Organic/inorganic hybrid solar battery and preparation method thereof

A solar cell and inorganic technology, which is applied in the field of hybrid solar cells to achieve the effects of improving efficiency, being simple and easy to process, and facilitating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

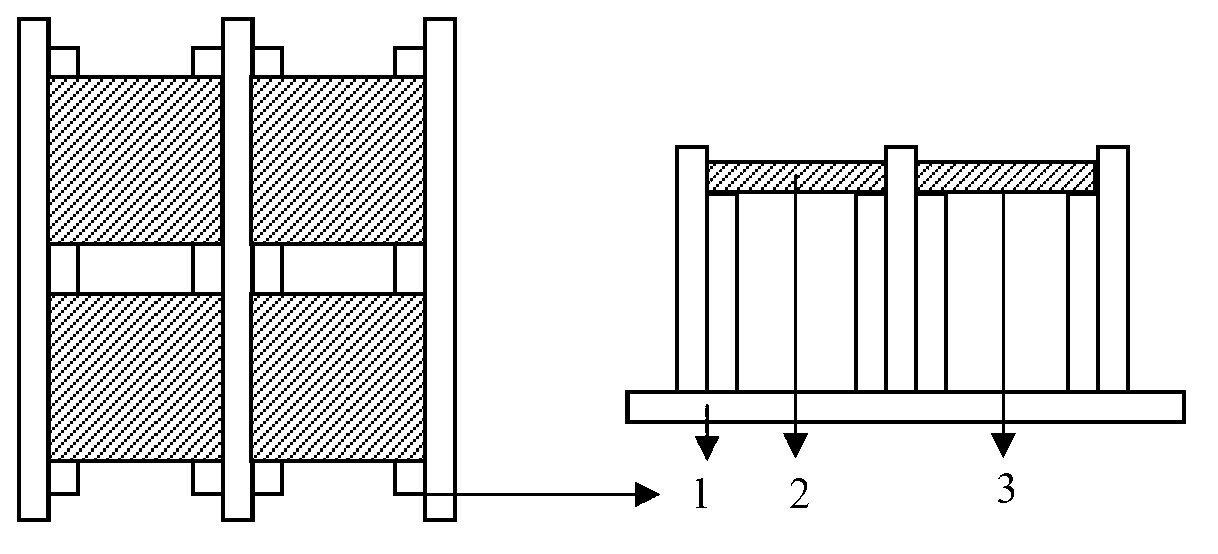

[0034] Example 1: Preparation of organic-inorganic hybrid solar cells by zinc oxide nanorods

