Turbine

A technology of turbines and gas turbines, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of coolant flow, difficult to realize cooling circuit, complicated sealing production, etc., and achieve high cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

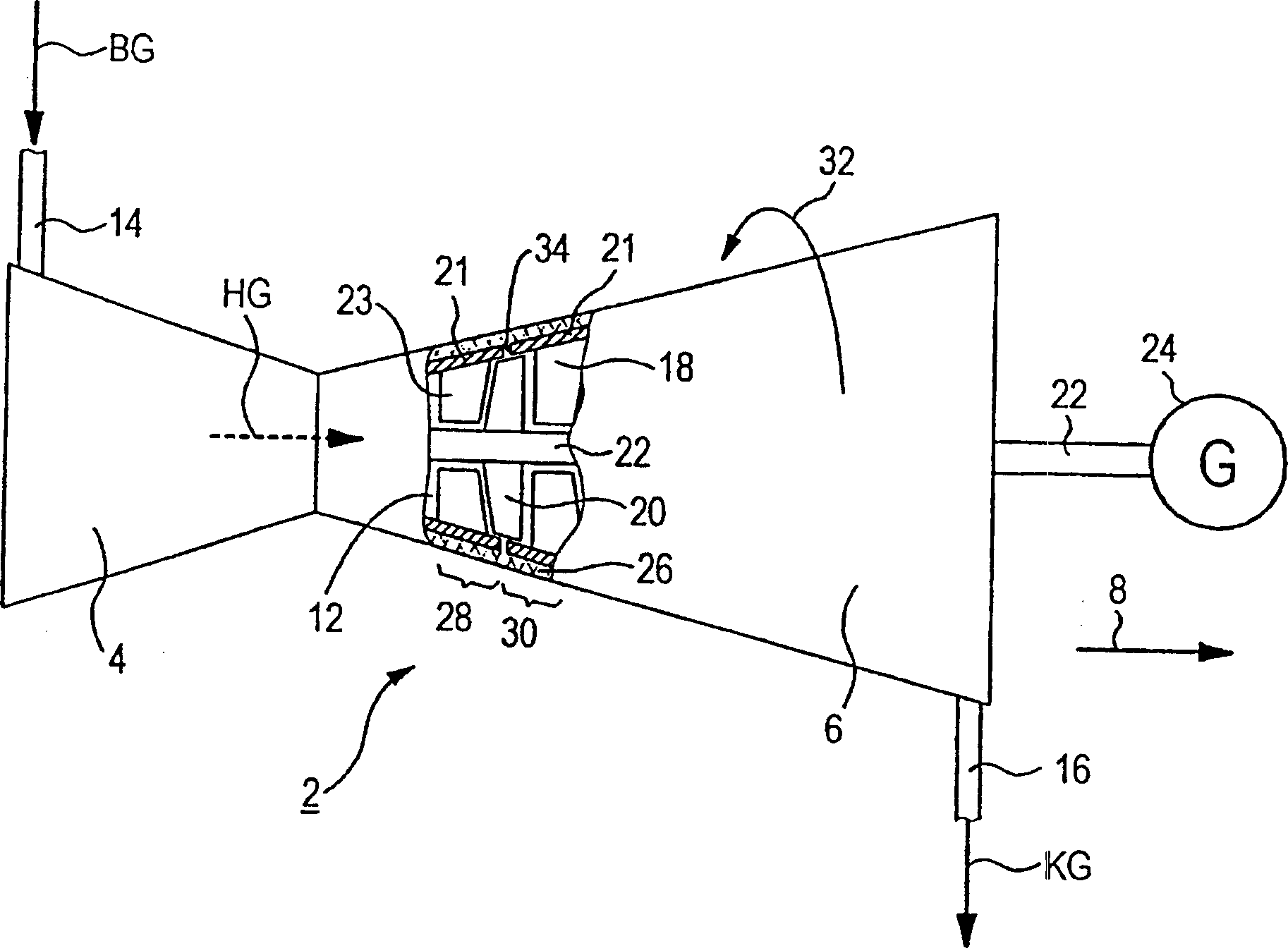

[0028] according to figure 1 , a turbine installation 2 , in particular a gas turbine installation of a turbomachine for an energy generating power plant, comprising a combustion chamber 4 and a turbine 6 arranged downstream of the combustion chamber 4 in the longitudinal or axial direction 8 of the turbine installation 2 . The turbine 6 is cut away to show a part of it, the gas space 12 of the turbine 6 can be seen. The flow path of the hot gas HG through the turbine 6 is designated as a gas space 12 .

[0029] In operation, the combustion chamber 4 is supplied via the intake pipe 14 with gas BG which burns in the combustion chamber 4 and forms said hot gas HG. The hot gas HG flows through the turbine 6 and the HG becomes cooled gas KG via the exhaust pipe 16 . The hot gas HG is guided in the turbine 6 by guide vanes 18 and moving vanes 20 . In this case, the shaft 22 on which the moving blade 20 is arranged is driven. The shaft 22 is connected to a generator 24 for gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com