Forming process method of thermal runaway prevention composite material battery box upper cover and product

A composite material and molding process technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as lack of maintenance ability, and achieve the goal of improving the ability to prevent thermal runaway, maintaining good maintenance, and reducing manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

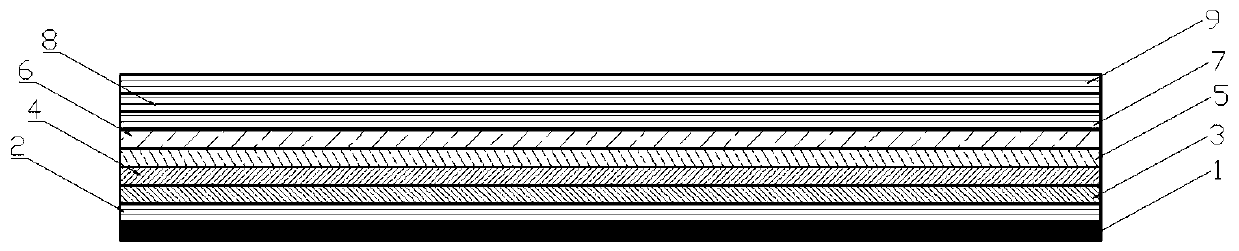

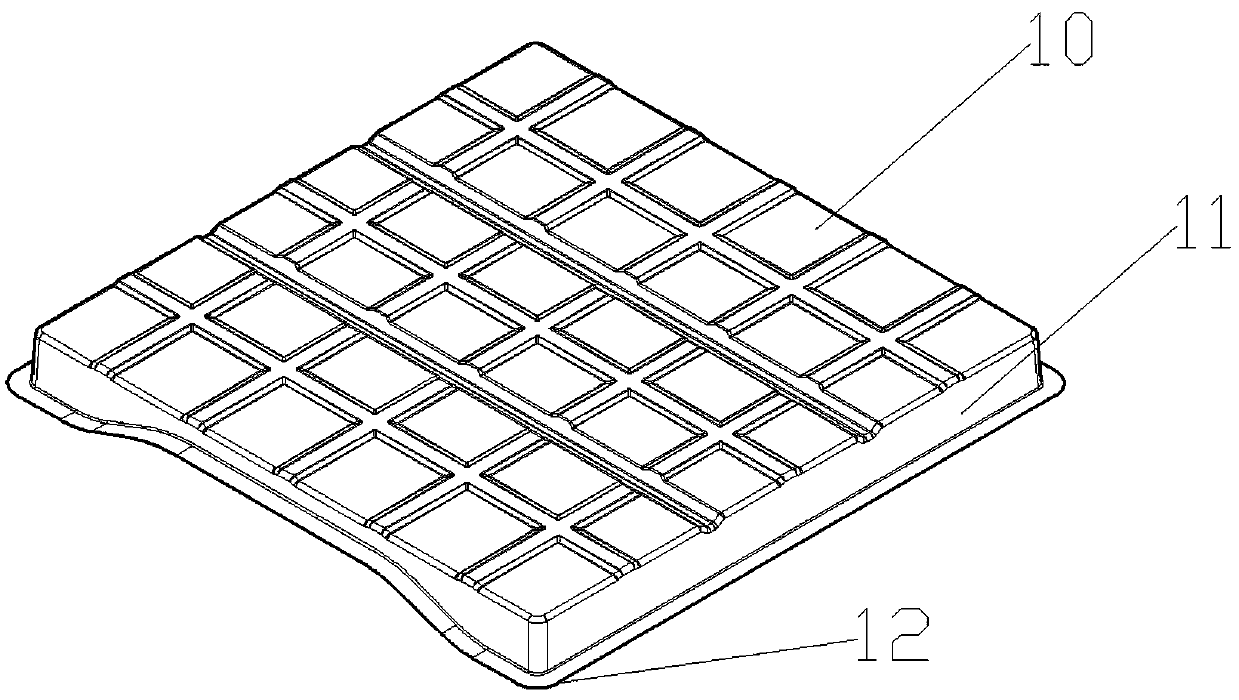

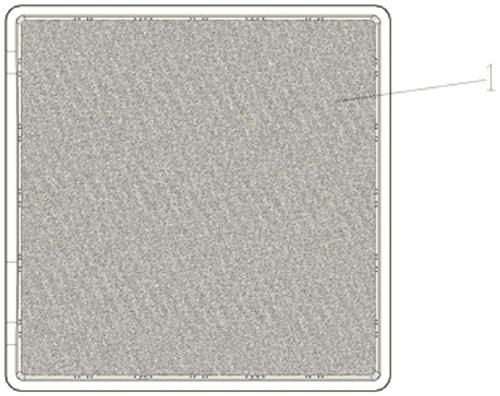

[0061] Such as Figure 1-4 As shown, a thermal runaway prevention composite material battery box cover, including mica paper layer 1, first composite material layer 2, second composite material layer 3, third composite material layer 4, fourth composite material layer laid in sequence from bottom to top Composite material layer 5, fifth composite material layer 6, sixth composite material layer 7, seventh composite material layer 8 and eighth composite material layer 9, the thickness of each layer after molding is 0.3mm, and the thickness of each layer before molding is 0.4mm, the total product thickness is 2.4±0.2mm, the local thickness of the top surface is 2.7±0.2mm, the first composite material layer 2 is a composite material layer with a mica mass fraction of 10%, and the second composite material layer 3 is a mica mass fraction 80% composite material layer, the third composite material layer 4 is a composite material layer with a mica mass fraction of 80%, the fourth com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com