Oil-proofing cover and scroll compressor comprising same

A technology for scroll compressors and oil shields, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc. It can solve the problems of easy loosening and falling of screws, compressor operation failure, and motor ignition, etc., and achieves reduction The effect of increasing the number of assemblies, improving reliability, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

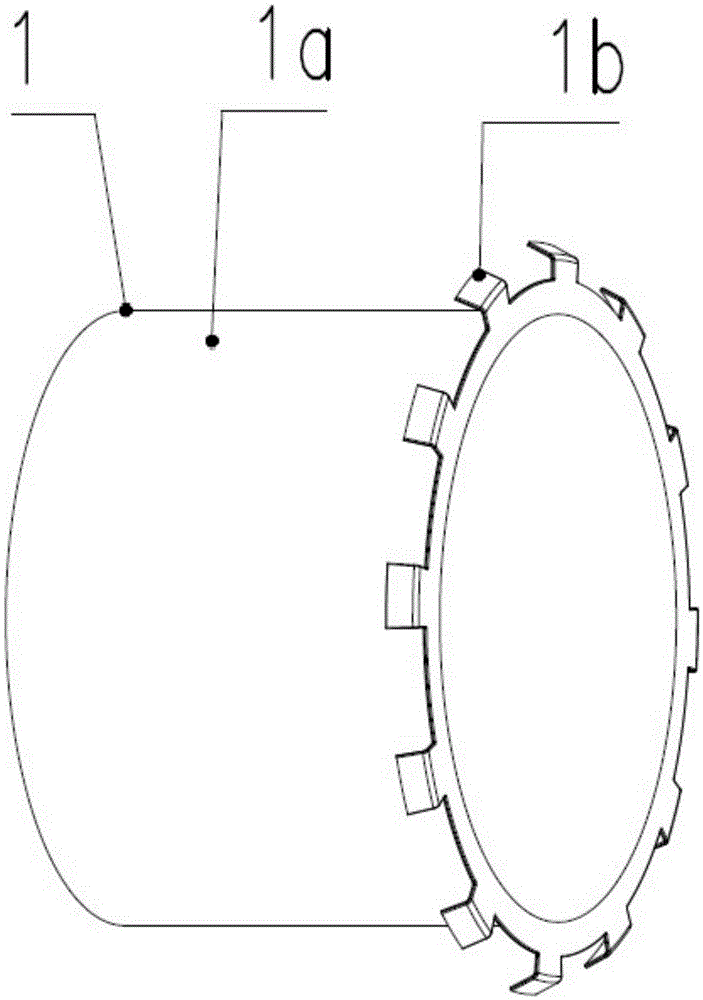

[0032] like figure 2 As mentioned above, the oil deflector 1 provided by one of the embodiments of the present invention generally includes a cylinder part 1a and a buckle part 1b. For the convenience of illustration, the oil deflector 1 is shown in the axial horizontal direction, but in actual use, the oil deflector may be placed axially vertically. Specifically, the buckle part 1b is ring-shaped and provided at one end of the cylinder part 1a. Preferably, the buckle part 1b includes a ring extending outward along one end of the cylinder part, and a toothed pawl structure protruding from the outer peripheral surface of the ring uniformly arranged along the outer periphery of the ring, and the toothed pawl The structure is a flexible structure or the toothed claw structure is made of micro-elastic material.

[0033] The tooth claw structure includes a first straight line segment, a second straight line segment and an arc segment, and the arc segment is connected between the...

