Micro leveling mechanism of projection objective of lithography machine

A technology of projection objective lens and lithography machine, which is applied to microlithography exposure equipment, optics, optical components, etc., can solve the problems of low control precision, difficult processing and design of support structure, inconvenient operation, etc., and achieves a simple mechanism structure. , The control of precision is simple and accurate, and the effect of easy processing and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

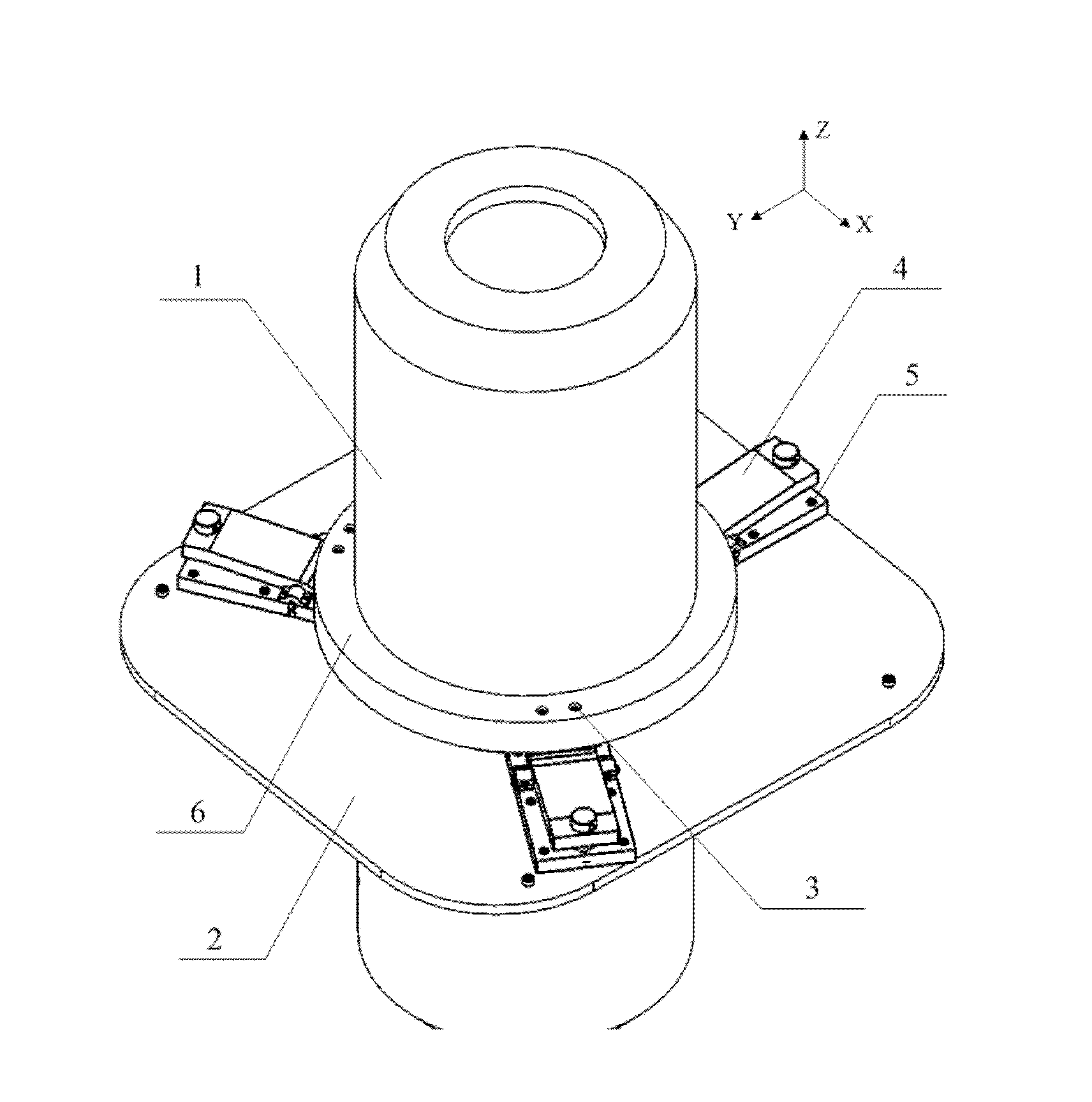

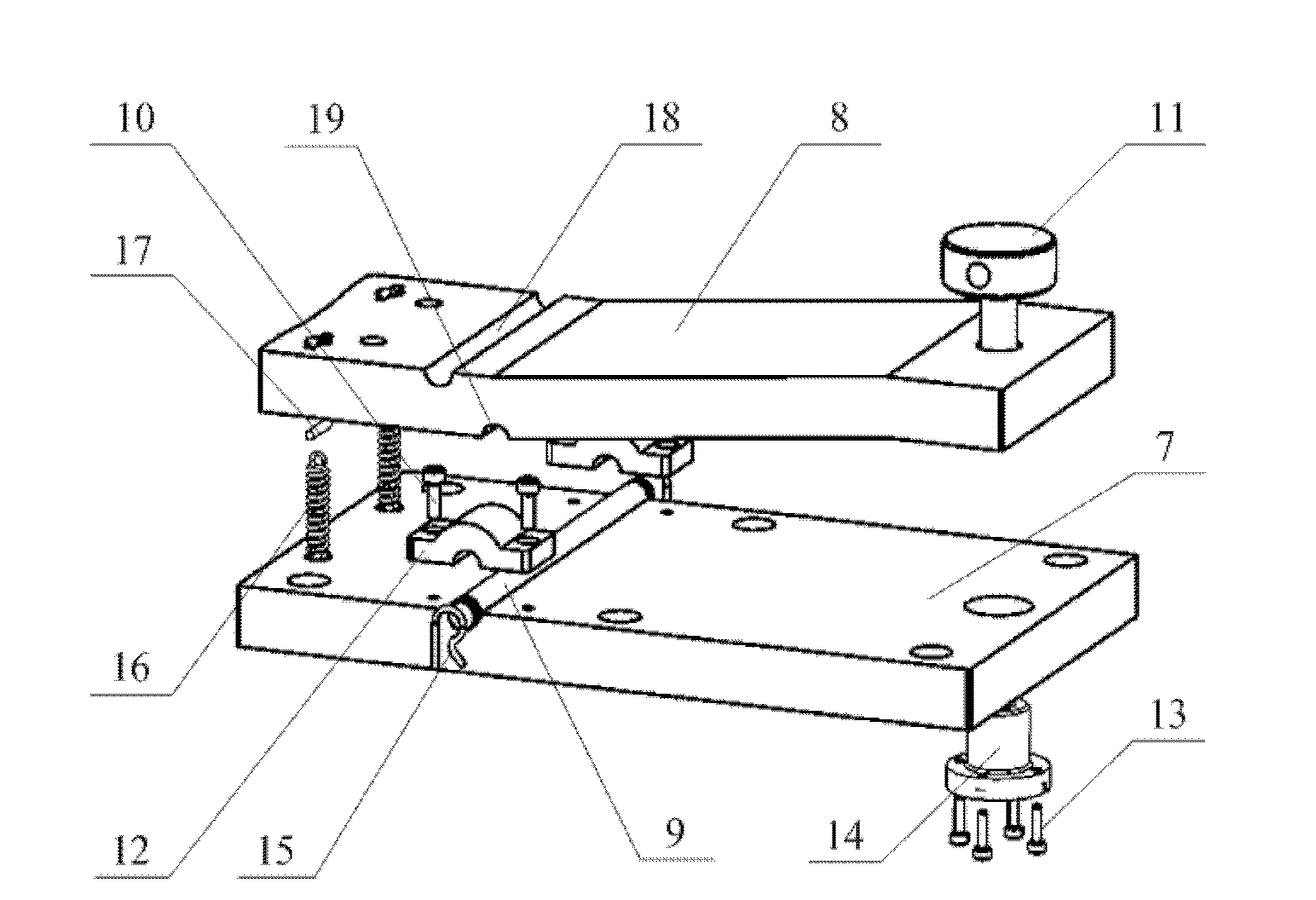

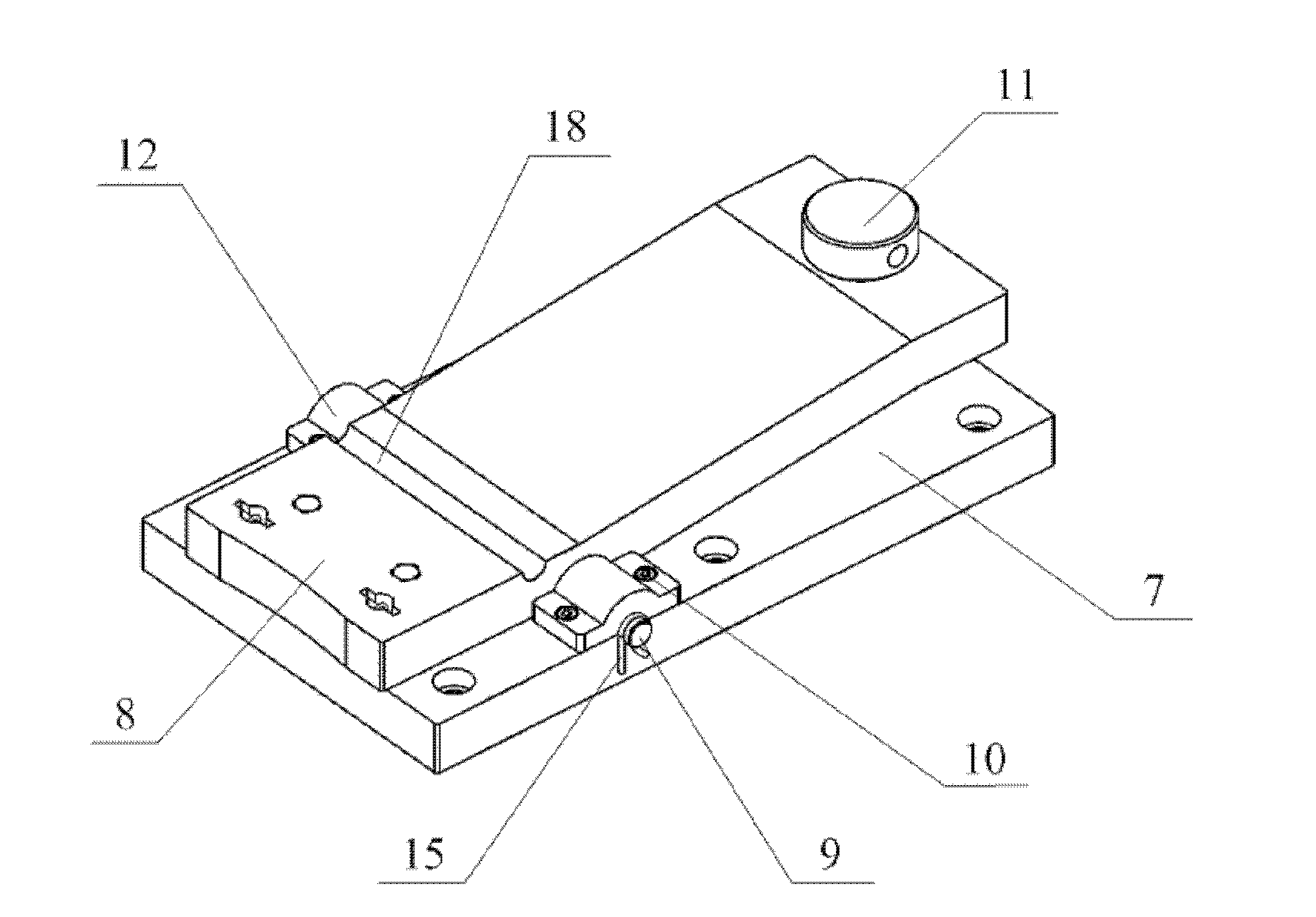

[0018] like figure 1 As shown, the projection objective lens micro-leveling mechanism of the lithography machine of the present invention is used to support and adjust the projection objective lens 1 with the objective lens flange 6, and the leveling mechanism includes a mounting substrate 2, a plurality of support adjustment lever mechanisms 4, fixing screws 5 and Install screw 3. Each support adjustment lever mechanism 4 is made of lever mounting base 7, adjustment lever 8, adjustment screw 11, shaft 9, shaft end cover 12, preload spring 16 and adjustment nut 14, etc., see figure 2 . The support adjustment lever mechanism 4 fixes the lever installation base 7 and the installation substrate 2 through the fixing screws 5 , and connects the installation flange 6 of the projection objective lens 1 with the front end of the adjustment le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com