Semiconductor element module and method for manufacturing the same

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of reduced thermal conductivity, inability to ensure reliability, and inability to obtain heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

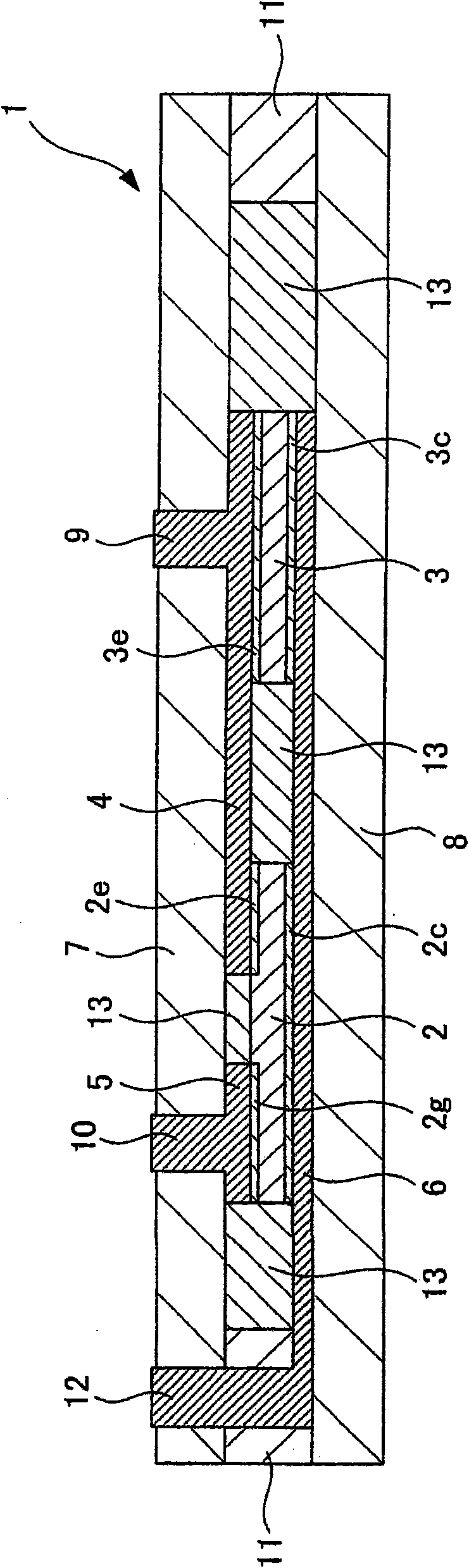

[0050] figure 1is a configuration diagram showing an exemplary embodiment of the semiconductor element module of the present invention. Note that the semiconductor element module 1 of the present embodiment is configured to include therein the insulated gate bipolar transistor 2 and the diode 3 as semiconductor elements, but may also be configured to include therein at least one semiconductor element. The semiconductor element module 1 is particularly suitable for semiconductor elements that generate a large amount of heat.

[0051] Such as figure 1 As shown, the semiconductor element module 1 of the present embodiment includes an insulated gate bipolar transistor 2, a diode 3, a flat ceramic substrate 7 (second insulating substrate), a flat ceramic substrate 8 (first insulating substrate) and Sealing member 11. The insulated gate bipolar transistor 2 and the diode 3 each have flat electrode surfaces formed on both surfaces thereof. The ceramic substrate 7 has high thermal...

Embodiment 2

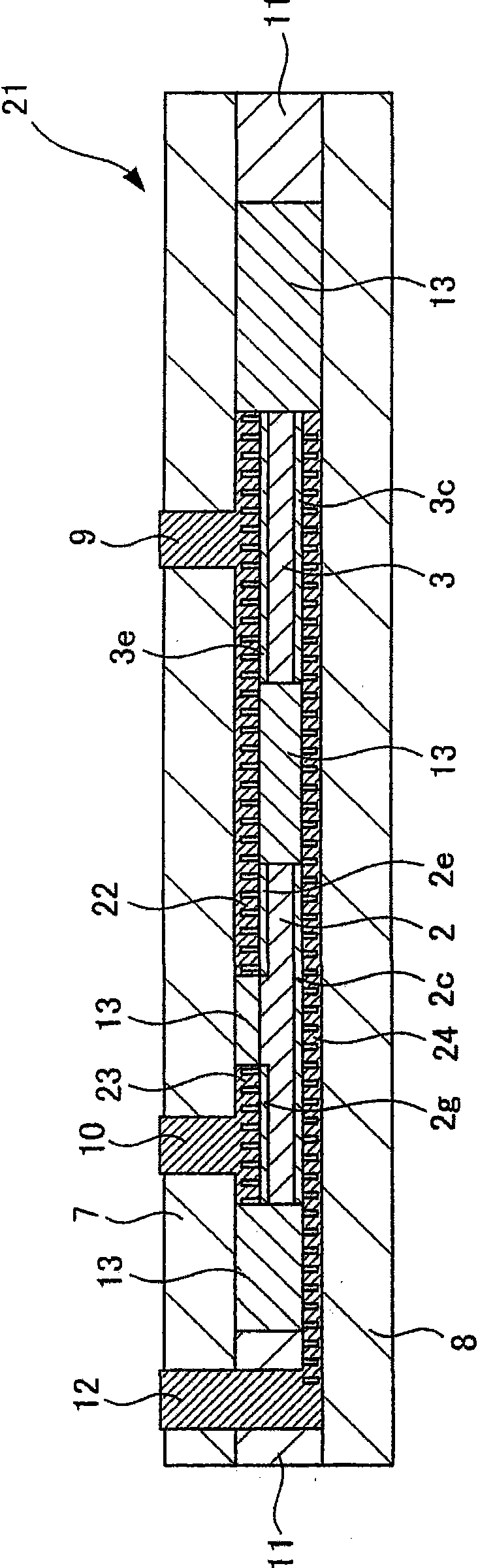

[0072] FIG. 2 is a structural diagram showing another exemplary embodiment of the semiconductor element module of the present invention. Note that the same reference numerals are used to denote the same as in Embodiment 1 ( figure 1 ) that are the same as the respective components of the semiconductor element module shown in ), and their repeated descriptions are omitted.

