A kind of preparation method of electromagnetic shielding cable

An electromagnetic shielding and cable technology, which is applied in the field of electromagnetic shielding cable preparation, can solve the problems of reducing cable weight and poor cable shielding effect, and achieve the effects of simplifying the production process, improving flexibility, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing an electromagnetic shielding cable, the electromagnetic shielding cable includes a conductive wire core and a coating layer, the coating layer includes two phases of an insulating phase and a conductive phase, and the insulating phase is made of silicone rubber-high temperature resistant silicate nanoparticles Composite material, the conductive phase of the cladding layer is made of silicone rubber-graphene composite material, the preparation method of the electromagnetic shielding cable comprises the following steps:

[0035] Step 1, material preparation, adding high temperature resistant silicate nanoparticles to sulfur-containing organic matter for surface modification; adding graphene oxide to sulfur-containing organic matter to modify the surface of graphene;

[0036] Step 2. Add the surface-modified high-temperature silicate nanoparticles into the silicone rubber, and then mix the rubber on the mixer. After the rubber mixing is completed, a u...

Embodiment 1

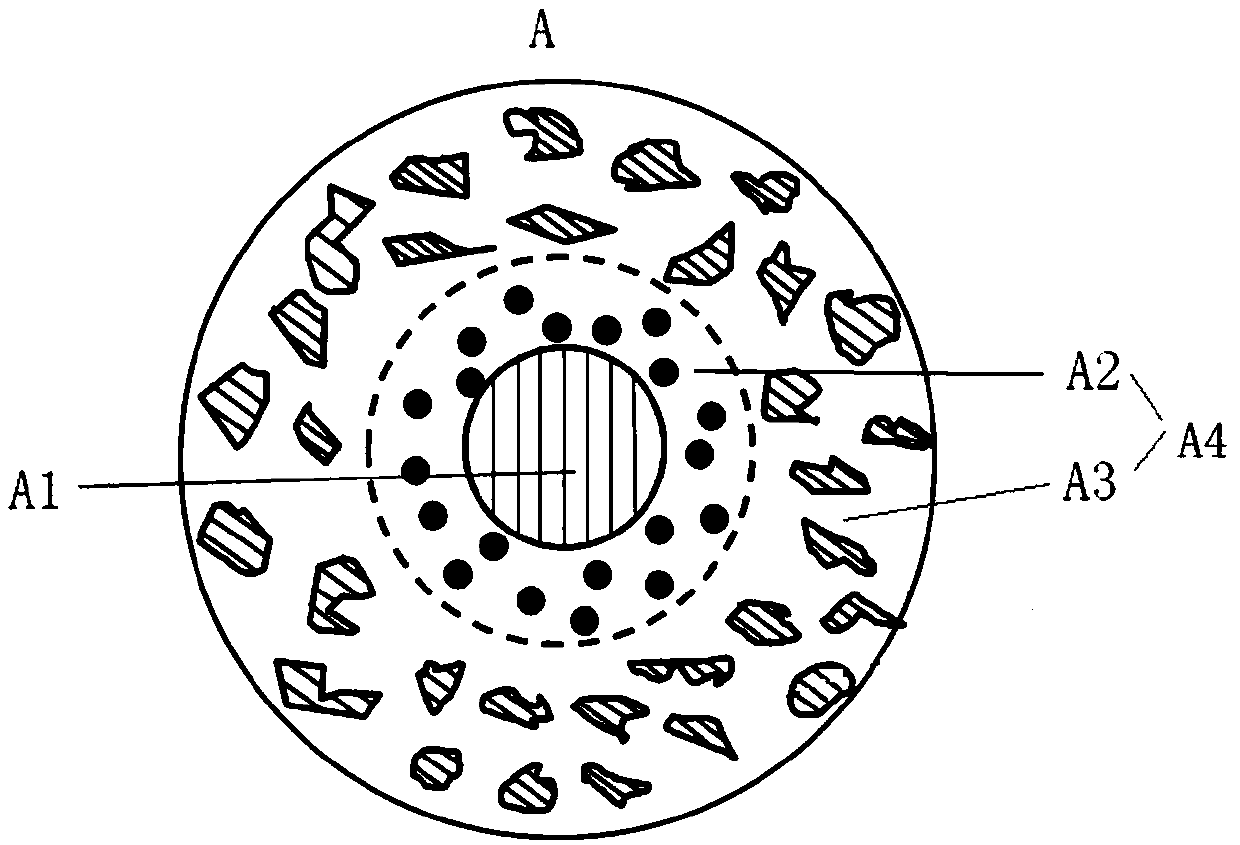

[0046] Such as figure 1 As shown, an electromagnetic shielding cable A includes a conductive core A1 and a coating layer A4 coated on the outside of the conductive core A1. The conductive core A1 and the coating layer A4 form a coaxial cable. The coating Layer A4 is a single-layer multi-phase structure. The cladding layer A4 includes an insulating phase A2 and a conductive phase A3 for electromagnetic shielding from the inside to the outside. The insulating phase A2 of the cladding layer A4 is made of silicone rubber-high temperature resistant silicate Made of nanoparticle composite material, the conductive phase A3 of the cladding layer A4 is made of silicone rubber-graphene composite material, high temperature resistant silicate nanoparticles and graphene are uniformly dispersed in the silicone rubber as the matrix material to form no physical Boundary single-layer structure.

[0047] The conductive core A1 may be formed by a single conductive core, or may be formed by inte...

