A kind of preparation method of permanent magnetic ferrite nylon master batch for compatibilization

A permanent magnet ferrite and ferrite magnet technology, which is applied in the field of preparation of permanent magnet ferrite nylon masterbatch for compatibilization, can solve the problems such as the absence of soft magnetic compatibilization masterbatch and the like, so as to improve the effective utilization rate and increase the Soft magnetic properties and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

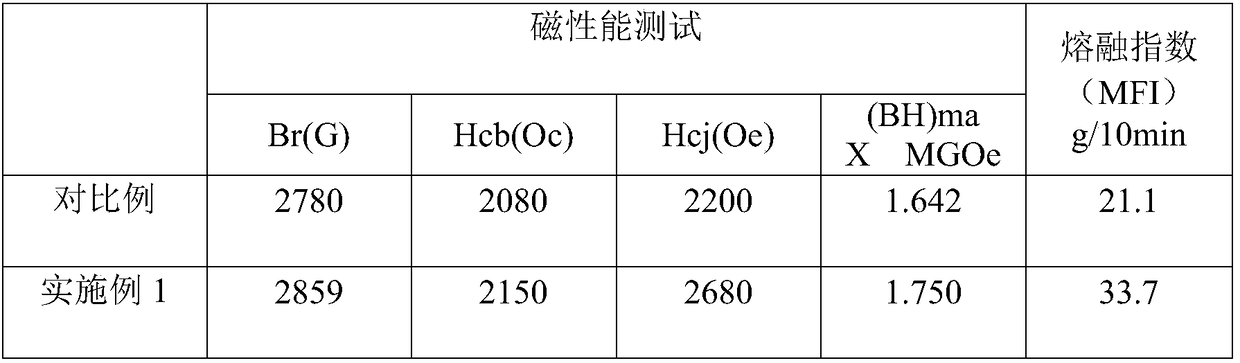

Embodiment 1

[0030] A preparation method of permanent magnet ferrite nylon masterbatch for compatibilization:

[0031] Take 50Kg ferrite magnetic powder (Fe2O3 accounts for 85wt%, magnesium oxide accounts for 10wt%, zinc oxide accounts for 5wt%, the average particle size of each component of the mixture is 1-4μm), add 0.5Kg first-generation PAMAM to ferrite magnetic powder The surface is modified by stirring and blending (the specific operation is: 0.5Kg first-generation PAMAM and 50Kg ferrite magnetic powder are placed in a high-speed mixer for stirring, infiltration and blending), and then 13.5Kg of nylon 6 powder containing dendritic units is added (the containing The dendritic macromolecule added by the nylon 6 of the dendron unit is a first-generation PAMAM) to blend, fully stir to ensure uniform mixing; then add 36Kg nylon 6 to the mixture, continue to stir and mix uniformly, and place the mixed mixture at 80 ℃ vacuum oven, dry.

[0032] The dried mixture is granulated in a single-s...

Embodiment 2

[0035] A preparation method of permanent magnet ferrite nylon masterbatch for compatibilization:

[0036] Get 30Kg ferrite magnetic powder (Fe2O3 accounts for 80wt%, magnesium oxide accounts for 10wt%, zinc oxide accounts for 10wt%, the average particle diameter of each component of the mixture is 1-4μm), add 1.0Kg second-generation PAMAM to ferrite The surface of the magnetic powder is modified by stirring and blending (the specific operation is: 1.0Kg second-generation PAMAM and 30Kg ferrite magnetic powder are placed in a high-speed mixer for stirring, infiltration and blending), and then 9Kg of nylon 6 powder containing dendritic units is added (the The dendritic macromolecule that the nylon 6 that contains dendritic unit is added is the second generation PAMAM) to carry out blending, fully stirs, guarantees to mix evenly; Then adds 60Kg nylon 66 in the mixture, continues to stir and mix evenly, puts the mixed material of mixing Dry in a vacuum oven at 85°C.

[0037] The ...

Embodiment 3

[0040] A preparation method of permanent magnet ferrite nylon masterbatch for compatibilization:

[0041] Take 60Kg of ferrite magnetic powder (Fe2O3 accounts for 90wt%, magnesium oxide accounts for 5wt%, zinc oxide accounts for 5wt%, and the average particle size of each component of the mixture is 1-4μm), add 2.0Kg third-generation PAMAM to the ferrite magnetic powder The surface is modified by stirring and blending (the specific operation is: 2.0Kg third-generation PAMAM and 60Kg ferrite magnetic powder are placed in a high-speed mixer for stirring, immersion and blending), and then 18Kg of nylon 6 powder containing dendritic units is added (the dendrite-containing The dendrimers added to the nylon 6 of the unit are three generations of PAMAM) for blending, fully stirred to ensure uniform mixing; then add 20Kg nylon 12 to the mixture, continue to stir and mix uniformly, and place the mixed mixture at 90°C Dry in a vacuum oven.

[0042] The dried mixture is granulated in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com