Chemical vapor deposition (CVD) device

A technology of chemical vapor deposition and air intake device, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of low film deposition rate, different heating temperature, and poor film quality, so as to avoid unavoidable The effect of breaking down, improving quality, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

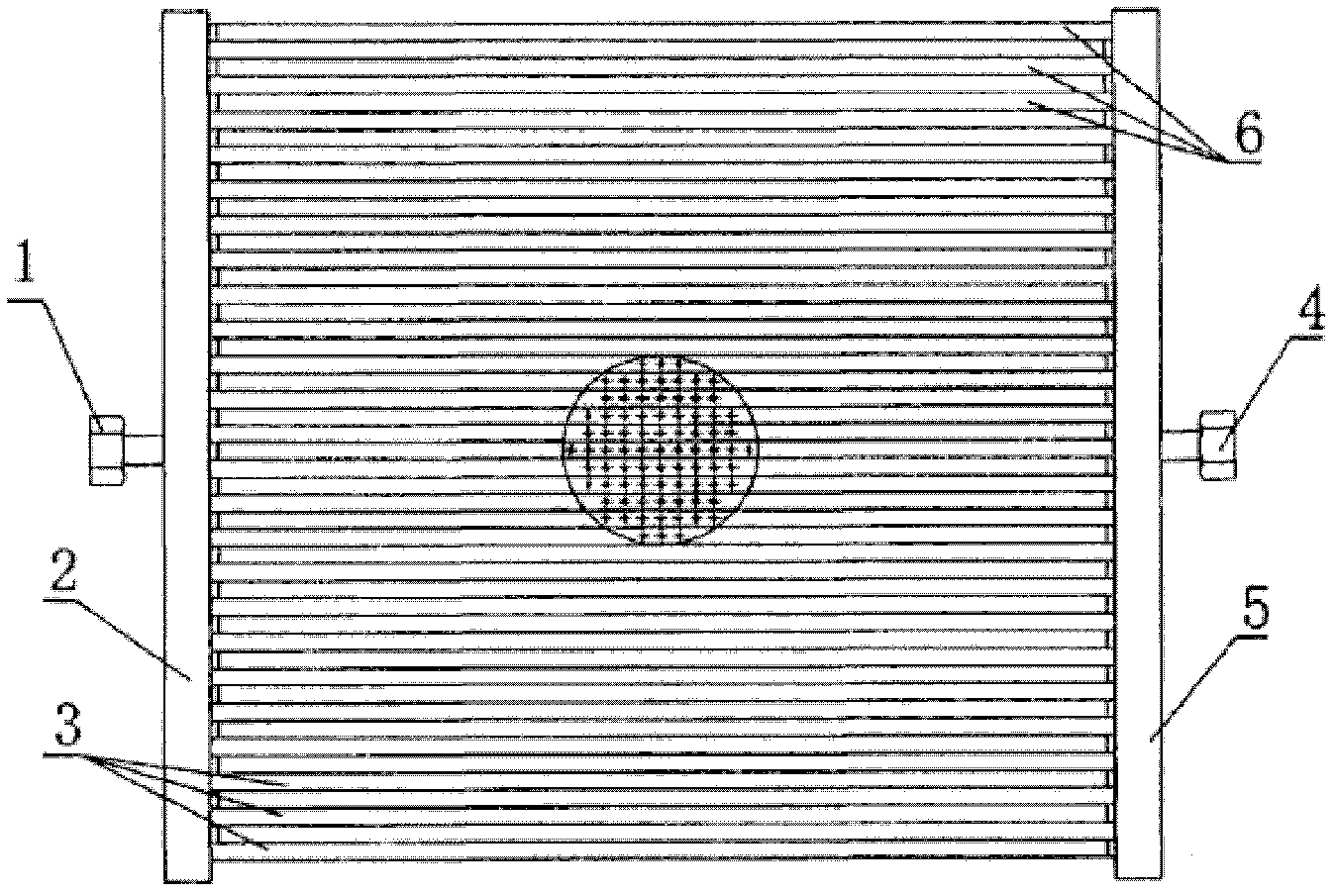

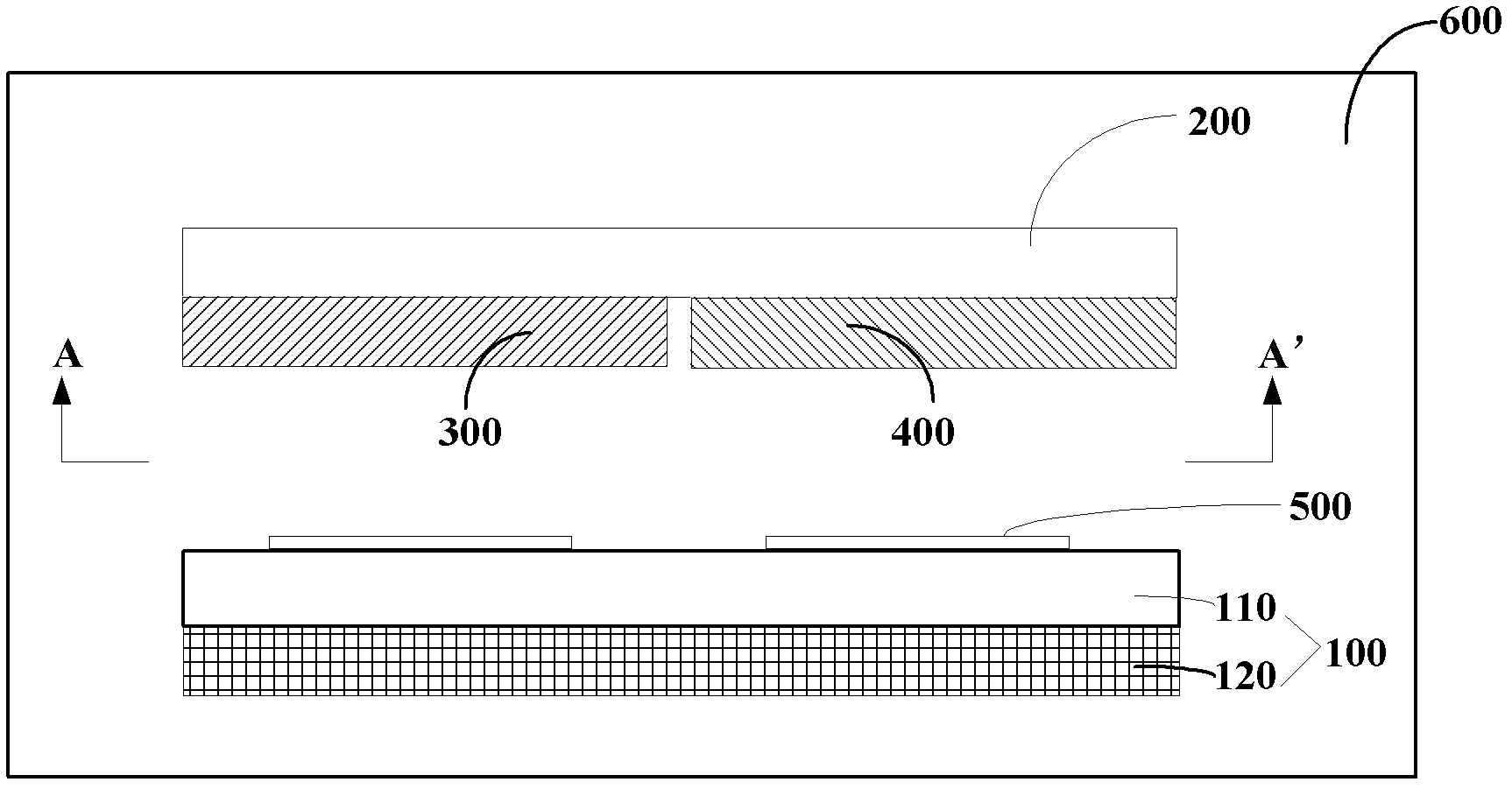

[0059] figure 2 is a schematic structural diagram of the CVD apparatus of this embodiment, image 3 is along figure 2 Schematic diagram of the structure obtained in the direction of AA'. Such as figure 2 and image 3 As shown, the CVD device described in this embodiment includes:

[0060] reaction chamber 600;

[0061] Cooling device 200;

[0062] The shower assembly located at the top of the reaction chamber 600, the shower assembly includes a first gas inlet device 300 and a second gas inlet device 400, which are used to transport the first gas and the second gas to the base 100 and the nozzle respectively. In the reaction zone between shower components, the heat transfer coefficient of the first air inlet device 300 is greater than the heat transfer coefficient of the second air inlet device 400;

[0063] The cooling device 200 is stacked with the first air intake device 300, the cooling device 200 is stacked with the second air intake device 400, and the first ai...