Embodiment 2

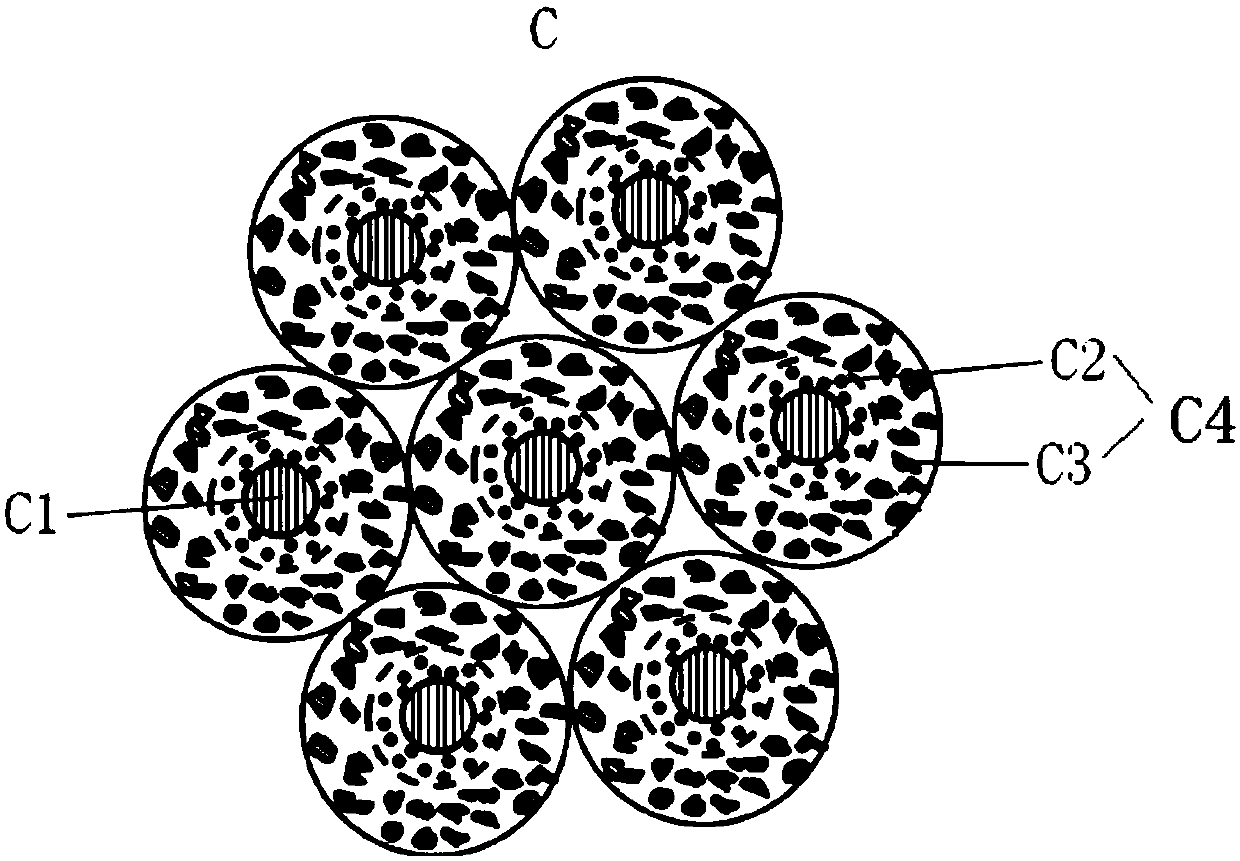

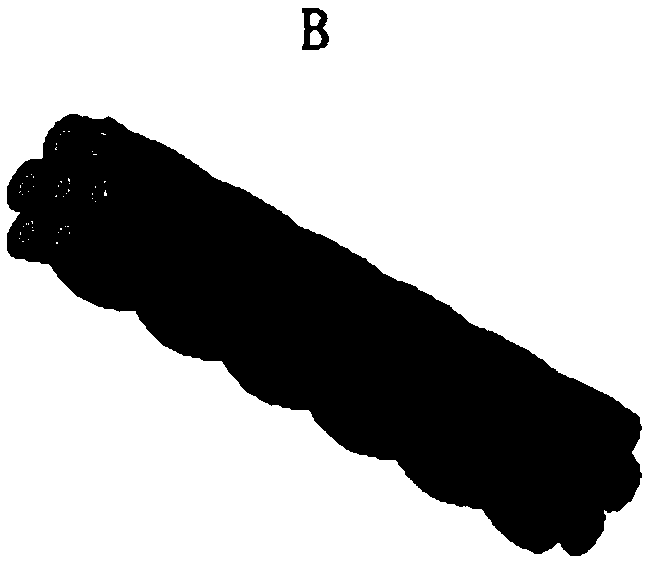

[0051] see figure 2 and image 3 As shown, the cross-sectional schematic diagram of the electromagnetic shielding cable B disclosed in the second embodiment of the present invention is shown in C, which includes a plurality of conductive cores C1 (a total of seven conductive cores are shown in the figure), and each conductive core C1 is covered A cladding layer C4, wherein the cladding layer C4 is composed of an insulating phase C2 and a conductive phase C3 as an electromagnetic shielding layer. Since the insulating phase C2 and the conductive phase C3 have the same base material, a single-layer cladding layer C4 can be formed. The cable as a whole has a helical twisted structure. The function of the conductive phase C3 is to individually shield each conductive core C1, which can not only prevent external factors from interfering with the electrical signals transmitted inside the conductive core C1, but also prevent interference between different electrical signals transmitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com