Patents

Literature

33 results about "Tilia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tilia is a genus of about 30 species of trees or bushes, native throughout most of the temperate Northern Hemisphere. In the British Isles, they are commonly called lime trees, or lime bushes, although they are not closely related to the tree that produces the lime fruit. Other names include linden for the European species, and basswood for North American species. The genus occurs in Europe and eastern North America, but the greatest species diversity is found in Asia. Under the Cronquist classification system, this genus was placed in the family Tiliaceae, but genetic research summarised by the Angiosperm Phylogeny Group has resulted in the incorporation of this genus, and of most of the previous family, into the Malvaceae.

Accelerating germination method of seed of Tilia tomentosa

InactiveCN101433136AImprove germination rateShort reproductive cycleCultivating equipmentsSoilless cultivationTomentoseTilia tomentosa

The invention discloses a Tilia tomentose seed presprouting method. The method comprises the following steps: selecting fully mature new seeds, picking off the seed vessel mechanically firstly, carrying out quick burning and immersion treatment, then immersing the seeds in gibberellin and cytokinin, and finally carrying out presprouting through a temperature changing lamination method adopting a warm temperature before a low temperature. The method brings about a short breeding cycle and a high sprouting rate of Tilia tomentose. The ideal sprouting rate can be achieved for about 23 days. Compared with the conventional presprouting method, the presprouting method greatly shortens the time needed by the presprouting of the seeds to achieve the aim of the rapid breeding of Tilia tomentose, and solves the problem of seed resource waste caused by the low seed sprouting rate of Tilia tomentose.

Owner:BEIJING FORESTRY UNIVERSITY

Nutrient soil for factory seedling raising of rice and preparation method of nutrient soil

Nutrient soil for factory seedling raising of rice is characterized by being prepared from components in parts by weight as follows: 50 parts of garden soil, 5 parts of tilia sawdust, 10 parts of calcined loess, 2 parts of quicklime, 10 parts of trinity mixture fill, 10 parts of rice husks, 0.5 parts of potassium sorbate, 3 parts of EM strains, 2 parts of eggshells, 5 parts of sea mud, 4 parts of bran, 5 parts of urea, 0.3 parts of tea saponin, 2 parts of a bactericide, 3 parts of pig bone meal, 3 parts of carbonized straw, 1 part of purple sweet potato anthocyanin, 1.5 parts of active humic acid, 10 parts of dry pig manure and 20 parts of spring water. When the nutrient soil is applied for seedling raising, the number of branches of root systems of seedlings is large, the seedlings have much root hair and high root capacity, seedling diseases are avoided, seedlings turn green and are not recovered after transplanting and survive directly after rooting, effective tillering is started in advance, and increasing of both yield and income can be realized.

