Patents

Literature

33results about How to "Reduce conduction resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

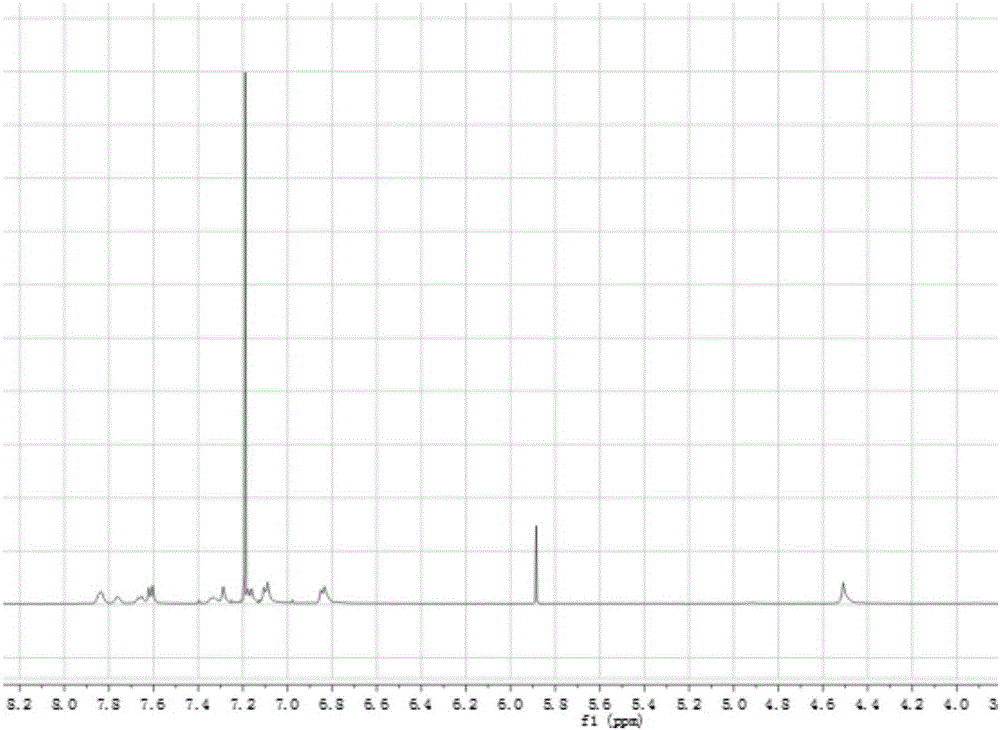

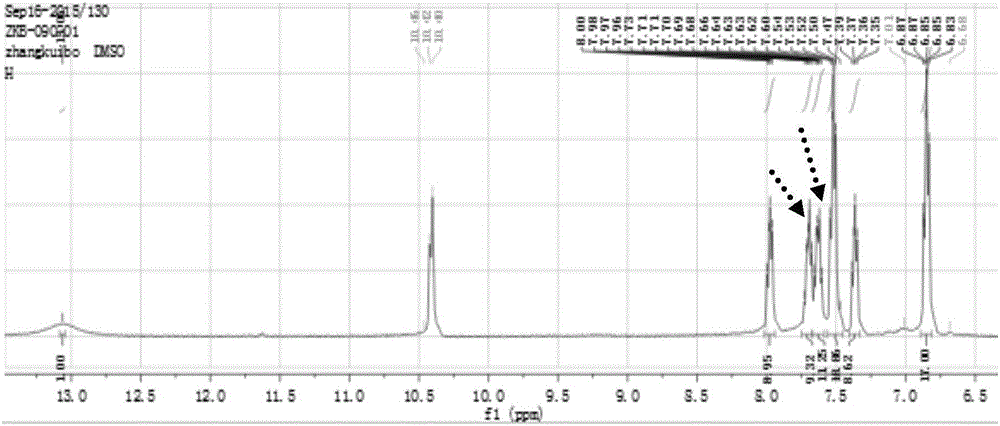

Novel block anion exchange membrane and preparation method thereof

InactiveCN105906812AHigh conductivity free volume increaseIncreased free volumeFuel cellsPolymer scienceFuel cells

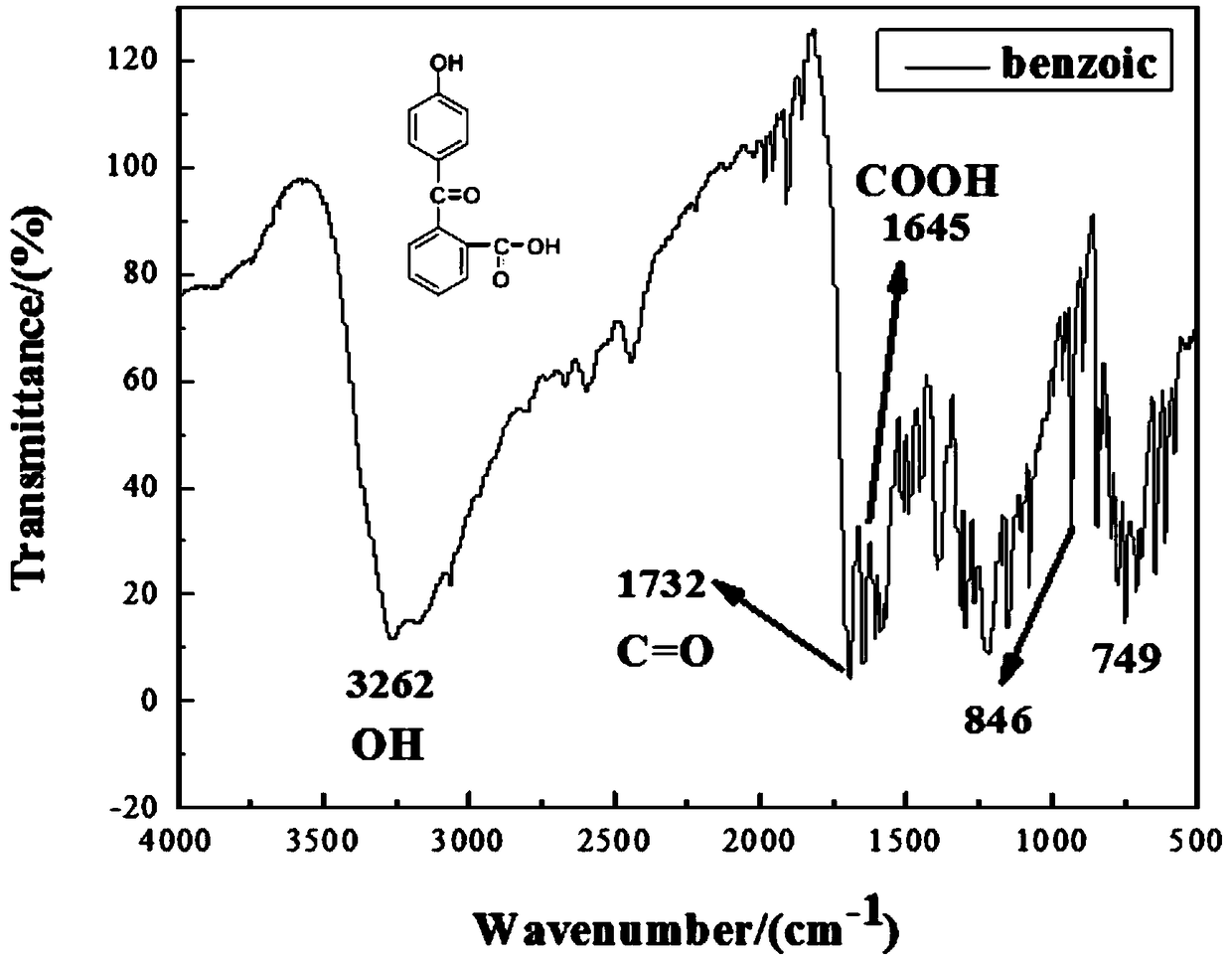

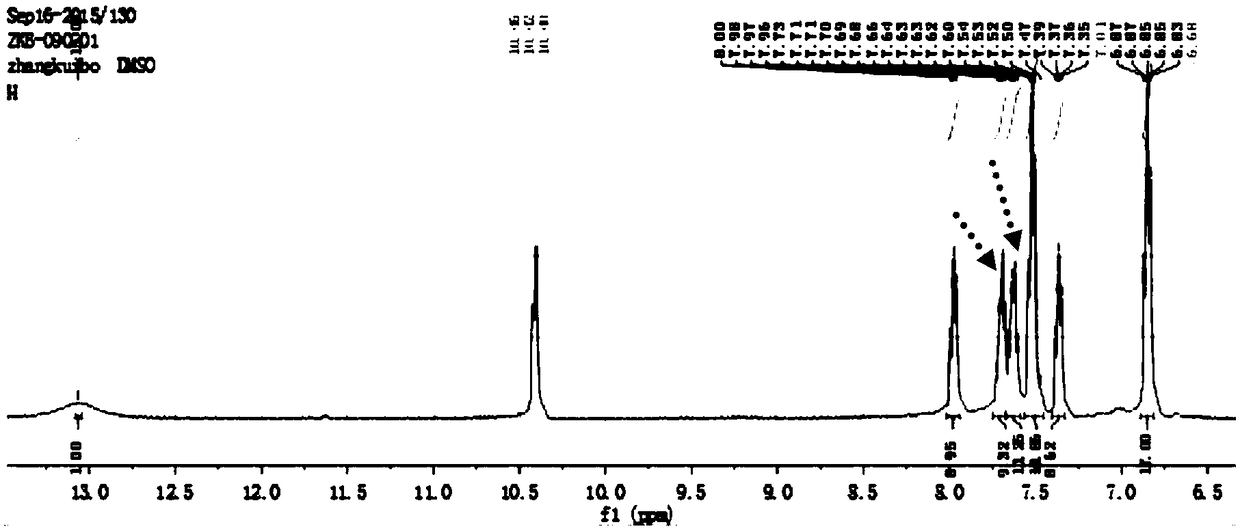

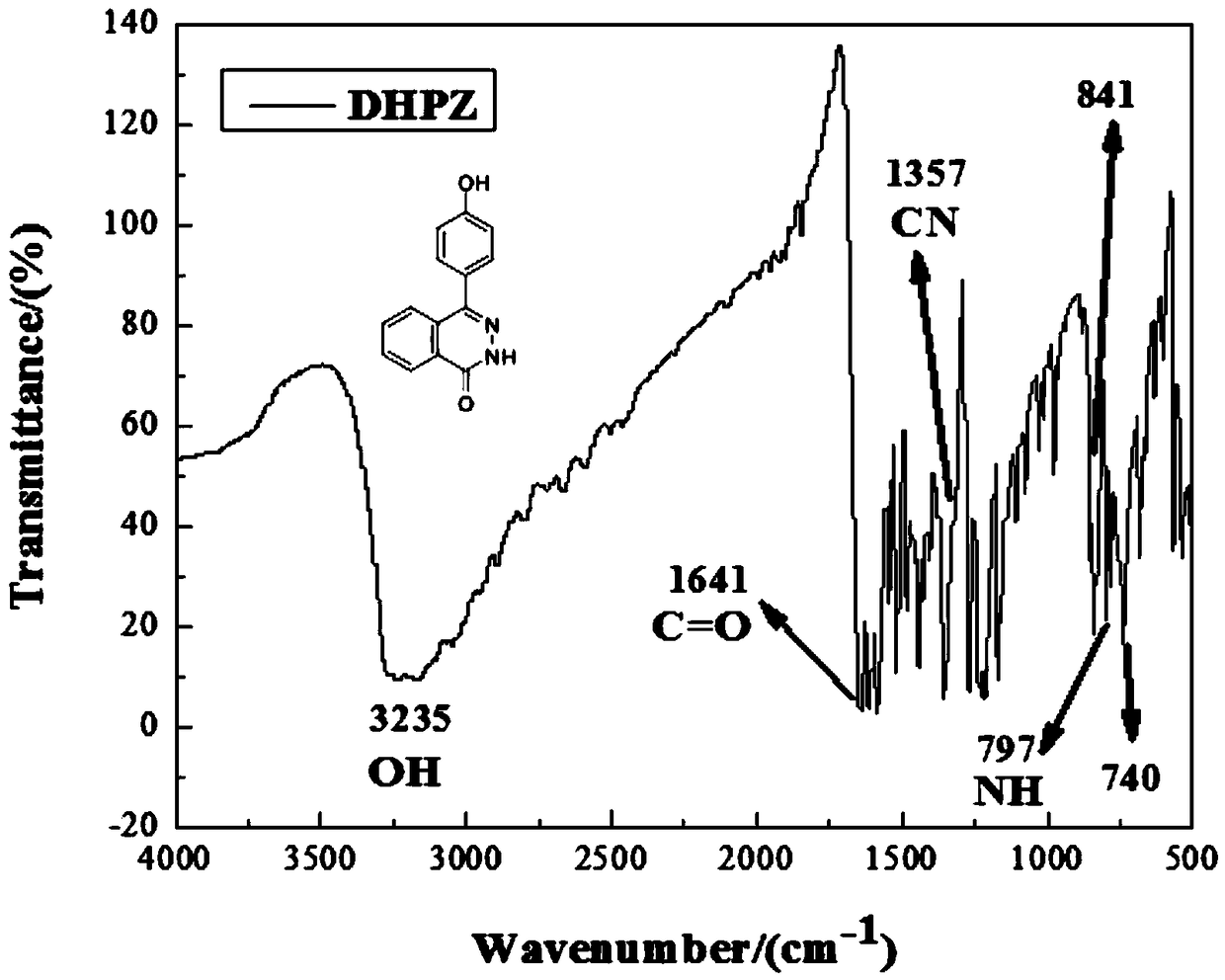

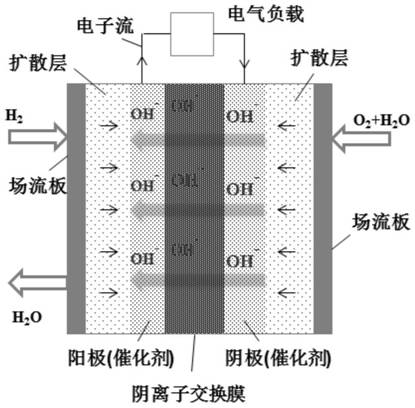

The invention discloses a novel block anion exchange membrane. A block main chain of the anion exchange membrane contains a bending unit (biphenyl fluorene) and a twisting unit (phthalazinone); according to the structure, a non-coplanar effect can be enhanced. A preparation method of the anion exchange membrane comprises the following steps of performing polycondensation on decafluorobiphenyl (slightly excessive) and bisphenol fluorine to prepare an oligomer 1; using the decafluorobiphenyl and 4-(4-hydroxyphenyl)-2,3-phthalazine-1-one to prepare an oligomer 2; polymerizing the oligomer 1 with the oligomer 2 to obtain a polymer main chain, and performing ionization treatment, membrane casting and alkali treatment on a chloromethylation main chain to obtain the anion exchange membrane. The anion exchange membrane has better chemical stability, and higher electric conductivity and resistance to swelling, and is suitable for being applied in the aspect of alkaline fuel cells.

