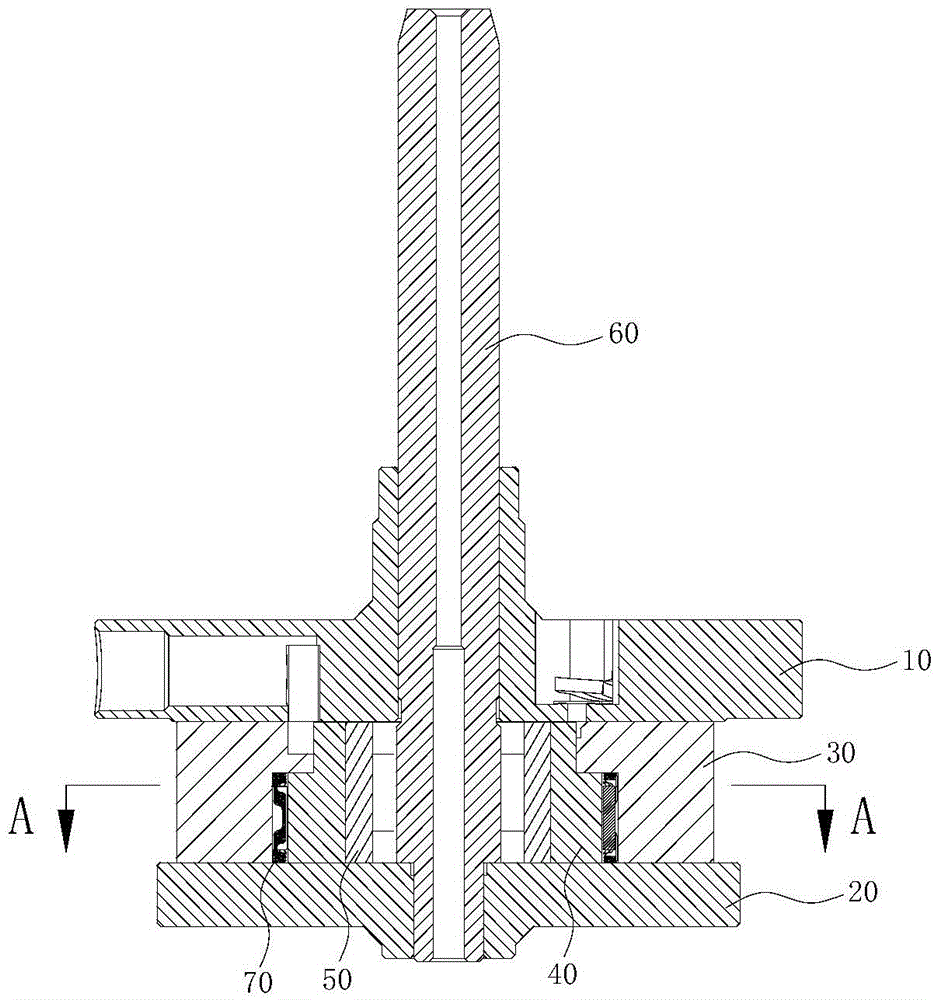

[0047] This embodiment provides a compressor pump body structure, such as figure 1 as well as figure 2 As shown, it includes an upper flange 10, a lower flange 20, a cylinder liner 30, a cylinder 40, a piston 50, a rotating shaft 60 and a needle cage assembly 70, wherein:

[0048] The cylinder liner 30 is located between the upper flange 10 and the lower flange 20, and is fixed by screws 100. The cylinder 40 is arranged in the cylinder liner 30 so as to be rotatable around its own axis, and the piston 50 is located in the cylinder 40, and is relatively The cylinder 40 can slide, but does not rotate relatively;

