A kind of preparation method of large-format thick multi-layer zirconium/steel metal composite plate

A metal composite board, large-format technology, applied in the direction of metal layered products, chemical instruments and methods, metal material coating technology, etc., can solve the production failure of thick multilayer zirconium/steel metal composite board, and the separation of titanium plate and steel plate , Combined with the problems of low strength, to achieve the effect of suitable promotion, low difficulty and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

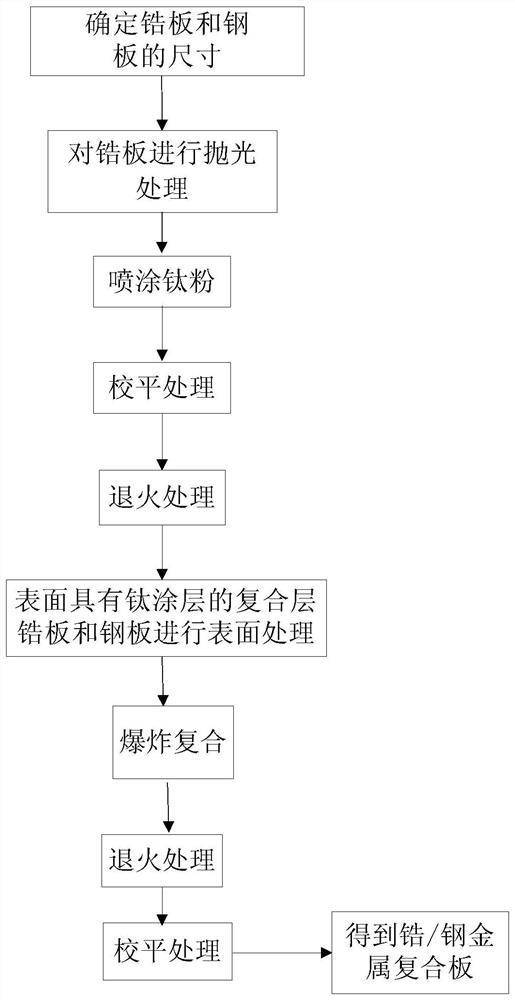

[0040] This embodiment includes the following steps:

[0041] Step 1. According to the size of the target product steel-metal composite plate, select a zirconium plate whose grade is R60702 and whose size is 5mm×1040mm×1540mm (thickness×width×length) and whose grade is Q345R whose size is 40mm×1000mm×1500mm (thickness× width × length) steel plate;

[0042] Step 2, polishing the surface of the zirconium plate selected in step 1 to obtain a composite layer zirconium plate; the surface roughness of the composite layer zirconium plate is 20 μm;

[0043] Step 3, spraying TA1 titanium powder on the composite layer zirconium plate obtained in step 2, to obtain a composite layer zirconium plate with a titanium coating on the surface;

[0044] Step 4. The composite layer zirconium plate with titanium coating on the surface obtained in step 3 is subjected to leveling treatment and annealing treatment in sequence, and then the steel plate selected in step 1 and the composite layer with ...

Embodiment 2

[0052] This embodiment includes the following steps:

[0053] Step 1. According to the size of the target product steel-metal composite plate, select a zirconium plate with a grade of R60700 and a size of 12mm×1040mm×1540mm (thickness×width×length) and a grade of Gr70 with a size of 260mm×2000mm×2500mm (thickness× width × length) steel plate;

[0054] Step 2, polishing the surface of the zirconium plate selected in step 1 to obtain a composite layer zirconium plate; the surface roughness of the composite layer zirconium plate is 15 μm;

[0055] Step 3, spraying TA2 titanium powder on the composite layer zirconium plate obtained in step 2 to obtain a composite layer zirconium plate with a titanium coating on the surface;

[0056] Step 4. The composite layer zirconium plate with titanium coating on the surface obtained in step 3 is subjected to leveling treatment and annealing treatment in sequence, and then the steel plate selected in step 1 and the composite layer with titani...

Embodiment 3

[0064] This embodiment includes the following steps:

[0065] Step 1. According to the size of the target product steel-metal composite plate, select a zirconium plate with a grade of R60702 and a size of 8mm×1840mm×1840mm (thickness×width×length) and a grade of 16Mn with a size of 100mm×1800mm×1800mm (thickness× width × length) steel plate;

[0066] Step 2, polishing the surface of the zirconium plate selected in step 1 to obtain a composite layer zirconium plate; the surface roughness of the composite layer zirconium plate is 12 μm;

[0067] Step 3, spraying TA1 titanium powder on the composite zirconium plate obtained in step 2 to obtain a composite zirconium plate with a titanium coating on the surface;

[0068] Step 4. The composite layer zirconium plate with titanium coating on the surface obtained in step 3 is subjected to leveling treatment and annealing treatment in sequence, and then the steel plate selected in step 1 and the composite layer with titanium coating on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com