Owner:陶尔中

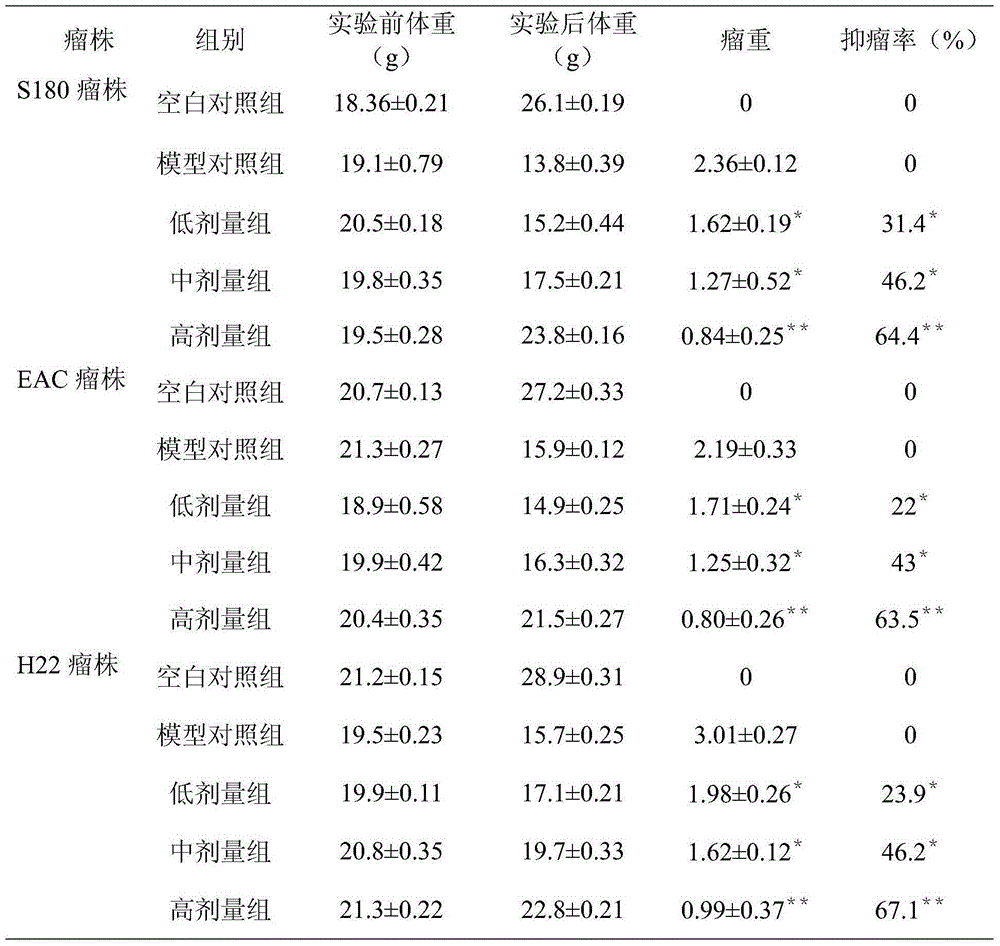

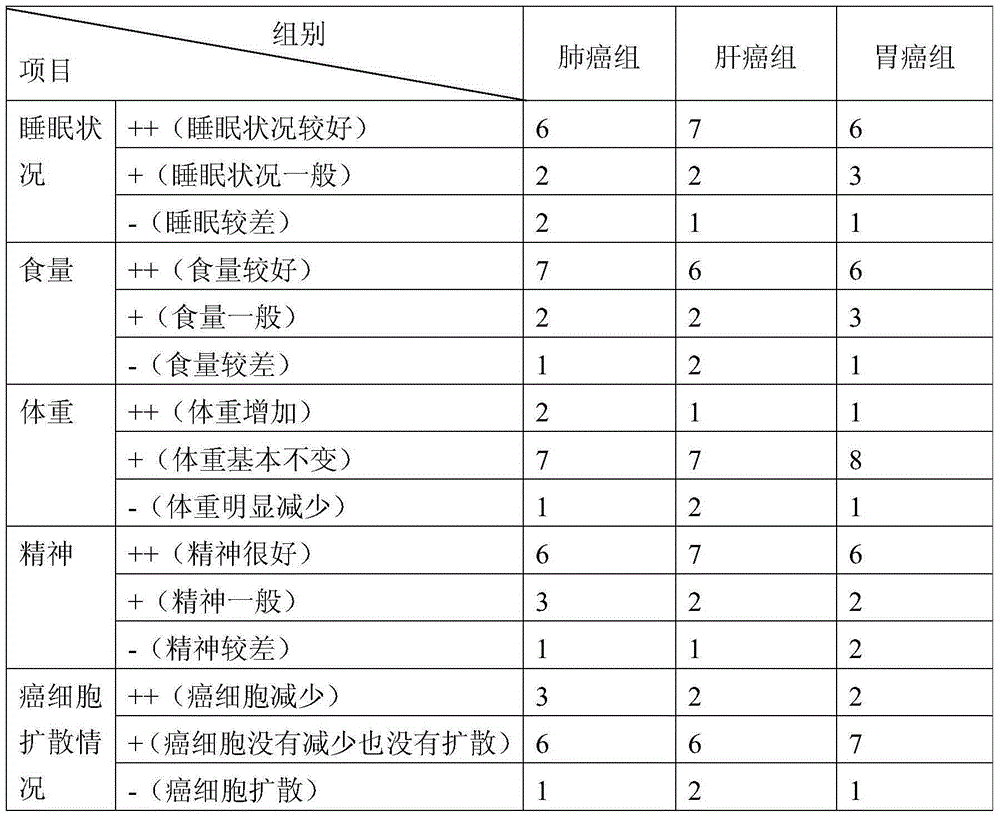

Functional food for preventing tumor and assisting in anti-tumor treatment and preparing method thereof