Owner:DALIAN UNIV OF TECH

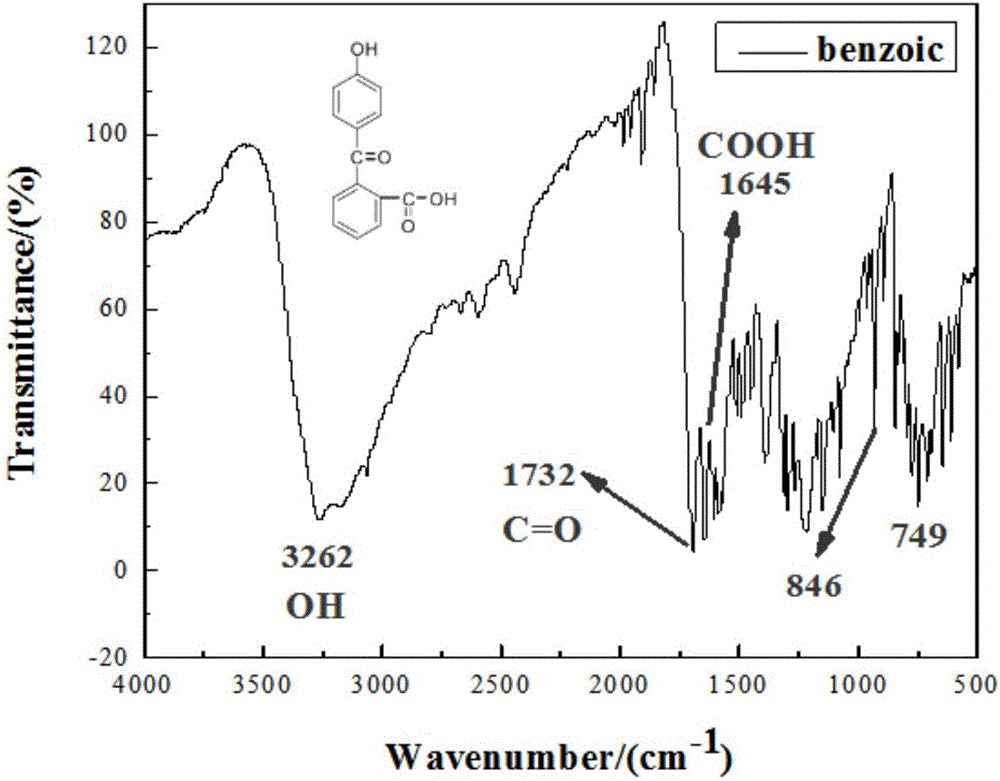

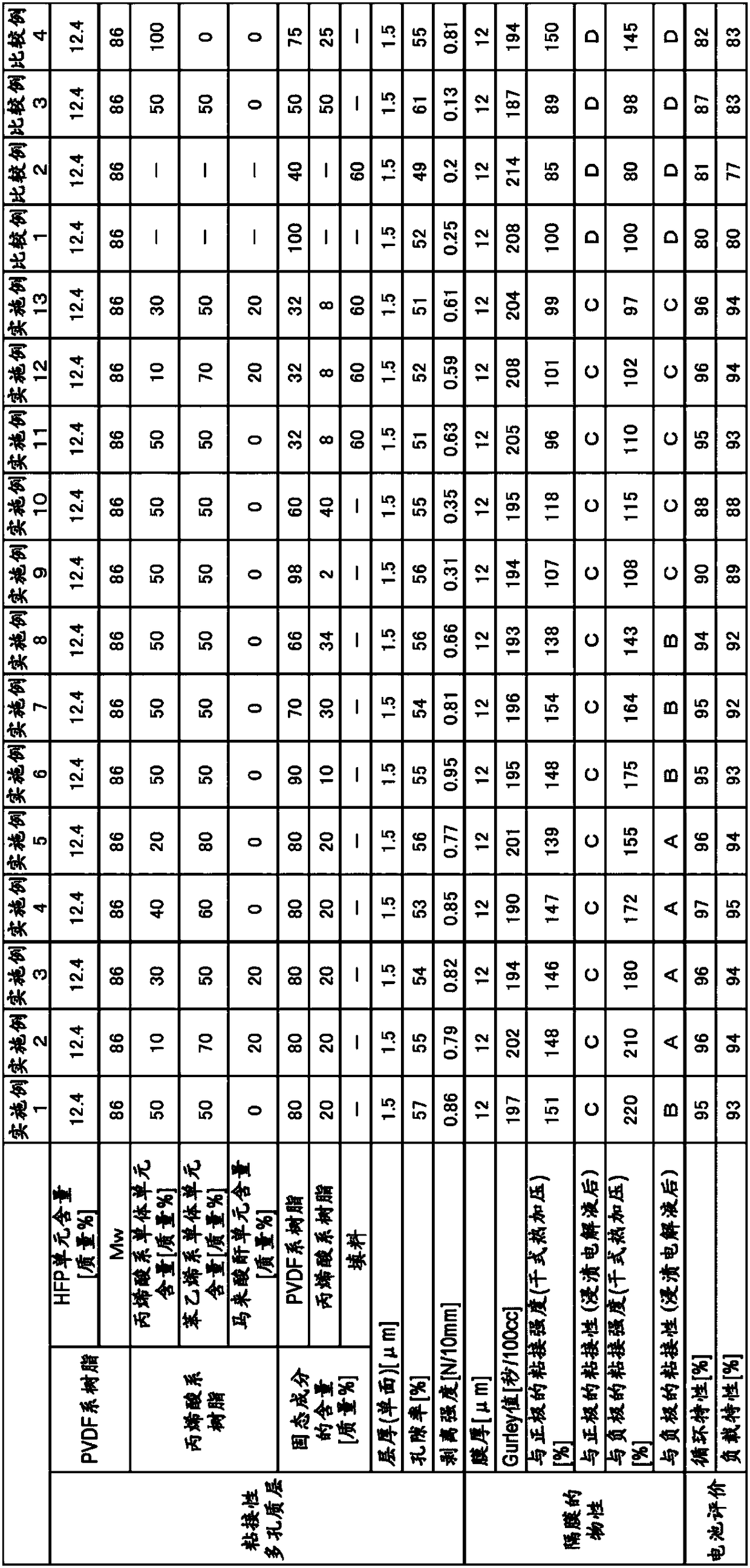

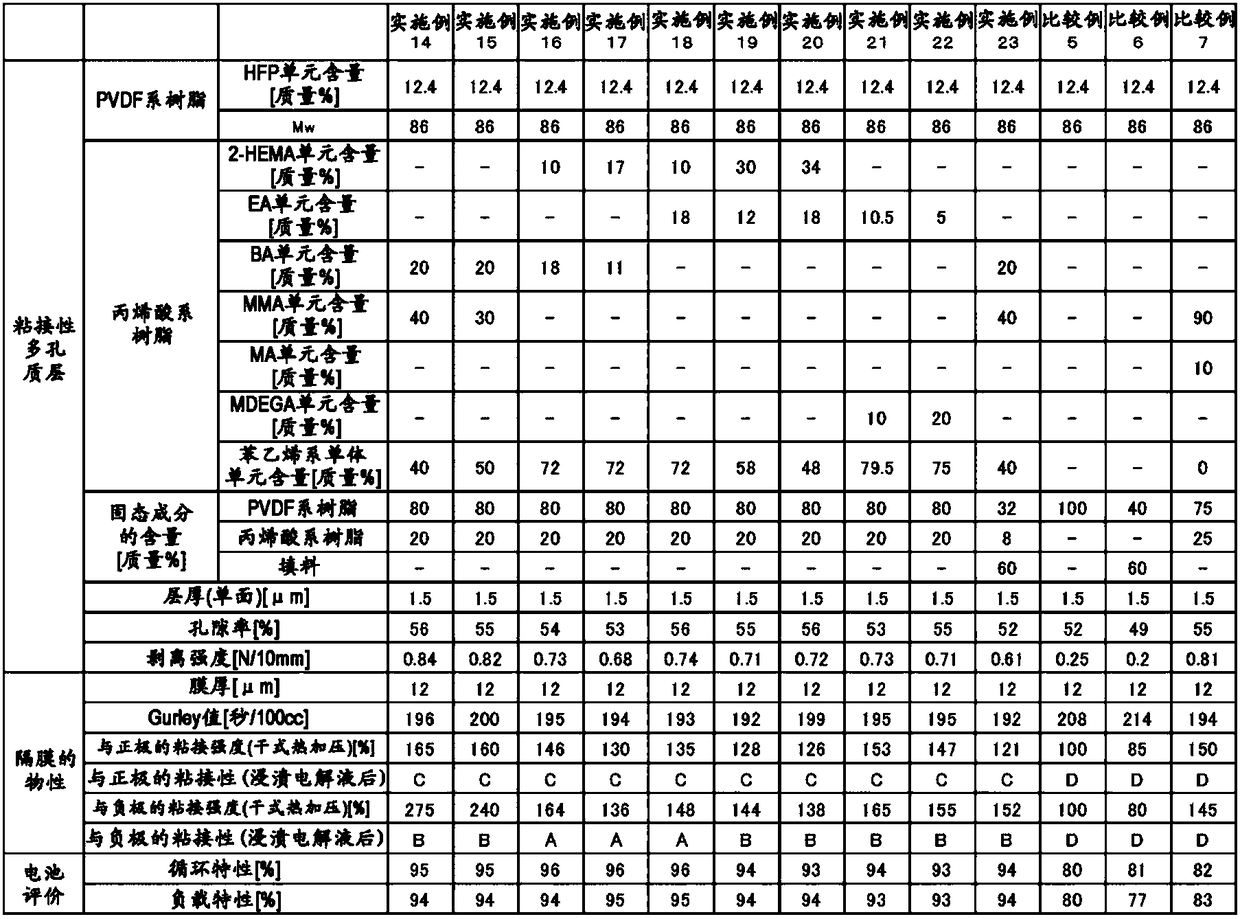

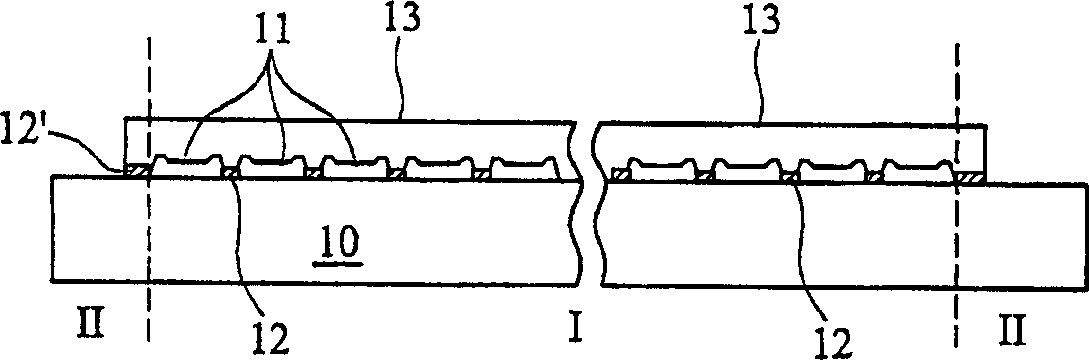

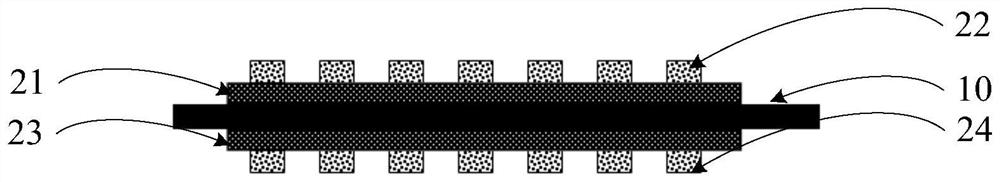

Separator for non-aqueous secondary battery and non-aqueous secondary battery

ActiveCN108448032AGood adhesionReduce conduction resistanceCell electrodesFinal product manufacturePorous substrateElectrolytic agent

The present invention relates to a separator for a non-aqueous secondary battery, and a non-aqueous secondary battery. The present invention provides a separator with good adhesion with an electrode based on drying hot pressing and with excellent adhesion with the electrode if even the separator for the non-aqueous secondary battery is dipped into electrolyte, or a separator for a non-aqueous secondary battery with good adhesion with the electrode based on drying hot pressing and with low ion conduction resistance. The separator for the non-aqueous secondary battery has a porous substrate, andan adhesive porous layer that is provided on one side or both sides of the porous substrate and contains an acrylic type resin and a polyvinylidene fluoride type resin, the acrylic type resin is a copolymer containing an acrylic type monomer and a styrene type monomer as monomer components, and a second monoacrylate type monomer that has an oxyalkylene structural unit with a repetition number offrom 2 to 10,000.

Owner:TEIJIN LTD

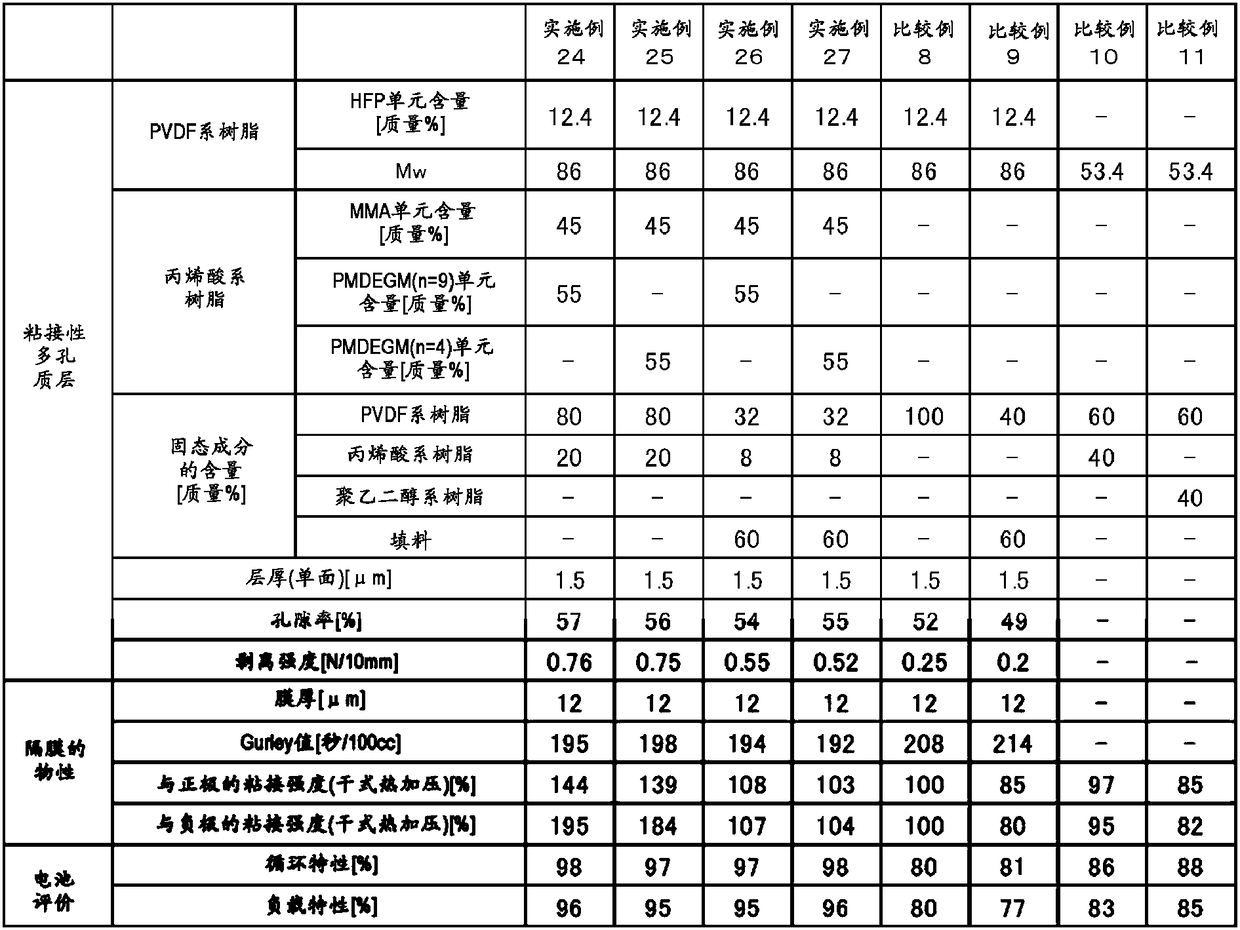

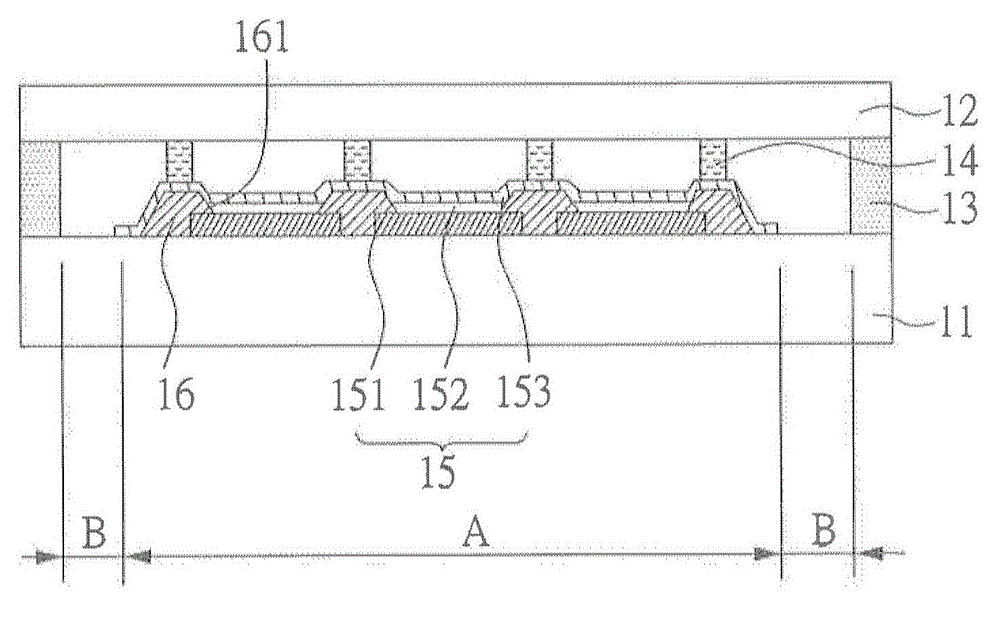

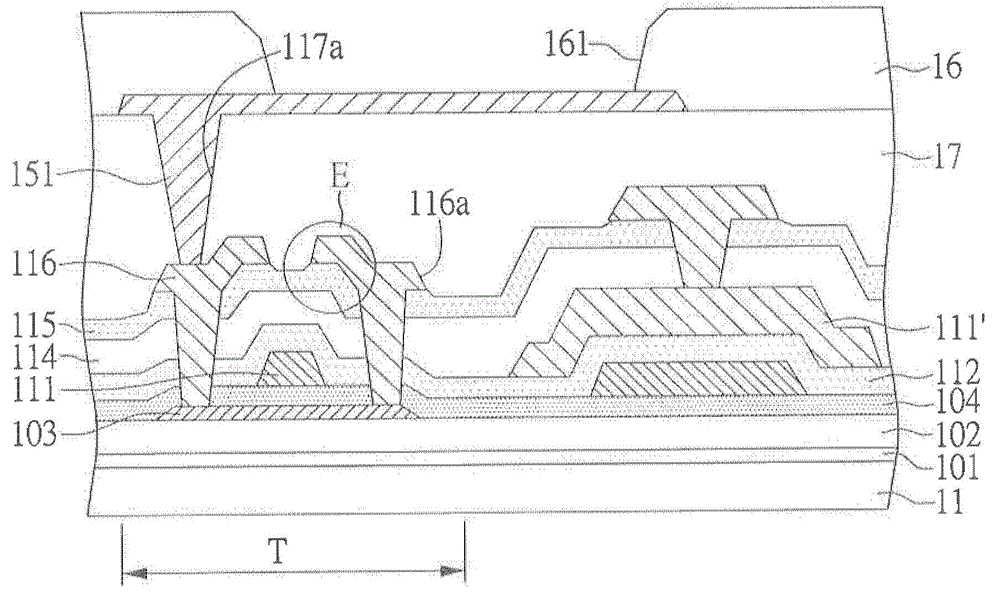

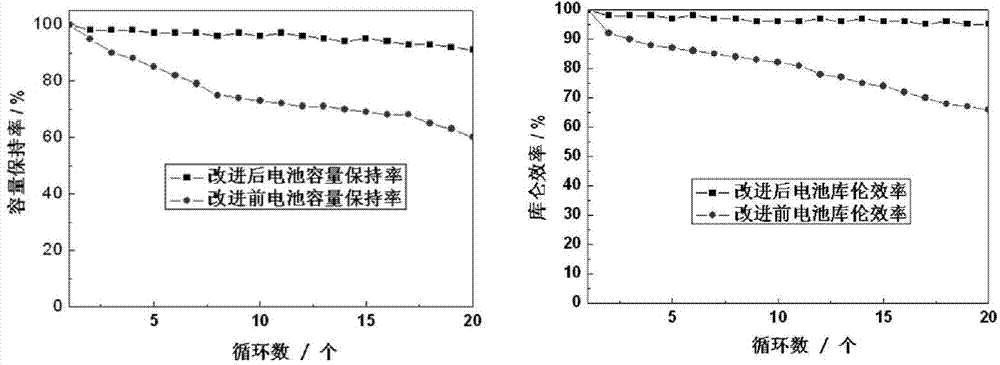

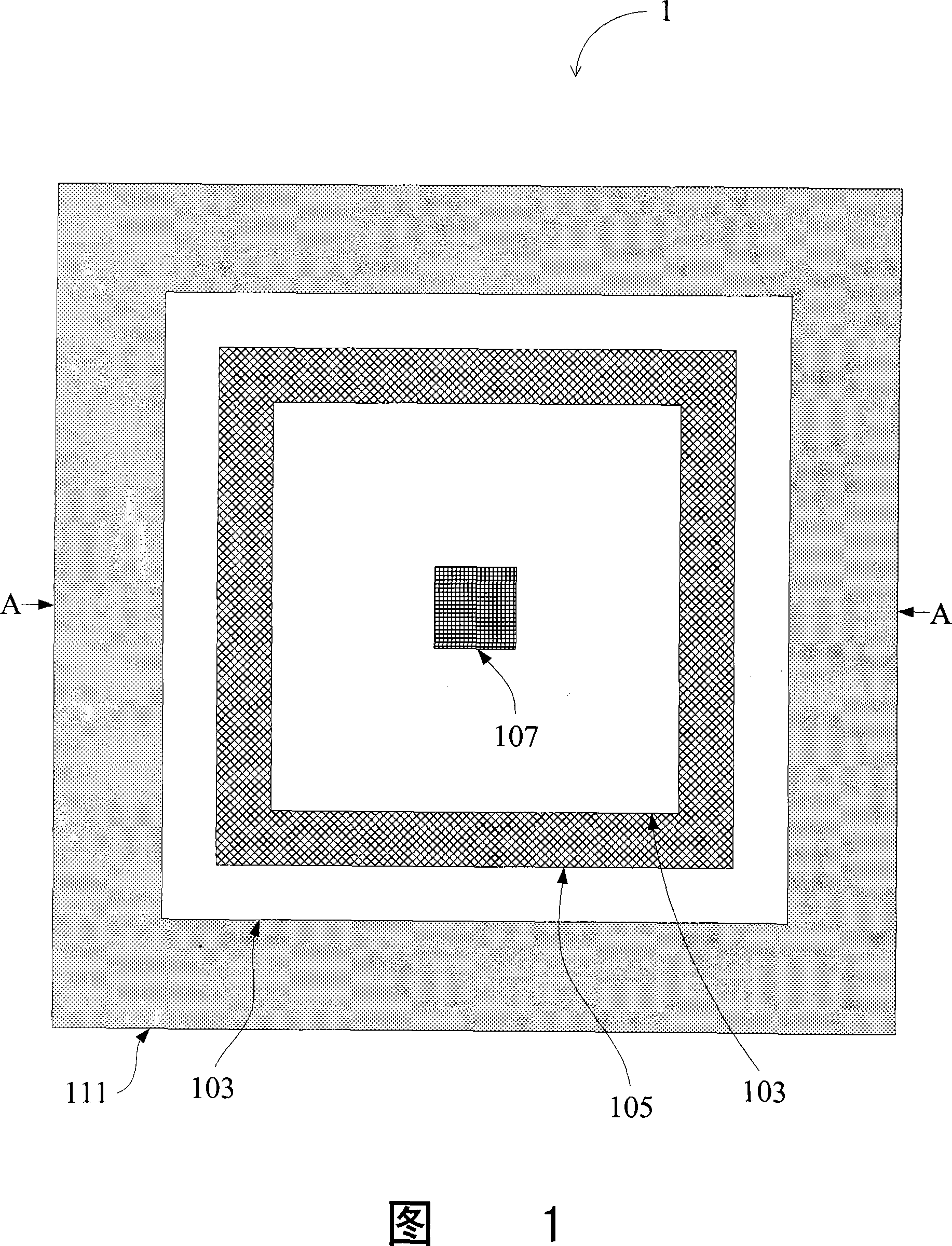

Display device

ActiveCN105097825AIncrease storage capacityReduce conduction resistanceSolid-state devicesNon-linear opticsDisplay devicePhysics

A display device is disclosed, which comprises: a first substrate; a first insulating layer disposed on the first substrate; a second insulating layer disposed on the first insulating layer; and a patterned metal layer disposed on the second insulating layer and comprising plural conductive lines, wherein an opening region is located between two adjacent conductive lines to expose the second insulating layer, and a thickness of the second insulating layer under the conductive lines of the patterned metal layer is larger than that exposed from the opening region.

