Pulse-assisted electrochemical deposition metal pipeline inner wall coating device and preparation method

A metal deposition and electrochemical technology, which is applied in the field of pulse-assisted electrochemical deposition metal pipe inner wall coating device and preparation, can solve the problems of uneven structure and thickness of the deposited layer, too large gap between cathode and anode of electrodeposition, difficult electrodeposition, etc. Achieve the effect of reducing equipment area, improving surface morphology and preventing anode passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

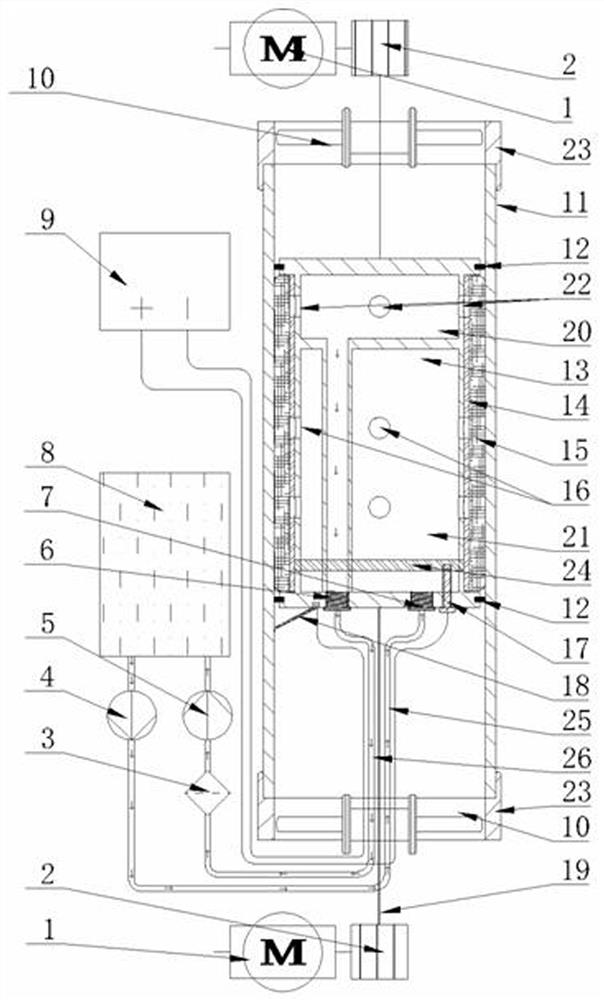

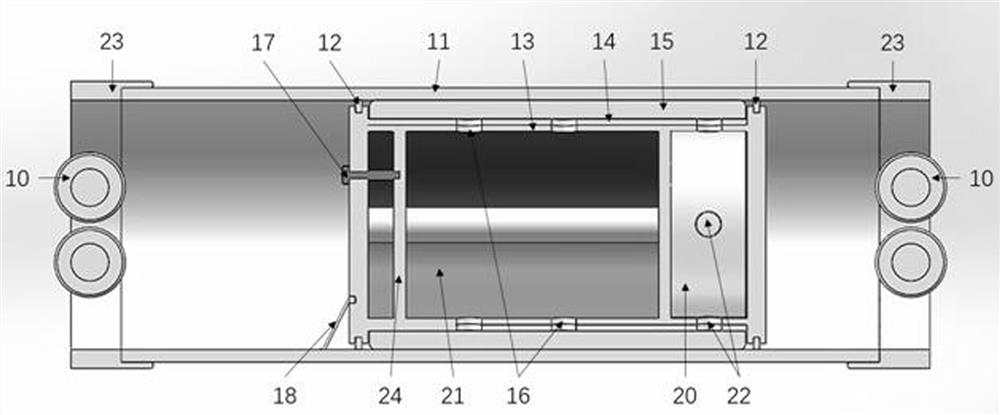

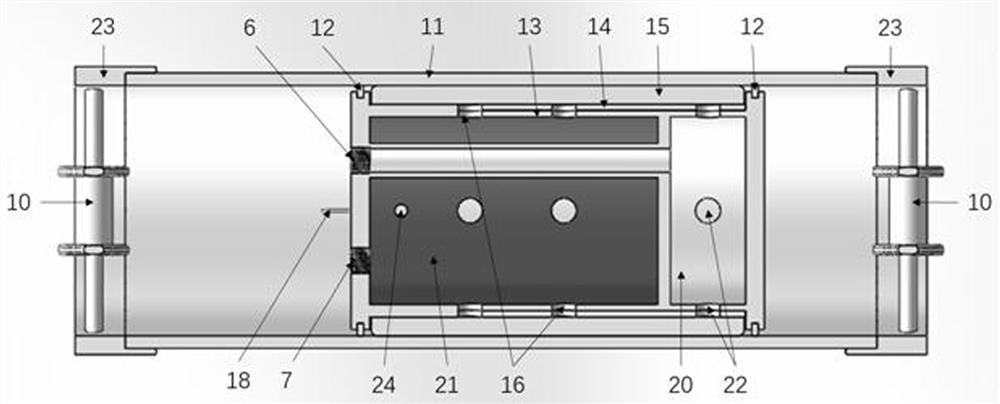

[0048] like figure 1 , figure 2 , image 3 As shown, the plating species in this embodiment is nickel-phosphorus alloy, and the preparation method of pulse-assisted electrochemical deposition of nickel-phosphorus alloy coating on the inner wall of metal pipeline is as follows:

[0049] 1) Fix the pipeline on the bracket 23 or the workbench, and pretreat the inner wall of the pipeline (such as: alkali degreasing, water washing, electric cleaning, activation, water washing).

[0050]2) Install and adjust the anode tube sleeve 14 and sealing rubber ring 12 in the plating chamber 13, and adjust the thickness of the liquid-absorbing cotton felt 15 so that it can be closely attached to the inner wall of the metal pipe 11; The probe 18 and the anode conductive bolt 17 are respectively connected to one end of the cathode and anode wires, and the other ends of the cathode and anode wires are respectively connected to the negative pole and the positive pole of the pulse power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com