Embodiment 2

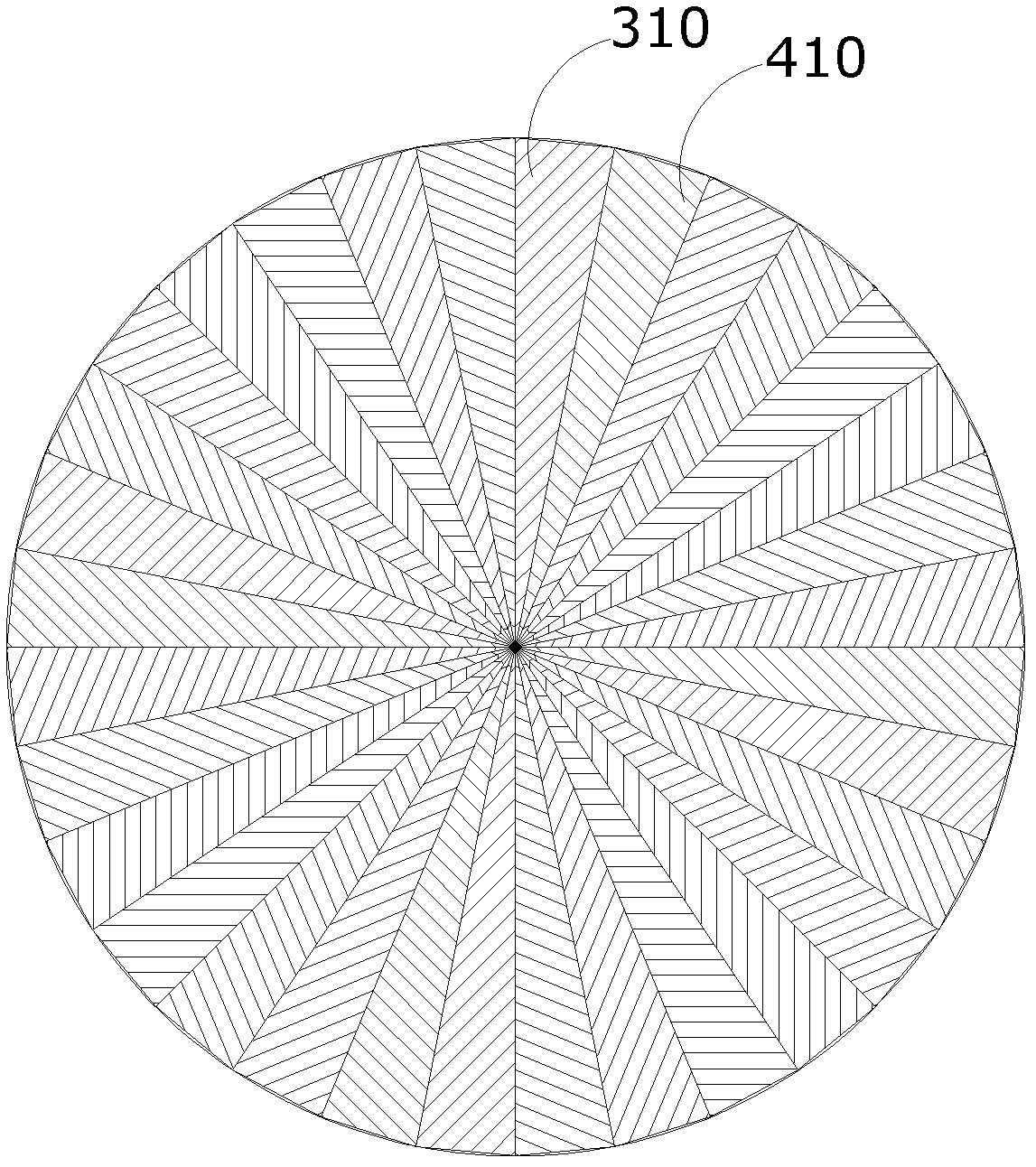

[0091] Figure 4 is a schematic structural diagram of a CVD device according to an embodiment of the present invention, Figure 5 is along Figure 4 Schematic diagram of the structure obtained in the middle BB' direction. see Figure 4 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: the gas diffusion pipe 310 in the first air intake device 300 and the gas diffusion pipe 410 in the second air intake device 400 are both rectangular, and the gas diffusion The tubes 310 and the gas diffusion tubes 410 are arranged alternately in sequence. During the heating process of the heating unit 120 , the first air intake device 300 and the second air intake device 400 have different temperatures.

[0092] In this embodiment, the first air intake device 300 and the second air intake device 400 are combined together, so that the structure of the entire shower assembly is relatively simple. The number and size of the gas diffusion tubes 310 and 410...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com