Owner:INNOLUX CORP

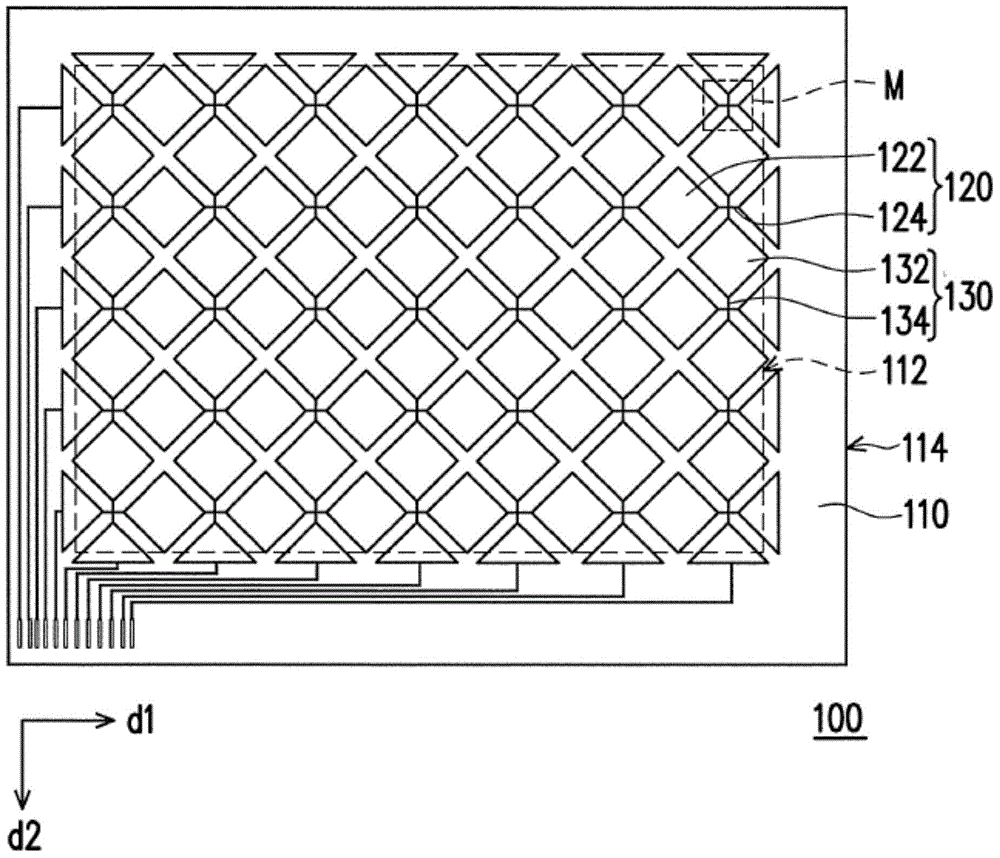

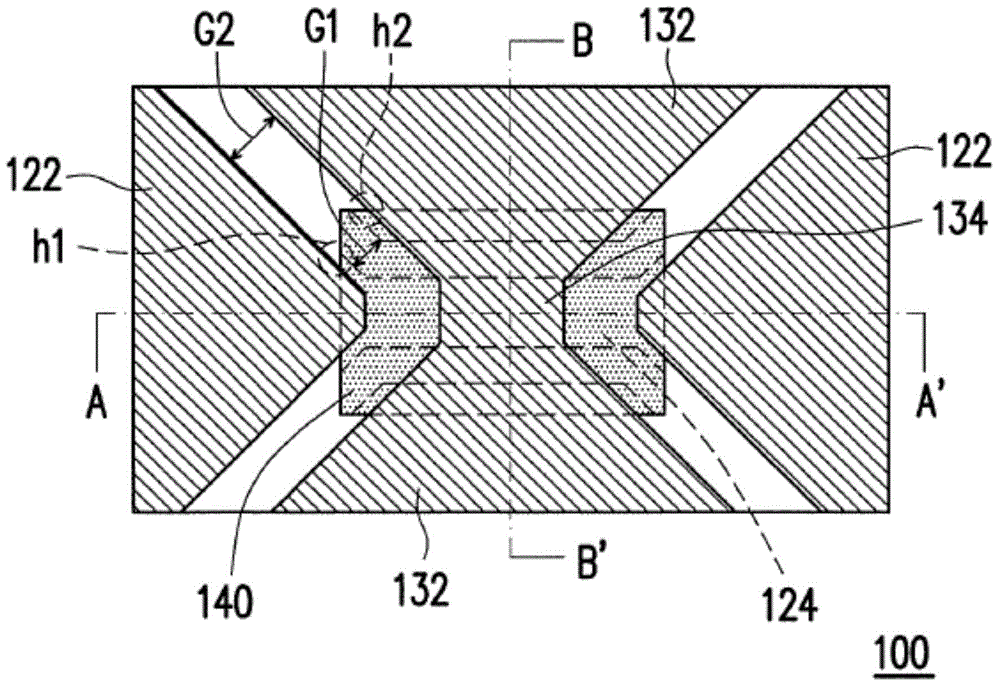

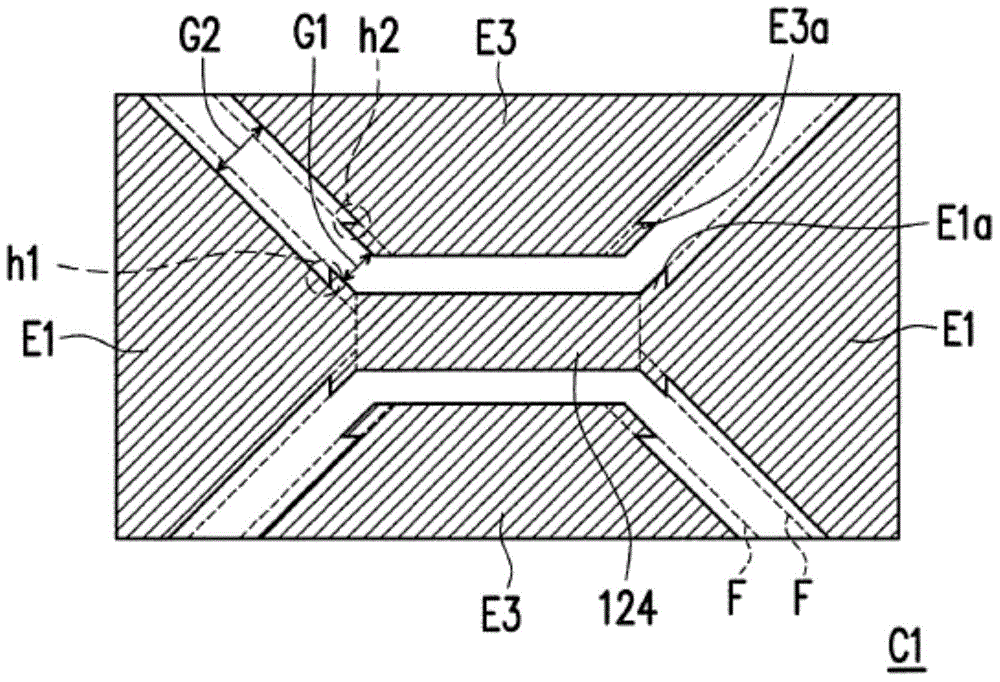

Touch panel

InactiveCN105320372AImprove touch sensitivityReduce conduction resistanceInput/output processes for data processingEngineeringTouch panel

The present invention provides a touch panel, comprising a substrate, a plurality of first conductive units, a plurality of second conductive units and a plurality of insulation patterns. Each first conductive unit comprises a plurality of first electrodes. Each second conductive unit comprises a plurality of second electrodes. Each first electrode comprises a first sub electrode and a second sub electrode which are stacked on the substrate in order. Each second electrode comprises a third sub electrode and a fourth sub electrode which are stacked on the substrate in order. The first sub electrodes and the third sub electrodes belong to a first conductive layer, and the second sub electrodes and the fourth sub electrodes belong to a second conductive layer. The first conductive layer has a plurality of differences. The differences are at least positioned at the boundaries of the first conductive units and the insulation patterns.

Owner:WINTEK CORP

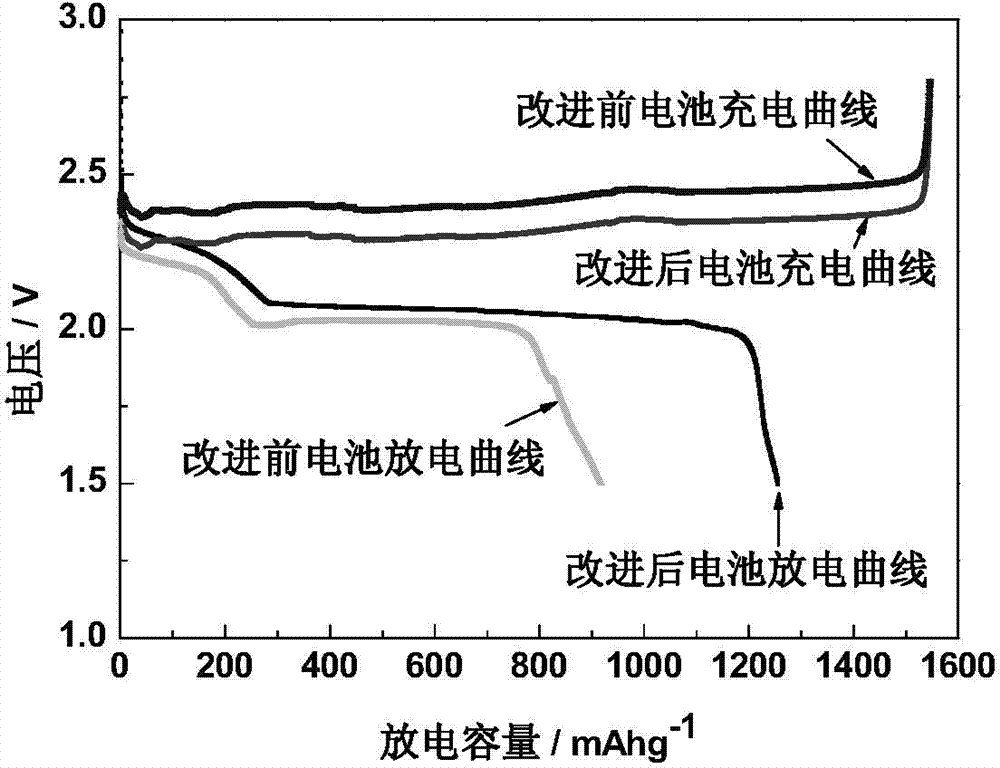

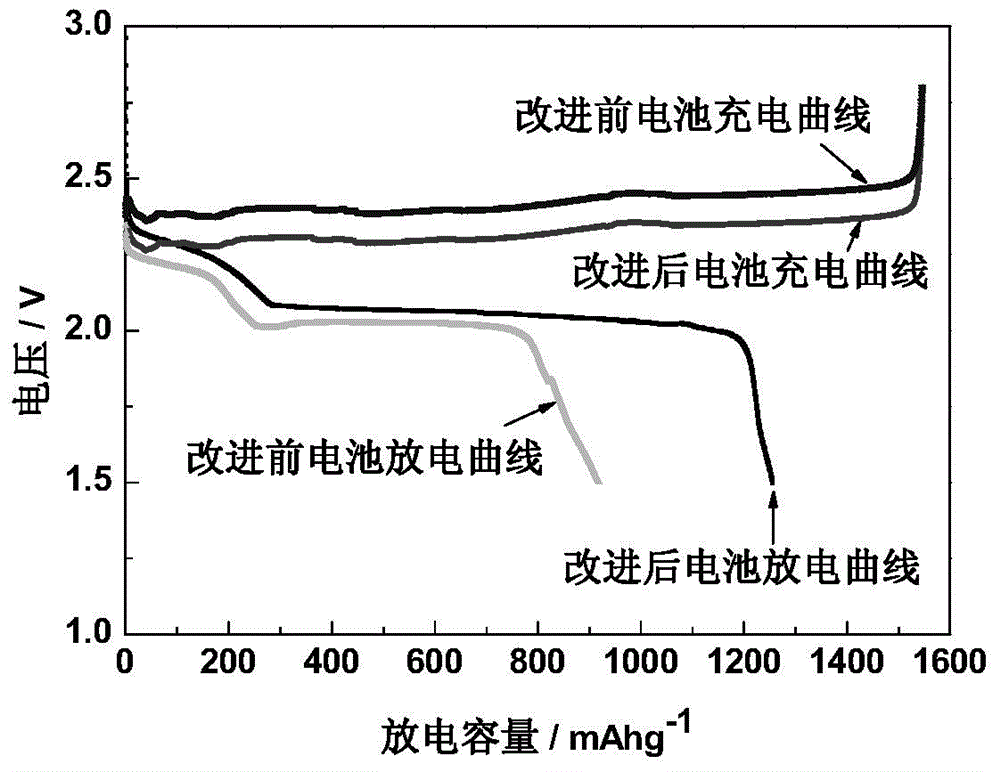

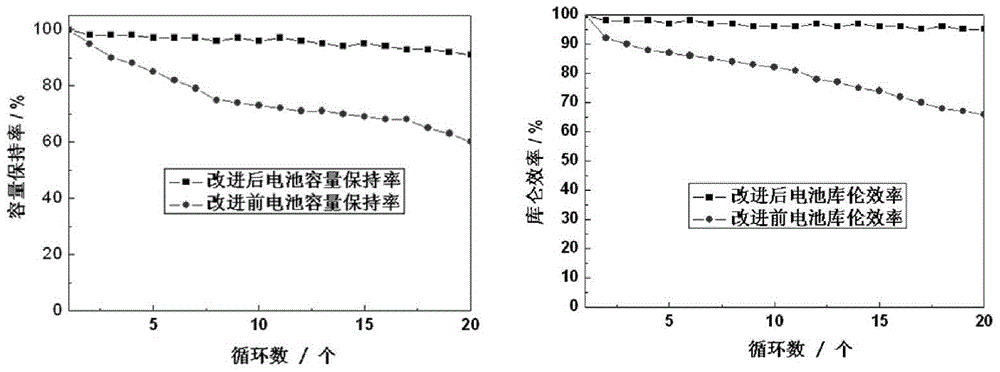

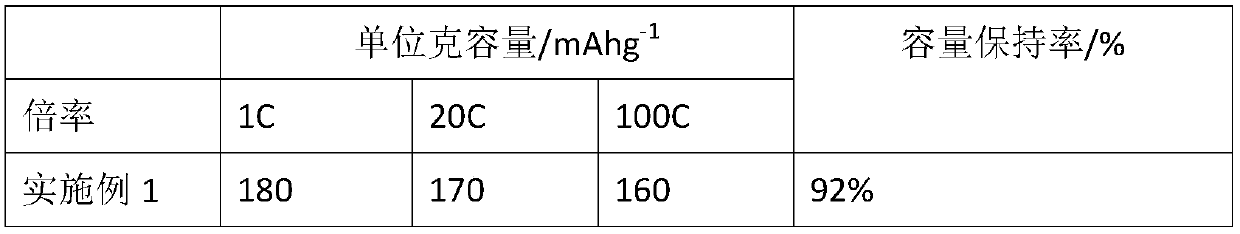

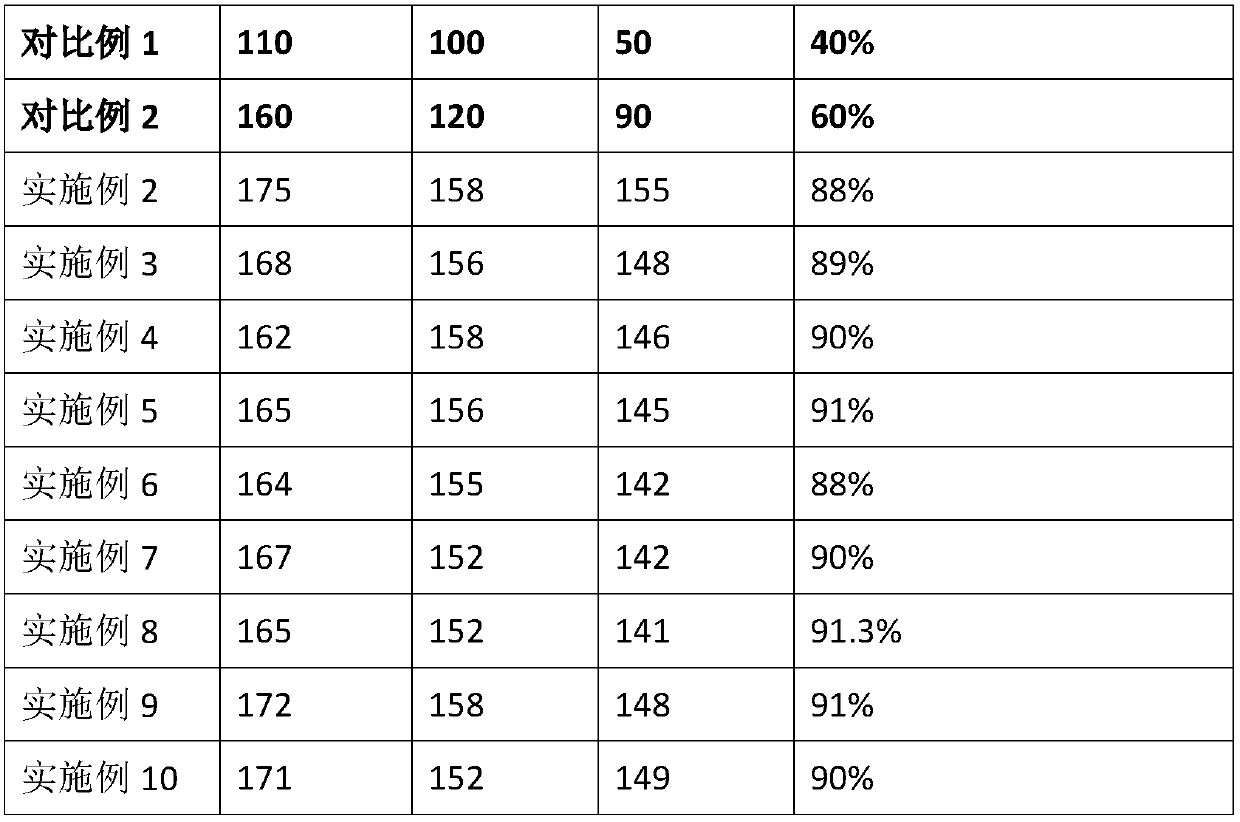

Oleophylic sulfur electrode preparation method

ActiveCN104716297AImprove wettabilityLow costPositive electrodesNon-aqueous electrolyte accumulator electrodesSilicon oxygenLithium–sulfur battery

The invention relates to an oleophylic sulfur electrode preparation method, silicone oil is penetrated into a positive porous electrode, and dried to obtain a porous oleophilic sulfur electrode, and the mass content of the silicone oil in the porous oleophilic sulfur electrode is 0.2-30%; by use of the oleophilic property of the silicone oil, an electrolyte uniformly infiltrates into the electrode, and especially lithium ion conduction in a high load sulfur electrode can be effectively achieved, so that the electrochemical performance of high load elemental sulfur can be played, and silicon oxygen bonds contained in the silicone oil can be effectively combined with lithium polysulfide in the discharge process, and self discharge phenomenon caused by dissolving and shuttling of the polysulfide can be suppressed, so that the objective of improving the lithium sulfur battery coulombic efficiency and cycle stability can be achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Schottky part and semiconductor making process for making same

InactiveCN101051655AReduce conduction resistanceLow costSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical junctionOhmic contact

The present invention provides a Schottky element and its semiconductor manufacturing process. The Schottky element comprises a substrate, a deep well, a Schottky contact, and an Ohmic contact. The substrate is doped with type I ion. The deep well zone is doped with type II ion and formed in the substrate. The Schottky contact contacts a first electrode with the deep well. The Ohmic contact contacts a second electrode with a heavily doped zone containing type II ion in the deep well. Wherein, the deep well zone has a geometry gap formed under the Schottky and containing a transverse size, the type I ion and the type II ion are complemented, and the transverse size is for adjusting the electric breakdown strength.

Owner:SYST GEN

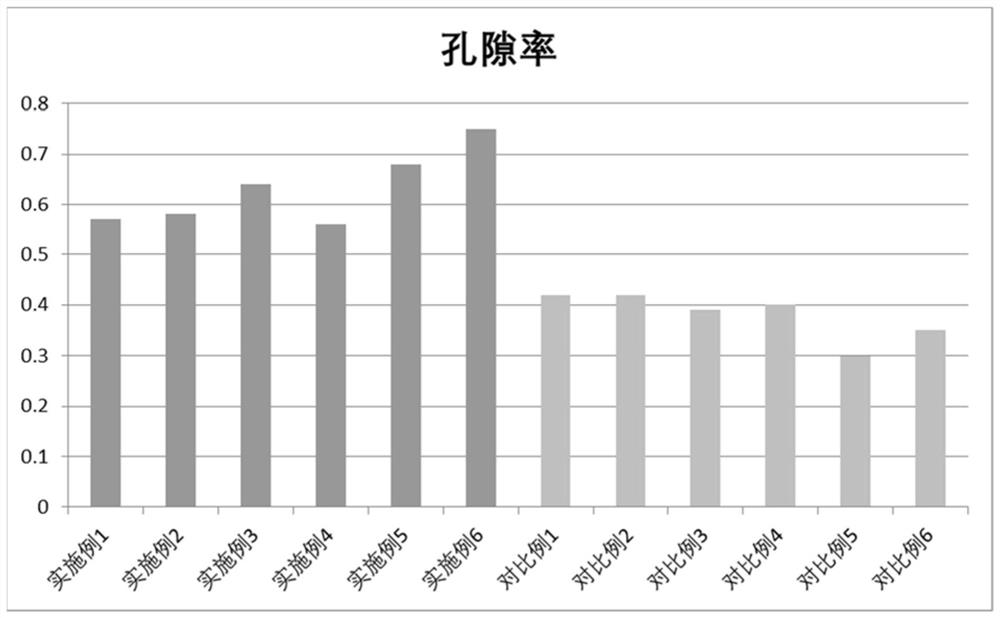

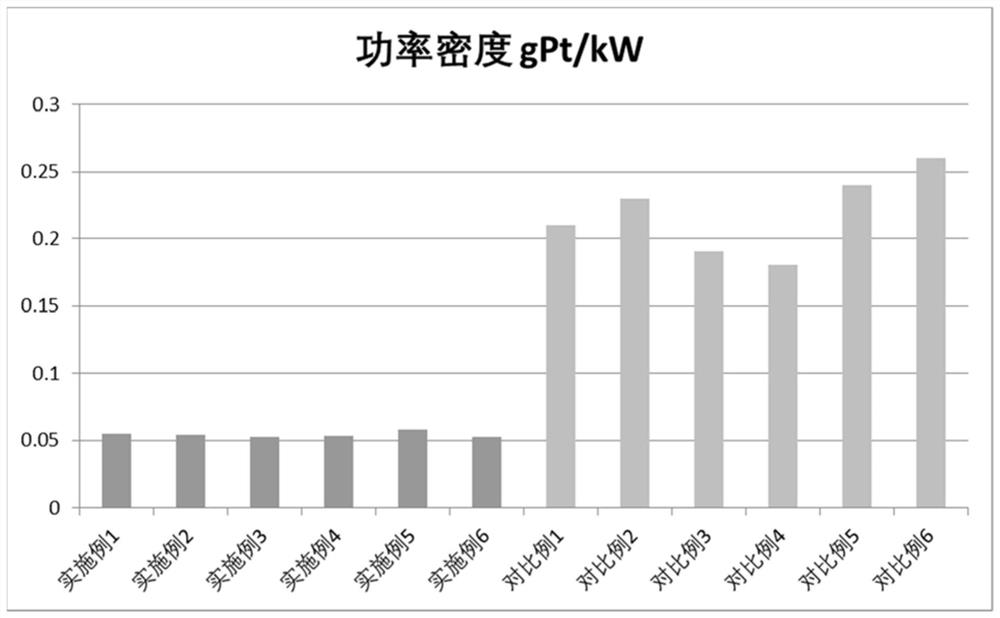

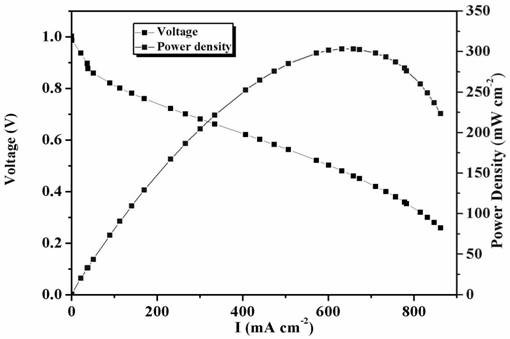

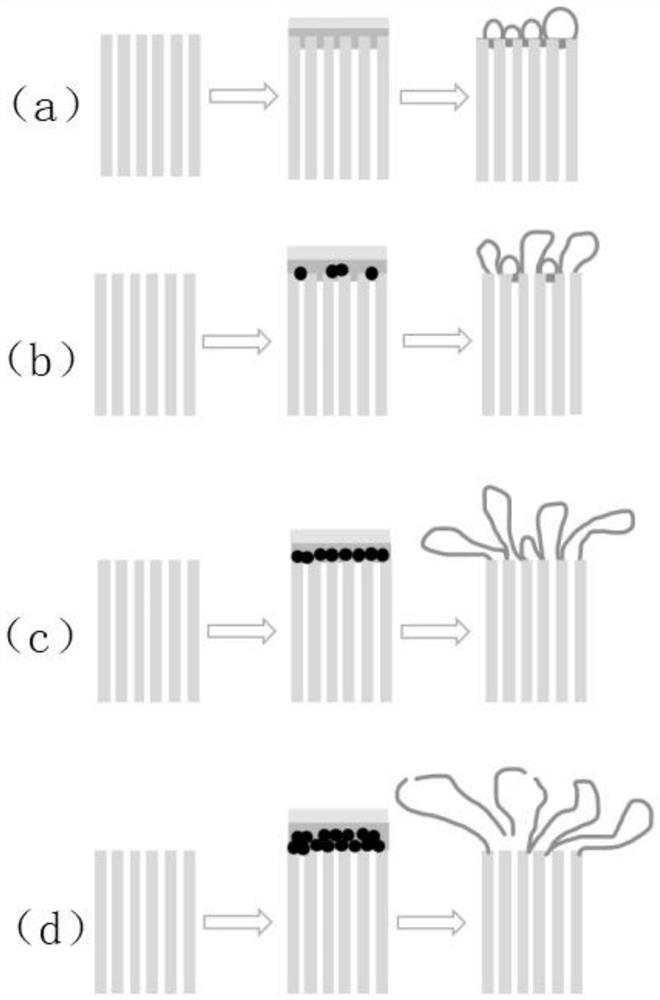

Membrane electrode for proton exchange membrane fuel cell and preparation method of membrane electrode