InactiveCN105011123AInhibit growthPromote apoptosisFood ingredient functionsFood preparationCancer preventionSide effect

The invention belongs to the technical field of health-care food production, and particularly relates to functional food for preventing tumor and assisting in anti-tumor treatment and a preparing method thereof. The functional food comprises, by weight, 50-100 parts of lentinan, 100-150 parts of polysaccharide of antler mushrooms, 50-100 parts of polysaccharide of tilia ganoderma lucidum, 100-150 parts of polysaccharide of grifola frondosa and 100-150 parts of polysaccharide of afaricus blazei murill. According to the functional food and the preparing method, the polysaccharide of the five fungi which are high in anti-tumor activity are prepared according to the scientific ratio to make the functional food, according to the prepared fungal polysaccharide functional food, the immunity is enhanced to inhibit increase of tumor cells, promote apoptosis of the tumor cells and prevent transfer of the tumor cells, and meanwhile the functional food can assist in improving the chemoradiotherapy effect and lowering the side effect brought by chemoradiotherapy and besides can prevent normal cells from conducting canceration to achieve the function of preventing the canner.

Owner:南京贝杉国际贸易有限公司

Pig raising manure deodorization preparation

InactiveCN105148307AGuaranteed freshGuaranteed living environmentBiocideDisinfectantsPagoda treePumpkin seed

The invention discloses a pig raising manure deodorization preparation. The pig raising manure deodorization preparation is characterized by comprising, by weight, 5 parts of tourmaline powder, 5 parts of glyceryl behenate, 10 parts of stearic acid, 3 parts of theophylline, 3 parts of curcumin, 3 parts of citric acid, 20 parts of lotus leaves, 10 parts of dried tangerine or orange peel, 5 parts of camphor, 10 parts of clove, 5 parts of pumpkin seeds, 5 parts of garland chrysanthemum, 10 parts of licorice, 5 parts of camellia, 5 parts of portulaca oleracea, 3 parts of coptis chinensis, 5 parts of bitter gourd, 3 parts of pagoda tree pod, 3 parts of peppermint roots, 10 parts of chili leaves, 5 parts of tilia bark and 500 parts of distilled water. The pig raising manure deodorization preparation has the advantages that effects of effectively removing smelly substances in pig raising manure can be realized by the pig raising manure deodorization preparation which is a deodorant, the pig raising manure deodorization preparation further has a sterilization function, accordingly, survival environments can be guaranteed to a certain extent while odor of the manure is removed, and the air freshness can be kept; the pig raising manure deodorization preparation is made of raw materials which are easily available, and is low in production and service costs.

Owner:郎溪县凌达养猪专业合作社

Ectomycorrhiza-enriched container seedling and cultivation method thereof

The invention discloses a container seedling rich in mycorrhiza which takes lightweight mixed materials with strong water absorption such as sterilized peat soil and biochar as a substrate, a seedlinggrowing container with the functions of air rot cutting and the like as a carrier, pure mycelia or spores of cultured ectomycorrhiza such as L.lividatus Berkeley and M.A.Curtis, russula heterophyllaFr., boletus edulis Bull.:Fr., tuber aestivum Vittad, tuber melanosporum Vittad and thelephora ganbajun Zang as an inoculant, seeds or seedlings of pinaceae plants such as pinus massoniana Lamb., pinus yunnanensis Franch and pinus elliottii Ehgelm, corylaceae plants such as corylus heterophylla Fisch .ex Trautv .var .sutchuenensis Franch. and corylus heterophyllaxavellanas, seeds or seedlings of fagaceae plants such as cyclobalanopsis gilva(Blume)Oerst, quercus acutissima Carruth., castanea mollisima, quercus aquifolioides Rehd and quercus franchetii Skan, and seeds or seedlings of tiliaceae plants such as Hunan tilia tuan Szyszyl. and craigia yunnanensis as a host plant, and is cultivated under suitable temperature, humidity and light conditions and a method for cultivating the mycorrhizacontainer seedling. Mycorrhizal seedlings cultivated by the method have the advantages of large quantity of mycorrhiza, good quality, high afforestation survival rate and rapid growth recovery, and mycorrhizal edible fungus fruiting bodies produced by the method are high in yield.

