Method for preparing lithium iron phosphate serving as positive active material of lithium battery

A positive electrode active material, lithium iron phosphate technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of large drying shrinkage, difficulty in industrial production, and high price of metal alkoxides, to achieve fine grain size and improve conductivity , the effect of controllable ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing lithium iron phosphate, a cathode active material of a lithium battery according to the present invention, the steps of the preparation process include:

[0030] 1. The lithium source, the iron source and the phosphorus source are formulated into a solution according to the molar ratio of 1-1.1:1:1, and the total concentration of metal ions in the solution is controlled at 0.5-2 mol / L.

[0031] 2. Add citric acid or ammonium citrate to the solution prepared in the first step, (at the same time, add doping metal source and organic carbon source as needed) keep the liquid temperature at 70-90°C in a water bath, and stir to concentrate the sol.

[0032] 3. After the sol is concentrated until the concentration of metal ions reaches 1.5-6mol / L, the sol is directly fed into the preheated to 650-750°C with a non-oxidizing atmosphere (can be pure nitrogen, pure argon, hydrogen containing 5-20%) Initiate self-propagating combustion reaction in the heater o...

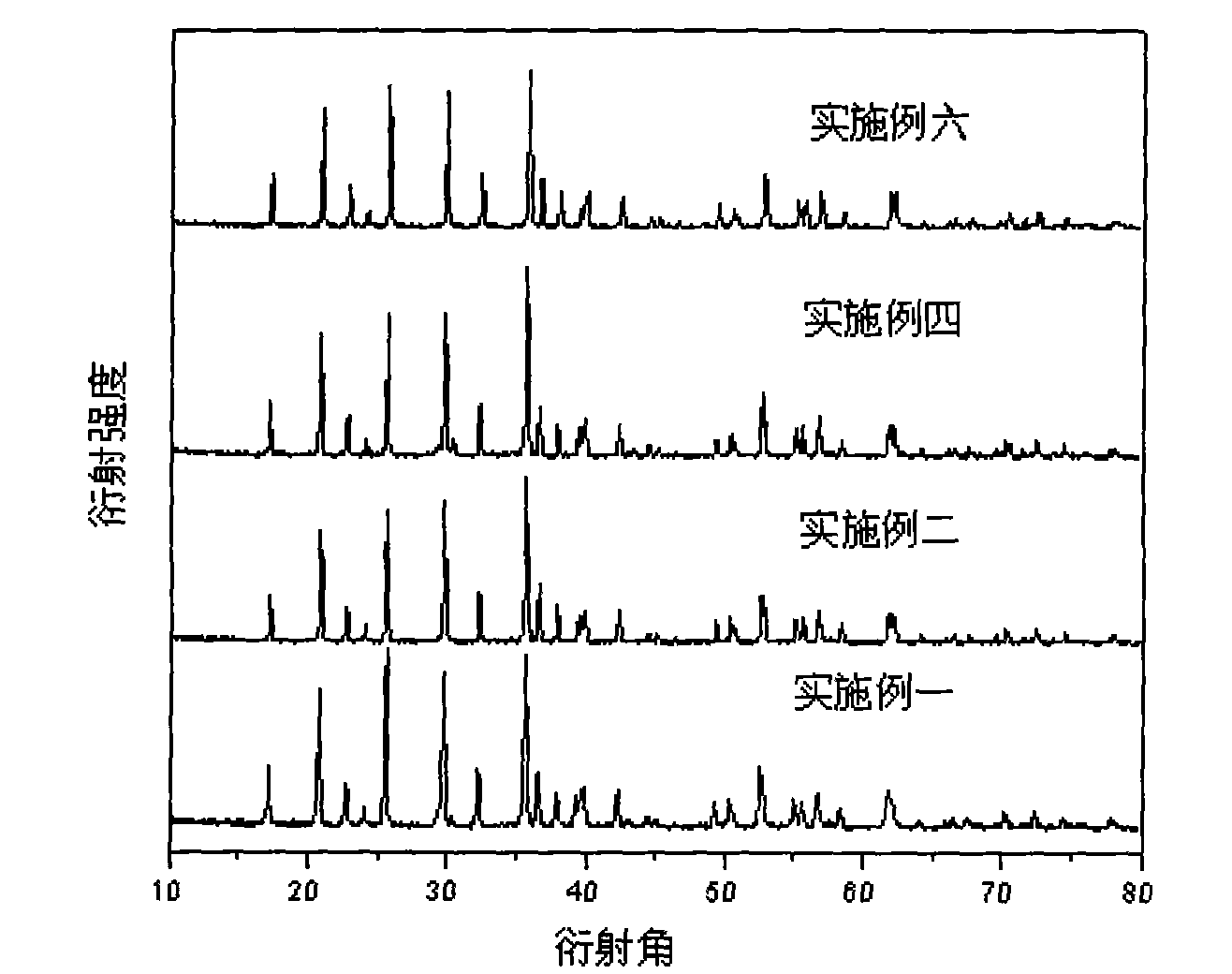

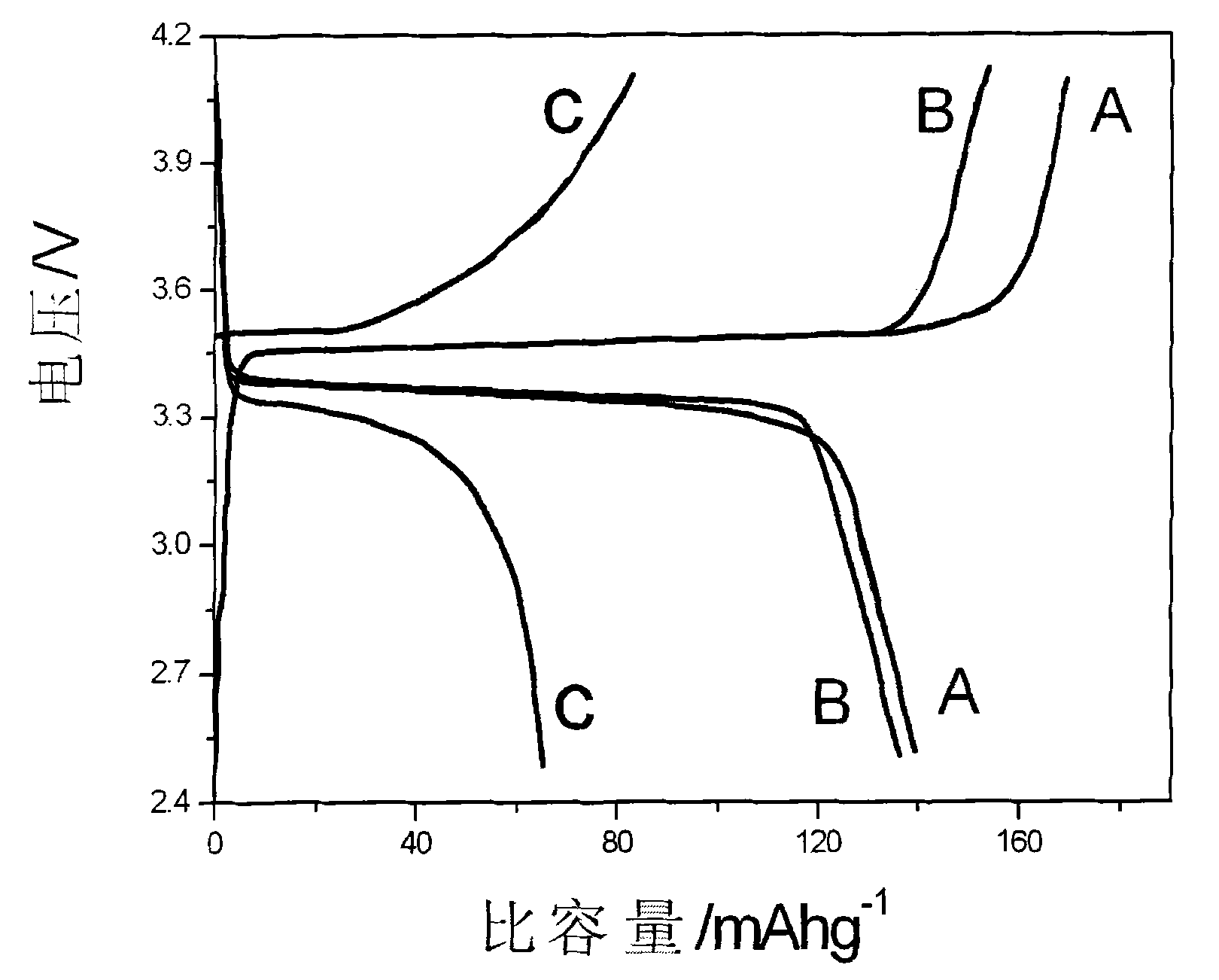

Embodiment 1

[0040] Lithium-ion battery cathode material LIFePO4 preparation method

[0041] 1. Fe(NO3) 3 .9H 2 O 82.45g, Li 2 CO 3 7.46g, H 3 PO 4 23.06g (Li:Fe:P=1:1:1), weighed with a 500g electronic balance (precision 0.01g), put it into a 500ml glass beaker, add 200ml of deionized water, and stir until completely dissolved.