ActiveCN113270593AIncrease profitEnhanced mass transferCell electrodesFinal product manufacturePtru catalystPhysical chemistry

The invention relates to a membrane electrode for a proton exchange membrane fuel cell and a preparation method of the membrane electrode. The preparation method comprises the following steps: A, spinning catalyst slurry onto a microporous layer on the surface of hydrophobic carbon paper by adopting a variable-voltage electrostatic spinning process to obtain a gas diffusion catalyst layer integrated electrode; B, assembling according to the assembly sequence of the gas diffusion catalyst layer integrated electrode, the proton exchange membrane and the gas diffusion catalyst layer integrated electrode, and after assembly, preparing the membrane electrode for the proton exchange membrane fuel cell through a hot pressing or cold pressing process. The catalyst layer is directly spun on the gas diffusion layer by means of an electrostatic spinning technology, the thickness of the catalyst layer and the loading capacity of a catalyst are reduced, the dispersity of the catalyst is improved, and a fibrous structure obtained through spinning is good in uniformity and rich and moderate in pore structure; water transmission and air mass transfer in a high-current density area of the fuel cell are improved, and the cell performance is improved.

Owner:上海唐锋能源科技有限公司

Preparation of proton conduction membrane

ActiveCN101475699BImprove conductivityStrong resistance to electrochemical corrosionCell component detailsProtonNetwork structure

The invention relates to a preparation method for a proton-conducting membrane, and belongs to the technical field of ion exchange membranes. The preparation method is characterized in that dimethyl sulfoxide is adopted to dissolve polyvinylidene fluoride and sodium allylsulfonate monomer containing proton conducting functional group; a flow casting method is adopted to form a membrane on a smooth solid surface through flow casting; the sodium allylsulfonate monomer is initiated to carry out polyreaction; and the products of the polyreaction and polyvinylidene fluoride molecular chain are formed into the proton-conducting membrane of macromolecular interpenetrating network structure. The preparation method can obtain an ion exchange membrane material with ideal proton conductibility, and overcomes the disadvantage that the prior melting mould pressing process cannot prepare homogeneous phase ion exchange membranes; moreover, the preparation method has the advantages of simple technological process, easy industrial scaling up and the like.

Owner:TSINGHUA UNIV

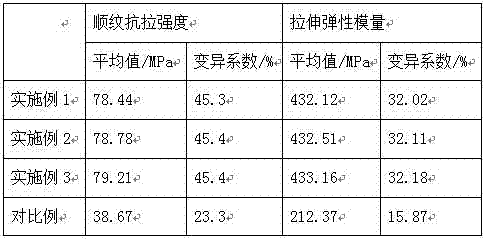

Processing method for improving tilia bast fiber knitting property

The invention belongs to the technical field of tilia bast fiber processing and particularly relates to a processing method for improving tilia bast fiber knitting property. The processing method comprises the following specific methodssteps: performing boiling, freezing and steam and treating fluid dipping treatment on tilia bast fiber and performing temperature-change drying, ultrasonic, variable pressure and constant-temperature drying treatment. In the step of performing boiling, freezing and steam and treating fluid dipping treatment on tilia bast fiber, degradation of hemicelluloses in the tilia bast fiber is effectively inhibited; as the hemicelluloses has an adhesion effect in cell walls, the bonding strength among the tilia bast fiber is enhanced, and the toughness and the breaking resistance of the tilia bast fiber are improved; furthermore, a the color and luster degree of the tilia bast fiber is effectively improved, and sun resistance of the tilia bast fiber is enhanced. In the step of performing temperature-change drying, ultrasonic, variable pressure and constant-temperature drying treatment, conduction resistance of moisture in the tilia bast fiber is reduced, permeability of the tilia bast fiber is improved, the combining capacity between components of the treating fluid and tilia bast fiber cellulose molecules is enhanced, hygroscopicity of the tilia bast fiber is reduced, and dimensional stability of the tilia bast fiber is improved; furthermore, breeding of mould and putrefying bacteria is effectively inhibited, service life of the tilia bast fiber is prolonged, and use quality of the tilia bast fiber is improved.

Owner:阜南县宏达工艺品厂

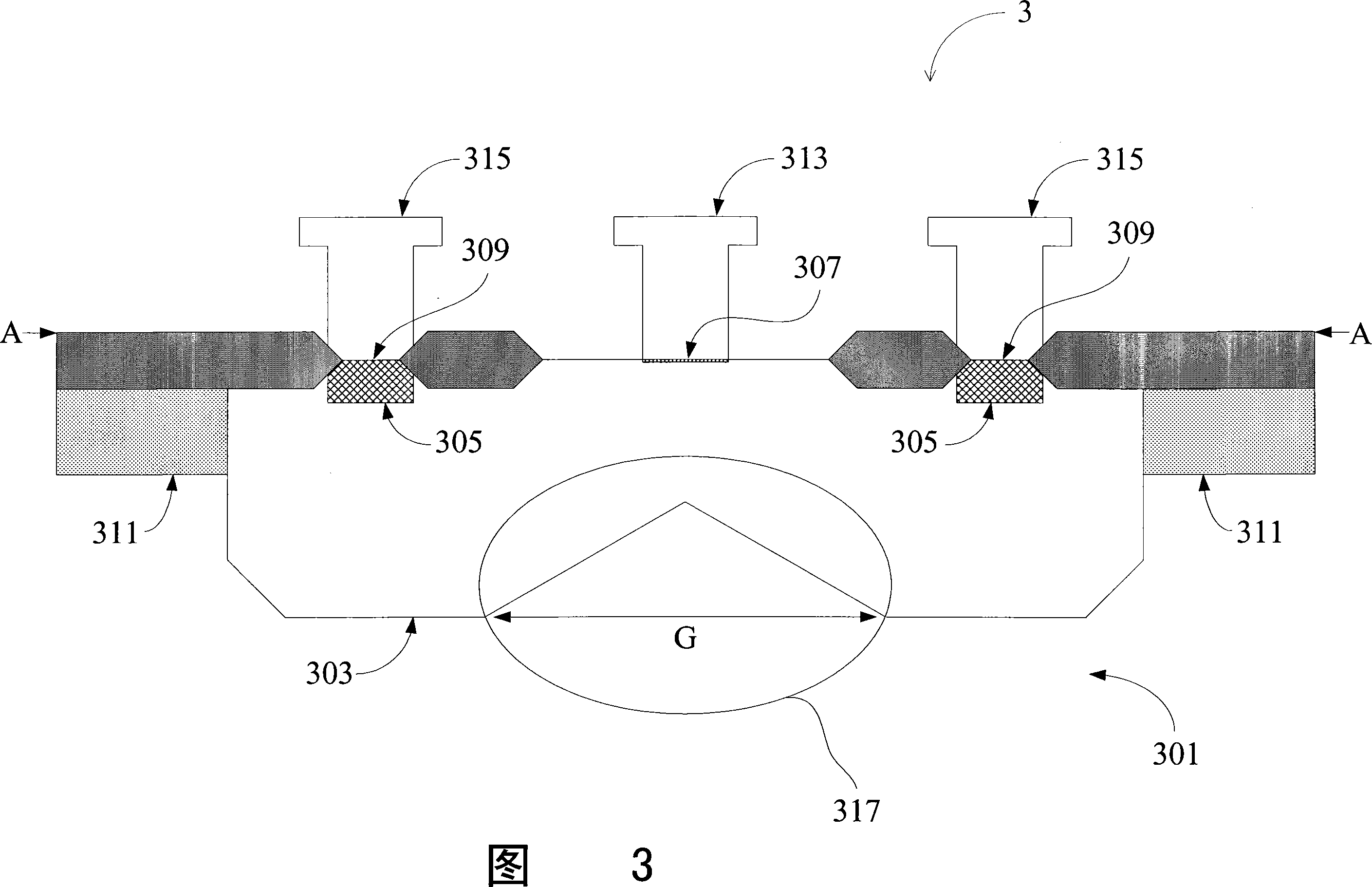

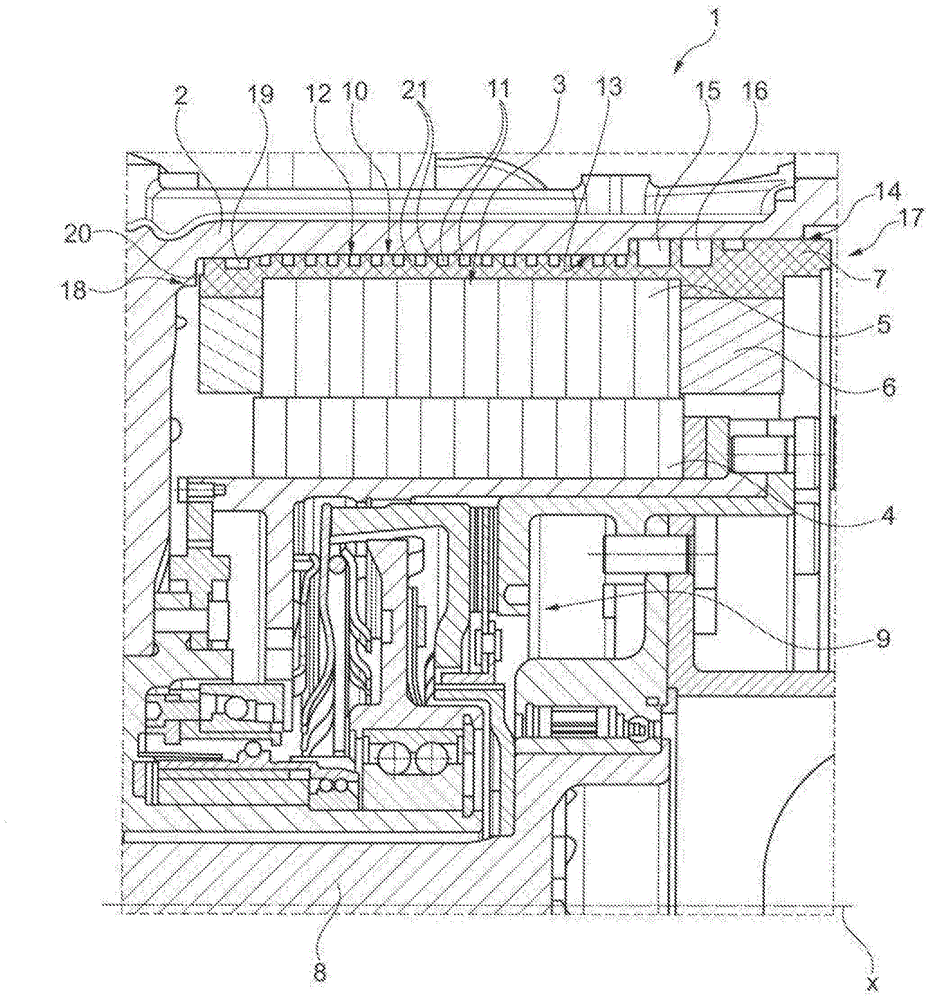

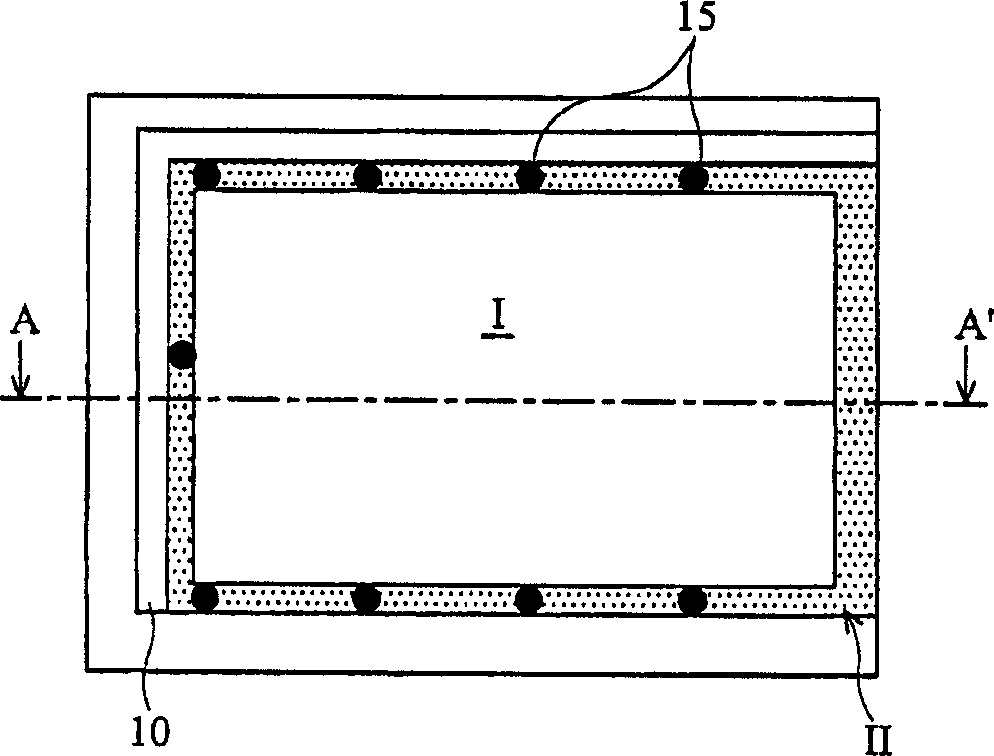

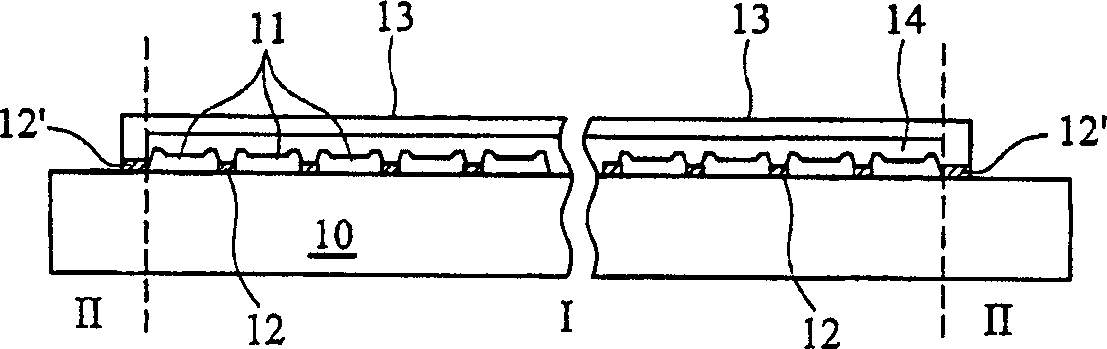

Electrical machine having a cooling device, and method for producing said electrical machine

ActiveCN105026000APrevent outflowEasy to manufactureEntertainmentManufacturing stator/rotor bodiesElectric machineElectrical and Electronics engineering

The invention relates to an electrical machine (1), and to a method for producing said electrical machine, said electrical machine having a housing (2) and a stator (3), which is held on said housing, and at least one rotor (4), which is arranged radially within the stator (3), a plastic body (7), which surrounds a soft-magnetic body (5) of the stator (3) at least radially on the outside, and a cooling device (10) between the stator (3) and the housing (2). In order to improve the cooling device (10), at least one recess (11), which carries a cooling medium, is made at least partially in the outer circumference of the plastic body (7) between the housing (2) and the stator (3).

Owner:SCHAEFFLER TECH AG & CO KG

Colour optical filter and its manufacturing method

InactiveCN1794019AReduce usageReduce conduction resistanceOptical elementsLight filterColor filter array

A color filter is featured as adding one or multiple conductive layer above covering layer between R / G / B color filtering units on color filter to form parallel structure being connected through to each other and being set between conductive layer and electrode layer, utilizing said parallel structure to decrease transmission impedance.

Owner:AU OPTRONICS CORP

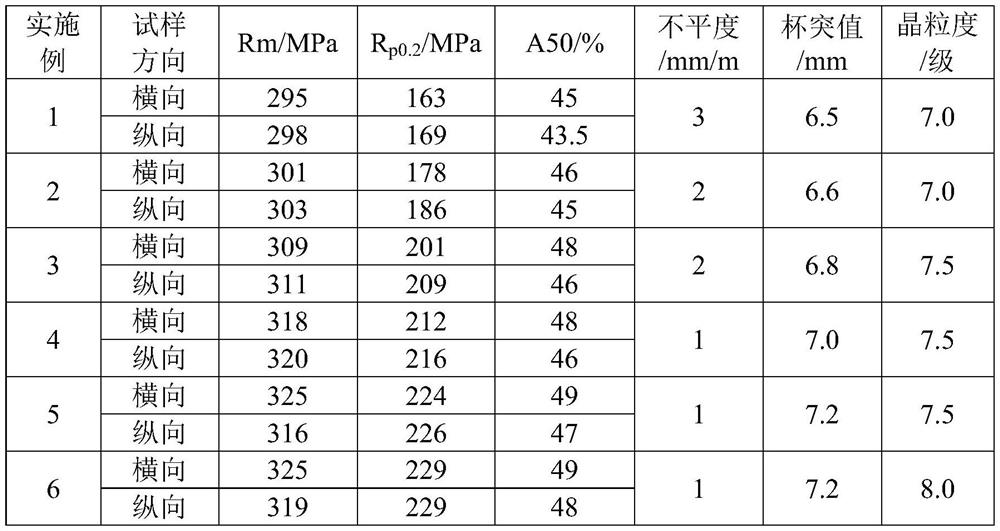

Preparation method of ultrathin titanium strip for bipolar plate of hydrogen fuel cell

PendingCN114589213AReduce contact resistanceGood thermal conductivityMetal rolling arrangementsWork lubrication devicesTitaniumTitanium plate

The invention discloses a preparation method of an ultrathin titanium strip for a bipolar plate of a hydrogen fuel cell, which comprises the following steps: S1, smelting 0-grade small-particle sponge titanium to obtain a pure titanium cast ingot; s2, the pure titanium cast ingot is subjected to forging and machining treatment, and a pure titanium plate blank is obtained; s3, the pure titanium plate blank is hot-rolled into a titanium strip coil, then the titanium strip coil is subjected to annealing, shot blasting and acid pickling treatment, and a hot-rolled and annealed titanium strip coil is obtained; s4, the hot-rolled and annealed titanium strip coil is cold-rolled into a first-rolling-process titanium strip coil, then the first-rolling-process titanium strip coil is subjected to annealing, shaping and double-face dull polish treatment, and a cold-rolled titanium strip intermediate is obtained; s5, the cold-rolled titanium strip intermediate is cold-rolled into a two-rolling-process titanium strip coil; s6, the secondary rolling process titanium strip coil is subjected to stretch bending and straightening treatment; and S7, the secondary rolling process titanium strip coil is subjected to annealing treatment, and a finished product titanium strip is obtained. The process is reasonable in design, and the obtained finished titanium strip is uniform in internal structure, excellent in appearance quality and suitable for large-scale popularization.

