Preparation method of anode active material lithium iron phosphate of lithium battery

A cathode active material, lithium iron phosphate technology, used in battery electrodes, circuits, electrical components, etc., can solve the problem that the performance is difficult to meet the requirements of high-power power batteries, and achieve fine grains, improved conductivity, and controllable composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing lithium iron phosphate, a cathode active material for lithium batteries, the steps of the preparation process comprising:

[0030] 1. Prepare lithium source, iron source and phosphorus source according to the molar ratio of 1~1.2 : 1 : 1 to make a solution, and control the total concentration of metal ions in the solution at 0.5~2mol / L.

[0031] 2. Spray-dry the solution at a temperature of 90-350°C to form powder.

[0032] 3. Calcining the obtained powder at a temperature of 400-750° C. for 3-12 hours in a protective atmosphere.

[0033] 4. Rapid cooling to room temperature in the same atmosphere can obtain pure olivine-type lithium iron phosphate or metal ion-doped lithium iron phosphate or a powder material composited with carbon. These materials can be used as large Positive electrode active material for power secondary lithium battery.

[0034] The lithium source mentioned above can be one or more of lithium salts such as lithium carbonate,...

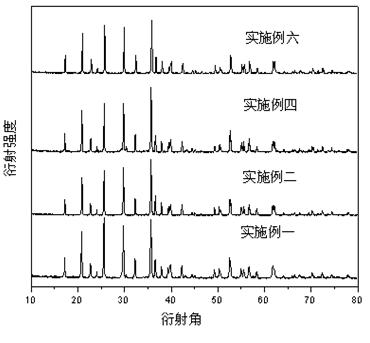

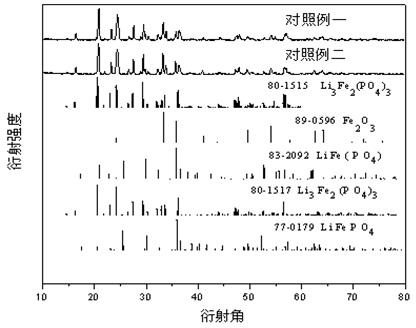

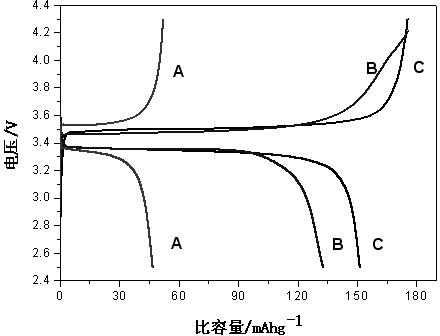

Embodiment 1

[0039] Lithium-ion battery cathode material LIFePO4 preparation method

[0040] 1. Fe(NO3) 3 .9H 2 O 82.45 g (analytical pure, content ≥ 98.5), Li 2 CO 3 7.46g (analytical pure, content ≥ 99), H 3 PO 4 23.06g (analytically pure, content ≥ 85) (Li:Fe:P=1:1:1), weighed with a 500g electronic balance (accuracy 0.01g), put it into a 500ml glass beaker, add 200ml deionized water, stir until completely dissolved.

[0041] 2. Preheat the spray dryer to an outlet temperature of 100°C.

[0042] 3. Put the above-mentioned prepared solution into the nozzle for atomization and drying. 38 g of a pale yellow powder are obtained.

[0043] 4. Put the above powder into a ceramic crucible, put it into a tubular resistance furnace, and then pass in nitrogen gas containing 5% hydrogen. After 20 minutes, turn on the electricity and raise the temperature.

[0044] 5. After the heat preservation is over, cool it down to room temperature (the whole process keeps flowing nitrogen with ...

Embodiment 2

[0047] Lithium-ion battery cathode material LIFePO4 / C composite powder preparation method

[0048] 1. Fe(NO3) 3 .9H 2 O 164.9 g, Li 2 CO 3 15.66g, H 3 PO 4 23.06g (Li:Fe:P=1.05:1:1), weighed with a 500g electronic balance (precision 0.01g), put it into a 500ml glass beaker, add 400ml of deionized water, and stir until completely dissolved.

[0049] 2. Add 5g of pre-dissolved polyethylene glycol 6000 and stir evenly.

[0050] 3. The spray dryer is preheated to an outlet temperature of 120°C, and the above-mentioned prepared solution is added to the nozzle for atomization and drying. 82 g of light mud yellow powder were obtained.

[0051] 4. Put the above powder into a ceramic crucible, put it into a tubular resistance furnace, and then pass in nitrogen gas containing 5% hydrogen. After 20 minutes, turn on the electricity and raise the temperature, and keep the temperature for 9 hours after the temperature rises to 600°C.

[0052] 5. After the heat preservation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com