Metal roof board system

A technology for metal roofs and panels, applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems such as water leakage, temperature deformation, temperature stress, and roof panel arching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

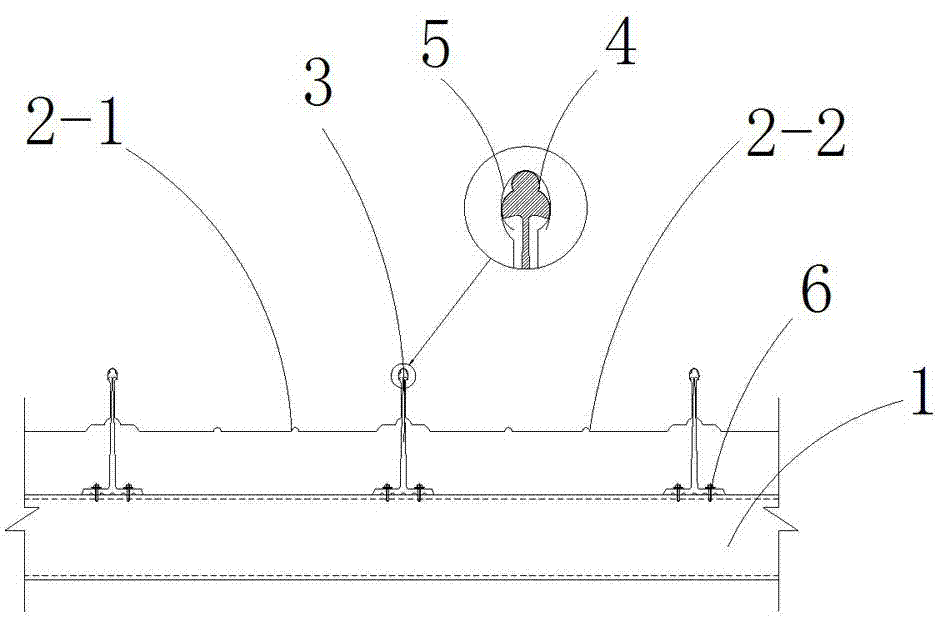

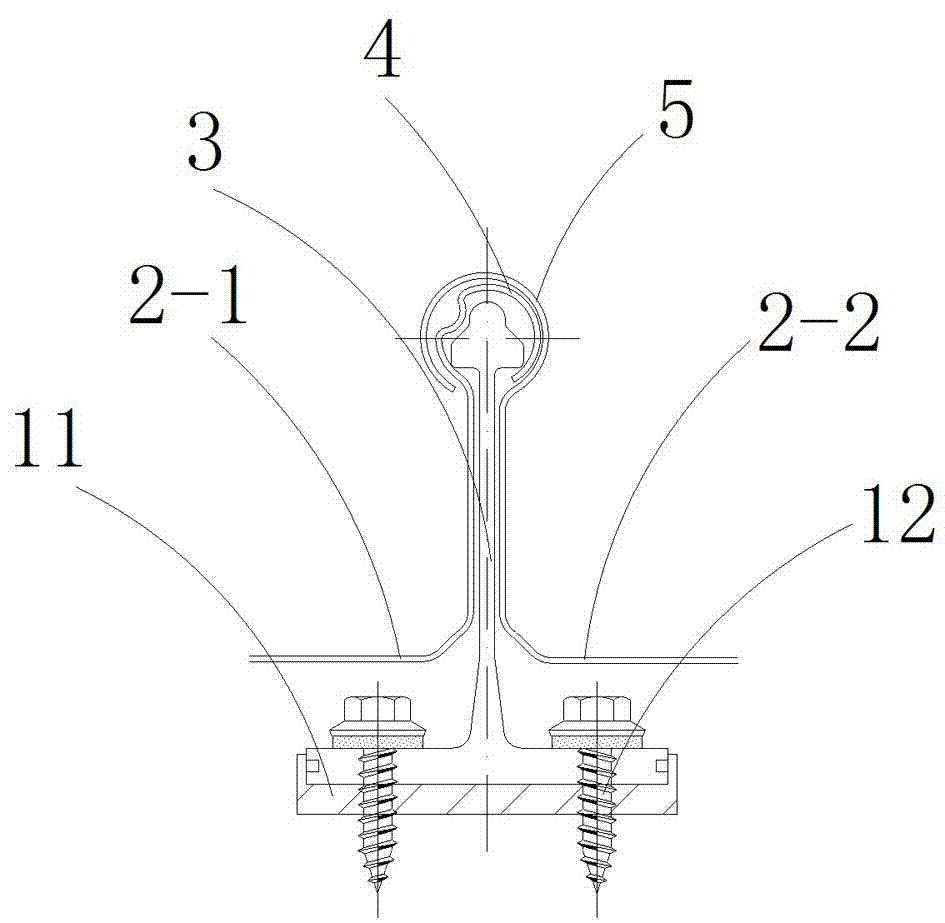

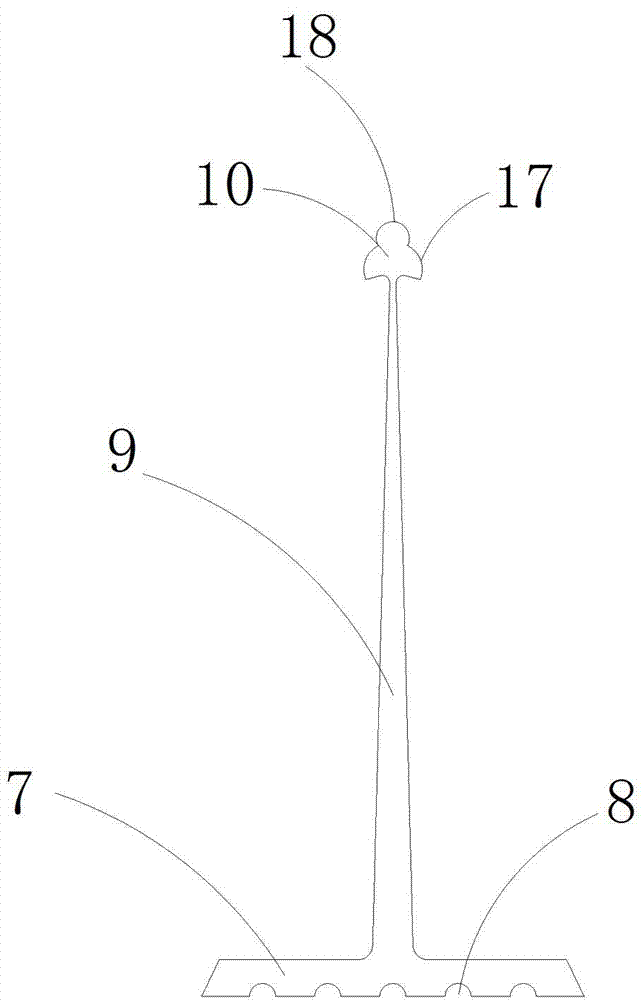

[0022] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a metal roof panel system includes a purlin 1 and at least two metal roof panels 2-1, 2-2, the upper part of the purlin 1 is evenly provided with a fixing seat 3, and the metal roof panel 2- 1, the two sides of 2-2 are distributed upwards, and the ends of the left side of the metal roof panels 2-1, 2-2 are provided with small curling edges 4, and the metal roof panels 2-1, 2 The end of the right side of -2 is provided with a large curl 5, a small curl 4 of a metal roof panel 2-2 wraps the head of the fixing seat 3, and a large curl 5 of another metal roof panel 2-1 wraps Live small curling 4. The fixed seat 3 and the purlin 1 are fixed by screws 6, the fixed seat 3 includes a support 7, the bottom of the support 7 is provided with an anti-skid groove 8, and the support 7 is provided with an upward Extended support support column 9, the head of the support support column 9 is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com