Owner:新疆湘润新材料科技有限公司

Preparation method of dye sensitization solar battery slurry

InactiveCN106158390AGood film formingGood dispersionLight-sensitive devicesPhotovoltaic energy generationComposite filmSlurry

The invention belongs to photoelectric cell electrode materials, and discloses a preparation method of dye-sensitized solar cell paste. It consists of the following steps: (1) preparing titanium dioxide powder, (2) preparing slurry, (3) curing the slurry and (4) concentrating the slurry; the dye-sensitized solar cell slurry obtained by the method has good film-forming property, The dispersion of particles in the slurry is good, the film layer does not crack after sintering, and the film has strong adhesion to the substrate after sintering; the method has low manufacturing cost, green and environmentally friendly manufacturing process, and the obtained composite film has excellent conductivity, which provides a solid foundation for large-scale industrial production. Easy way.

Owner:陆鹏

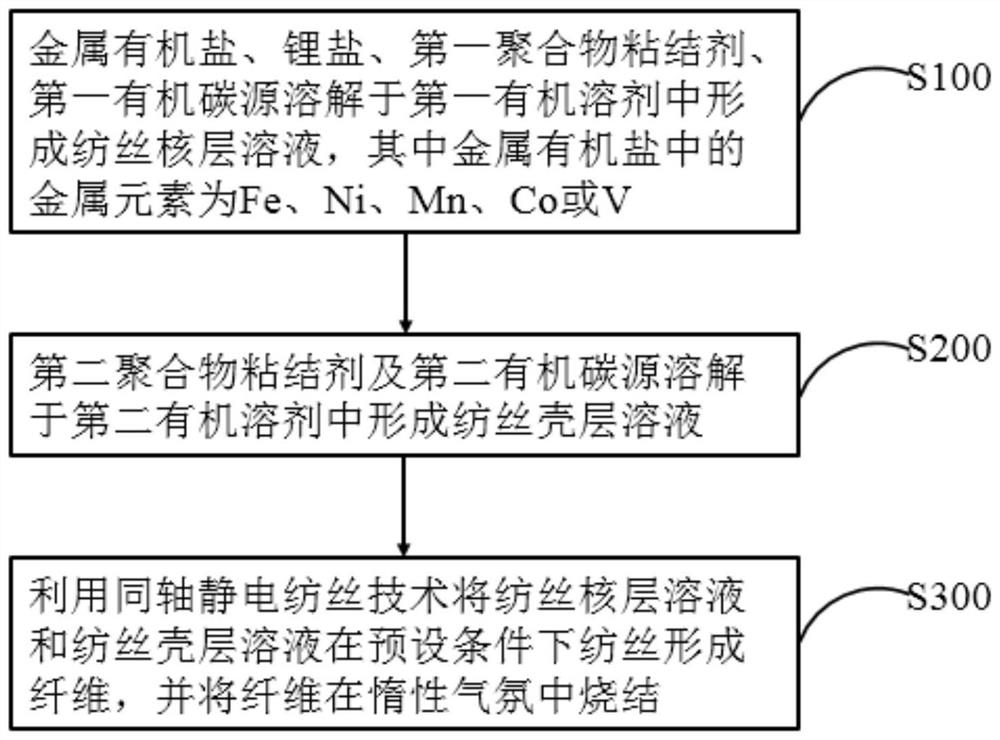

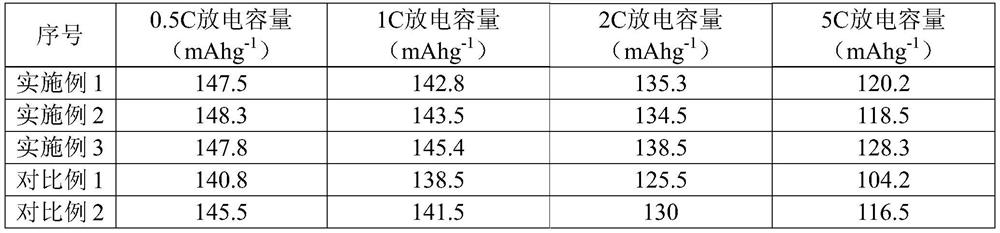

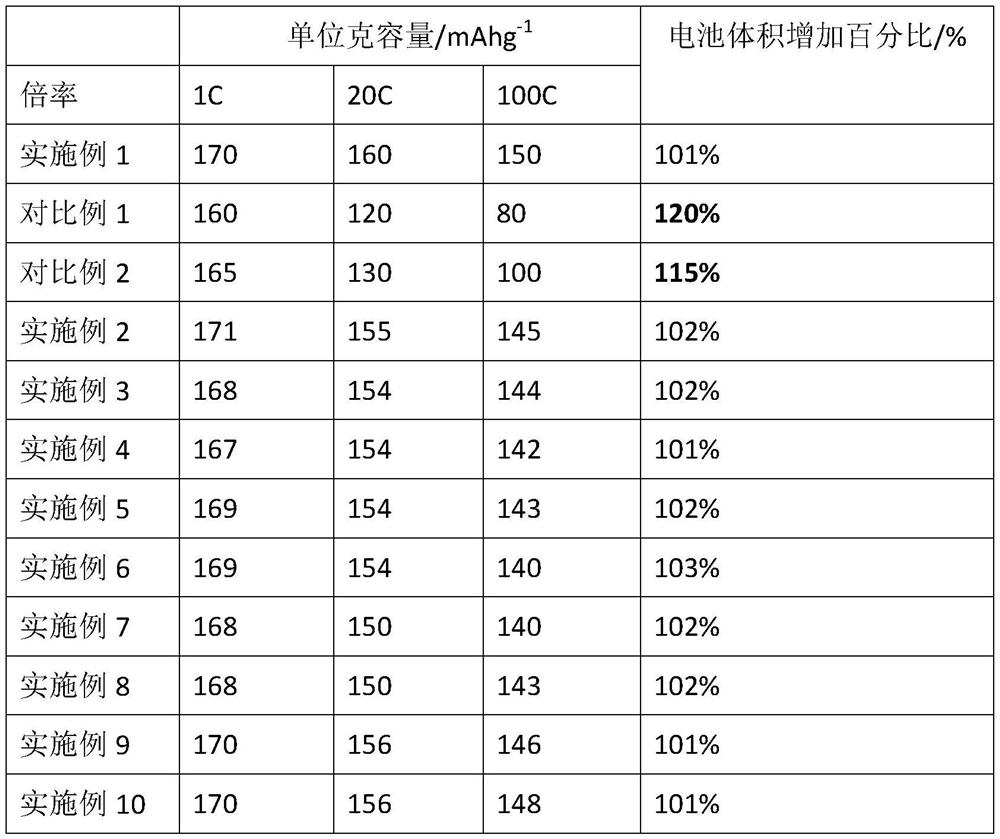

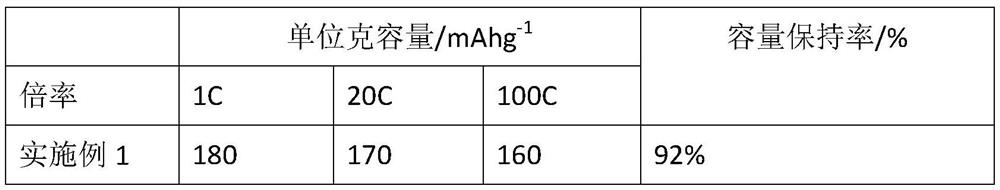

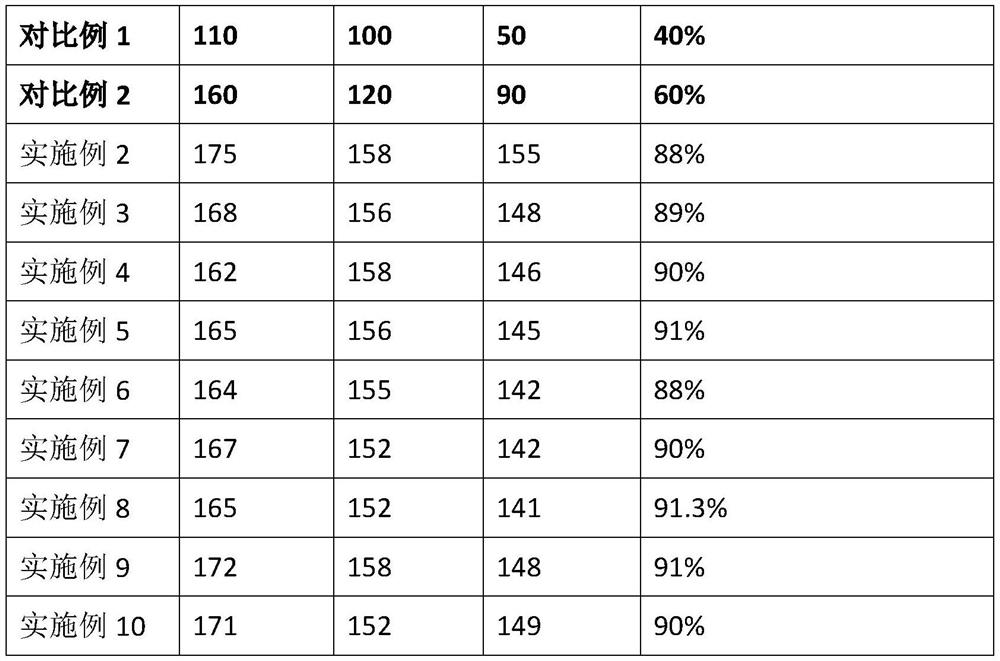

Carbon-coated nanofiber material, preparation method thereof and battery

InactiveCN113540444AImprove electronic conductanceImproved magnification performanceSecondary cellsPositive electrodesCarbon coatingFiber

The invention relates to the field of lithium ion battery electrode materials, in particular to a carbon-coated nanofiber material, a preparation method thereof and a battery. The preparation method of the carbon-coated nanofiber material comprises the following steps: dissolving metal organic salt, lithium salt, a first polymer binder and a first organic carbon source in a first organic solvent, and preparing a spinning core layer solution, wherein metal elements in the metal organic salt are Fe, Ni, Mn, Co or V; dissolving a second polymer binder and a second organic carbon source in a second organic solvent to prepare a spinning shell solution; and spinning the spinning core layer solution and the spinning shell layer solution under a preset condition by using a coaxial electrostatic spinning technology to form fibers, and sintering the fibers in an inert atmosphere. According to the method, the fiber can be subjected to in-situ carbon coating, and the electrical property of the battery is improved. The invention also provides the carbon-coated nanofiber material prepared by the preparation method and a battery comprising the material.

Owner:南方电网电动汽车服务有限公司

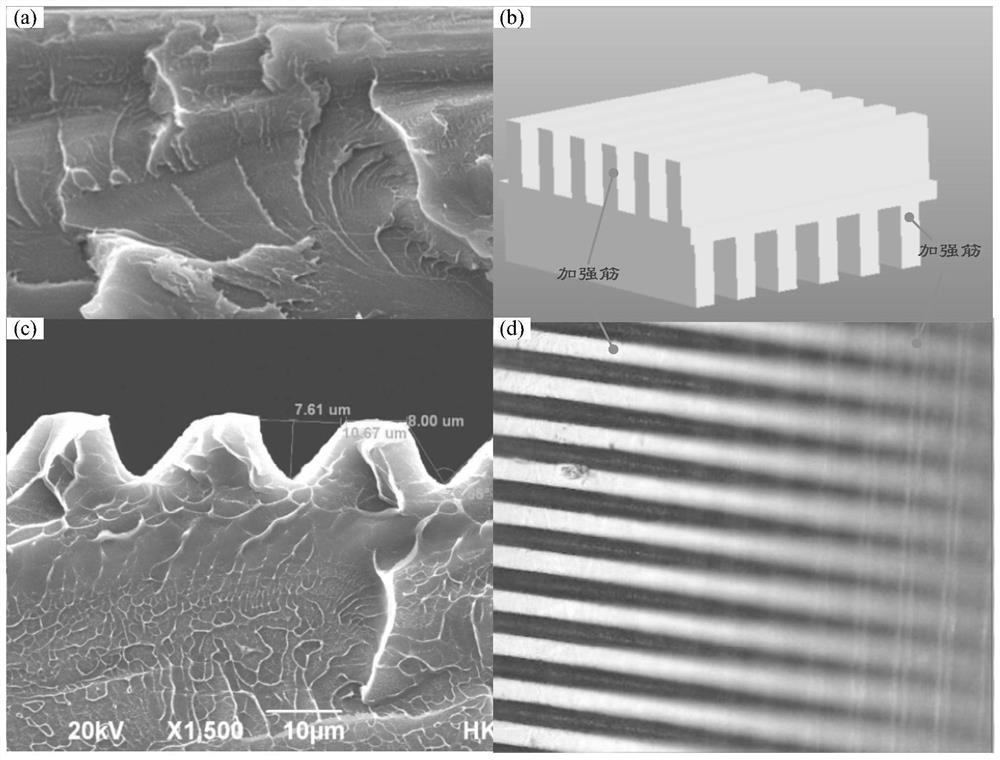

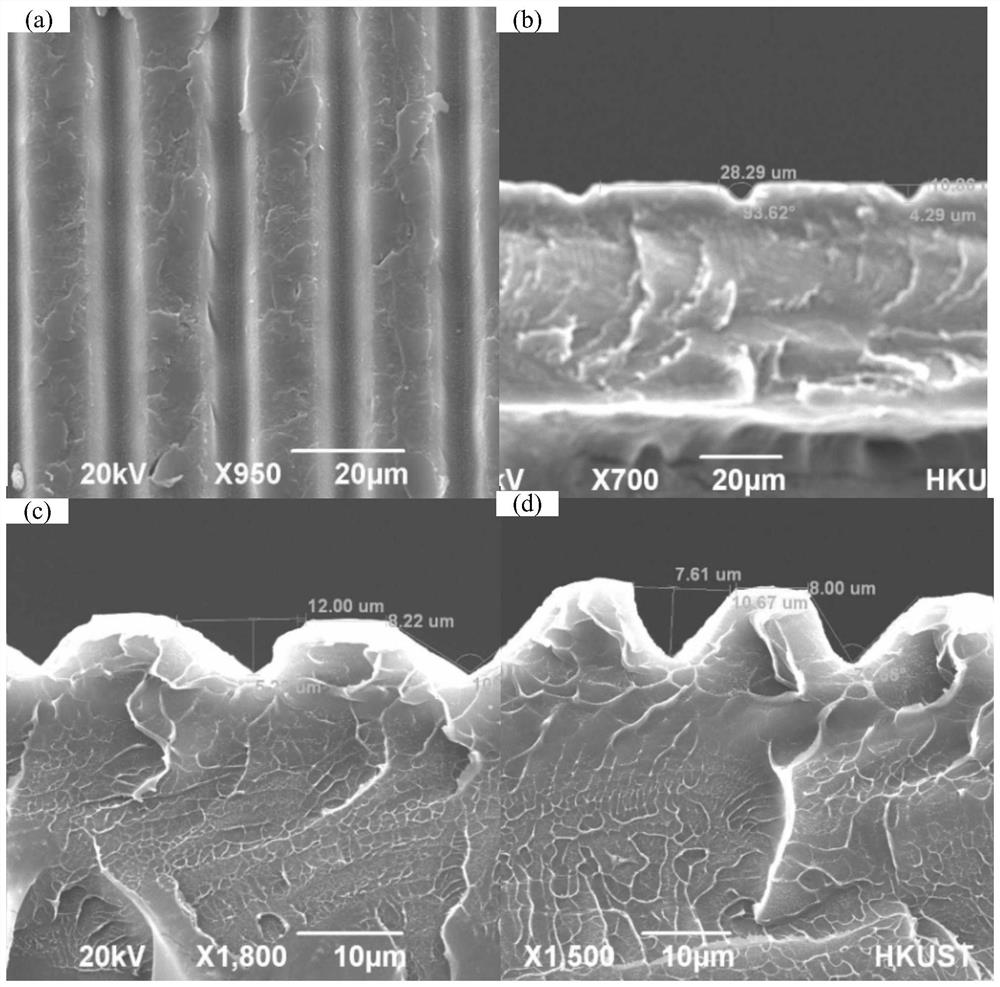

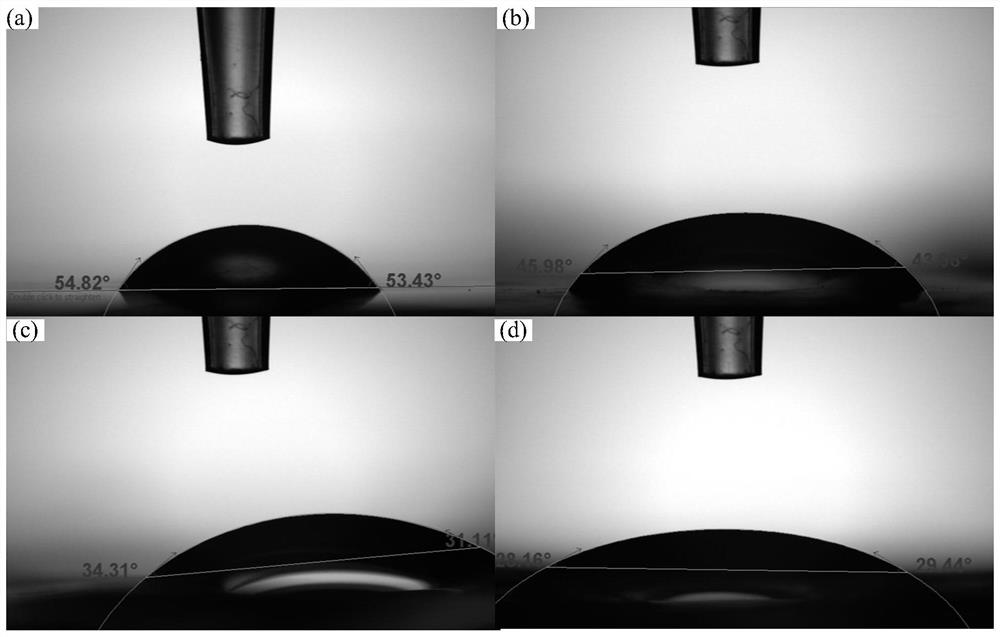

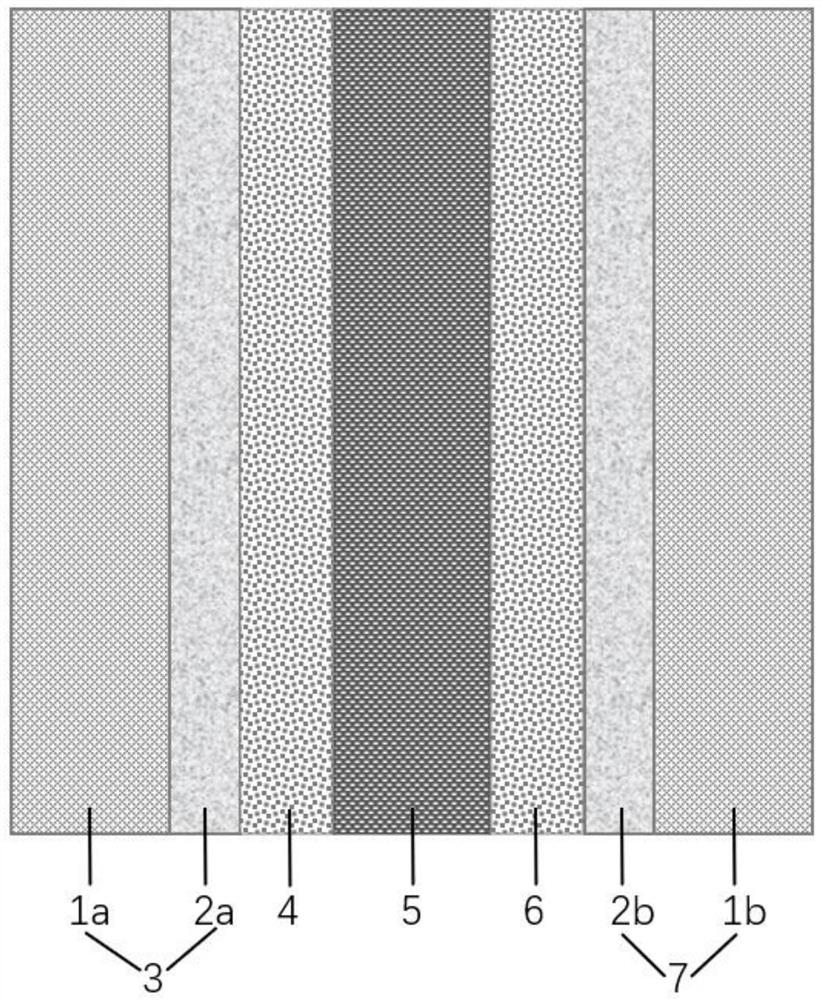

High-strength ultrathin integrated proton exchange membrane

PendingCN112054224AReduce conduction strokeLower internal resistanceRegenerative fuel cellsStationary system fuel cellsElectrical batteryInternal resistance

The invention relates to the field of electrochemical energy storage, in particular to a high-strength ultrathin integrated proton exchange membrane. Mutually perpendicular micron-sized reinforcing ribs are processed on two sides of the proton exchange membrane with excellent ion selectivity by adopting an advanced femtosecond processing or micro-nano imprinting technology, so that the reinforcingribs on the upper side and the lower side are used as supports, and the ultrathin middle layer realizes the construction of the high-strength ultrathin integrated proton exchange membrane with ion selectivity. The reinforcing ribs on the two sides of the proton exchange membrane can greatly reduce the thickness of the middle layer and ensure that the middle layer has high mechanical strength, andtherefore the internal resistance of the proton exchange membrane and the internal resistance of the whole battery can be greatly reduced on the premise that the mechanical strength and stability ofthe proton exchange membrane are ensured. According to the invention, by utilizing the characteristic of excellent ion selectivity and combining with advanced processing means which are easy for large-scale production, such as femtosecond processing or micro-nano imprinting, the preparation and batch production of the high-strength ultrathin integrated proton exchange membrane can be realized.

