Platinum alloy nano core-shell cube and preparation method thereof

A nano-core-shell and platinum alloy technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of controllable composition, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 0.017mmol of platinum acetylacetonate and 0.05mmol of cobalt acetylacetonate into a three-neck flask, add 8ml of oleylamine and 2mL of oleic acid, heat and stir at 130°C for 5min under the protection of argon to obtain the first mixed solution A. The first mixed solution A was quickly transferred to an oil bath at 225°C, and after the temperature was stabilized for 5 minutes, carbon monoxide was introduced to react for 30 minutes to obtain a black suspension B. After cooling to room temperature, it was washed with chloroform three times, and vacuum-dried overnight at 60 °C to obtain platinum-cobalt nano-core-shell cubes.

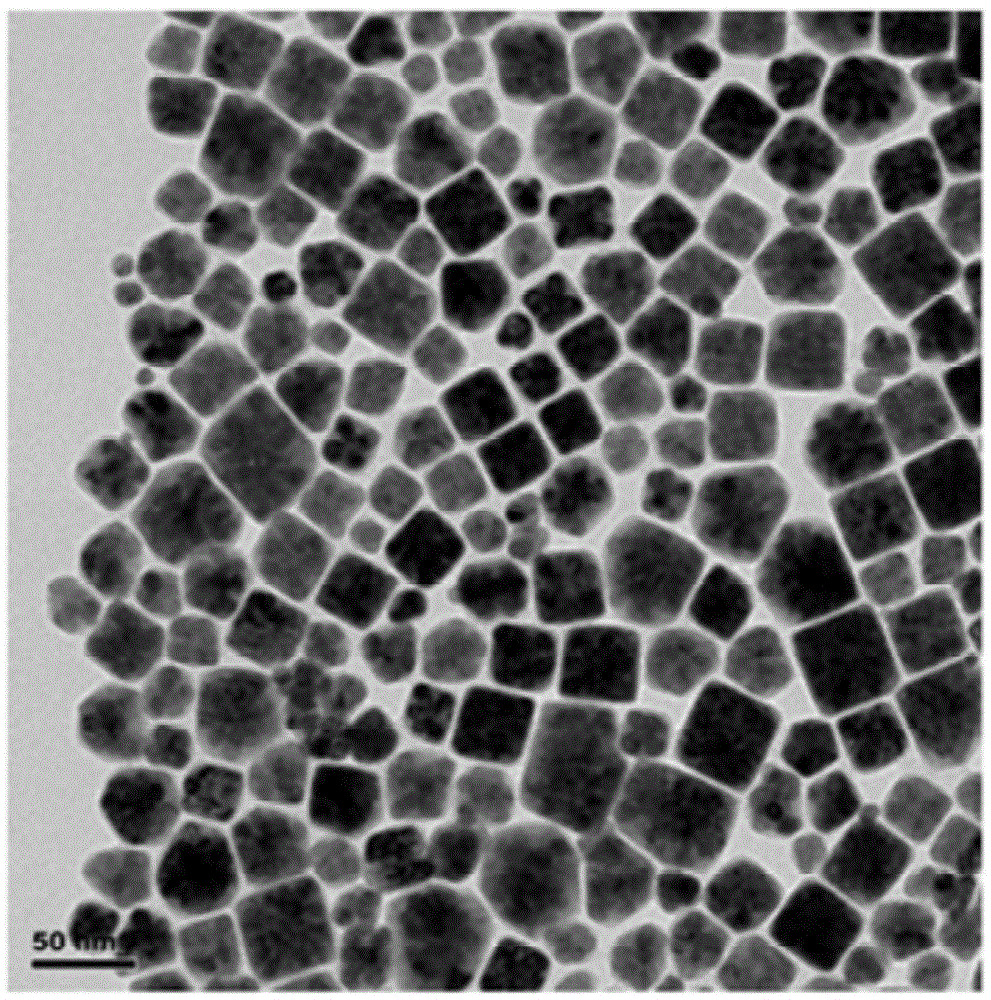

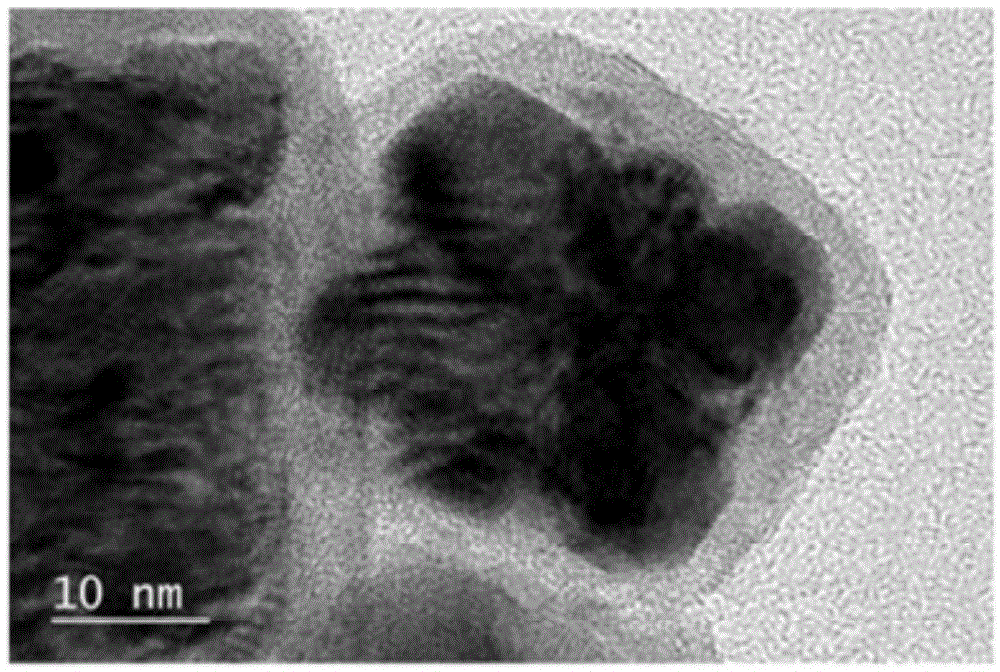

[0030] attached figure 1 The TEM image of the prepared platinum-cobalt nano-core-shell cube particles, attached figure 2 The high-resolution TEM image of the prepared platinum-cobalt nano-core-shell cube particles was obtained by figure 1 and figure 2 It can be seen that the particle size of the obtained platinum-cobalt nano-core-shell cube...

Embodiment 2