[0042] 2. Add 21g of C6H8O7.H2O and stir until completely dissolved.

[0043] 3. Stir and concentrate the above liquid in a water bath at a temperature of 75-85°C until its volume is reduced to 100ml.

[0044] 4. After the above-mentioned concentrated liquid is transferred to a ceramic beaker, it is placed in a stainless steel tube protected by a nitrogen flow in a tubular resistance furnace and preheated to 750°C. Incubate under these conditions for 5 minutes.

[0045] 5. After the time is up, the ceramic dish is sent to the cooling section, where it is cooled to room temperature (nitrogen is passed through the entire stainless steel tube).

[0046] 6. ...

Embodiment 2

[0048] Preparation method of LIFePO4 / C composite powder for positive electrode material of lithium ion battery

[0049] 1. Fe(NO3) 3 .9H 2 O 82.45g, Li 2 CO 3 7.83g, H 3 PO 4 23.06g (Li:Fe:P=1:1.05:1), weighed with a 500g electronic balance (precision 0.01g), put it into a 500ml glass beaker, add 200ml of deionized water, and stir until completely dissolved.

[0050] 2. Add 21g of C6H8O7.H2O and stir until completely dissolved. In addition, add 2.5 g of pre-dissolved methyl cellulose.

[0051] 3. In a water bath at a temperature of 75-85°C, stir and concentrate the above liquid until its volume is reduced to 100ml.

[0052] 4. After the above-mentioned concentrated liquid is transferred to a ceramic beaker, it is placed in a stainless steel tube protected by a nitrogen flow in a tubular resistance furnace and preheated to 750°C. Incubate under these conditions for 15 minutes.

[0053] 5. After the specified time is reached, the ceramic dish is sent to the cooling sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com