Owner:THE HONG KONG UNIV OF SCI & TECH

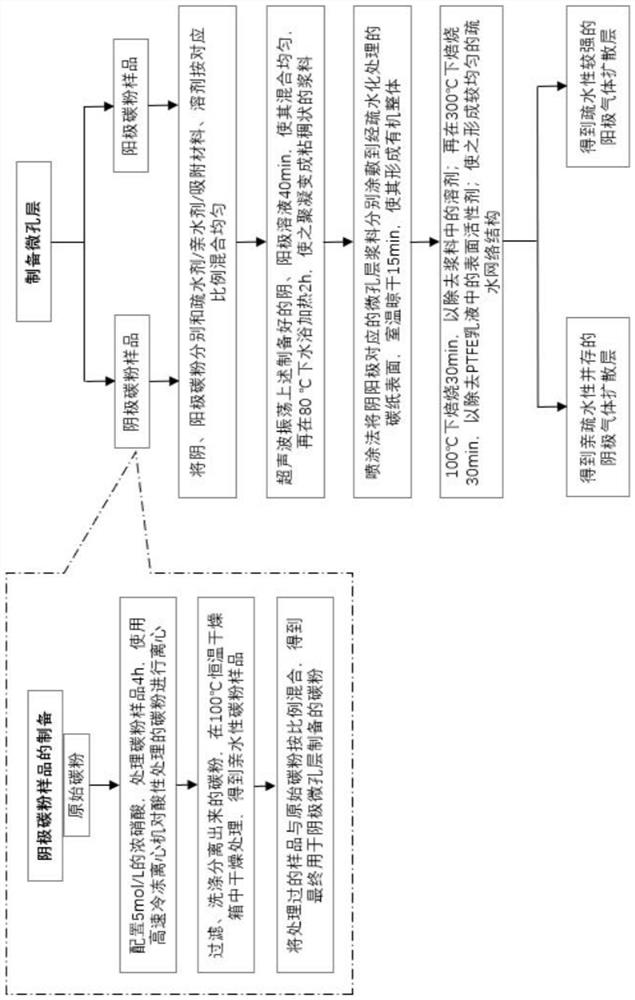

Gas diffusion layer structure of electrochemical oxygen generator membrane electrode and preparation method

PendingCN114164444AIncrease the rate of electrolysisImprove gas diffusivityElectrodesPorous substrateElectrolysis

The invention discloses a gas diffusion layer structure of an electrochemical oxygenerator membrane electrode and a preparation method, the gas diffusion layer structure comprises a cathode gas diffusion layer and an anode gas diffusion layer, the cathode gas diffusion layer comprises a cathode conductive porous substrate layer and a cathode microporous layer arranged at the inner side of the cathode conductive porous substrate layer; the anode gas diffusion layer comprises an anode conductive porous substrate layer and an anode microporous layer arranged on the inner side of the anode conductive porous substrate layer, the anode microporous layer comprises carbon particles and a binder, and the cathode microporous layer comprises carbon particles, a binder, a water absorbent and an adsorption material. Compared with the prior art, the electrochemical oxygen generator has the advantages that the conductivity is good, the hydrophilic and hydrophobic properties of the cathode gas diffusion layer and the anode gas diffusion layer are different, the gas diffusion performance and the water management performance of the electrochemical oxygen generator are improved, the water-gas distribution performance of the cathode gas diffusion layer and the anode gas diffusion layer is optimized, the electrolysis rate of the anode side water is further improved, and the electrochemical oxygen generator is more stable. And oxygen can be stably produced under the condition of low humidity.

Owner:江西德合医疗器械有限公司

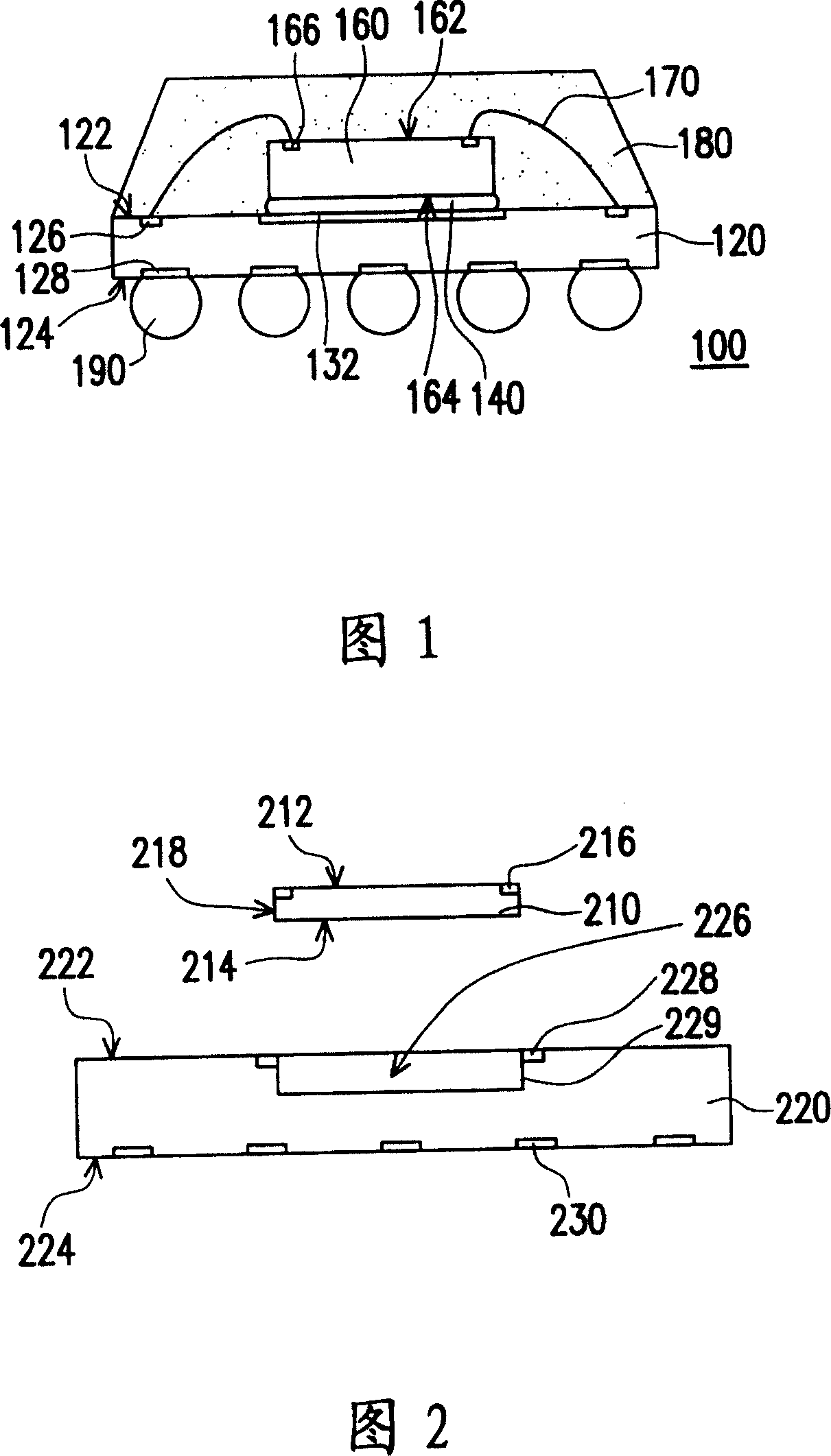

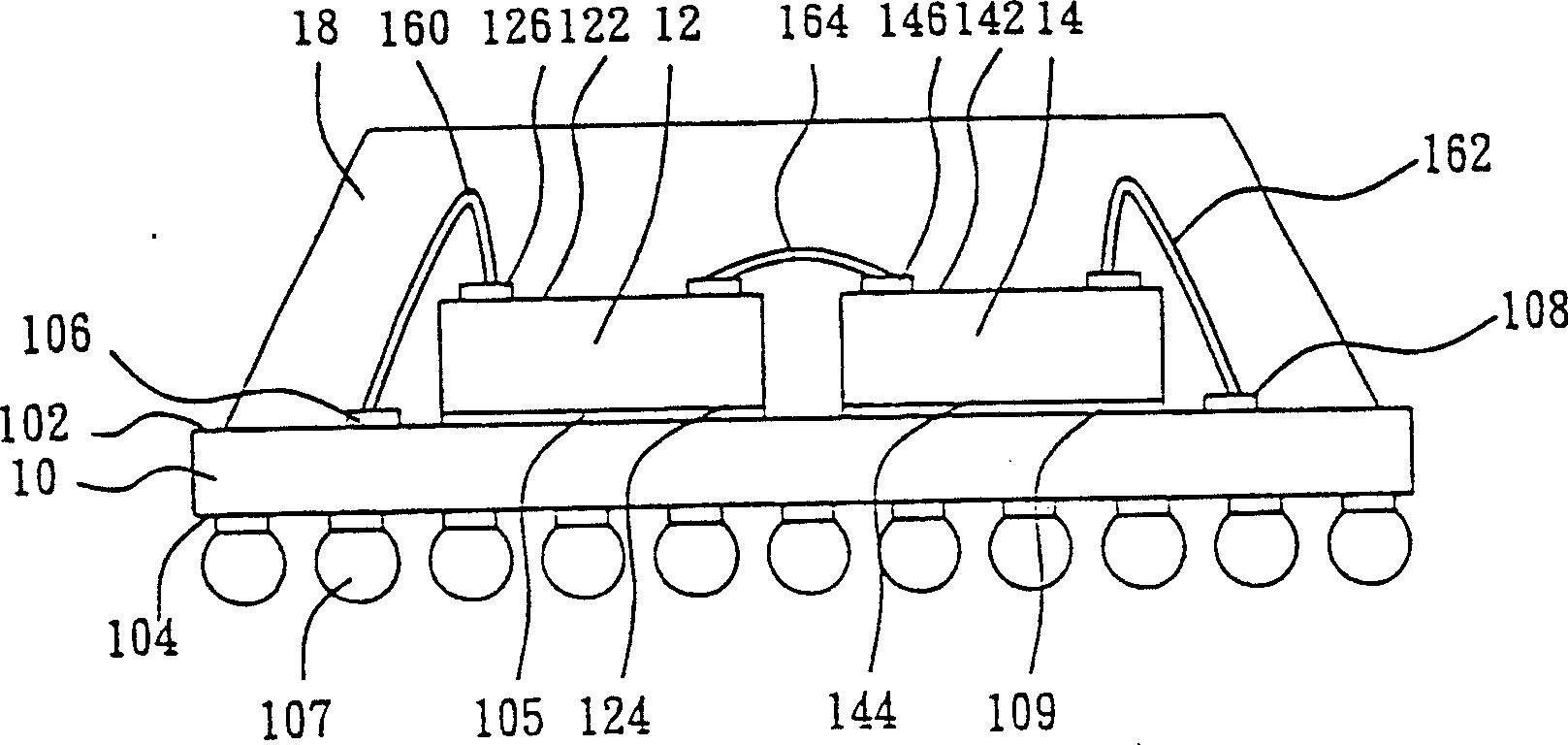

Bridging chip package structure

ActiveCN100364076CSmall attenuationReduce parasitic effectsSemiconductor/solid-state device detailsSolid-state devicesEngineeringBridge type

The invention relates to a seal structure of chip of bridging-typed and its manufacture method, at last including a substrate, a chip and at least a conductor; the substrate has a first surface and its corresponding second surface, a depressed section and at least a contact of substrate, whose contact is on the first surface of substrate. The chip has a active surface and at least a contact of substrate which is on the active surface of chip. The chip is in the depressed section of substrate, whose at least one sidewall is near the depressed section, the active surface of chip and the first plane of substrate are installed for the public plane. Conductor is extending on the active surface of chip and the first plane on substrate, linking the contact of chip to that of substrate. The invention can shorten the distance between chip and substrate, increasing the electrical property efficiency of chip structure, which is more suitable for practical use and has use value in industry.

Owner:ADVANCED SEMICON ENG INC

A block anion exchange membrane and its preparation method

InactiveCN105906812BHigh conductivity free volume increaseIncreased free volumeFuel cellsPolymer scienceChemical stability

The invention discloses a novel block anion exchange membrane. A block main chain of the anion exchange membrane contains a bending unit (biphenyl fluorene) and a twisting unit (phthalazinone); according to the structure, a non-coplanar effect can be enhanced. A preparation method of the anion exchange membrane comprises the following steps of performing polycondensation on decafluorobiphenyl (slightly excessive) and bisphenol fluorine to prepare an oligomer 1; using the decafluorobiphenyl and 4-(4-hydroxyphenyl)-2,3-phthalazine-1-one to prepare an oligomer 2; polymerizing the oligomer 1 with the oligomer 2 to obtain a polymer main chain, and performing ionization treatment, membrane casting and alkali treatment on a chloromethylation main chain to obtain the anion exchange membrane. The anion exchange membrane has better chemical stability, and higher electric conductivity and resistance to swelling, and is suitable for being applied in the aspect of alkaline fuel cells.

Owner:DALIAN UNIV OF TECH

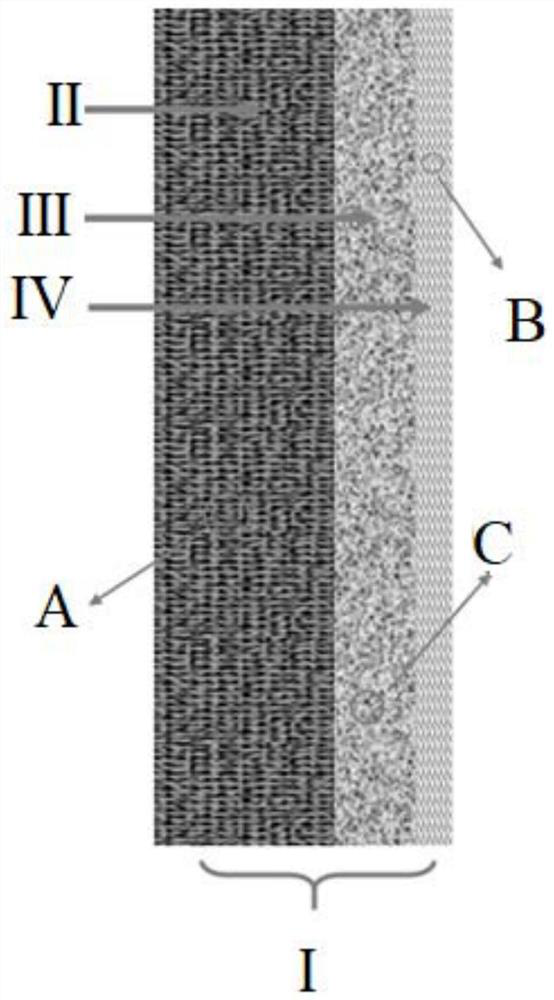

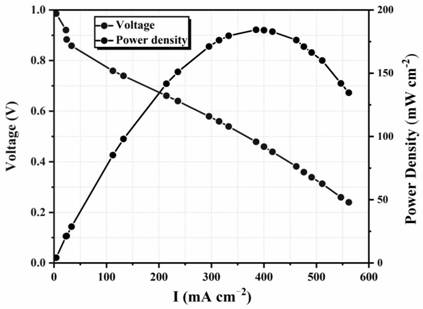

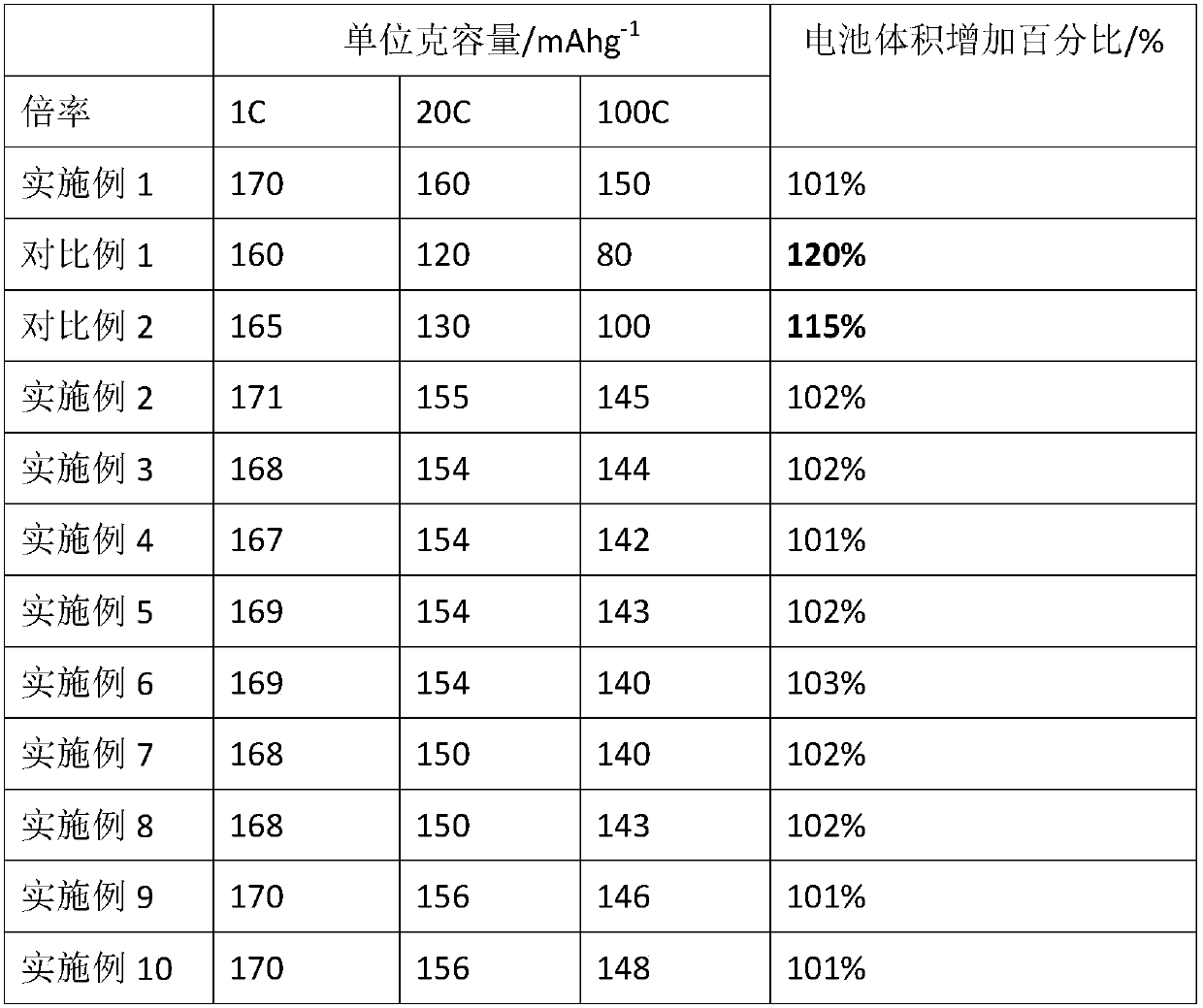

A kind of preparation method of membrane electrode and fuel cell

ActiveCN108011109BEasy to prepareReliable preparation methodCell electrodesFuel cellsPtru catalystFuel cells

The invention provides a preparation method of a membrane electrode, comprising: coating the catalyst slurry on both surfaces of an anion exchange membrane and performing cross-linking treatment to obtain a basic film-coated electrode; placing the basic film-coated electrode in the cathode and anode gas diffusion Hot pressing is performed between the layers to obtain a membrane electrode; the catalyst slurry contains an anion exchange resin with the same components as the anion exchange membrane, and the anion exchange resin has a group capable of crosslinking. The preparation method of the membrane electrode provided by the invention has the same composition as that of the anion exchange resin in the catalytic layer, both of which have groups capable of crosslinking, and are formed by crosslinking the anion exchange membrane and the catalytic layer An overall cross-linked membrane-covered electrode, the membrane electrode prepared by this post-crosslinking method has high mechanical strength, and can also reduce the OH between the cathode and anode catalyst layer and the anion exchange membrane in the membrane electrode. ‑ conduction resistance.

