A preparation method of ultra-high temperature ceramic matrix composite material with axial gradient and plane homogeneity

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of C/C composite material preparation, can solve problems such as the reduction of mechanical properties, and achieve the effect of avoiding uneven distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

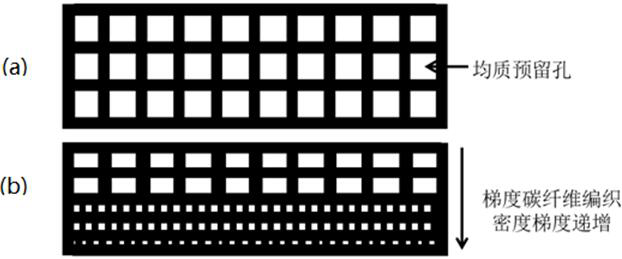

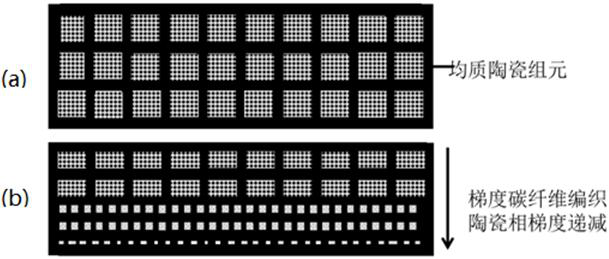

[0082] like figure 1 As shown in the figure, the preform is prepared by the method of fine braided puncture, and the gradient structure of the density of the preform is controlled by controlling the diameter of the steel needle (which is a metal steel needle), wherein the puncture tool used for the near ablation end of the fine braided puncture preform is prepared The diameter of the piercing tool used to prepare the ablation transition section of the finely braided puncture preform is 0.2 mm, and the diameter of the puncturing tool used to prepare the far ablation end of the finely braided puncture preform is 0.1 mm.

[0083] (1) The finely braided puncture preform forms a carbon fiber preform structure with gradient changes in carbon fiber content and density from the near ablation end to the far ablation end, with a total thickness of 20mm, and is reserved for the introduction of ultra-high temperature ceramics. Refractory metal and alloy wire or rod, with a density of 0.9 ...

Embodiment 2

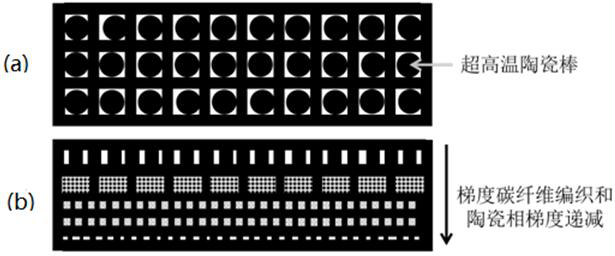

[0091] The preform is prepared by the method of fine weaving puncture, and the ultra-high temperature ceramic needle is used as the puncturing tool. When weaving the near ablation end, the diameter of the three-dimensional weaving is selected to form a gradient of carbon fiber content and density from the near ablation end to the far ablation end. The carbon fiber prefab structure,

[0092] (1) The density of the carbon fiber preform near the ablation end is 0.9g / cm 3, the density of the carbon fiber preform increases from the near ablation end to the far ablation end, while the density of the carbon fiber preform at the far ablation end is 1.1g / cm 3 . At the same time, in the process of axial needling, the ultra-high temperature ceramic rod ZrC was selected as the needling structure at the same time, and the ultra-high temperature ceramic rods of different densities were implanted in different axial regions in the carbon fiber preform. Among them, the diameter of the cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com