Cationic polymer and preparation method thereof, and anionic exchange membrane and preparation method thereof

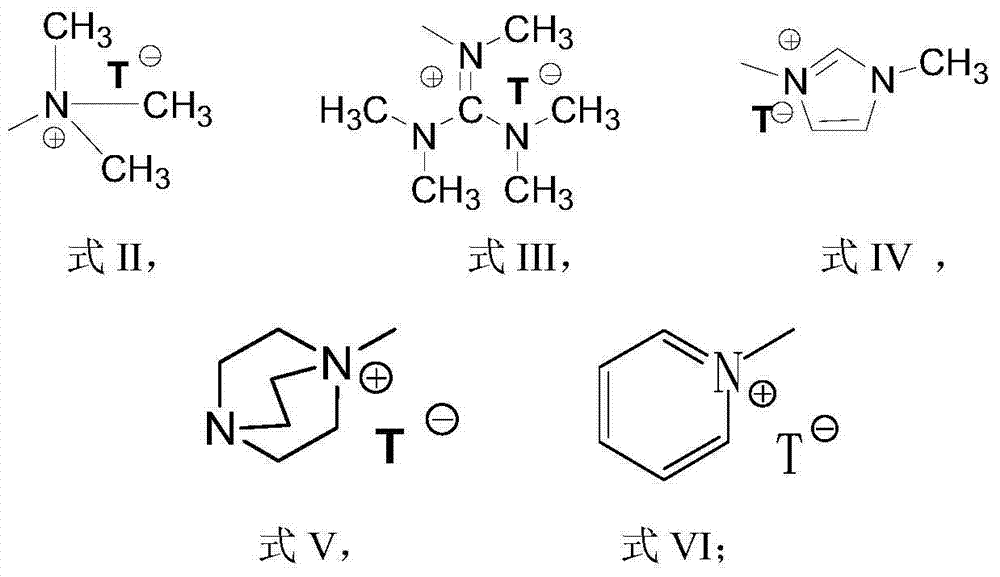

A technology of cationic polymer and anion exchange membrane, applied in the field of anion exchange membrane and its preparation, cationic polymer, can solve the problems of low conductivity, poor alkali resistance, low mechanical strength of anion exchange membrane, etc. The effect of strong alkali resistance and easy and accurate control of ionic group content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

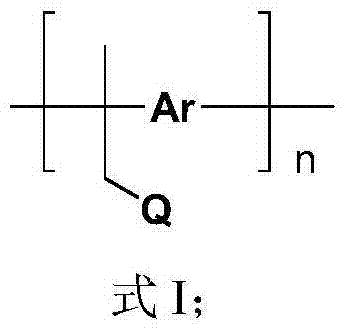

[0052] The cationic polymer of the present embodiment has a structural formula as shown in formula I-1:

[0053]

[0054] However, n is an integer of 10-150.

[0055] The preparation method of the cationic polymer of the present embodiment comprises: according to the ratio that the molar ratio of quaternary ammonium monomer, aryl monomer and trifluoromethanesulfonic acid is 1:1:10, make quaternary ammonium monomer, aryl monomer The solid and trifluoromethanesulfonic acid were added to a three-necked flask with nitrogen, stirred and reacted at 60°C for 24 hours, and then the reaction solution was slowly dropped into ice water, and the precipitate was collected and dried to obtain the cation shown in formula I-1 polymer. The structure of the obtained polymer was confirmed to be consistent with the expectation by H NMR spectrum and elemental analysis. The intrinsic viscosity of the obtained cationic polymer was 0.5 dL / g.

[0056] The reaction formula is as follows:

[0057...

Embodiment 6

[0063] The cationic polymer of the present embodiment has a structural formula as shown in formula I-2:

[0064]

[0065] However, n is an integer of 10-150.

[0066] The preparation method of the cationic polymer of the present embodiment, is to adopt embodiment 1 gained with CF 3 SO 3 - The cationic polymer of anion carries out ion exchange, specifically comprises: adopting the method identical with embodiment 1 to obtain the anion shown in formula I-1 as CF 3 SO 3 - Cationic polymer, the polymer is placed in a concentration of 1mol / L sodium chloride solution and soaked for 48 hours, the anion shown in the formula I-2 is Cl - of cationic polymers. The structure of the obtained polymer was confirmed to be consistent with the expectation by H NMR spectrum and elemental analysis.

Embodiment 7

[0068] The cationic polymer of the present embodiment has a structural formula as shown in formula I-3:

[0069]

[0070] However, n is an integer of 10-150.

[0071] The preparation method of the cationic polymer of the present embodiment comprises: according to the ratio that the molar ratio of quaternary ammonium monomer, aryl monomer and trifluoromethanesulfonic acid is 1.1:1:30, quaternary ammonium monomer, aryl monomer The solid and trifluoromethanesulfonic acid were added to a three-necked flask with nitrogen, stirred and reacted at 25°C for 8 hours, and then the reaction solution was slowly dropped into ice water, and the precipitate was collected and dried to obtain the cation shown in formula I-3 polymer. The structure of the obtained polymer was confirmed to be consistent with the expectation by H NMR spectrum and elemental analysis. The resulting cationic polymer had an intrinsic viscosity of 1.6 dL / g, indicating a high molecular weight polymer.

[0072] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com