Embodiment 2

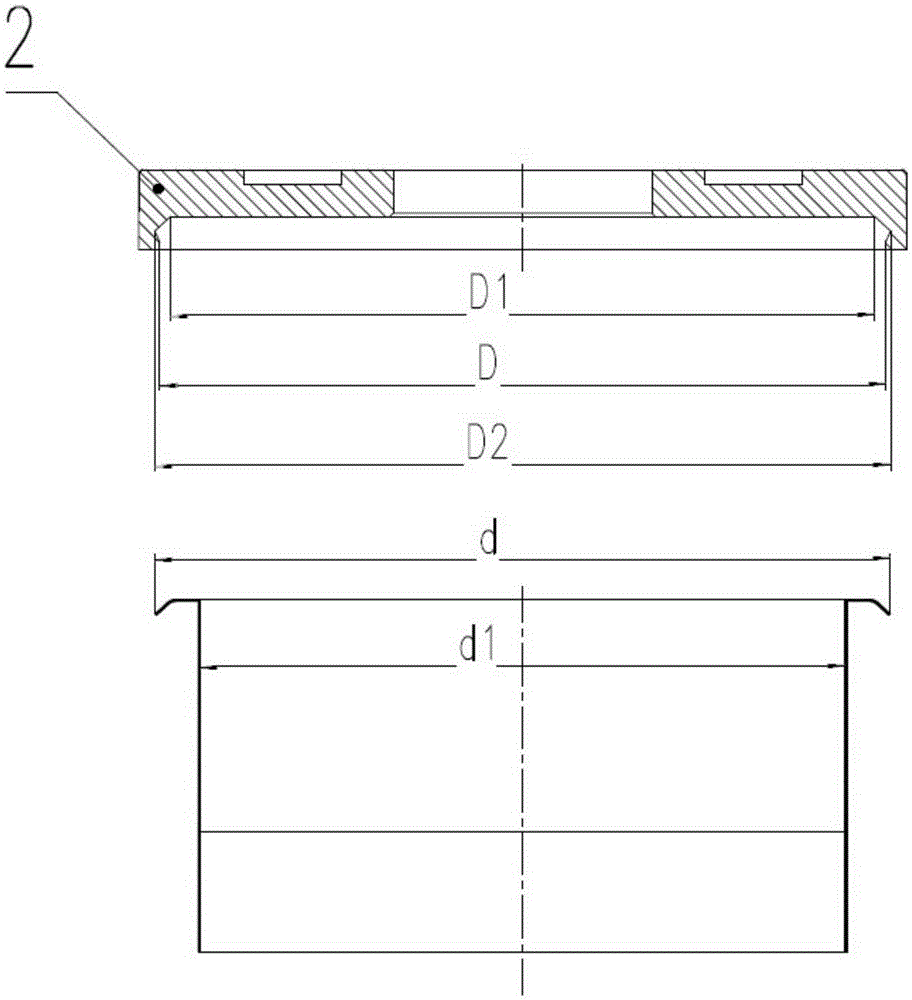

[0040] like Image 6 and Figure 7 As shown in , the oil shield 1 provided by Embodiment 2 of the present invention generally also includes a cylinder portion 1a and a buckle portion 1b. However, different from the first embodiment, the inner diameter of the locking portion 1b is smaller than the inner diameter of the cylindrical portion 1a, and the outer diameter 1b of the locking portion is also smaller than the outer diameter of the cylindrical portion 1a. For the convenience of illustration, the oil deflector 1 is also shown in the axial horizontal direction, but in actual use, the oil deflector can be placed vertically in the axial direction.

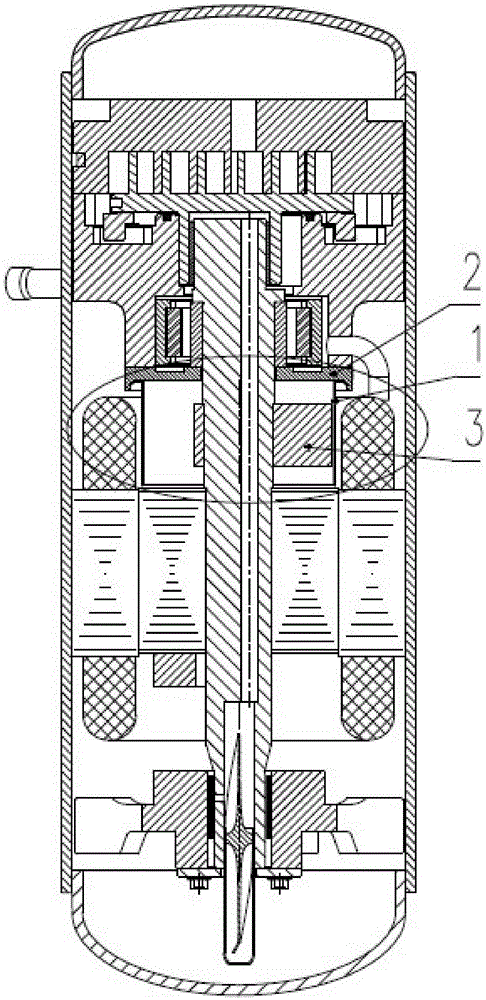

[0041] When the oil shield provided in Embodiment 2 is assembled into the airtight casing of the scroll compressor, the main balance weight 3 is accommodated in the cylinder part of the oil shield 1; the buckle part of the oil shield 1 is buckled on the upper bracket bearing The lower end of the cover plate 2.

[0042] The coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com