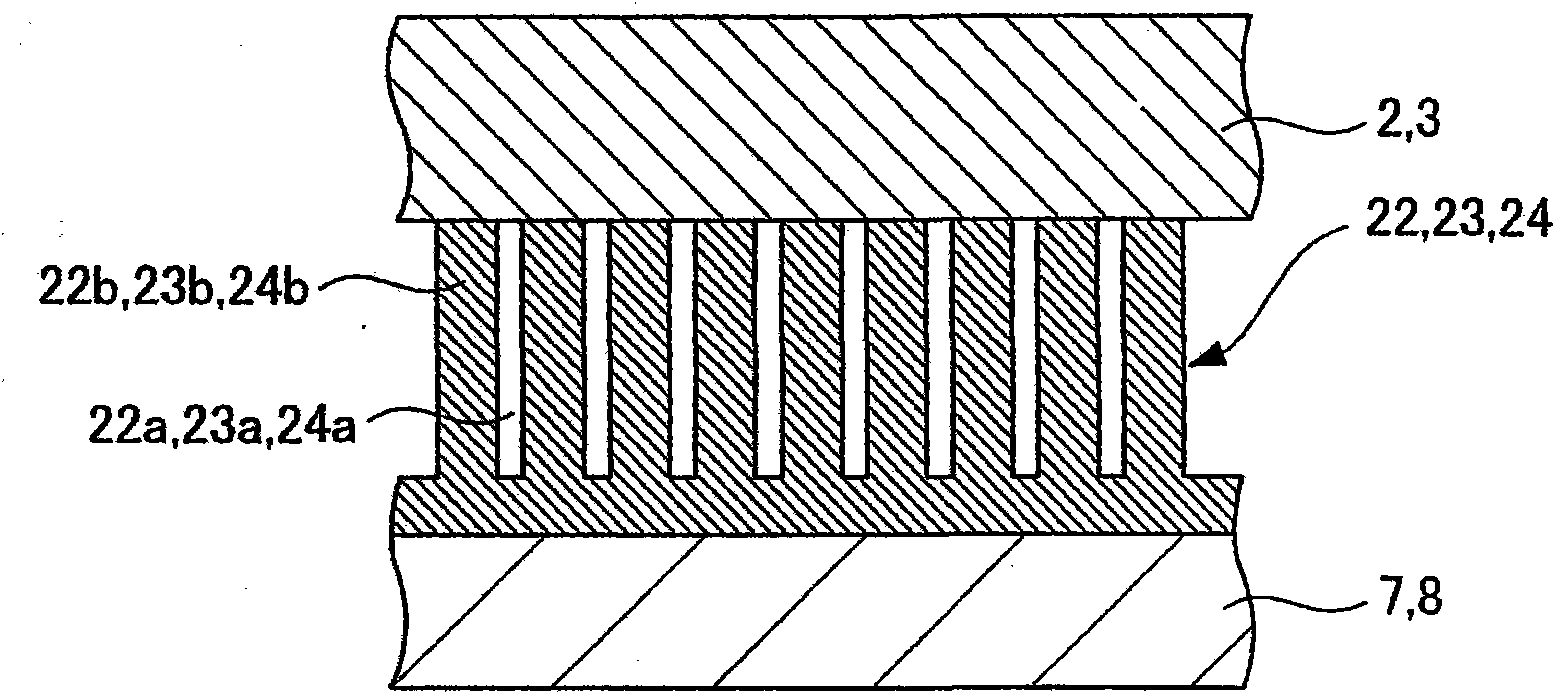

[0073] As shown in FIG. 2( a), the semiconductor element module 21 of this embodiment has substantially the same structure as that of Embodiment 1, except that the collector electrode surface 2c, the emitter electrode surface 2c, and the emitter electrode are arranged on the surface of the insulated gate bipolar transistor 2. Surface 2e and gate electrode surface 2g and electrode surface 3c and electrode surface 3e provided on the surface of diode 3 respectively form wiring circuit layers 22, 23, 24 of ceramic substrates 7, 8.

[0074] As with the wiring circuit layers 4 and 5 in Embodiment 1, on the inner...

Embodiment 3

[0084] Figure 4 is a structural diagram showing another exemplary embodiment of the semiconductor element module of the present invention. Note that the same reference numerals are used to denote the same as Embodiments 1 and 2 ( figure 1 Components that are the same as those of the semiconductor element module shown in 2), and their repeated descriptions are omitted.

[0085] The semiconductor element module of this embodiment is obtained by directly bonding a heat sink 41 (cooling means) made of metal excellent in heat dissipation to Embodiment 1 or 2 ( figure 1 Or 2) The ceramic substrate 8 of the semiconductor element module 1 or 21 shown.

[0086] Specifically, the bonding surface of the ceramic substrate 8 of the semiconductor element module 1 or 21 and the bonding surface of the heat sink 41 are activated by physical sputtering through ion beam irradiation or the like, and then pressure-welded to each other at room temperature, thereby The bonding surfaces are bonde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com