Hollow structure lithium-ion battery positive electrode material and preparation method thereof

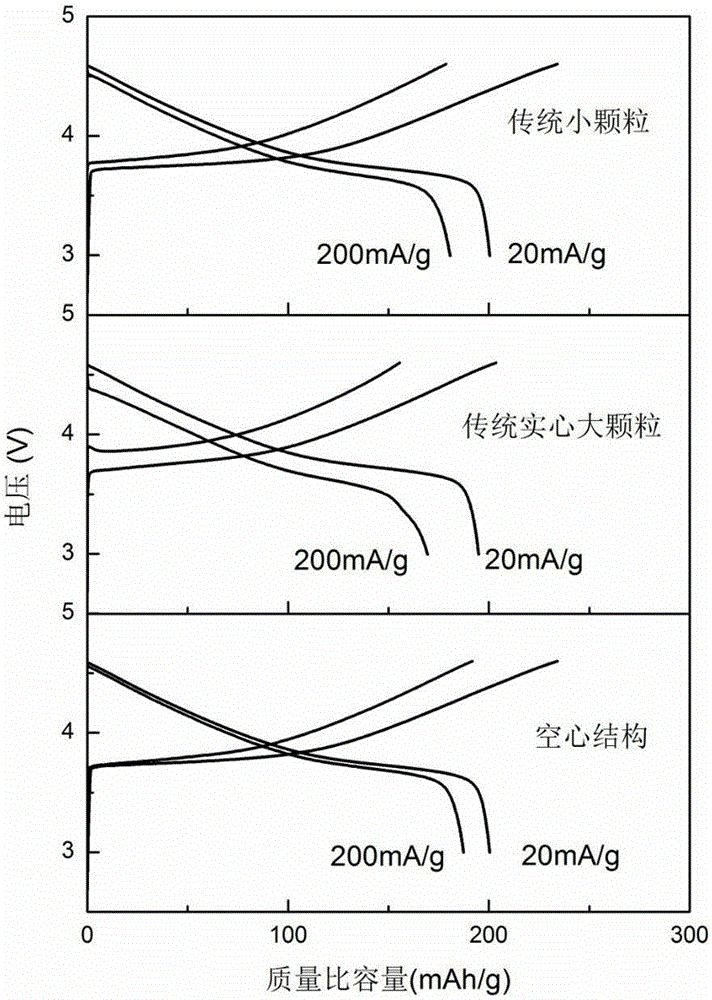

A lithium-ion battery, hollow structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of limited improvement of the electrochemical performance of positive electrode materials, and avoid poor ion diffusion performance and electron transport performance. The effect of increasing rate performance and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