Owner:UNIV OF SCI & TECH OF CHINA

A kind of fluorinated graphene modified lithium titanate material and its preparation and application

ActiveCN111244402BEliminate surface defectsReduce conduction resistanceCell electrodesSecondary cellsLithiumPhysical chemistry

The invention provides a fluorinated graphene modified lithium titanate material and a preparation method thereof. A fluorinated graphene-modified lithium titanate material, which is composed of fluorinated graphene and lithium titanate; the mass fraction of lithium titanate in the overall material is 55%-98%, and the better one is 62%- 97%, optimally 70%‑94%. The surface of the material contains C‑F‑Ti bonds and F‑Ti bonds; lithium titanate accounts for 55%‑98% of the overall material, carbon accounts for 1%‑25% of the overall material, and fluorine accounts for the overall The mass fraction of the material is 0.2%-20%; better: the mass fraction of lithium titanate in the overall material is 62%-97%, the mass fraction of carbon element in the overall material is 2%-20%, and the fluorine element accounts for the overall material The mass fraction of lithium titanate is 0.5%-18%; optimal: lithium titanate accounts for 70%-94% of the overall material, carbon accounts for 5%-18% of the overall material, and fluorine accounts for 70%-94% of the overall material. The mass fraction is 0.8%‑15%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

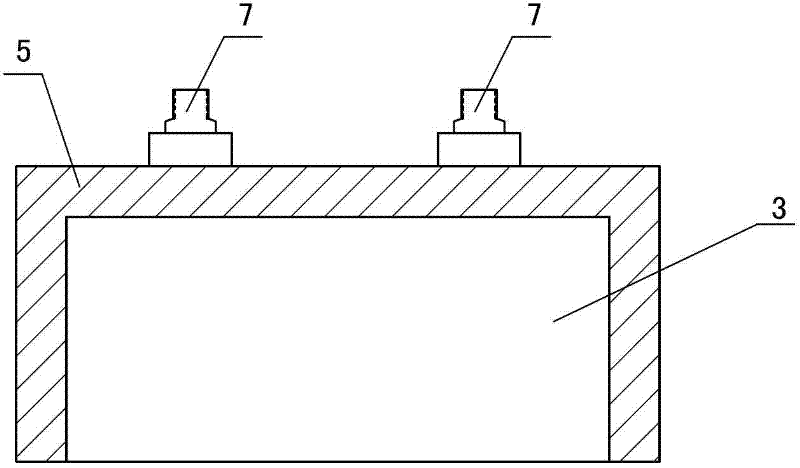

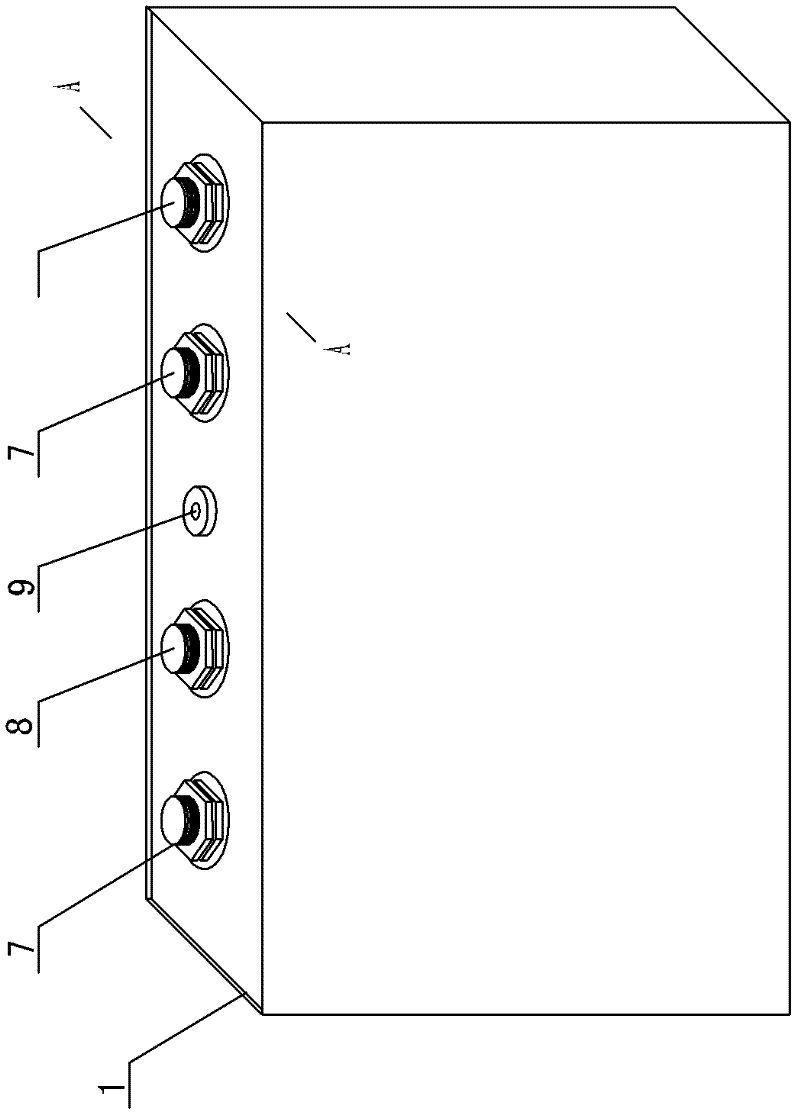

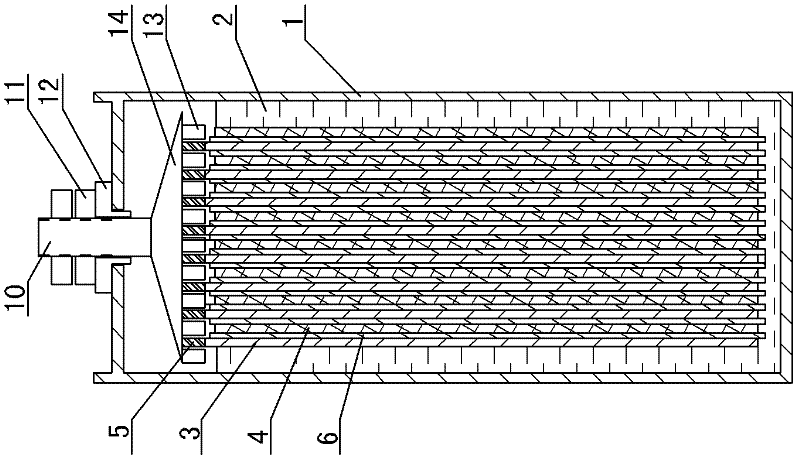

Large-capacity nickel-hydrogen square battery with low internal resistance

InactiveCN102694209AExtend your lifeReduce distanceAlkaline accumulatorsAlkaline accumulator electrodesChemical reactionHydrogen

The invention provides a large-capacity nickel-hydrogen square battery with low internal resistance. The large-capacity nickel-hydrogen square battery comprises a shell containing electrolyte, and a plurality of positive plates and a plurality of negative plates which are soaked in the electrolyte, wherein the peripheral edges of each positive plate and negative plate are respectively provided with a flow guiding body; the positive plates and the negative plates are arranged at intervals; and the adjacent electrode plates are separated by an insulated diaphragm; the flow guiding body on the positive plate is connected with a positive post assembly; and the flow guiding body on the negative plate is connected with a negative post assembly; the large-capacity nickel-hydrogen square battery with low internal resistance is characterized in that each positive plate is less than 0.4 mm thick, each negative plate is less than 0.25mm thick, and the positive post assembly is as thick as the negative post assembly; the long sides of each positive plate and each negative plate are respectively provided with the flow guiding body, or the length of the flow guiding body is not smaller than one half of the perimeter of each positive plate or each negative plate. The large-capacity nickel-hydrogen square battery with low internal resistance has small charge diffusion resistance in a charging process, reduces the voltage, and is not easy to generate gassing; moreover, the thickness of the electrode plate is reduced to lead deep active substance timely participate in a chemical reaction, so that the internal resistance of the battery is reduced.

Owner:SHANDONG UNIV OF TECH

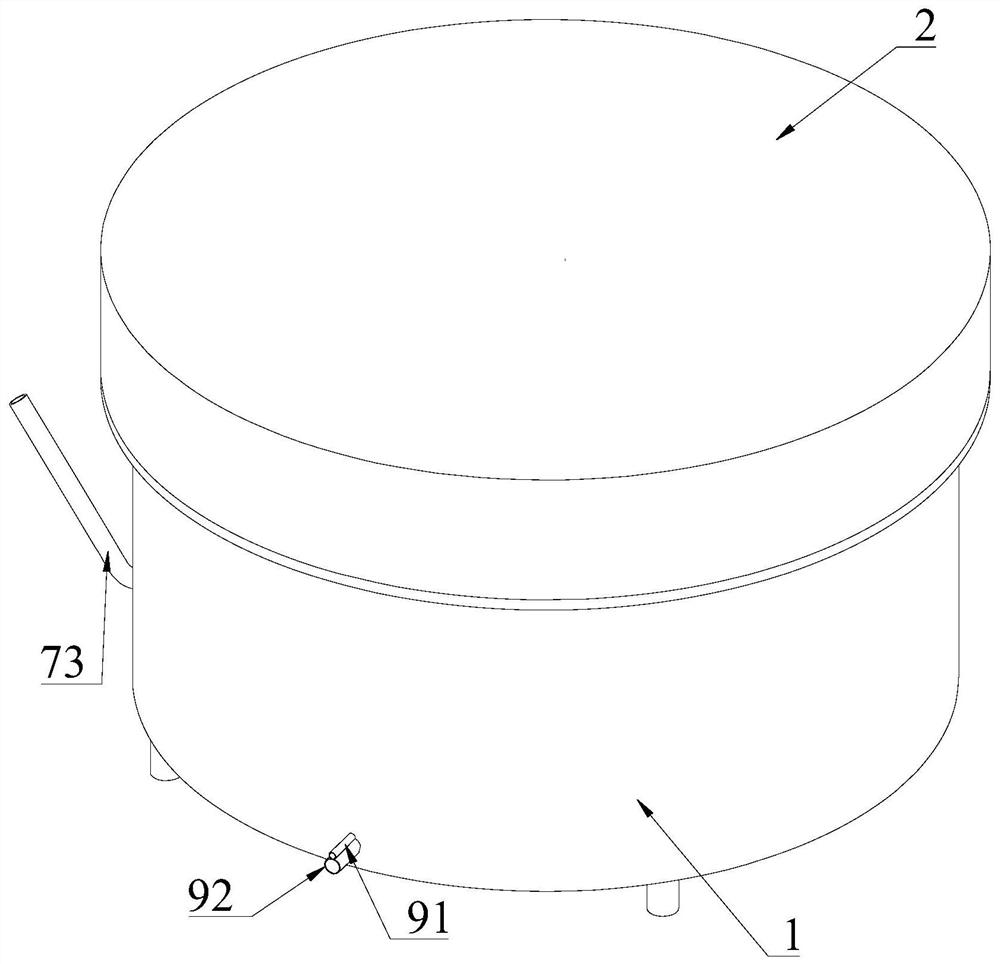

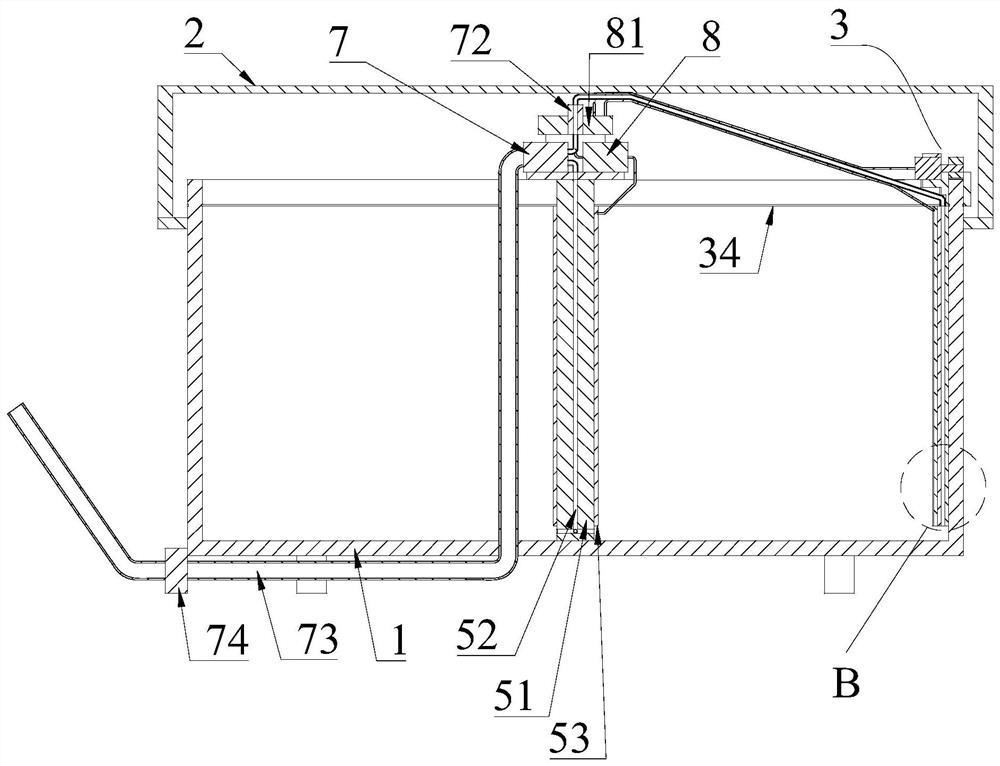

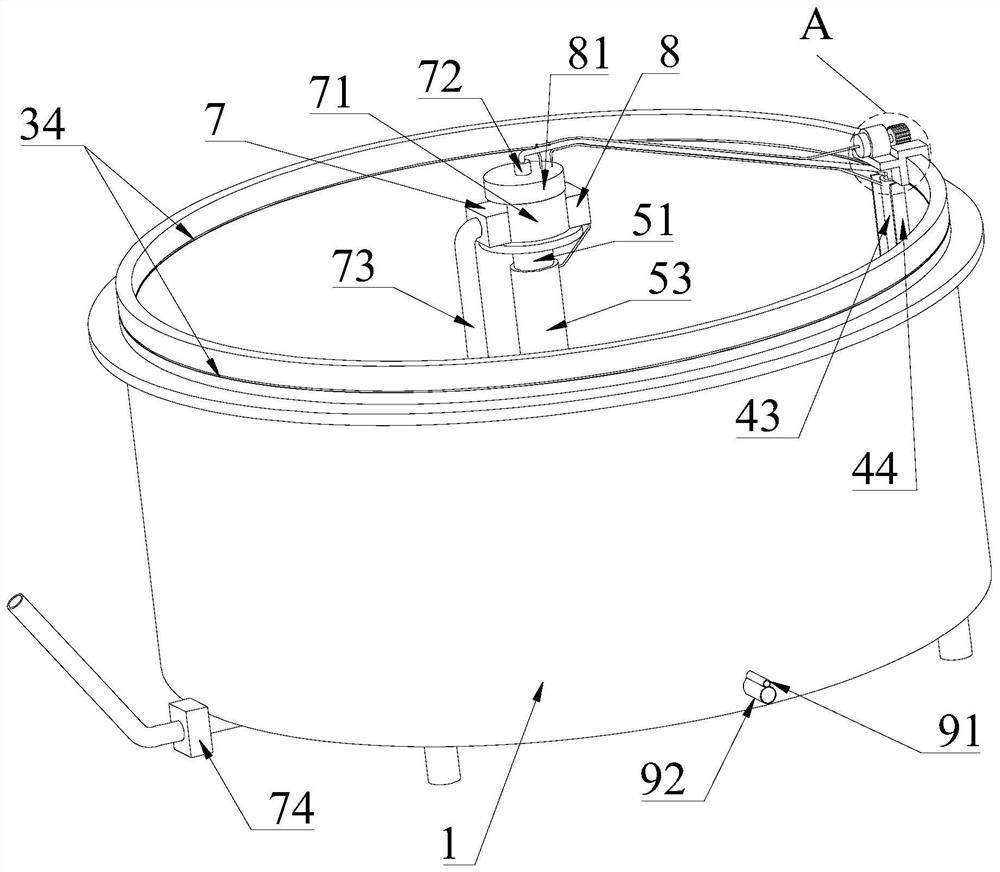

Microalgae population culture device and microalgae culture method

ActiveCN113136315AEvenly distributedInhibition of reproductive growthBioreactor/fermenter combinationsBiological substance pretreatmentsWater flowEnvironmental engineering

The present invention relates to the field of microalgae culture, and discloses a microalgae population culture device and a microalgae culture method. The microalgae population culture device comprises: a cylinder body of a cylindrical hollow structure with an opening at the top end; a cylinder cover; a driving structure; a combined rod which comprises a rod body, a first inflation channel and a first light bar; a central column which comprises a column body, a second inflation channel and a second light bar; a compression fan which is arranged on the column body and communicates with the first inflation channel and the second inflation channel; a power source which is arranged on the column body and electrically connected with the driving structure, the first light bar and the second light bar. Through the arrangement of the technical scheme, the light distribution is uniform; the aeration range is wide and uniform, and the vortex-shaped water flow state and floating bubbles can prevent microalgae cells from settling and reduce wall attachment and bottom sinking in cooperation with the stirring effect; other foreign microalgae or organisms are prevented from entering the culture system, and the structure is compact and cleaning is convenient.