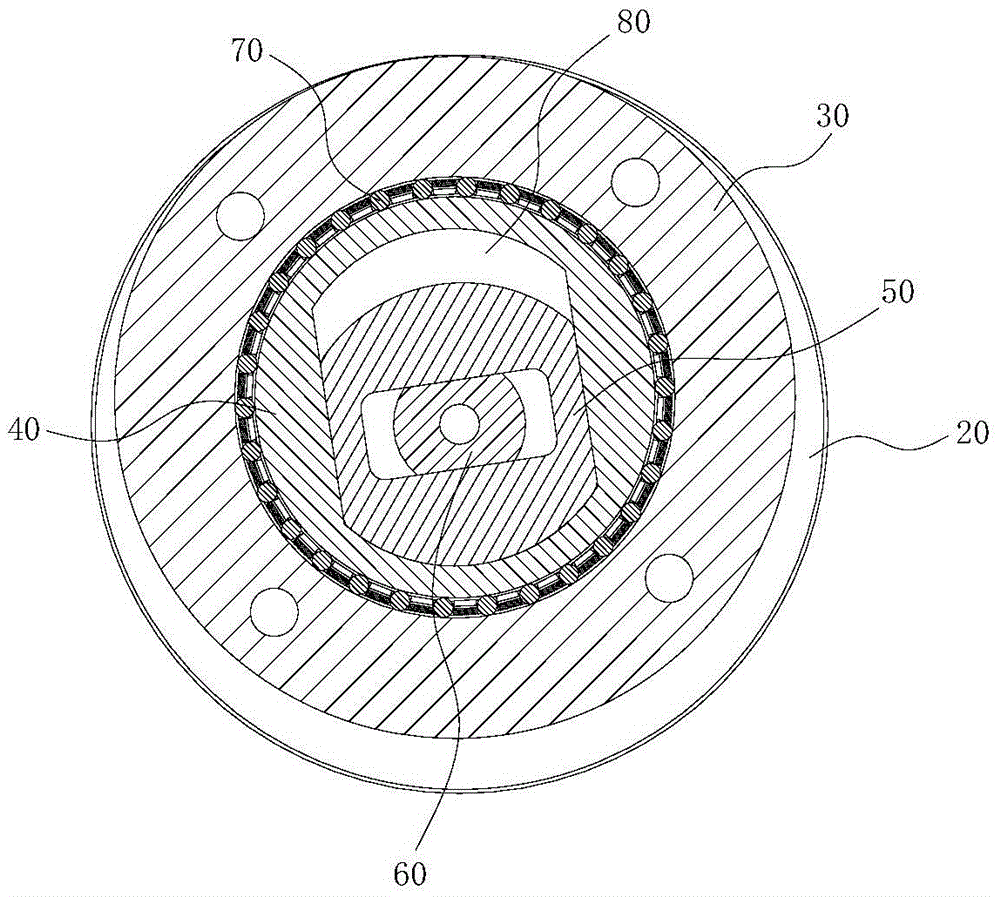

[0049] refer to image 3 , a variable volume cavity 80 is formed between the cylinder liner 30, the cylinder 40 and the piston 50, and the volume of the variable volume cavity 80 can change with the sliding of the piston 50;

[0050]The rotating shaft 60 is set through the upper flange 10, the piston 50 and the lower flange 20 in turn. The axis of the rotating shaf...

Embodiment 2

[0087] This embodiment provides a compressor, including the pump body structure of the compressor in the preferred embodiment 1, specifically, as Figure 22 As shown, the compressor includes a liquid separator assembly 90, a casing assembly 91, a motor assembly 92, a compressor pump body structure 93, an upper cover assembly 94 and a lower cover assembly 95, wherein the liquid separator assembly 90 is arranged on the casing The outside of the assembly 91 is connected to the first air intake passage 101 of the upper flange 10 of the compressor pump body structure 93, the upper cover assembly 94 is assembled on the upper end of the housing assembly 91, and the lower cover assembly 95 is assembled on the upper end of the housing assembly 91. At the lower end, the motor assembly 92 and the compressor pump body structure 93 are located inside the housing assembly 91, and the motor assembly 92 is arranged above the compressor pump body structure 93, and the motor output end of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com