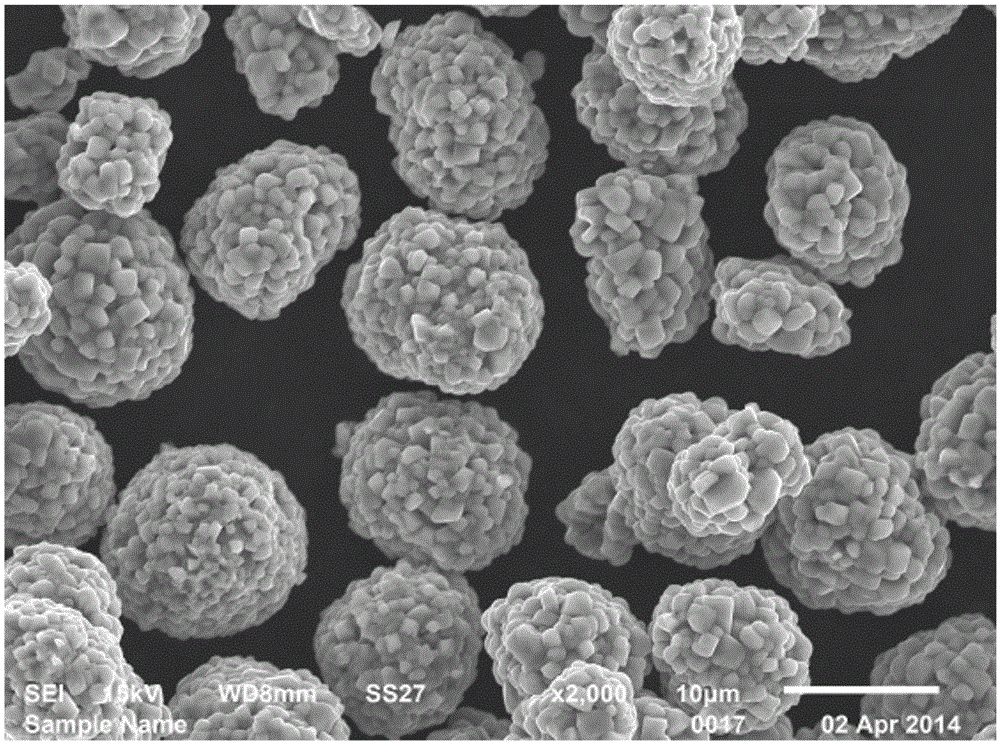

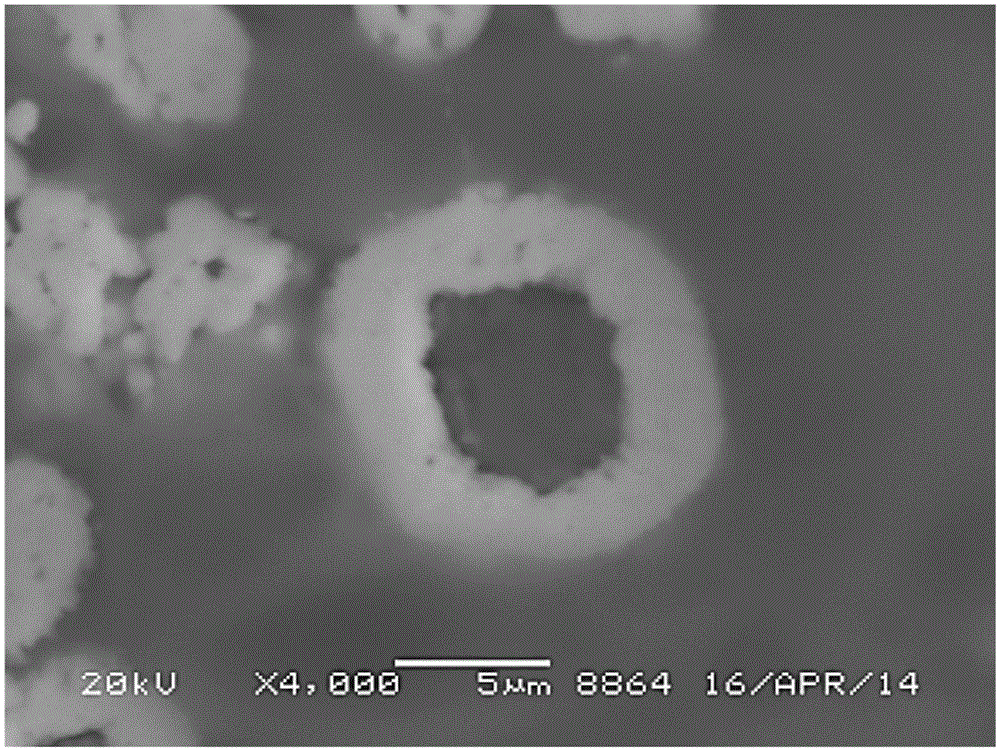

Embodiment 1

[0026] Use nickel, cobalt, and manganese sulfate as raw materials to prepare a metal salt solution (the molar ratio of nickel, cobalt, and manganese is 1:1:1), and select liquid caustic soda with a mass percentage of 32% as a precipitant, with a mass percentage of 18% The ammonia water is used as a complexing agent, and it is added into the reaction kettle in parallel. The coprecipitation is divided into three stages. In the first stage, the pH of the reaction system is controlled to be 11, the ammonia concentration is 15g / l, the temperature is 60°C, and the reaction time is 5 hours; Stage control reaction system pH=11.5, ammonia concentration 13g / l, temperature 60°C, reaction time 3 hours; third stage control reaction system pH=12, ammonia concentration 10g / l, temperature 60°C, reaction time 5 Hour. Get the precursor Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 , and then mixed with lithium carbonate (the molar ratio of lithium to the total amount of nickel, cobalt and manganese is 1.05:1...

Embodiment 2

[0030]Use nickel and manganese sulfate as raw materials to prepare a metal salt solution (the molar ratio of nickel and manganese is 1:1), select liquid caustic soda with a mass percentage of 16% as a precipitant, and ethylenediaminetetraacetic acid with a mass percentage of 10% Disodium is used as a complexing agent, and it is added into the reaction kettle concurrently. Co-precipitation is divided into two stages. In the first stage, the pH of the reaction system is controlled to be 11, the concentration of disodium edetate is 2g / l, and the temperature is 50°C. The reaction time is 5 hours; in the second stage, the pH of the reaction system is controlled to be 11.6, the concentration of disodium edetate is 3 g / l, the temperature is 30° C., and the reaction time is 5 hours. Get the precursor Ni 0.5 mn 0.5 (OH) 2 , and then mixed evenly with lithium acetate (the molar ratio of lithium to the total amount of nickel and manganese is 1.07:1), and then calcined in sections with ...

Embodiment 3

[0033] Use nickel, cobalt, and manganese sulfate as raw materials to prepare a metal salt solution (the molar ratio of nickel, cobalt, and manganese is 1.67:1.67:6.66), and select sodium carbonate with a mass percentage of 15% as a precipitant, with a mass percentage of 18% The ammonia water is used as a complexing agent, and it is added into the reaction kettle in parallel. The coprecipitation is divided into two stages. The first stage controls the reaction system to PH=8, the ammonia concentration is 1g / l, the temperature is 60°C, and the reaction time is 4 hours; In the second stage, the pH of the reaction system is controlled at 8.5, the ammonia concentration is 1 g / l, the temperature is 45° C., and the reaction time is 6 hours. Get the precursor Ni 0.167 co 0.167 mn 0.666 CO 3 , and then mixed with lithium hydroxide (the molar ratio of lithium to the total amount of nickel, cobalt and manganese is 1.55:1) and then calcination in sections with temperature control. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com