Metal composite pipe fitting preparation device and preparation method

A technology for metal composite pipes and preparation devices, which is applied in the field of layered metal composite composite materials, can solve the problems of difficult control of surface layer metal thickness, low injection molding efficiency, and difficult control of process parameters, etc., so as to improve molding efficiency and quality, Effect of preventing deformation and cracking and eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and should not be used to limit the scope of protection of this patent. In addition, the terms "first", "second", etc. are used for descriptive purposes only, and should not be understood as indicating or implying relative importance or implicitly specifying the quantity of the indicated technical features.

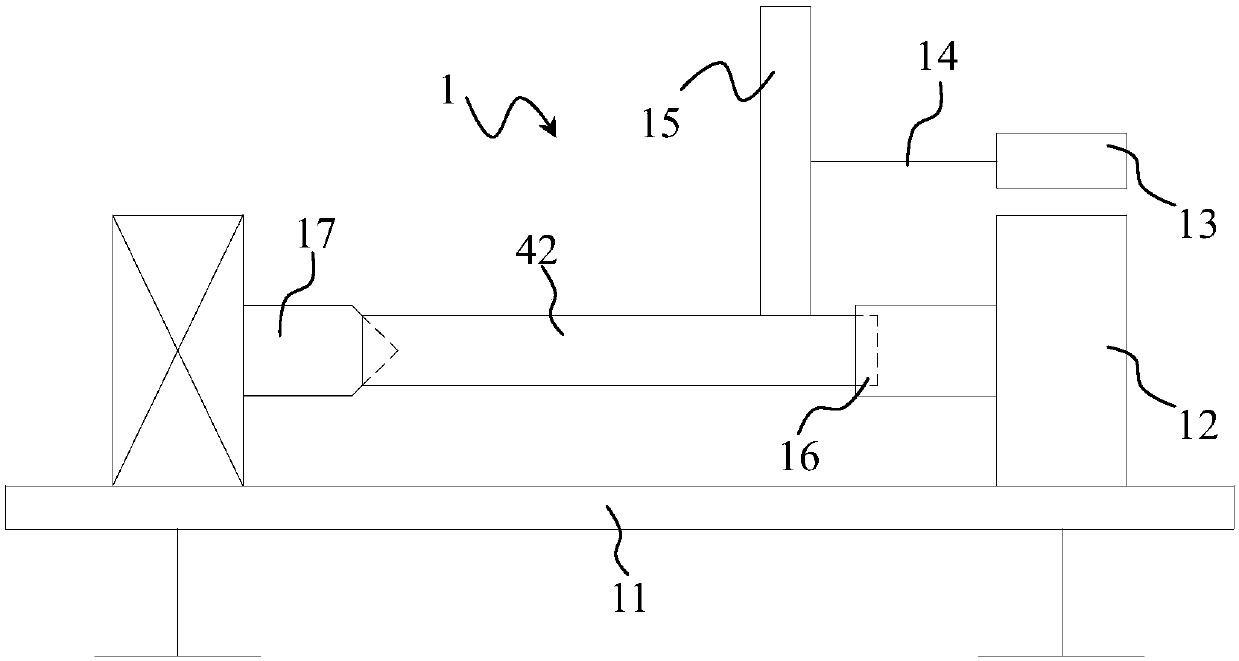

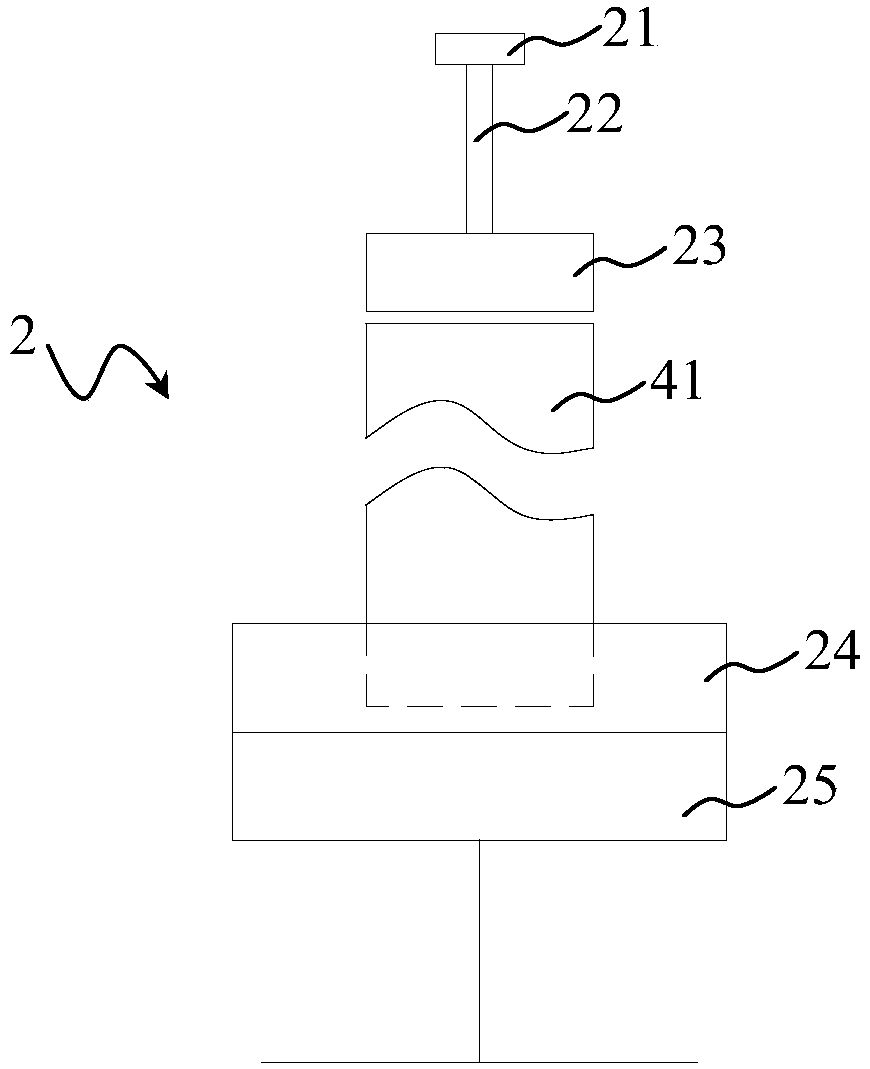

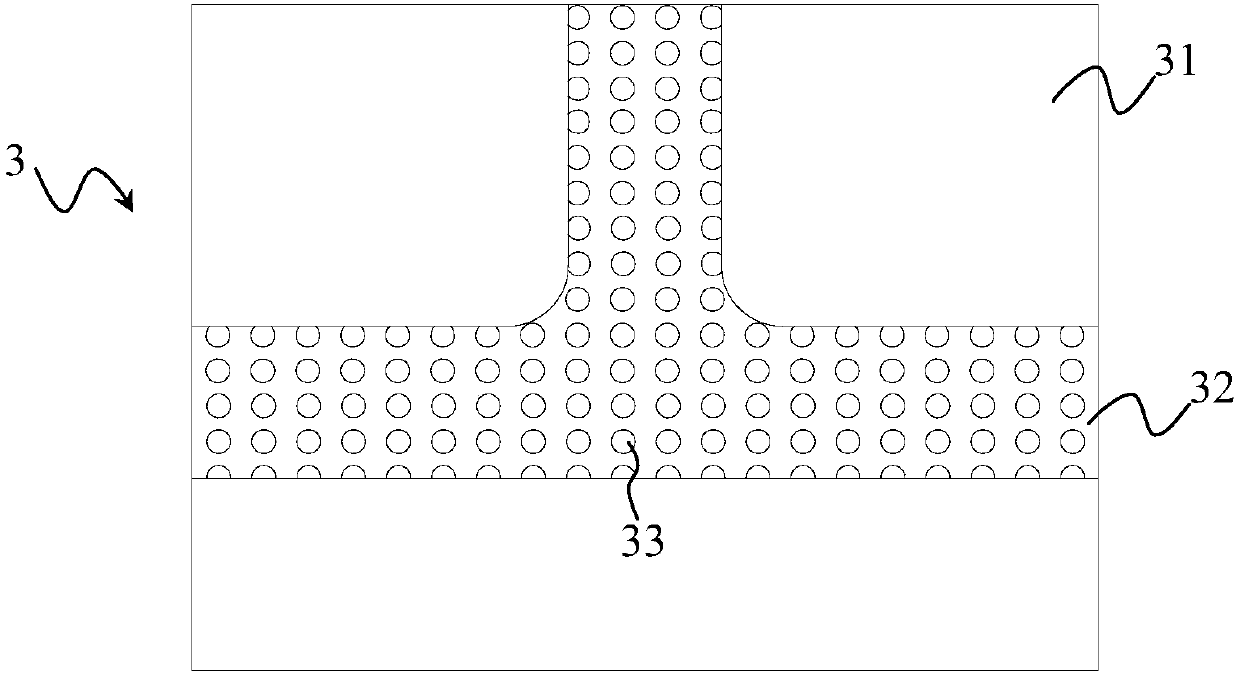

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 , this embodiment discloses a metal composite pipe fitting preparation device, including an alkali solution pool, a metal inner liner pipe surface treatment device 1, a metal outer pipe surface treatment device 2, a composite device, a cold push forming device, a solid solution treatment furnace, a recycling The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com