Double-pumping-prevention oil pump

A technology for preventing oil pumping and pump barrels, which is applied to pumps, pump components, variable capacity pump components, etc., can solve problems such as the failure to solve the problem of sand entering the pump, and achieve the goal of preventing damage and avoiding partial wear of rods and tubes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

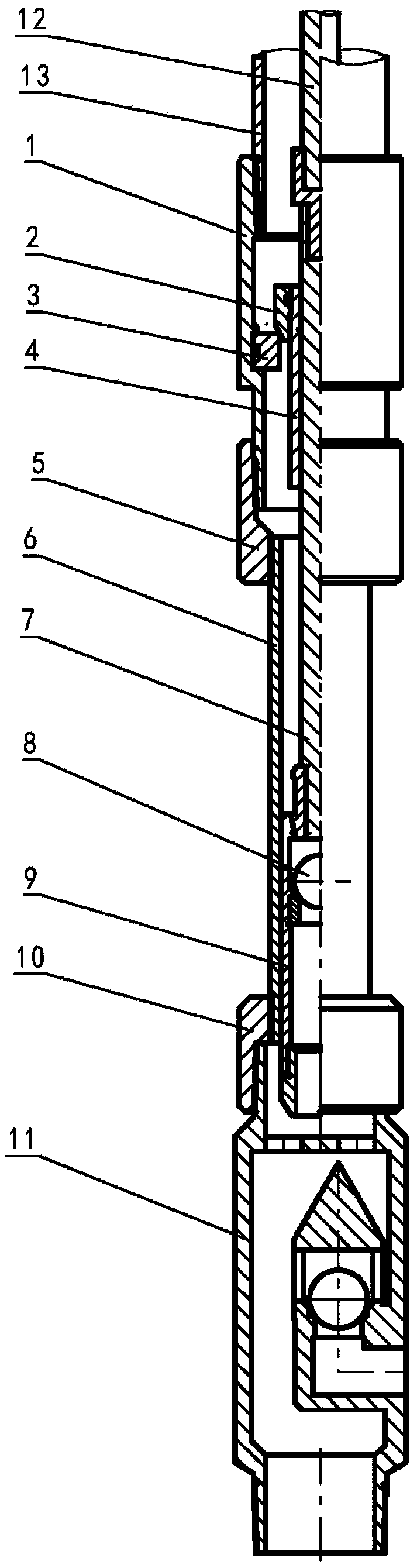

[0017] The invention provides a double anti-suction pump, such as figure 1 As shown, it includes pump cylinder 6, pump cylinder 6 is connected with working cylinder 1 through upper joint 5, and pump cylinder 6 is connected with offset and fixed valve 11 through lower joint 10; ring valve seat 3 is fixed at the variable diameter of working cylinder 1; The slide bar 7 is covered with a sliding sleeve 4, and the upper end of the sliding sleeve 4 is fixed with an annular valve plug 2; the annular valve plug 2 is matched with the ring valve seat 3.

[0018] The upper end of the slide rod 7 is connected with a sucker rod column 12 .

[0019] The lower end of the slide rod 7 is sequentially connected with a floating valve assembly 8 and a plunger 9 through threads from top to bottom; The lower end of the column 12 reciprocates axially in the pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com