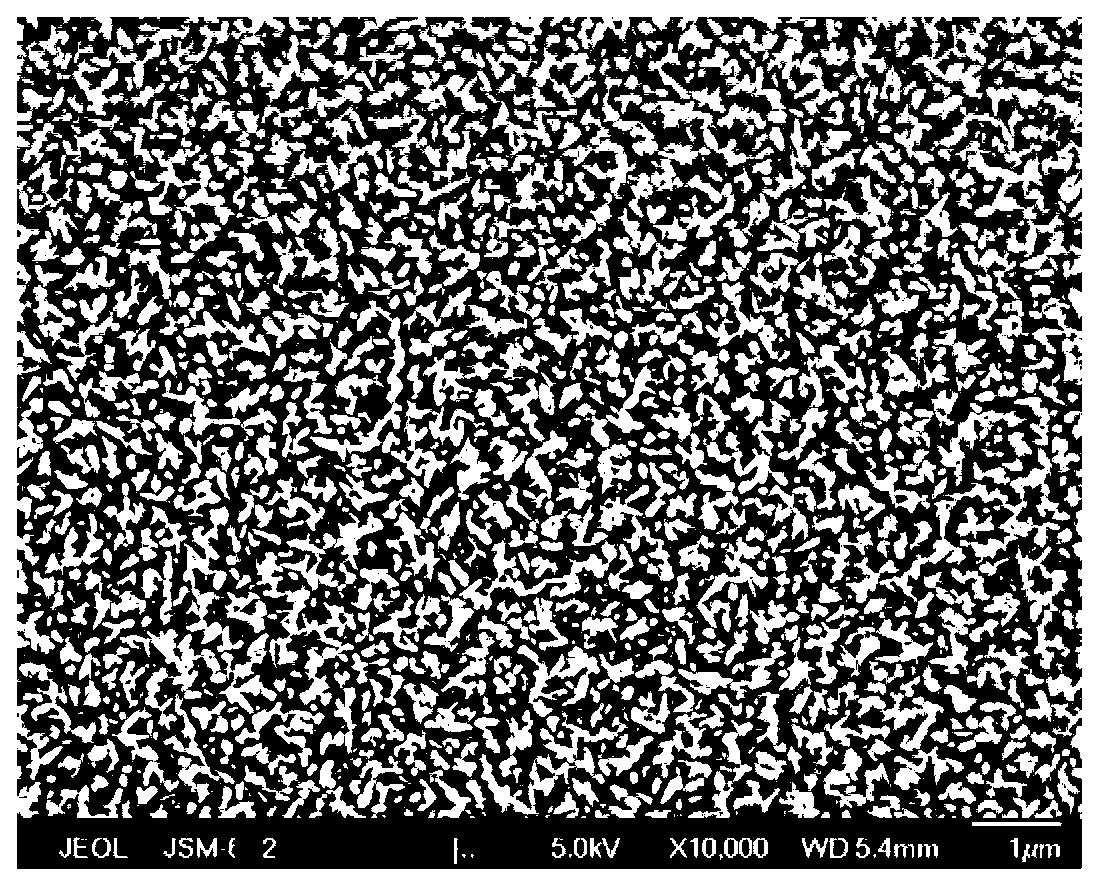

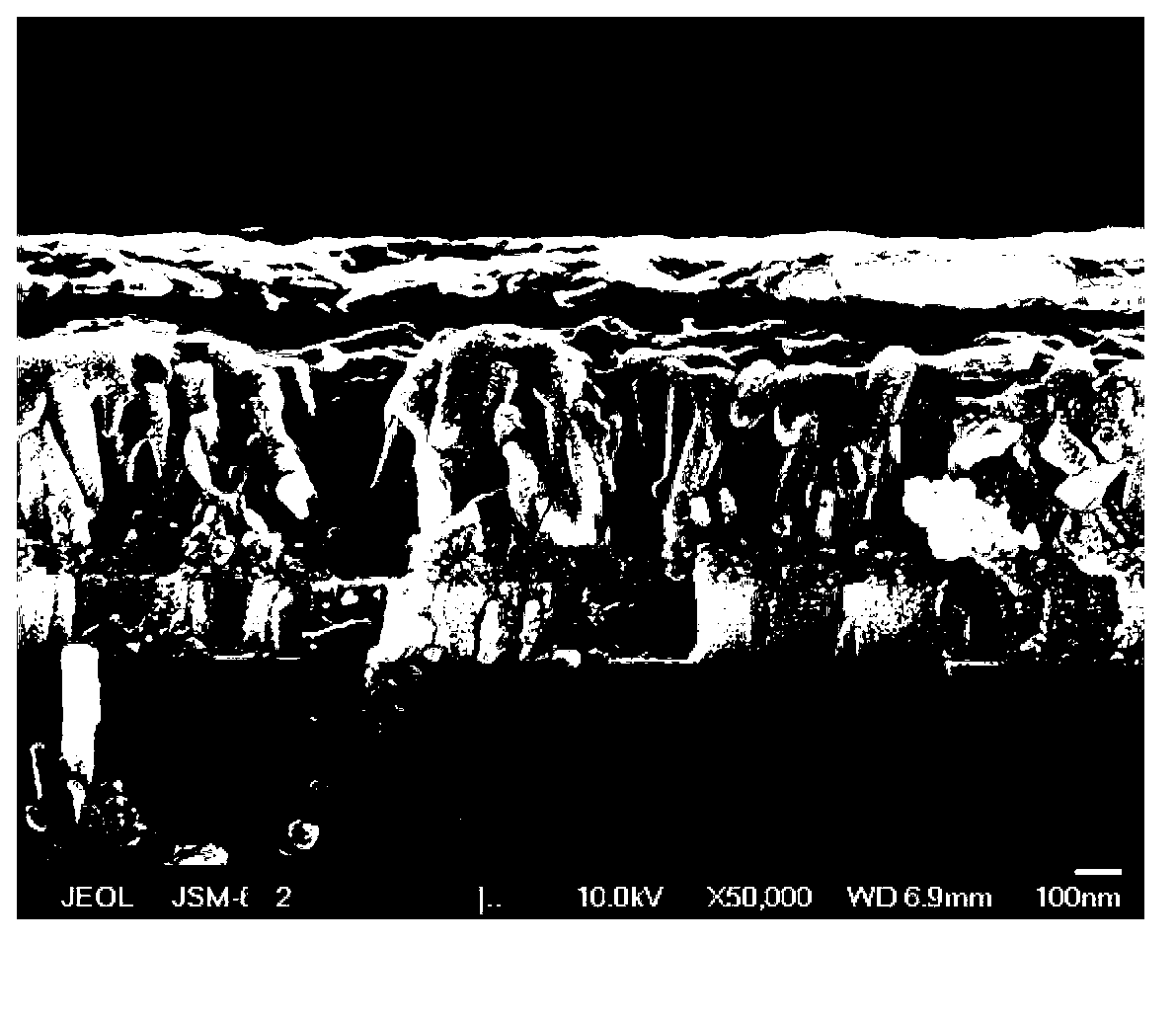

[0035](1) Preparation of one-dimensional zinc oxide nanomaterials: Divide the ITO conductive glass into small pieces of 1.2cm×1.2cm, cover and etch with scotch tape, the etching area is preferably 0.3cm×1.2cm, and the etching solution is the volume fraction 15% hydrochloric acid. After the etching is completed, ultrasonically wash with deionized water, acetone, and isopropanol for 15 minutes respectively. Drop a few drops of seeded ethylene glycol methyl ether sol on the dry conductive glass surface, spin-coat at 3000rpm for 60s, and calcined at 300°C for 20min. The concentrations of zinc acetate and ethanolamine in the seed sol are both 0.75M. Inverted growth of ZnO nanorods in a hydrothermal kettle (see figure 1 ), the concentrations of zinc nitrate and hexamethylenetetramine in the growth solution were both 25mM, and the growth conditions were 92°C for 90min. Cool for 1 hour ...

Embodiment 2

[0040] Example 2: Preparation of organic-inorganic hybrid solar cells by dye-modified nanorod HSC

[0041] The steps of etching, washing, seed layer preparation of ITO conductive glass, preparation of one-dimensional zinc oxide nano-semiconductor material, and heating pretreatment are the same as those in Example 1. The pure organic dye D205 was chosen for the sensitization of one-dimensional nanomaterials. Soak the prepared one-dimensional zinc oxide nanomaterial in D205 dye solution with a concentration of 0.3mM, take it out after 1h, rinse the excess dye on the surface, and dry it. Spin-coat P3HT solution, mask, vapor-deposit silver electrodes, and other steps are the same as in Example 1.

[0042] like Figure 5 As shown, the organic-inorganic hybrid solar cells prepared by using the zinc oxide one-dimensional materials in Examples 1 and 2 as photoanodes have higher photoelectric conversion efficiency than bulk heterojunction hybrid cells and double-layer structure hybri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com