Preparation method of flexible pyroelectric film

A thermoelectric thin film and flexible technology, which is applied in the field of thermoelectric material preparation, can solve the problems of low melting point of flexible substrates and the inability of thin film preparation to proceed smoothly, and achieves the effects of satisfying heat treatment conditions, improving performance in all aspects, and heating quickly and uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

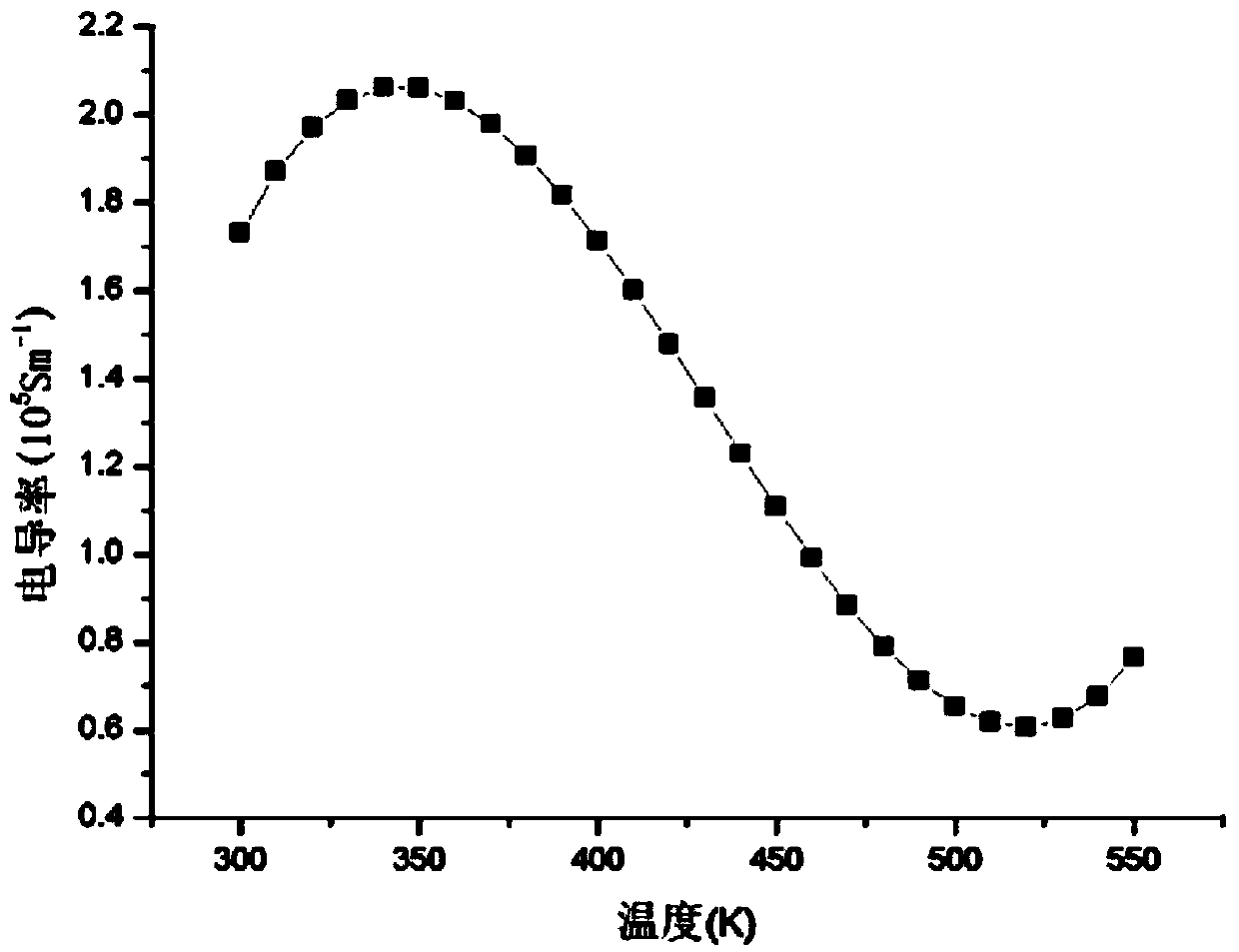

[0037] The invention provides a method for preparing a flexible thermoelectric film. The method adopts the combination of screen printing method / casting method and microwave sintering process, which can break through the process of preparing a film on a flexible substrate with a low melting point by thermoelectric materials with a high melting point. The bottleneck of the process is to obtain high-quality thermoelectric thin films with excellent thermoelectric properties in a short time and at a low sintering temperature.

[0038] The preparation method of the flexible thermoelectric thin film of the present invention comprises the following steps:

[0039] S100: Synthetic thermoelectric material ingot.

[0040] There are many ways to synthesize ingots of thermoelectric materials, such as zone melting method, plasma discharge sintering method, hydrothermal method, hot pressing method, etc.

[0041] In one of the embodiments, the zone melting method is preferred for the synthe...