Owner:QUZHOU UNIV

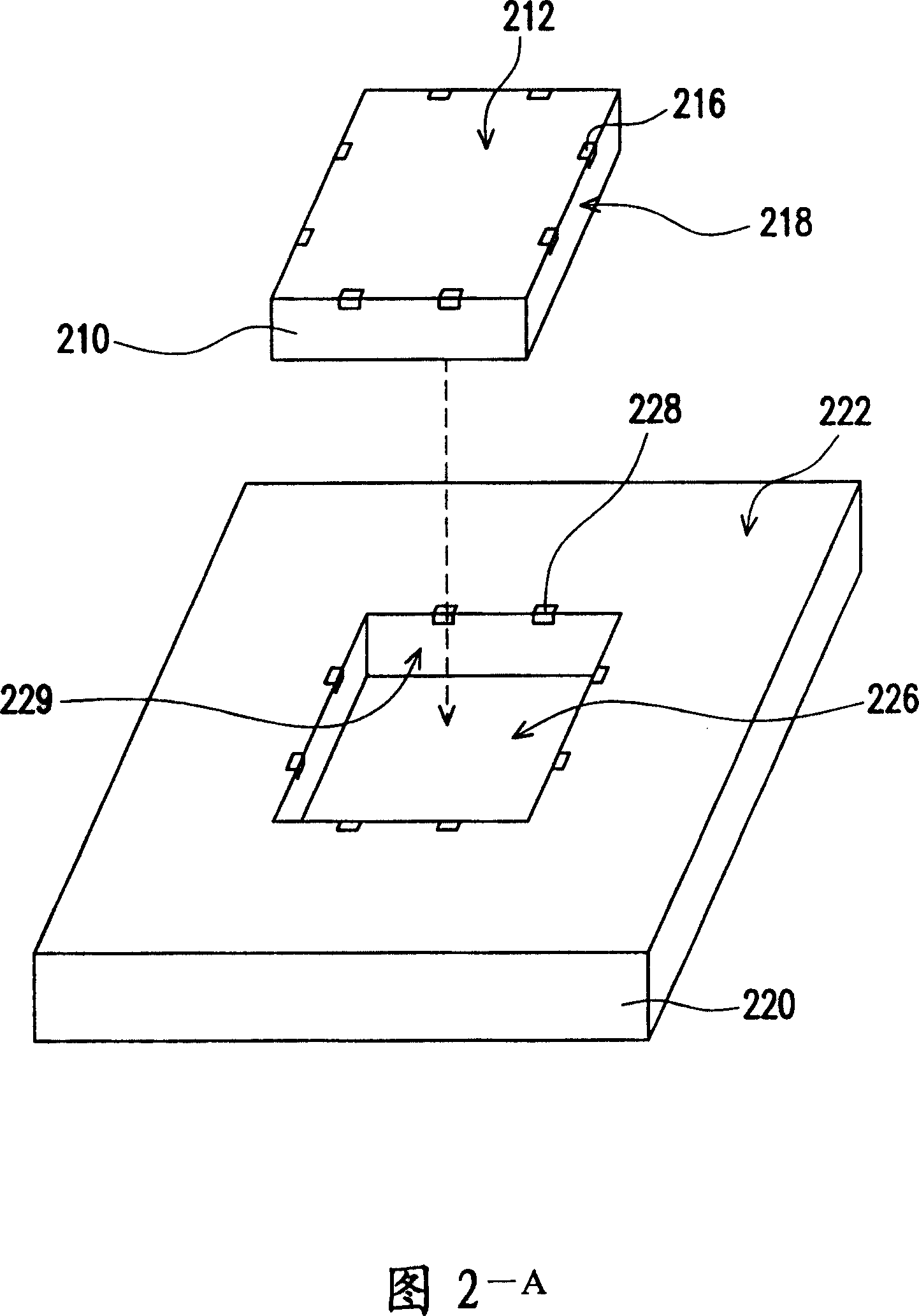

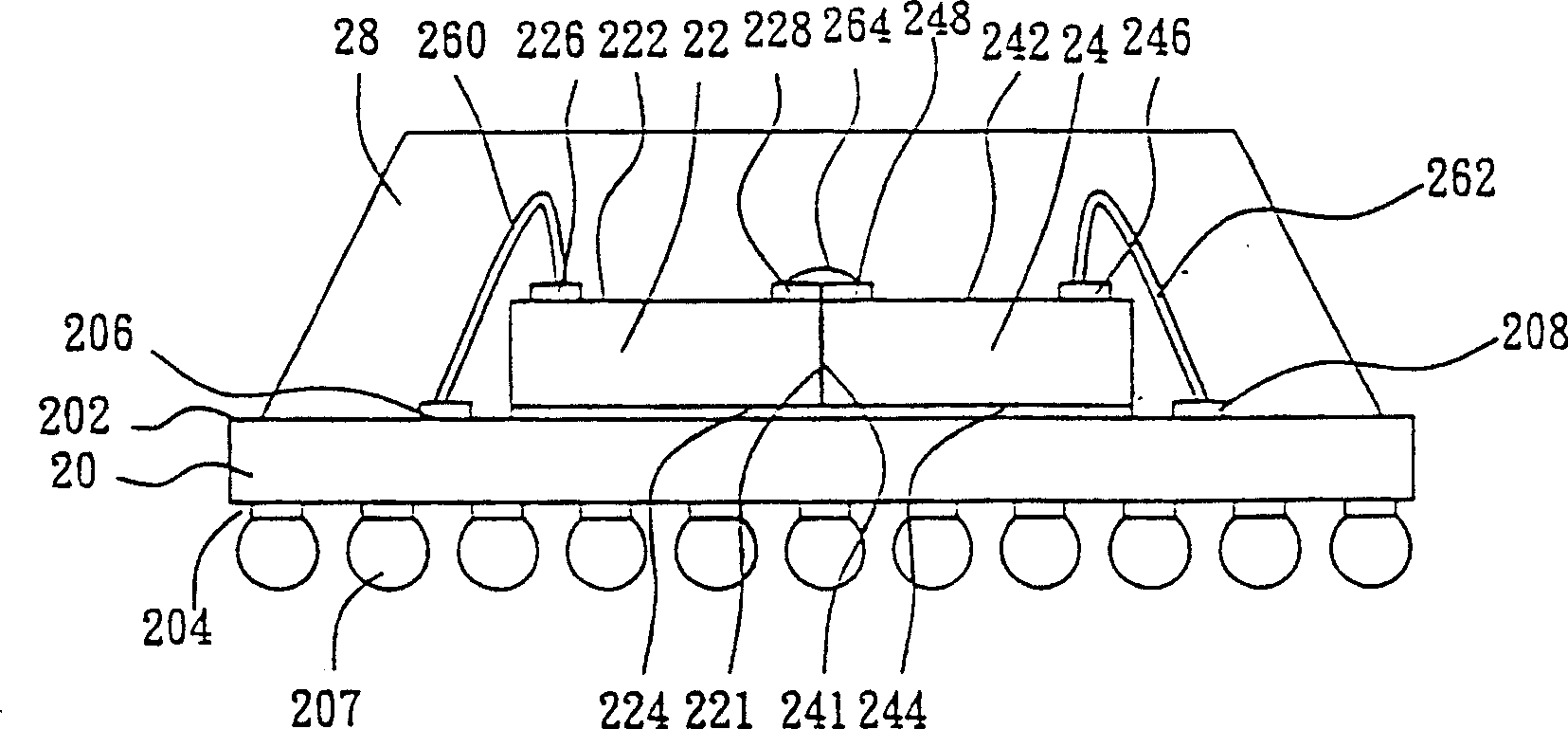

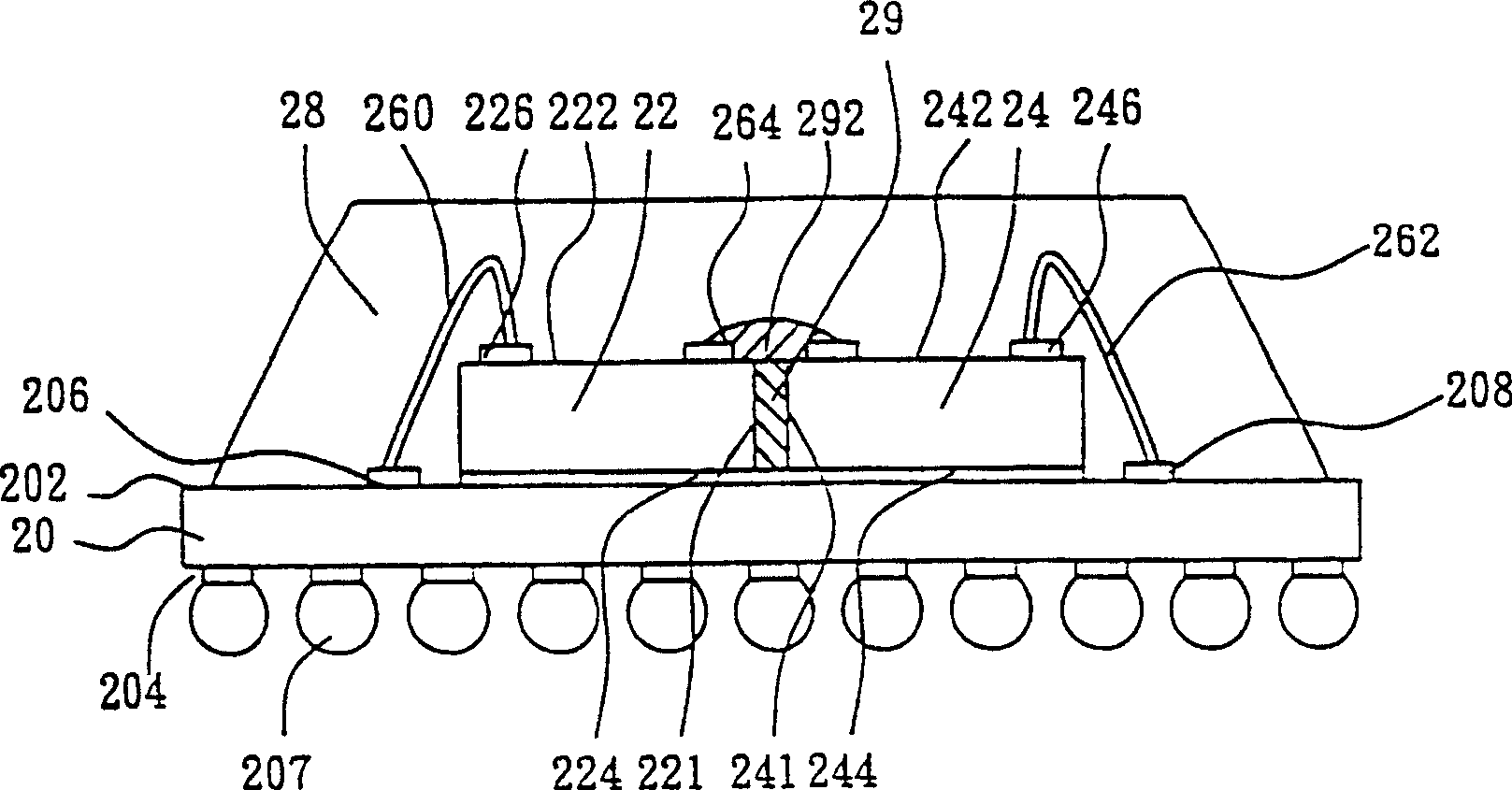

Bridging multi-chip packaging structure

InactiveCN100474581CSmall attenuationAvoid Impedance MismatchesSemiconductor/solid-state device detailsSolid-state devicesEngineeringActive surface

The present invention relates to a bridged type multi-chip package structure. It mainly includes a carrier plate, a first chip, a second chip and at least a conductive body. Said carrier plate has an upper surface and correspondent lower surface, several carrier plate contacts are positioned on upper surface of said carrier plate. The first chip has a first active surface, said first chip also has at least a first contact which is placed on first active surface of said first chip. Similarly, the second chip has a second active surface, said second active surface also has at least a second contact. Which is placed on second active surface of said second chip. The first side wall of first chip is adjacent to second side wall of second chip, and the first active surface of first chip and second active surface of second chip are placed on a common plane. The conductive body is extended on first active surface of first chip and second active surface of second chip so as to make first contact of first chip and second contact of second chip be electrically connected.

Owner:ADVANCED SEMICON ENG INC

A kind of preparation method of lipophilic sulfur electrode

ActiveCN104716297BImprove lipophilicityImprove discharge capacityPositive electrodesNon-aqueous electrolyte accumulator electrodesSilicon oxygenLithium–sulfur battery

The invention relates to a preparation method of an lipophilic sulfur electrode. Silicone oil is permeated into the inside of a positive electrode porous electrode, and a porous lipophilic sulfur electrode is prepared after drying. The mass content of silicone oil in the lipophilic sulfur electrode is 0.2-30%; The lipophilicity allows the electrolyte to infiltrate evenly into the electrode, especially in the high-load sulfur electrode to effectively realize the conduction of lithium ions, thereby ensuring the electrochemical performance of high-load elemental sulfur. Moreover, the silicon-oxygen bond contained in silicone oil can effectively bind lithium polysulfides during the discharge process, inhibiting the self-discharge phenomenon caused by polysulfide dissolution shuttling, thereby achieving the purpose of improving the coulombic efficiency and cycle stability of lithium-sulfur batteries.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Fluorinated graphene modified niobium pentoxide material as well as preparation and application thereof

ActiveCN111244403AStable structureImprove cycle performanceCell electrodesNiobium pentaoxideGraphene

The invention provides a fluorinated graphene modified niobium pentoxide material as well as a preparation method and application thereof. The fluorinated graphene modified niobium pentoxide materialis formed by compounding fluorinated graphene and niobium pentoxide, wherein niobium pentoxide accounts for 55%-98% of the mass fraction of the whole material, preferably 62%-97%, and the best 70%-94%; C-F-Nb bonds and F-Nb bonds are contained on the surface of the material, niobium pentoxide accounts for 55%-98% of the mass fraction of the whole material, the carbon element accounts for 1%-25% ofthe mass fraction of the whole material, and the fluorine element accounts for 0.2%-20% of the mass fraction of the whole material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of fluorinated graphene modified niobium pentoxide material and its preparation and application

ActiveCN111244403BStable structureImprove cycle performanceCell electrodesPhysical chemistryGraphite

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

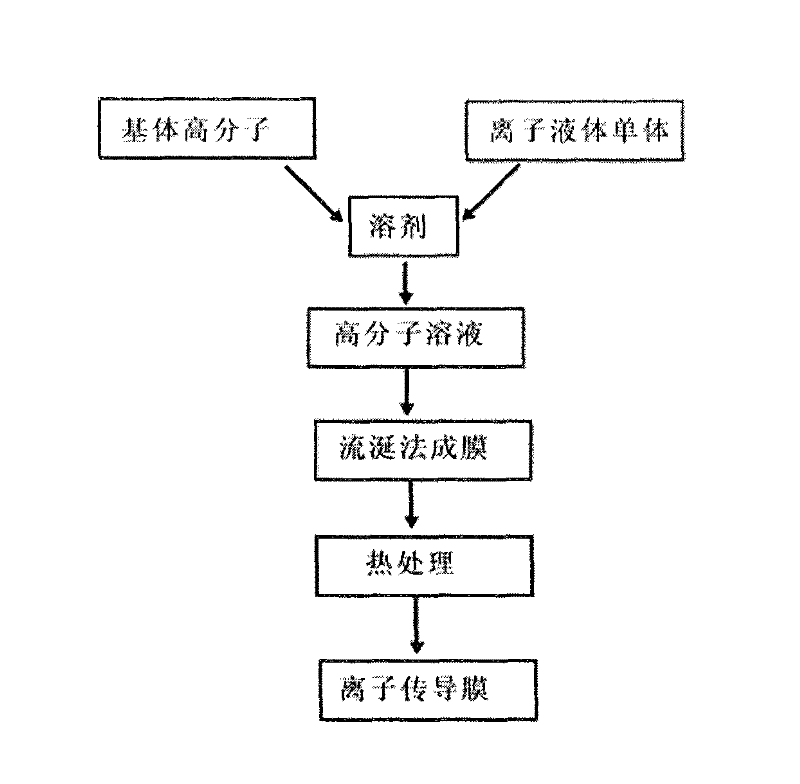

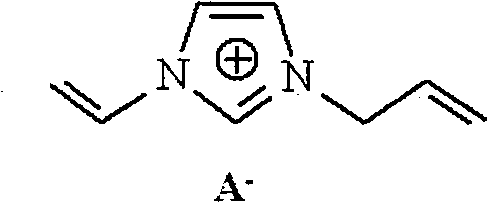

Method for preparing interpenetrating network type conducting film of polyion liquid

InactiveCN101613481BImprove conductivityStrong resistance to electrochemical corrosionDouble bondSolvent

The invention provides a method for preparing an interpenetrating network type conducting film of polyion liquid, belonging to the technical field of production of a high polymer conducting film. The method is characterized in that a polyvinylidene fluoride with stable chemical property as a substrate material is dissolved in strongly polar solvent with an ion liquid monomeric compound containingcarbon-carbon double bonds, such as 1-allyl-3-vinyl imidazole chloride, so as to prepare uniform solution after mixing; a film is prepared by a salivation method; and after heat treatment, the film triggers a monomer to perform a polymerization reaction, and forms the ion conducting film of the interpenetrating network with substrate high molecules. The conducting film can play a role of ionic conduction in electrodialysis, diffusion dialysis and electrochemical sensors. The conducting film material has simple preparation process, avoids using sulfonating agent and other strong oxidation substances in the preparing process, is advantageous to environmental protection, and simultaneously solves the problem that a homogeneous ionic conducting film cannot be obtained by the fusion method of ionic exchange resin.

Owner:TSINGHUA UNIV

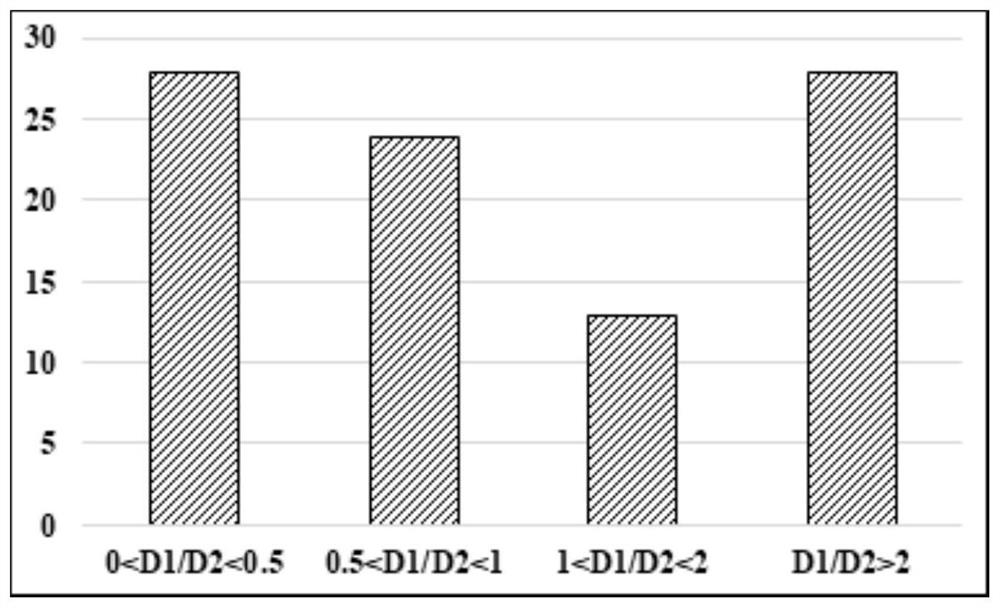

Pole piece and battery

PendingCN114447272AIncrease surface areaIncrease the area of electrical circulationElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesElectrolytic agentThermodynamics

The invention provides a pole piece which comprises a current collector, a first coating and second coatings, the surface of the current collector is coated with the first coating, and the surface, away from the current collector, of the first coating is coated with the at least two second coatings at intervals. According to the embodiment of the invention, the surface, far away from the current collector, of the first coating is coated with the at least two second coatings, so that the contact surface area of the pole pieces and electrolyte and the electric circulation area between the pole pieces can be increased, the combination direction between lithium ions and electrons is increased, the conduction impedance of the battery is reduced, lithium precipitation of the battery is inhibited, and the service life of the battery is prolonged. And the service life of the battery is prolonged.

Owner:ZHUHAI COSMX BATTERY CO LTD

Fluorinated graphene modified lithium titanate material and preparation and application

ActiveCN111244402AElimination of Lithium Titanate Surface DefectsReduce electron conduction resistanceCell electrodesSecondary cellsLithiumGraphene

The invention provides a fluorinated graphene modified lithium titanate material and a preparation method thereof. The fluorinated graphene modified lithium titanate material is formed by compoundingfluorinated graphene and lithium titanate, the lithium titanate accounts for 55%-98% of the mass fraction of the whole material, preferably 62%-97%, and the best 70%-94%. The surface of the material contains a C-F-Ti bond and an F-Ti bond; the lithium titanate accounts for 55%-98% of the mass fraction of the overall material, the carbon element accounts for 1%-25% of the mass fraction of the overall material, and the fluorine element accounts for 0.2%-20% of the mass fraction of the overall material; preferably, the lithium titanate accounts for 62%-97% of the mass fraction of the overall material, the carbon element accounts for 2%-20% of the mass fraction of the overall material, and the fluorine element accounts for 0.5%-18% of the mass fraction of the overall material; for the best, the lithium titanate accounts for 70%-94% of the mass fraction of the whole material, the carbon element accounts for 5%-18% of the mass fraction of the whole material, and the fluorine element accountsfor 0.8%-15% of the mass fraction of the whole material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

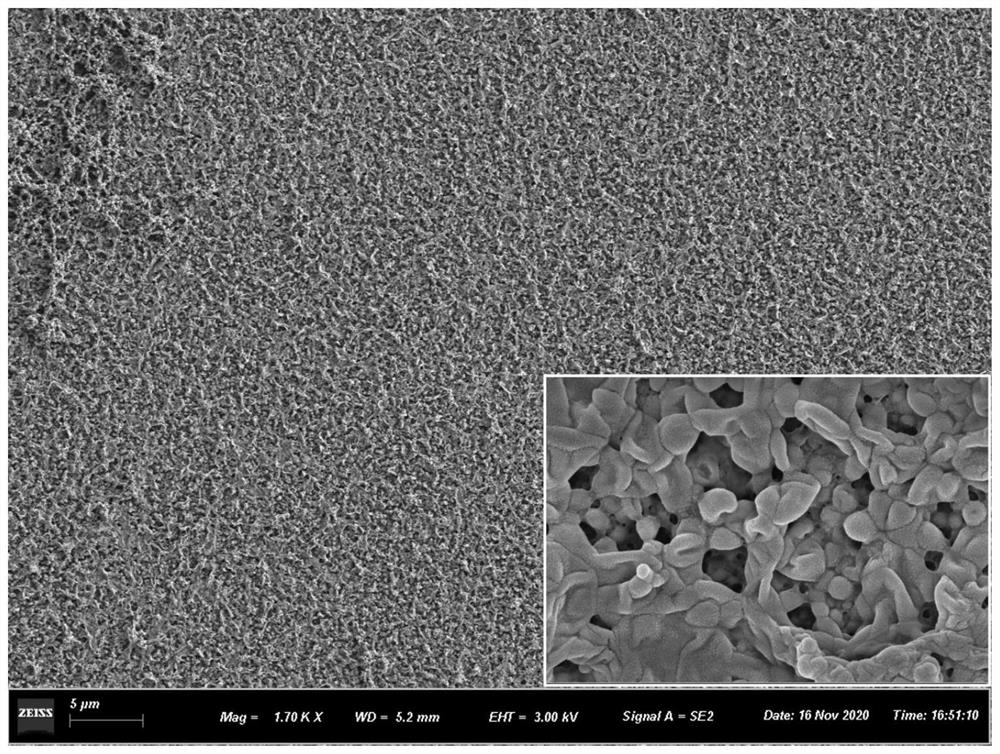

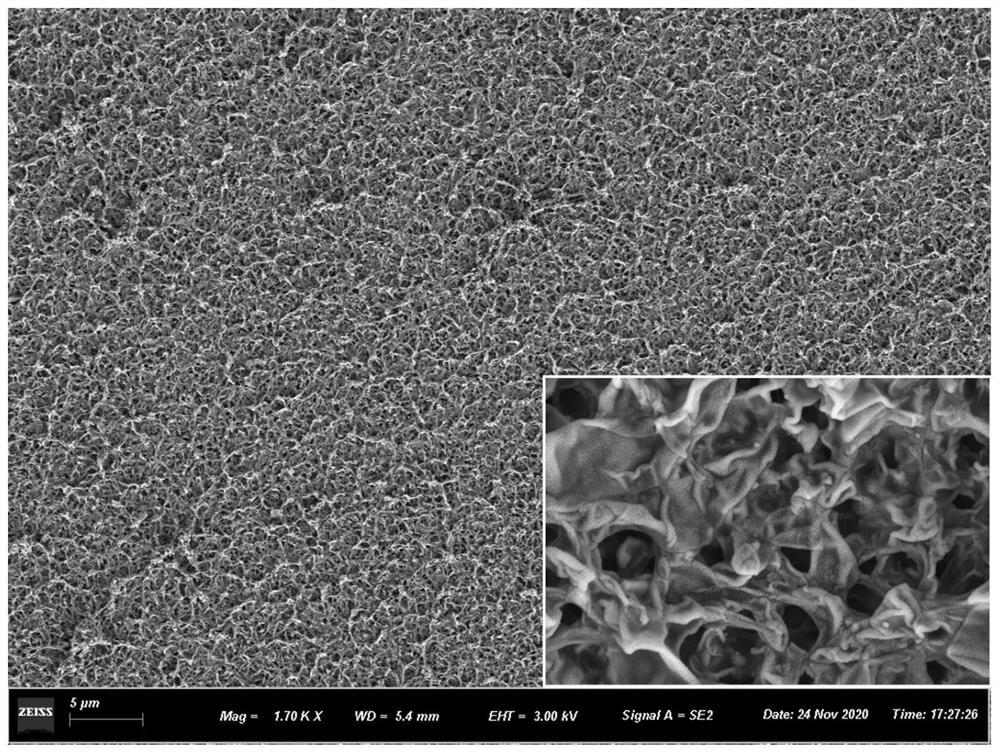

A kind of preparation method of high flux reverse osmosis membrane and obtained high flux reverse osmosis membrane

ActiveCN113289500BReasonable growth restrictionImprove throughputSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHigh fluxReverse osmosis

The invention provides a method for preparing a high-flux reverse osmosis membrane, comprising the following steps: Step 1, making a support structure; Step 2, depositing a nano-calcium carbonate layer on the support structure; Step 3, depositing a nano-calcium carbonate layer on the The interfacial polymerization reaction on the support structure forms a reverse osmosis membrane containing a polyamide functional layer. The invention improves the surface roughness of the support layer by in-situ depositing nano-calcium carbonate on the surface of the support structure, which is beneficial to the adsorption of the aqueous phase solution. The growth of the polyamide reduces the depth of the polyamide in the pores of the support structure, reduces the water conduction resistance, and improves the flux of the reverse osmosis membrane. The invention also provides a high-flux reverse osmosis membrane, the water flux of the high-flux reverse osmosis membrane is 79-123LMH, and the desalination rate is 95.74-99.39%.

Owner:湖南澳维新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com