Owner:HUNAN ACAD OF FORESTRY

Medicament for treating skin eczema

InactiveCN104383087ATo achieve the purpose of expelling evil and strengthening the bodyPteridophyta/filicophyta medical ingredientsImmunological disordersBuglossoidesEczematous Disorders

The invention relates to a medicament for treating skin eczema. The medicament is prepared from the following materials in parts by weight: 500-1000 parts of sabia parviflora, 700-1200 parts of bambooleaf fig herb, 500-1000 parts of lycopodium obscurum, 500-800 parts of ranunculaceae clematis tangutica, 600-900 parts of buglossoides arvensis, 500-800 parts of arcangelisia loureiri, 600-900 parts of northern androsace umbellata, 500-1000 parts of tilia, 600-900 parts of herba chloranthi serrati, 500-800 parts of saussurea graminea, 500-800 parts of purslane speedwell herb and 500-900 parts of yellow flowered rabdosia. According to the medicament disclosed by the invention, the medicament components interact, have synergistic effects, and are combined together, so that the medicament can be used for tonifying the spleen and nourishing blood, clearing heat and removing dampness, and dispelling wind and arresting itching, and the purposes of treating both symptoms and root causes and eliminating pathogen and supporting vital qi can be achieved.

Owner:魏磊

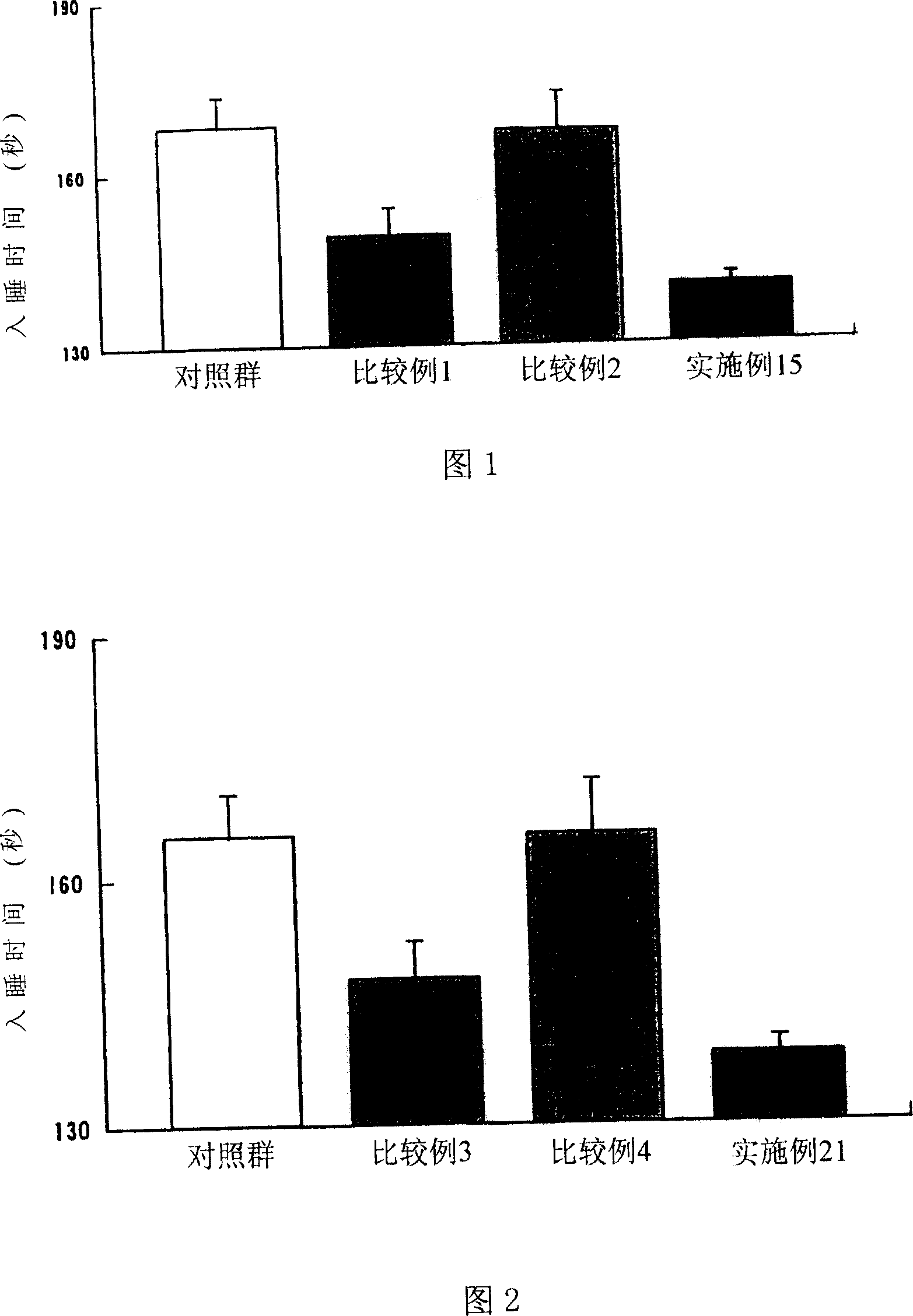

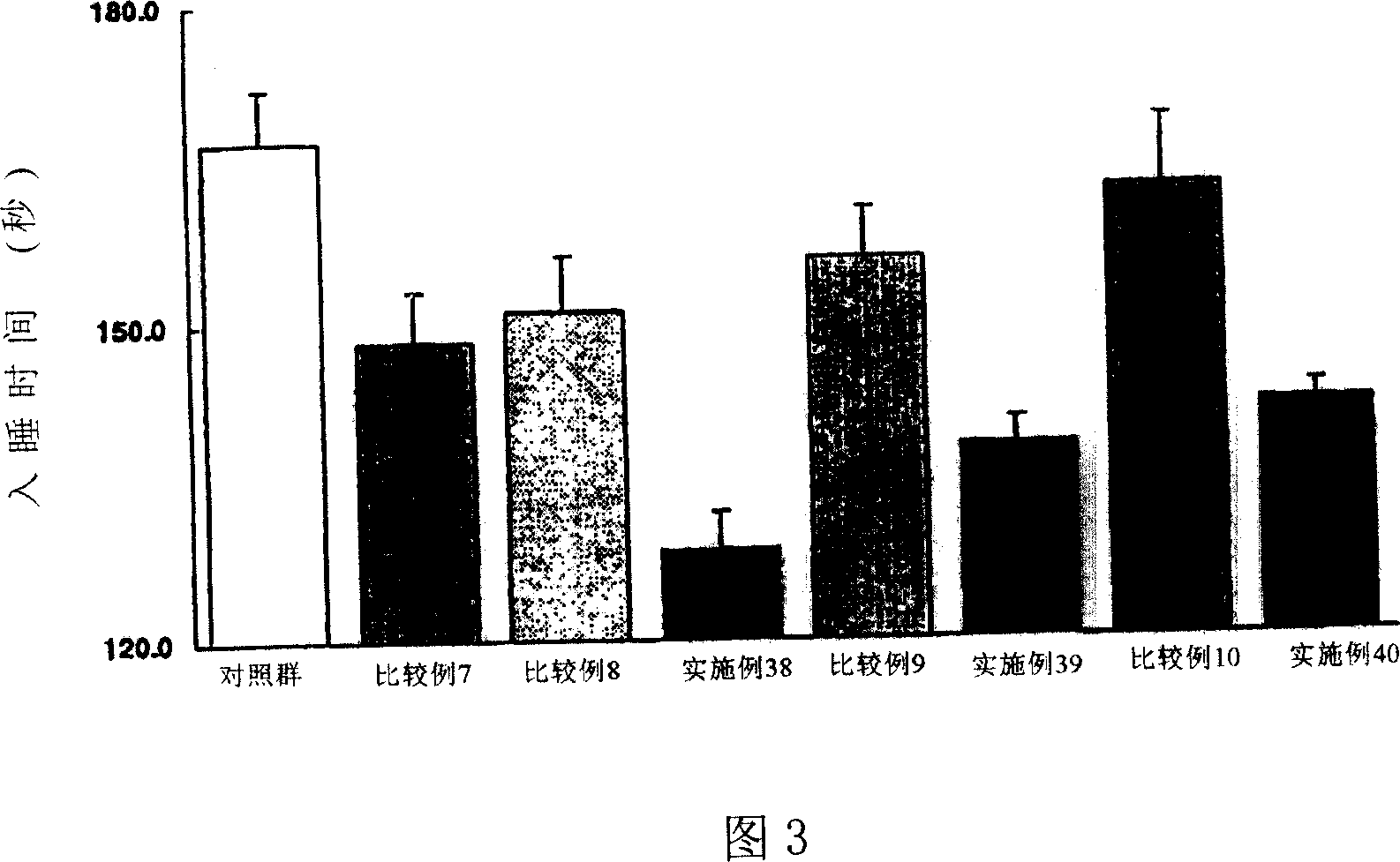

Medicine composition for improving sleep

InactiveCN1935227AImprove sleepingNo side effectsNervous disorderPlant ingredientsPiper methysticumRhizome

