Lightweight power battery box capable of steel and aluminum riveting

A power battery and lightweight technology, which is applied to battery pack components, isolation of the battery from its environment, circuits, etc., can solve the problems of poor shock resistance of the power battery pack box, large deformation of the flange edge, and trachoma box, etc. Achieve the effect of easy riveting automation operation, good air tightness and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

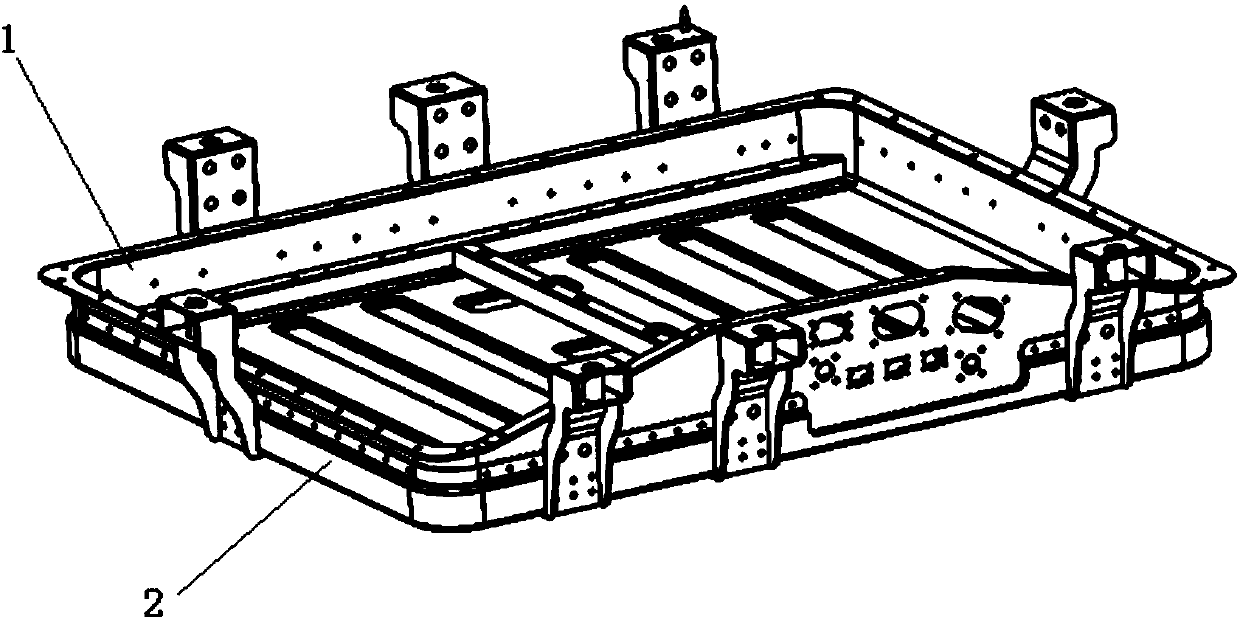

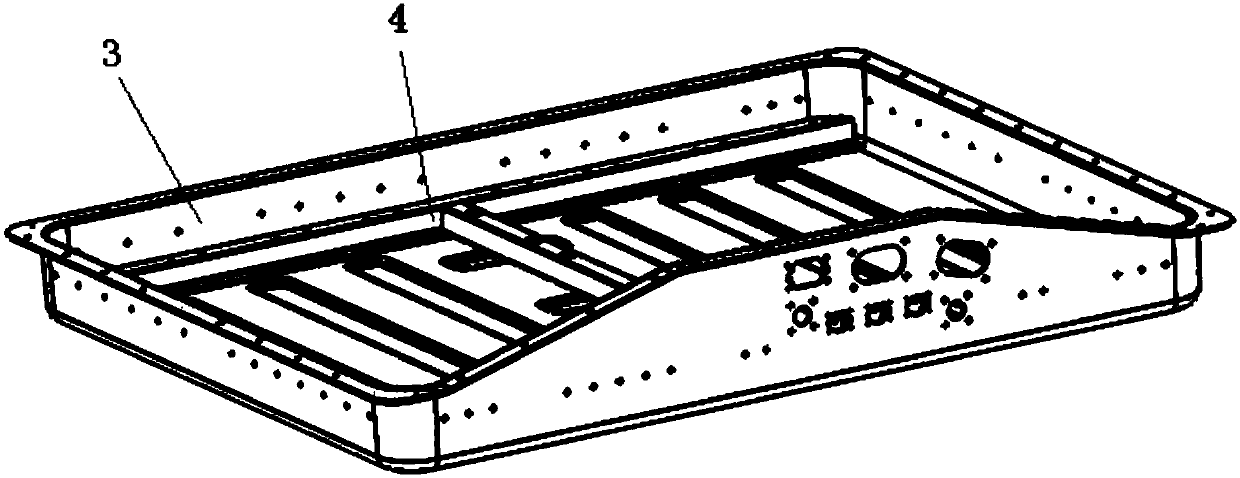

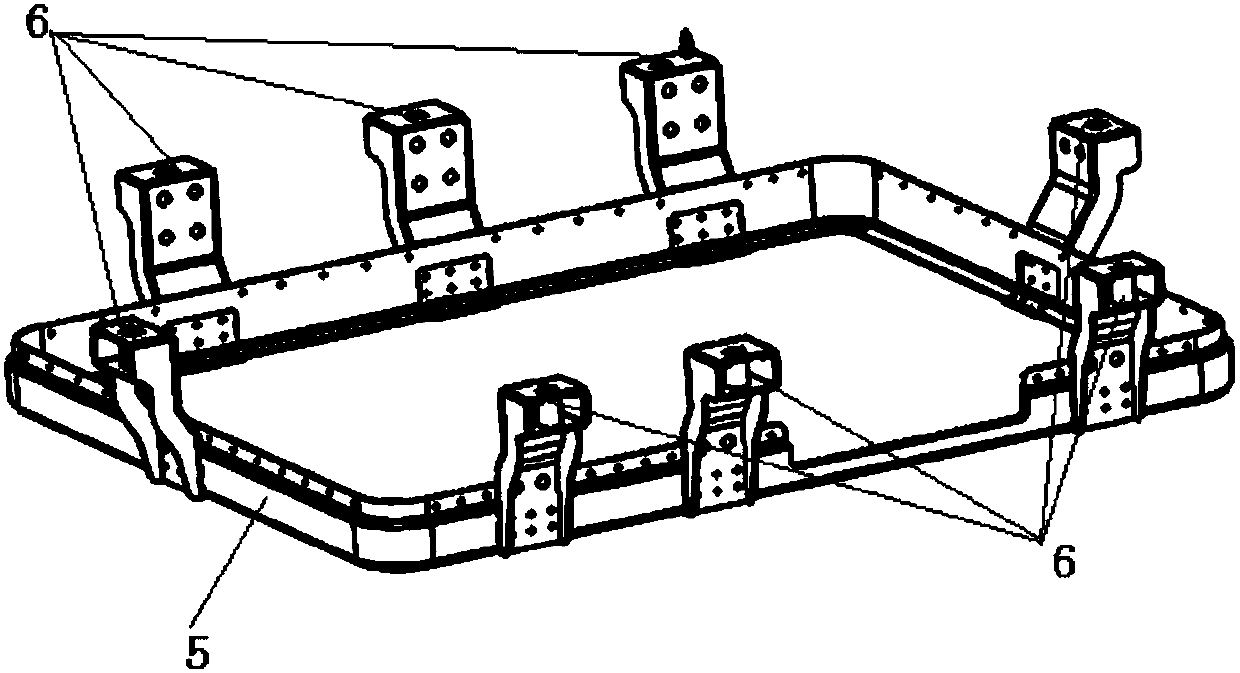

[0040] like Figure 1 to Figure 9 As shown, a steel-aluminum riveted lightweight power battery box includes an inner tank assembly 1 and a bracket assembly 2. The inner tank assembly 1 is fixedly connected to the bracket assembly 2 by lock riveting and glue bonding. The tank assembly 1 includes a protective shell 3 and an H-shaped installation beam 4. The installation beam 4 is locked inside the protective shell 3 by adding installation threads through a riveting process. The bracket assembly 2 includes a bottom shell wrapping 5, and the bottom shell wrapping The outer surface of 5 is provided with a number of lifting lugs 6 formed by sheet metal bending or stamping at intervals, and the bottom shell edge 5 is made of aluminum alloy extruded profiles, which are processed by auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com