Embodiment 1

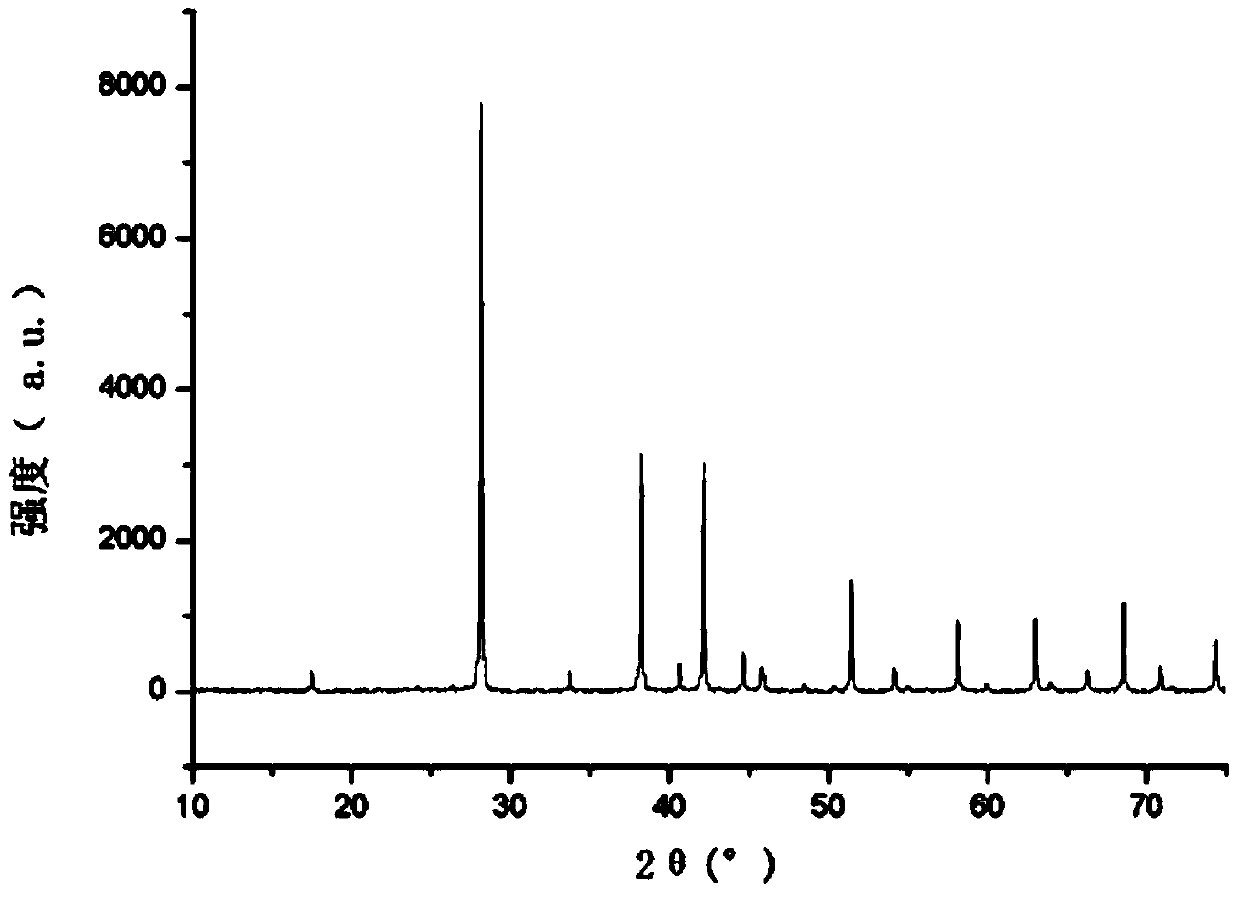

[0075] (1) According to antimony-doped Bi 2 Te 3 Composition ratio of base thermoelectric materials Weigh commercial tellurium, bismuth and antimony metal elements as reaction raw materials;

[0076] (2) put into zone melting furnace after the reaction raw material that weighs is mixed and carry out smelting, obtain Bi 2 Te 3 The base thermoelectric material ingot is cast; wherein, the melting temperature used is 950°C, the width of the melting zone is 35mm, the temperature gradient is 15°C / cm, and the growth rate of the thermoelectric material ingot is 20mm / h.

[0077] (3) Using a ball mill to ball mill the thermoelectric material ingot obtained in step (2) and then sieve it to obtain a thermoelectric material powder with a particle size of 1 μm to 10 μm; wherein, the rotational speed of the ball mill is 350 r / min, and the ball milling time is 24 hours.

[0078] (4) The mixture of dibutyl phthalate and PVB is used as a binder, Span-80 is used as a dispersant, and a mixture...

Embodiment 2

[0087] (1) According to antimony-doped Bi 2 Te 3 Composition ratio of base thermoelectric materials Weigh commercial tellurium, bismuth and antimony metal elements as reaction raw materials;

[0088] (2) put into zone melting furnace after the reaction raw material that weighs is mixed and carry out smelting, obtain Bi 2 Te 3 The base thermoelectric material ingot is cast; wherein, the melting temperature used is 850°C, the width of the melting zone is 30mm, the temperature gradient is 40°C / cm, and the growth rate of the thermoelectric material ingot is 25mm / h.

[0089](3) Using a ball mill to ball mill the thermoelectric material ingot obtained in step (2) and then sieve to obtain a thermoelectric material powder with a particle size of 1 μm to 10 μm; wherein, the rotational speed of the ball mill is 500 r / min, and the ball milling time is 20 hours.

[0090] (4) Dibutyl phthalate is used as a binding agent, 1-methyl-2-pyrrolidone is used as a dispersant, and terpineol is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com