Additive manufacturing device and method based on meniscus constrained electrodeposition

A technology of additive manufacturing and meniscus, applied in the field of additive manufacturing, can solve the problems of high porosity of deposits, poor surface finish, simple structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

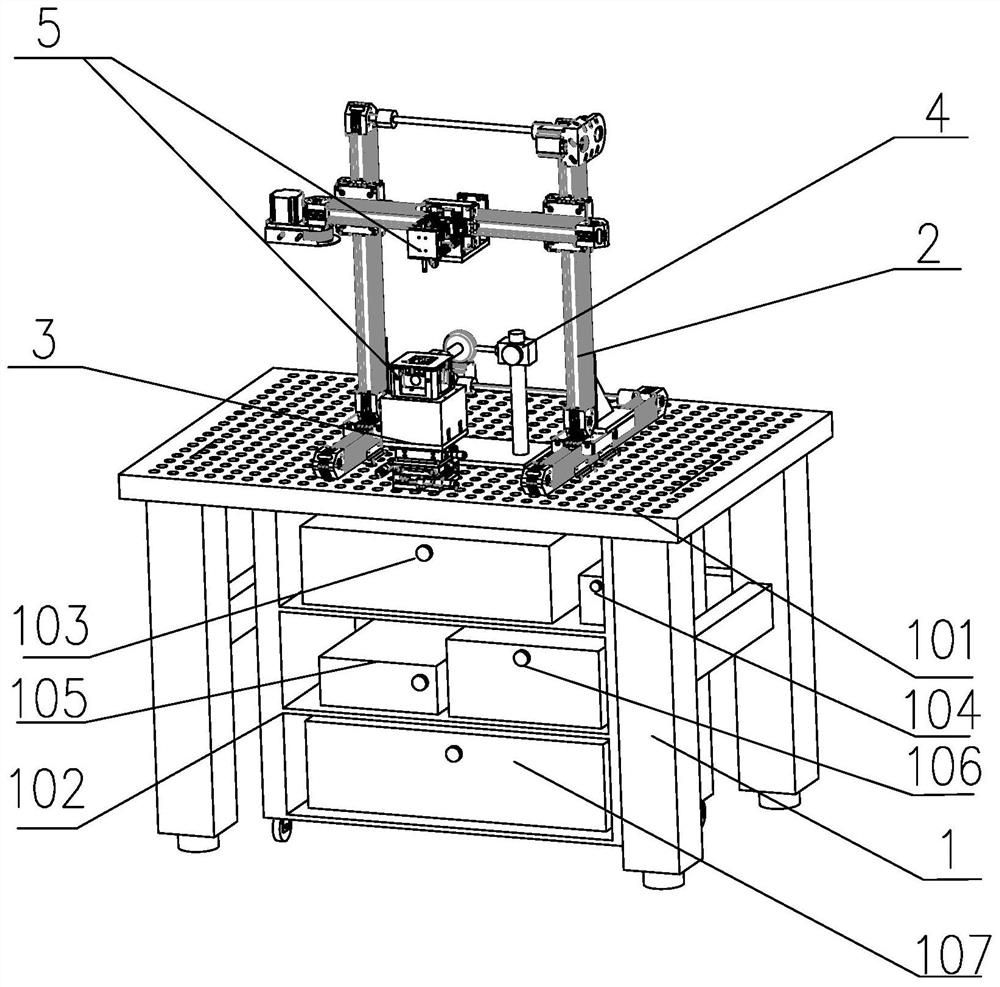

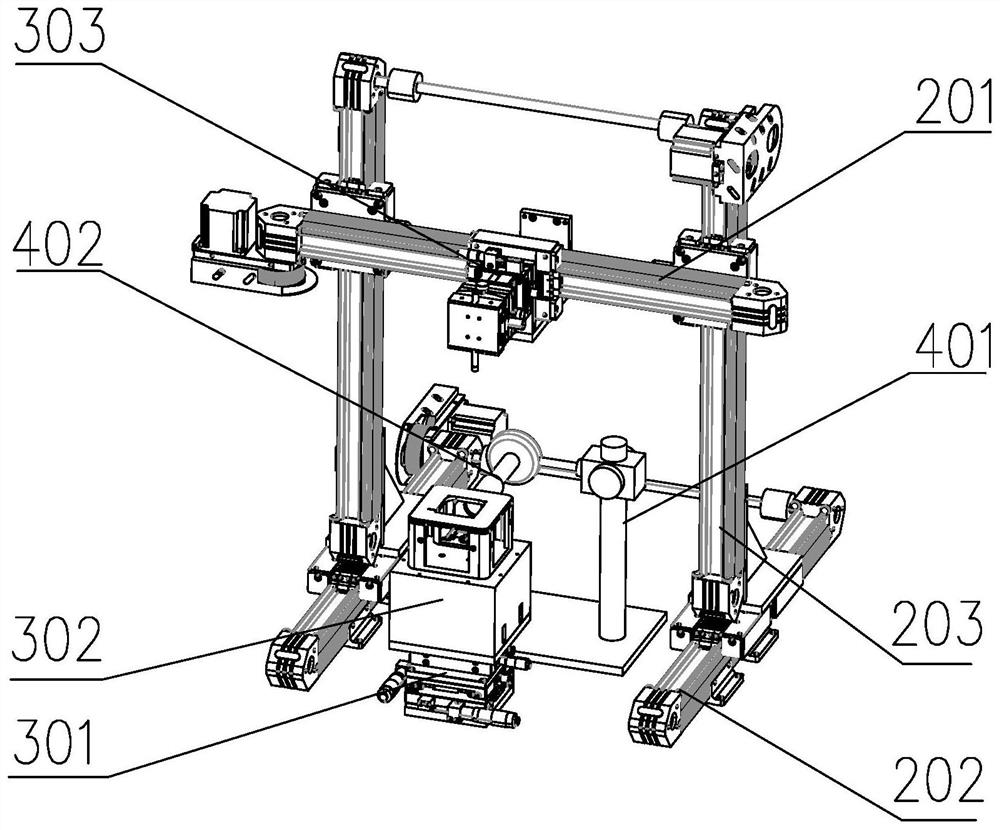

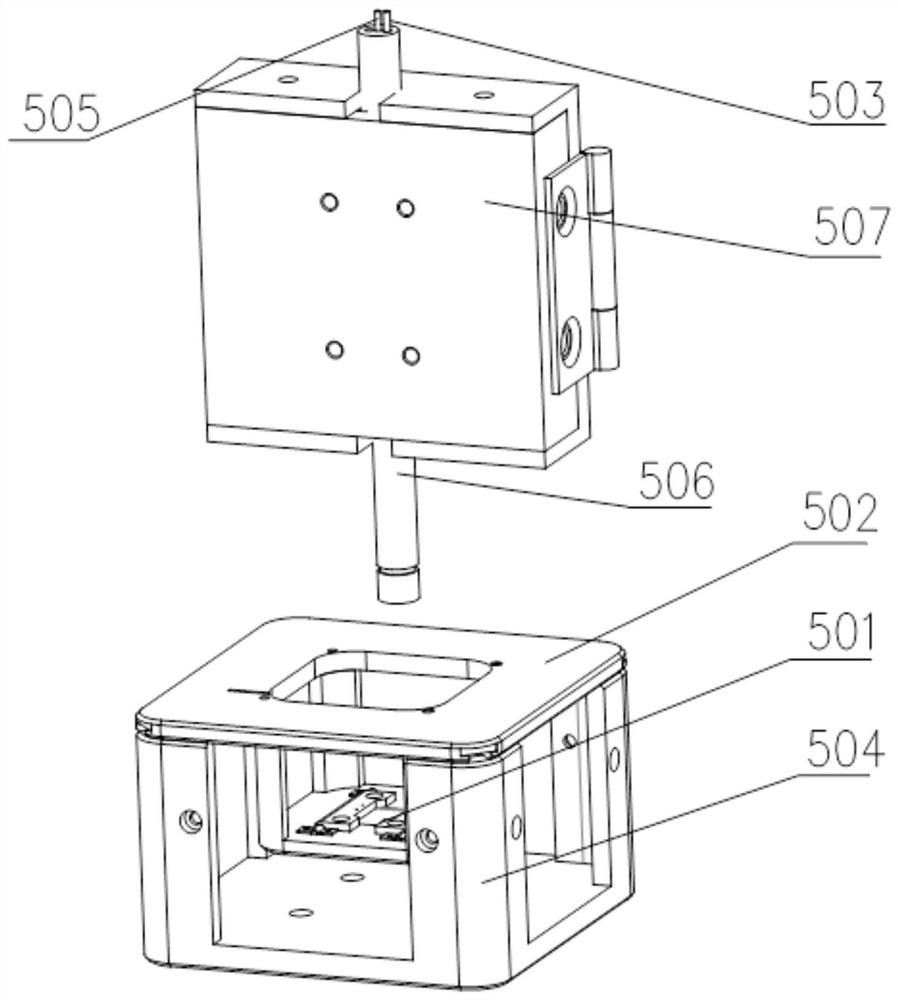

[0037] Additive manufacturing devices based on meniscus-confined electrodeposition, such as Figure 1 ~ Figure 3 As shown, it includes a vibration isolation module 1, an additive manufacturing motion platform 2, a precise positioning module 3, a monitoring module 4 and an electrode module 5,

[0038] The vibration isolation module 1 includes a vibration isolation platform 101 , a control system frame vehicle 102 , a precise positioning controller 103 , a potentiostat module 104 , a pipette air pressure controller 105 , a macro movement controller 106 and a general control system 107 . The vibration isolation platform 101 is the base of the additive manufacturing motion platform 2, which is responsible for offsetting the vibration of the entire system from the outside; the bottom of the control system frame car 102 is equipped with 4 rollers, which can be moved, and the control system frame car is equipped with The components of the entire control system, the uppermost layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com