Method for preparing layered titanium-based composite material based on powder laying - hot pressing sintering

A titanium-based composite material and hot-pressing sintering technology, which is applied in the field of powder coating and hot-pressing sintering to prepare layered titanium-based composite materials, can solve the problems of difficult layer thickness, low bonding strength, complicated material preparation process, etc. Achieve the effect of less defects, high interface bonding strength and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

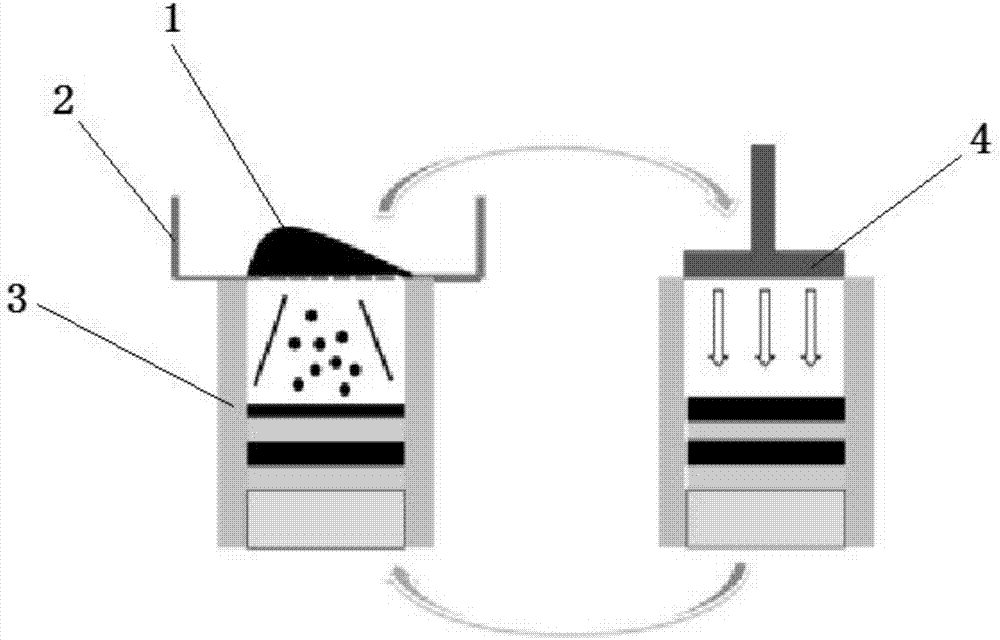

[0026] Specific implementation mode 1: A method for preparing layered titanium-based composite materials by powder spreading-hot pressing and sintering in this embodiment is carried out according to the following steps:

[0027] 1. Powder spreading: set a sieve above the mold, pour the plastic layer powder through the sieve into the mold, use a steel pressure head to flatten and compact the plastic layer powder, and then pour the high-strength layer powder into the mold through the sieve. Then use a steel pressure head to flatten and compact the high-strength layer powder, and repeat the above operations according to the required number of layers to obtain a composite material powder body;

[0028] The plastic layer powder is pure titanium powder, titanium alloy or a titanium-based composite material containing a low-content reinforcement; the content of the reinforcement in the titanium-based composite material containing a low-content reinforcement is ≤ 3vol.%;

[0029] The ...

specific Embodiment approach 2

[0039]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the plastic layer powder in step 1 is TC4 powder. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the plastic layer powder in step 1 is a titanium-based composite material with a reinforcement content of 3 vol.%. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com