Slip ring type planet rolling drawing wheel

A slip ring type, planetary gear technology, applied in the field of wire drawing production equipment in the wire product industry, can solve the problems of the influence of the quality of the drawn wire and the high requirements of the planetary gear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

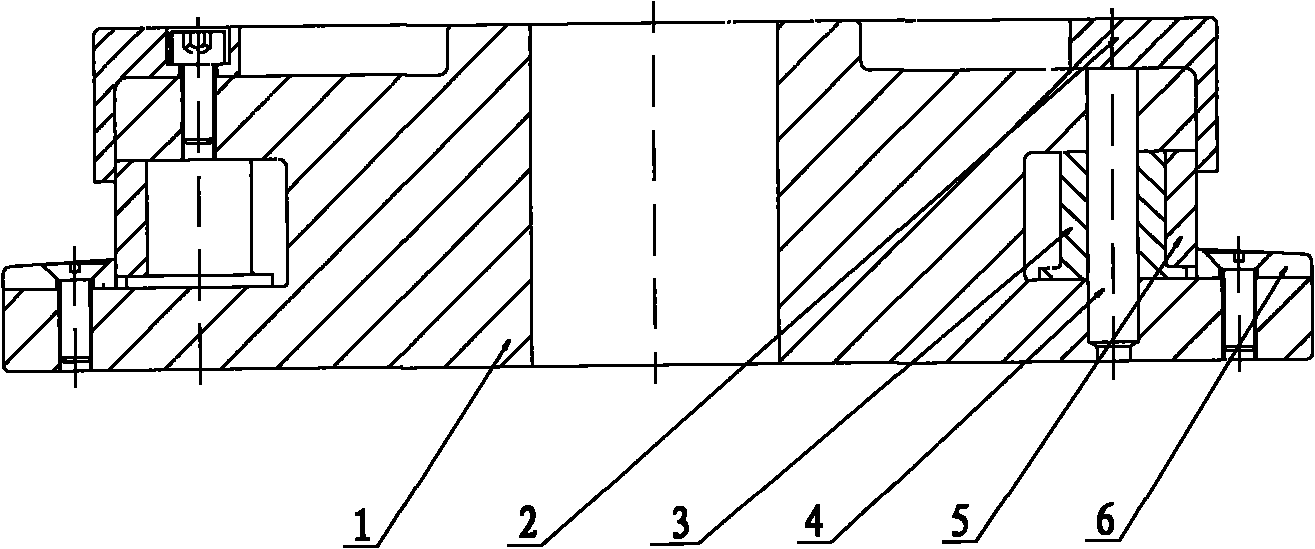

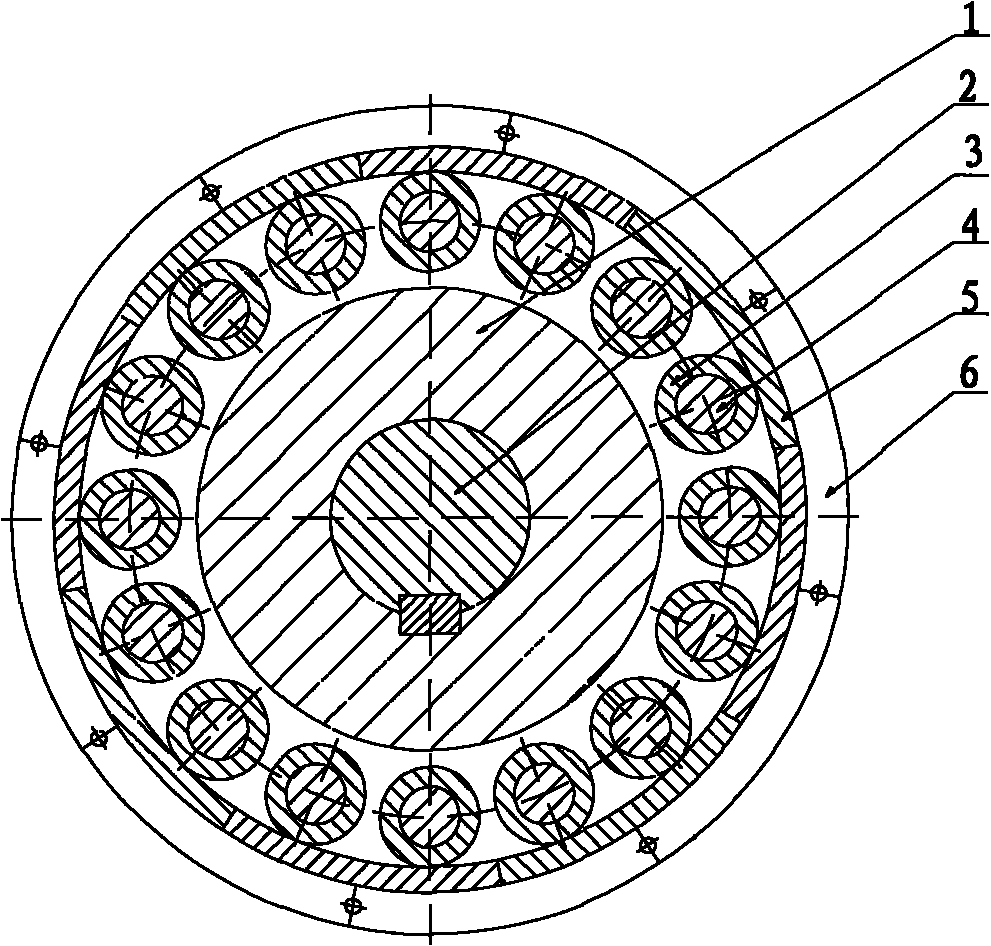

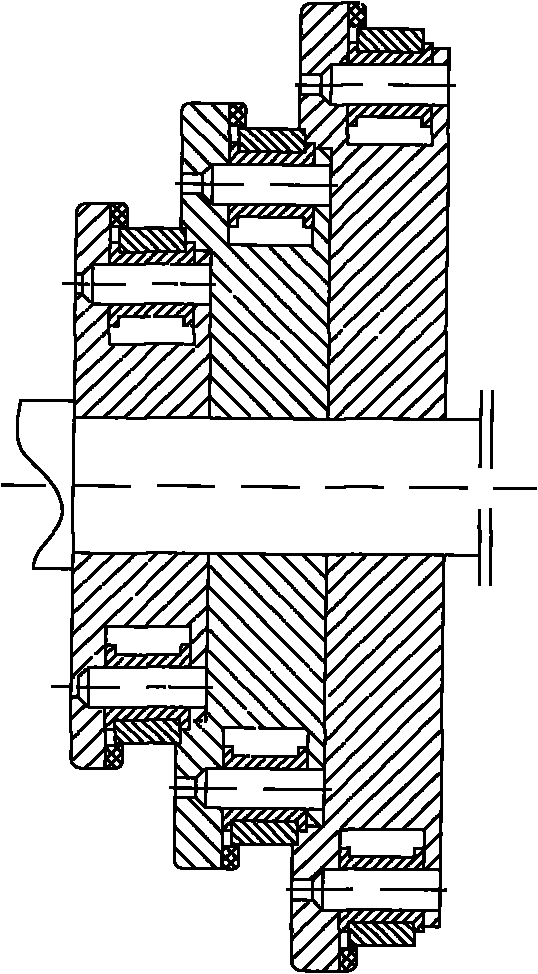

[0010] In the present invention, the slip ring type planetary rolling intermediate reel is looped on the planetary wheel shaft 4 by a set of freely rotating planetary wheels 3, the planetary wheel shaft 4 is installed on the drawing wheel body 1, and the slip ring 5 is looped on the planetary wheel 3 Out of the outer circle, the pressure ring 2 and the anti-friction piece 6 are fixed on the drawing wheel body 1 by screws; the slip ring planetary rolling tower wheel is slippered on the planetary wheel shaft 4 by a set of freely rotating planetary wheels 3, The planetary wheel shaft 4 is installed on the drawing wheel body 1, the slip ring 5 is looped outside the outer circle of the planetary wheel 3, the anti-scratch sheet 6 is fixed on the drawing wheel body 1 by rivets, and N pieces of slip ring type planetary rolling tower wheel Assembled on the transmission shaft 2 to form a slip ring type planetary rolling cone wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com