Cone rolling sand-making machine

A sand making machine and roller grinding technology, applied in the field of conical roller sand making machines, can solve the problems of low output, high energy consumption, fast wear and so on, and achieve the effects of long life, low energy consumption and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

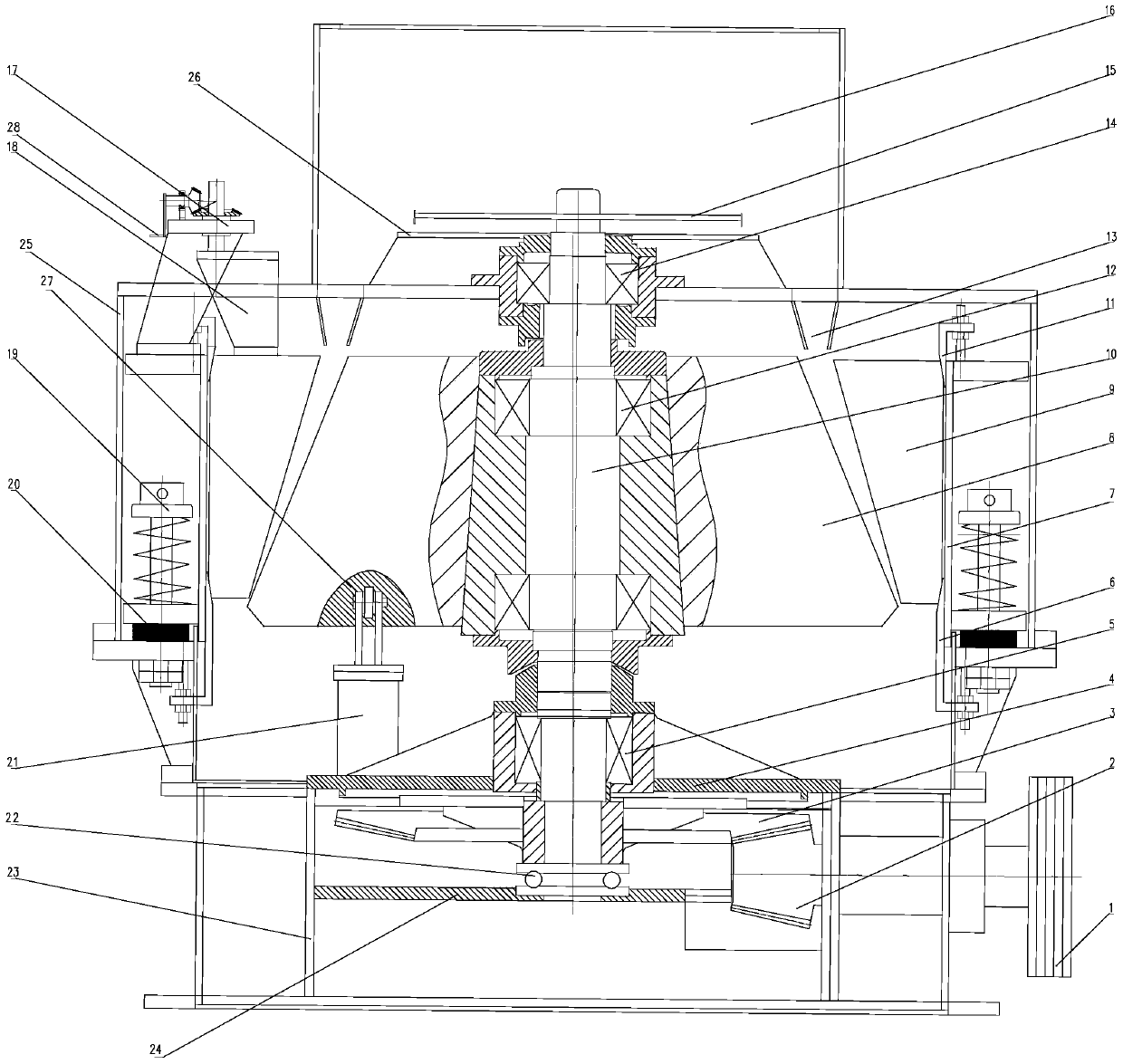

[0023] Such as figure 1As shown, the conical roller sand making machine includes a machine base 23, an eccentric main shaft 10, an inner cone 8 and an outer cone 9, and the machine base 23 is fixedly connected with the machine base cover 4 and the shaft end fixing plate 24 by bolts. The center of the seat cover 4 is provided with a lower rolling bearing 5, which is sleeved on the eccentric main shaft 10, and a thrust bearing 22 is provided on the shaft end fixing plate 24, and the moving ring of the thrust bearing 22 is installed in the central hole of the machine base 23, and the thrust bearing 22 is connected with the bottom end of the eccentric main shaft 10, so that the eccentric main shaft 10 is rotatably connected on the support 23, the outer vertebral body 9 is covered outside the inner cone body 8, there is a gap between the outer vertebral body 9 and the inner cone body 8, and the inner cone body A rolling bearing 12 is respectively installed on the top and the bottom...

Embodiment 2

[0026] The wheel shaft of driving bevel gear is connected with a motor transmission, if the sand-making grain size needs to be adjusted, start the motor to change the gap between the inner cone 8 and the outer cone 9. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com