Preparation method of ultrathin neodymium-iron-boron permanent magnet surface protective coating

A technology of protective coating and permanent magnet, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problem of magnetic performance decline, etc., to eliminate the reduction of the size of the magnet and the elimination of the neodymium-rich phase. loss, the copper layer is uniform and dense, and the deposition is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

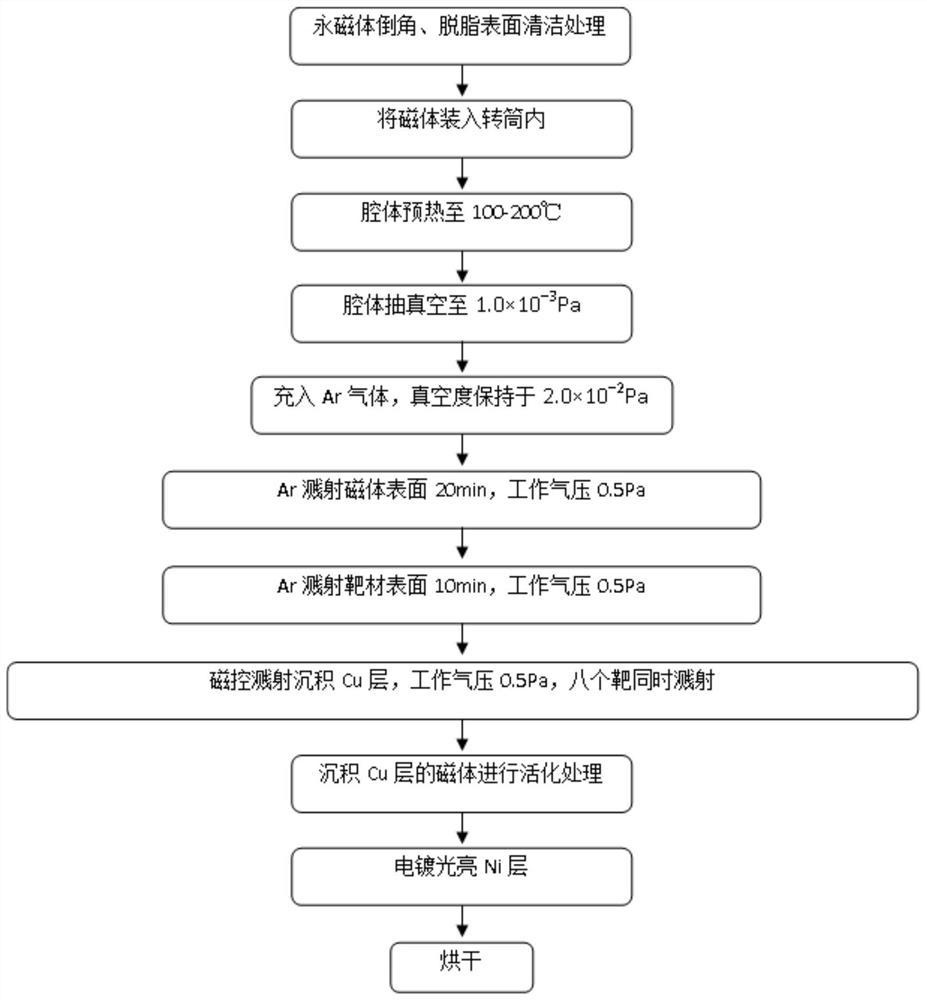

[0036] Such as figure 1Said, the present invention is a preparation method of ultra-thin NdFeB permanent magnet surface protective coating, the permanent magnet is a sheet with a thickness of ≤1mm, the NdFeB permanent magnet is a sintered NdFeB magnet, and the preparation The method comprises the following process steps:

[0037] S1. Clean the surface of the NdFeB permanent magnet, and dry it for use after treatment;

[0038] S2. Place the NdFeB permanent magnet on the workpiece bracket, heat up and preheat the NdFeB permanent magnet, and simultaneously evacuate the sealed cavity;

[0039] S3. Use argon as the cleaning gas to sputter the surface of the NdFeB permanent magnet to remove surface oxides, etc.;

[0040] S4. Use argon as the cleaning gas to sputter the surface of the target and remove surface oxides, etc.;

[0041] S5, magnetron sputtering is carried out to NdFeB permanent magnet, obtains the magnet of surface deposition Cu-Sn / Cu gradient coating;

[0042] S6, p...

Embodiment 1

[0078] 1) Soak the NdFeB magnet in a degreasing agent solution for 15 minutes, ultrasonically clean it for 1 minute, rinse it twice with clean water without removing the surface dirt, and place it on the workpiece bracket after drying;

[0079] 2) Turn on the heating device to keep the chamber temperature at 150°C, and at the same time turn on the vacuum pump to stabilize the vacuum degree of the chamber at 1.0×10-3Pa;

[0080] 3) Argon is used as the cleaning gas to remove oxides on the surface of the magnet and the surface of the target by sputtering;

[0081] 4) Turn on the power supply of the ion source, magnetron sputtering copper-tin coating on the surface of the magnet, the sputtering time is 1.5h, and the thickness of the coating is 5 μm;

[0082] 5) activating the permanent magnet on which the copper layer was deposited using a dilute sulfuric acid solution with a concentration of 0.5 wt%, for 5 s;

[0083] 6) Plating bright nickel on the surface of the above-mention...

Embodiment 2

[0086] 1) Soak the NdFeB magnet in a degreasing agent solution for 15 minutes, ultrasonically clean it for 1 minute, rinse it twice with clean water without removing the surface dirt, and place it on the workpiece bracket after drying;

[0087] 2) Turn on the heating device to keep the chamber temperature at 150°C, and at the same time turn on the vacuum pump to stabilize the vacuum degree of the chamber at 1.0×10-3Pa;

[0088] 3) Argon is used as the cleaning gas to remove oxides on the surface of the magnet and the surface of the target by sputtering;

[0089] 4) Turn on the power supply of the ion source, magnetron sputtering copper-tin coating on the surface of the magnet, the sputtering time is 2.0h, and the thickness of the coating is 6.5 μm;

[0090] 5) activating the permanent magnet on which the copper layer was deposited using a dilute sulfuric acid solution with a concentration of 0.5 wt%, for 5 s;

[0091] 6) Plating bright nickel on the surface of the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com