Carbon-coated nanofiber material, preparation method thereof and battery

A nanofiber, carbon coating technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electronic and ionic conductance, poor performance of lithium-ion batteries, etc., to achieve large specific surface area, increase reactivity The effect of site, enhanced rate capability and cycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

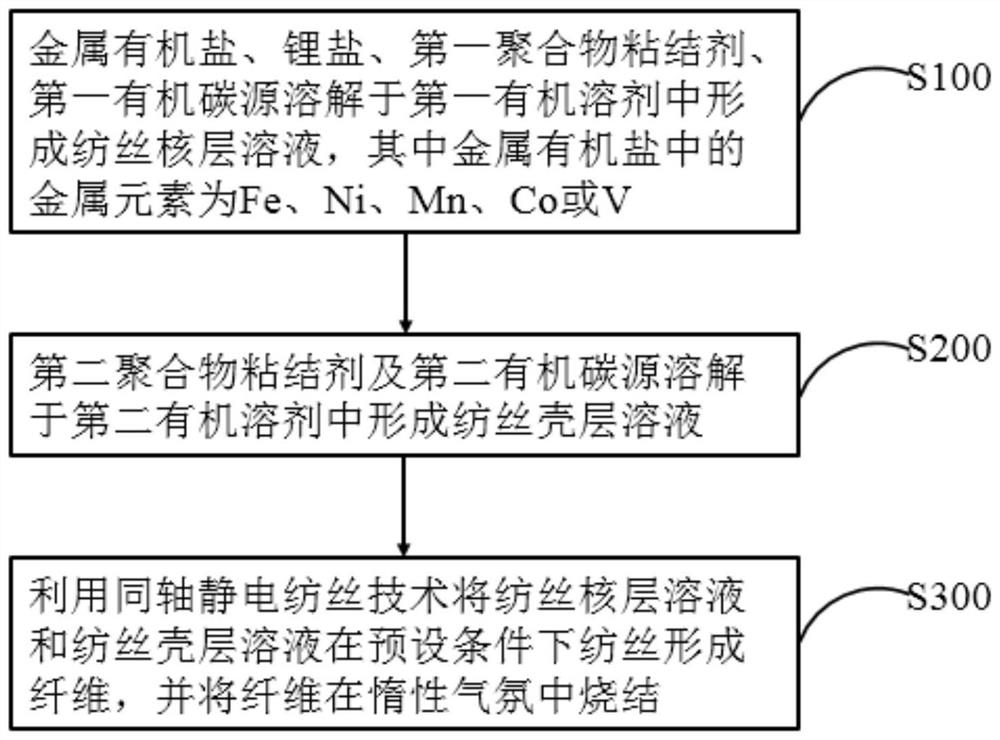

[0035] A preparation method of carbon-coated nanofibrous material, comprising the following steps:

[0036] Dissolving the metal organic salt, lithium salt, the first polymer binder, and the first organic carbon source in the first organic solvent to prepare a spinning core layer solution; the metal elements in the metal organic salt are Fe, Ni, Mn, Co or V;

[0037] Dissolving the second polymer binder and the second organic carbon source in the second organic solvent to prepare a spinning sheath solution;

[0038] The coaxial electrospinning technology is used to spin the spinning core layer solution and the spinning shell layer solution under preset conditions to form fibers with a core-shell structure, and sinter the fibers with the core-shell structure in an inert atmosphere.

[0039] The in-situ carbon-coated three-dimensional carbon skeleton nanofiber material is formed by coating the carbon layer on the surface of the nanofiber material in situ by coaxial electrospinn...

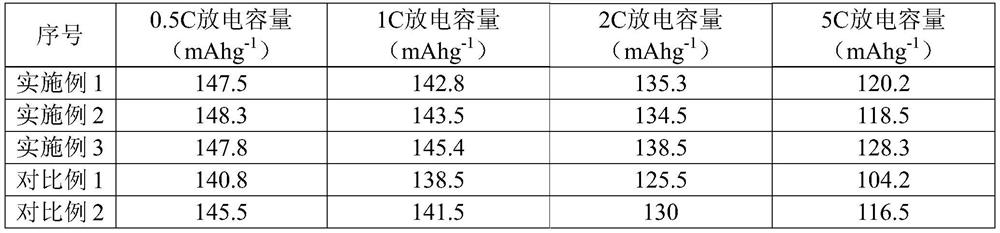

Embodiment 1

[0067] figure 1 It is a schematic diagram of the process flow for preparing carbon-coated nanofibers in this example, and the specific steps are as follows:

[0068] 1) Preparation of spinning core layer solution

[0069] Lithium acetate, manganese acetate, iron acetate and phosphoric acid were dissolved in deionized water at a molar ratio of 1:0.6:0.4:1 to prepare a first solution with a concentration of 0.5 mol / L. Polyvinylpyrrolidone (PVPK90) and glucose were dissolved in ethanol, wherein the mass fractions of polyvinylpyrrolidone and glucose were both 5%, to prepare a second solution. The first solution and the second solution are mixed according to a volume ratio of 1:1, and stirred evenly to obtain a spinning core layer solution.

[0070] 2) Preparation of spinning sheath solution

[0071] Polyvinylpyrrolidone (PVPK90) and glucose were dissolved in ethanol, wherein the mass fractions of polyvinylpyrrolidone and glucose were both 5%, to prepare a spinning sheath soluti...

Embodiment 2

[0076] The preparation method of this example is basically the same as that of Example 1, except for the concentration of the first solution in the spinning core layer solution. Specific steps are as follows:

[0077] 1) Preparation of spinning core layer solution

[0078] Lithium acetate, manganese acetate, iron acetate and phosphoric acid were dissolved in deionized water at a molar ratio of 1:0.6:0.4:1 to prepare a first solution with a concentration of 0.55 mol / L. Polyvinylpyrrolidone (PVPK90) and glucose were dissolved in ethanol, wherein the mass fractions of polyvinylpyrrolidone and glucose were both 5%, to prepare a second solution. The first solution and the second solution are mixed according to a volume ratio of 1:1, and stirred evenly to obtain a spinning core layer solution.

[0079] 2) Preparation of spinning sheath solution

[0080] Polyvinylpyrrolidone (PVPK90) and glucose were dissolved in ethanol, wherein the mass fractions of polyvinylpyrrolidone and gluc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com