The present invention provides a medicine composition for improving sleep. Said medicine composition includes the following several portions: antihistamine; one or two kinds of Chinese medicinal materials selected from uncariae uncis cum ramulus, humulus lupulus, ginseng radix, avena sativa, viscum album, glycyrrhizae radix, poria, cnidii rhizome, anemarrhenae rhizome, arisaematis tuber, moutan cortex, potentilla anserine, camomile, piper methysticum and tilia spp.; perfume component; compound selected from vitamin and / or mineral substance; and any one component selected from melatonin compounds.

Owner:SS PHARMA CO LTD

Dry extrusion wall-breaking method for pollen

A dry extrusion wall-breaking method for pollen comprises the following steps of: (1) soaking pollen in pure water for 30 minutes and filtering the pollen to remove dust and impurities; (2) adding the pollen obtained in step (1) into a food screw extruder to extrude the pollen at a cavity temperature of between 40 and 65 DEG C, a pressure of between 2 and 12 MPa, a rotation speed of 14 to 60 R / min and a stroke of 80 to 150 centimeters, and injecting out the pollen at a high speed from a die opening with a 2 to 6 millimeter diameter for wall breaking; and (3) drying the pollen for 1 to 2 hours under reduced pressure and filling the pollen in bags for package to obtain the product. The pollen can be pure pollen or a mixture of any several kinds of the pollen. The pollen is selected from hawthorn pollen, rape pollen, thyme pollen, buckwheat pollen, silymarin