Machining method for fastening sealing hoops made of FRP composite building material for prefabrication assembly system

A composite building material, prefabricated assembly technology, applied in building reinforcements, buildings, building components, etc., can solve the problems of heavy steel stirrups, increasing the overall weight of components, and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

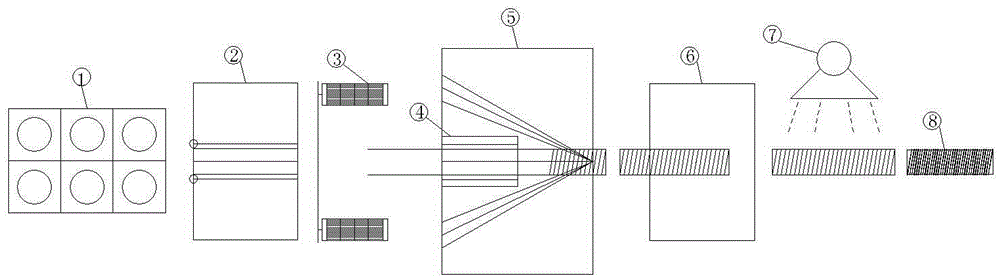

[0038] The processing method of prefabricated assembly system FRP composite building material fastening closed stirrups is characterized in that the FRP material is combined through a composite hinge plate and a composite hinge groove, and the iron wire of the iron wire coil is formed through the FRP rib forming tube and the FRP rib outlet plate As the inner core, it is dried in an oven and ventilated and cooled by a blower to form an FRP composite building material buckled and closed spiral stirrup wire. Design drawings require binding.

[0039] Include the following steps:

[0040] (1) Dipping: Evenly distribute the FRP material and impregnate it in the resin by pultrusion process;

[0041] (2) Preforming: The FRP material processed in step (1) is divided into several Φ0.6mm fiber bundles through a composite hinged wire plate, of which 6 fiber bundles are compounded through a composite hinged wire groove, and then combined with iron wire coils through FRP Rib-forming tubes...

Embodiment 2

[0049] A processing method for fastening closed stirrups of prefabricated assembly system FRP composite building materials, comprising the following steps:

[0050] (1) Dipping: Evenly distribute the FRP material and impregnate it in the resin by pultrusion process;

[0051] (2) Preforming: The FRP material processed in step (1) is divided into several Φ0.6mm fiber bundles through a composite hinged wire plate, of which 6 fiber bundles are compounded through a composite hinged wire groove, and then combined with iron wire coils through FRP Rib-forming tubes and FRP rib outlet plates are formed into inner cores, and 12 resin-impregnated fiber bundles are covered outside the inner cores, and then the fibers are wound outside to obtain FRP composite blanks;

[0052] (3) Semi-cured drying: The FRP composite blank processed in step (2) is dried in an oven at a temperature of 100°C for 10 minutes, and the FRP and iron wire are heated, and composited by hinged winding to form a semi-...

Embodiment 3

[0059] A processing method for fastening closed stirrups of prefabricated assembly system FRP composite building materials, comprising the following steps:

[0060] (1) Dipping: Evenly distribute the FRP material and impregnate it in the resin by pultrusion process;

[0061] (2) Preforming: The FRP material processed in step (1) is divided into several Φ0.6mm fiber bundles through a composite hinged wire plate, of which 6 fiber bundles are compounded through a composite hinged wire groove, and then combined with iron wire coils through FRP Rib-forming tubes and FRP rib outlet plates are formed into inner cores, and 12 resin-impregnated fiber bundles are covered outside the inner cores, and then the fibers are wound outside to obtain FRP composite blanks;

[0062] (3) Semi-cured drying: The FRP composite blank processed in step (2) is dried in an oven at a temperature of 90°C for 7 minutes, the FRP and iron wire are heated, and composited by hinged winding to form a semi-cured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com