[0032] Weigh 0.02mmol of platinum acetylacetonate and 0.05mmol of cobalt acetylacetonate into a three-neck flask, add 8ml of oleylamine and 2mL of oleic acid, heat and stir at 130°C for 5min under the protection of argon to obtain the first mixed solution A. The first mixed solution A was quickly transferred to an oil bath at 220°C, and after the temperature was stabilized for 5 minutes, carbon monoxide was introduced to react for 30 minutes to obtain a black suspension B. After cooling to room temperature, it was washed with chloroform three times, and vacuum-dried overnight at 60 °C to obtain platinum-cobalt nano-core-shell cubes. The platinum-cobalt nano-core-shell cube obtained in this example has similar structure and characteristics to the platinum-cobalt nano-core-shell cube obtained in Example 1.

Embodiment 3

[0034] Weigh 0.017mmol of platinum acetylacetonate and 0.05mmol of cobalt acetylacetonate into a three-necked flask, add 8ml of octadecylamine and 2mL of oleic acid, heat and stir at 140°C for 5min under the protection of argon to obtain the first mixed solution A. The first mixed solution A was quickly transferred to an oil bath at 230°C, and after the temperature was stabilized for 5 minutes, carbon monoxide was introduced to react for 40 minutes to obtain a black suspension B. After cooling to room temperature, it was washed with chloroform three times, and vacuum-dried overnight at 60 °C to obtain platinum-cobalt nano-core-shell cubes. The platinum-cobalt nano-core-shell cube obtained in this example has similar structure and characteristics to the platinum-cobalt nano-core-shell cube obtained in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com