Graphite material with SiC coating and preparation method thereof

A graphite material and coating technology, applied in the field of graphite material with SiC coating and its preparation, can solve the problems of low bonding strength between SiC coating and graphite material, low bonding strength, limited activity, etc., and achieve high bonding Strength, high bonding strength, effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

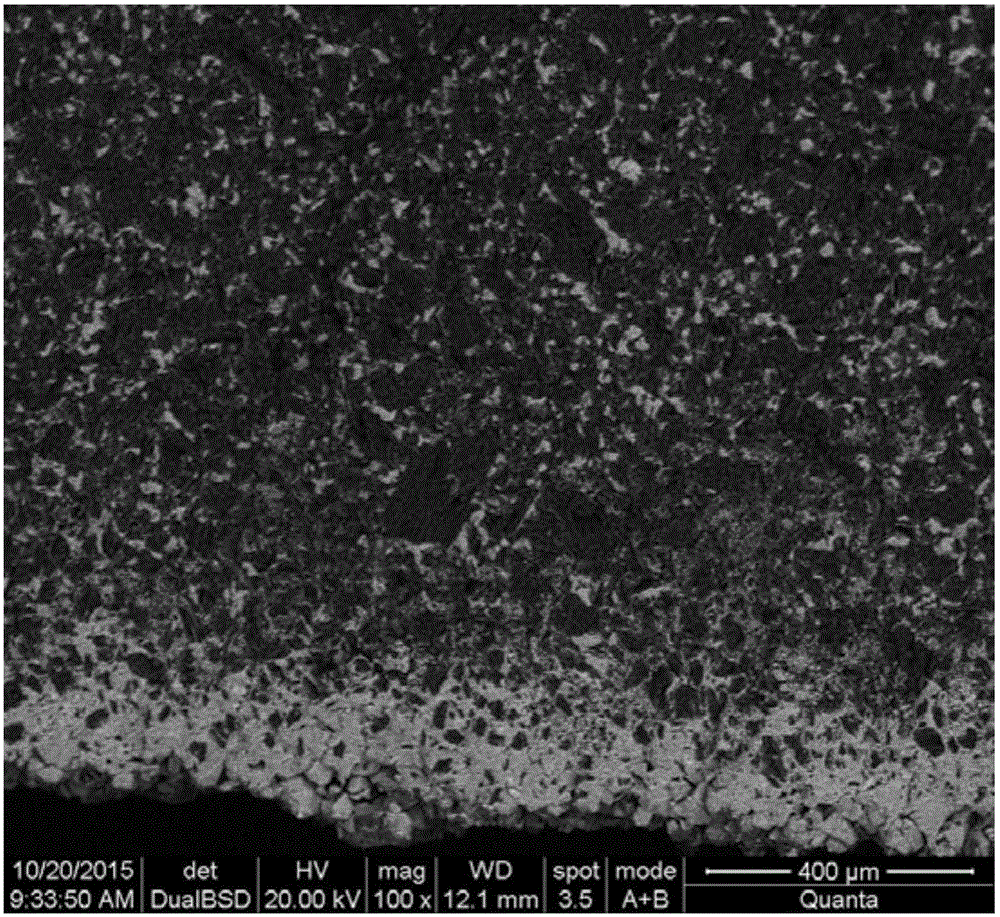

[0033] A graphite material with a SiC coating of the present invention, comprising a graphite substrate and a SiC coating, the SiC coating comprising a primary SiC layer and a secondary SiC layer, the primary SiC layer penetrates into the interior of the graphite substrate relative to the surface of the graphite substrate, and is in a gaseous state Silicon reacts with the graphite matrix in situ to form a secondary SiC layer on top of the primary SiC layer.

[0034] In this embodiment, the primary SiC layer has a composition gradient from the surface of the graphite substrate to the interior of the graphite substrate, with a depth of 2.0 mm.

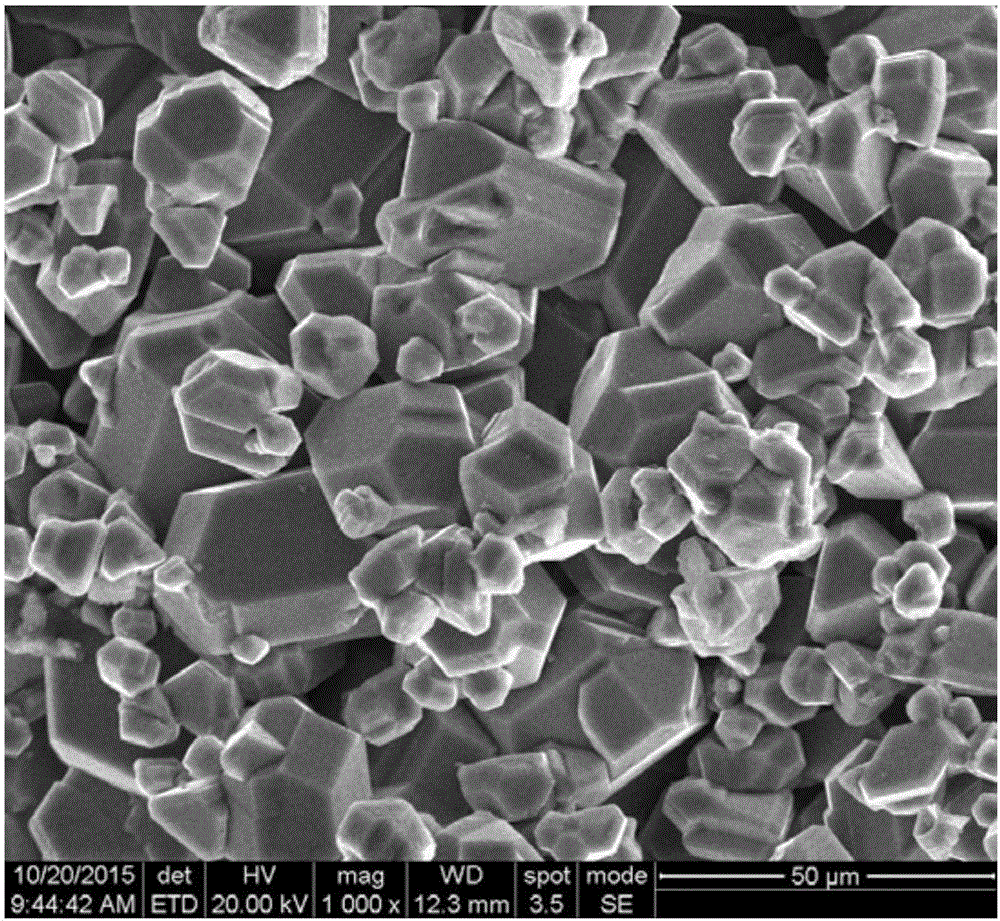

[0035] In this embodiment, the SiC in the primary SiC layer and the secondary SiC layer are both polycrystalline β-SiC.

[0036] In this embodiment, the thickness of the secondary SiC layer is 100 μm.

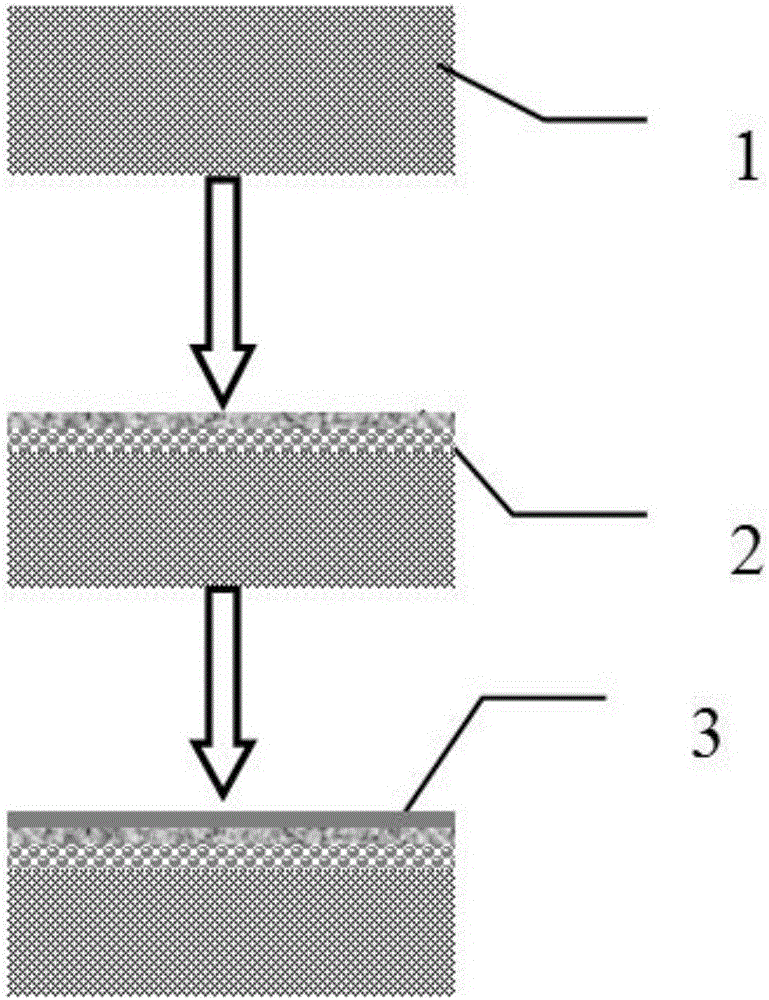

[0037] The preparation method of the graphite material with SiC coating of the present embodiment, such as figure 1 shown, including t...

Embodiment 2

[0045] A graphite material with a SiC coating of the present invention, comprising a graphite substrate and a SiC coating, the SiC coating comprising a primary SiC layer and a secondary SiC layer, the primary SiC layer penetrates into the interior of the graphite substrate relative to the surface of the graphite substrate, and is in a gaseous state Silicon reacts with the graphite matrix in situ to form a secondary SiC layer on top of the primary SiC layer.

[0046] In this embodiment, the primary SiC layer has a composition gradient from the surface of the graphite substrate to the interior of the graphite substrate, with a depth of 3.0 mm.

[0047] In this embodiment, the SiC in the primary SiC layer and the secondary SiC layer are both polycrystalline β-SiC.

[0048] In this embodiment, the thickness of the secondary SiC layer is 50 μm.

[0049] The preparation method of the graphite material with SiC coating of the present embodiment, such as figure 1 shown, including th...

Embodiment 3

[0054] A graphite material with a SiC coating of the present invention, comprising a graphite substrate and a SiC coating, the SiC coating comprising a primary SiC layer and a secondary SiC layer, the primary SiC layer penetrates into the interior of the graphite substrate relative to the surface of the graphite substrate, and is in a gaseous state Silicon reacts with the graphite matrix in situ to form a secondary SiC layer on top of the primary SiC layer.

[0055] In this embodiment, the primary SiC layer has a composition gradient from the surface of the graphite substrate to the interior of the graphite substrate, with a depth of 2.5 mm.

[0056] In this embodiment, the SiC in the primary SiC layer and the secondary SiC layer are both polycrystalline β-SiC.

[0057] In this embodiment, the thickness of the secondary SiC layer is 75 μm.

[0058] The preparation method of the graphite material with SiC coating of the present embodiment, such as figure 1 shown, including th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com