pollen, chestnut pollen, chrysanthemum pollen, orange pollen, dandelion pollen, tilia europea, pine pollen, acacia pollen, maize pollen, sunflower pollen, astragalus sinicus pollen and the like. The pollen wall-breaking efficiency of the method is up to 99 percent. The sanitation, safety and stability of the pollen product are improved. The method is simple in process, can be operated continuously and is high in yield.

Owner:NANJING NORMAL UNIVERSITY +1

Method for installation cutting tilia miqucliana

ActiveCN107018896AAddress resource shortagesRemoved in timePlant tissue cultureHorticulture methodsObserved SurvivalSurvival rate

The invention belongs to the technical field of plant seedling propagation, and discloses a method for installation efficiently cutting tilia miqucliana. The method comprises the following steps of A, selecting and cultivating a female parent; B, building a cutting cultivation room; C, selecting and treating a cutting medium; D, selecting and treating cutting slips; E, cutting; F, transplanting, fertilizing and managing cutting seedlings. According to the method for installation efficiently cutting the tilia miqucliana provided by the invention, the rootage duration of the tilia miqucliana can be greatly shortened to 15d, the survival rate of cutting is 95 percent or more, and 12 times of cutting can be carried out one year, so that the problem of market resource vacancy of the tilia miqucliana is effectively solved, and the application prospect is wide.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

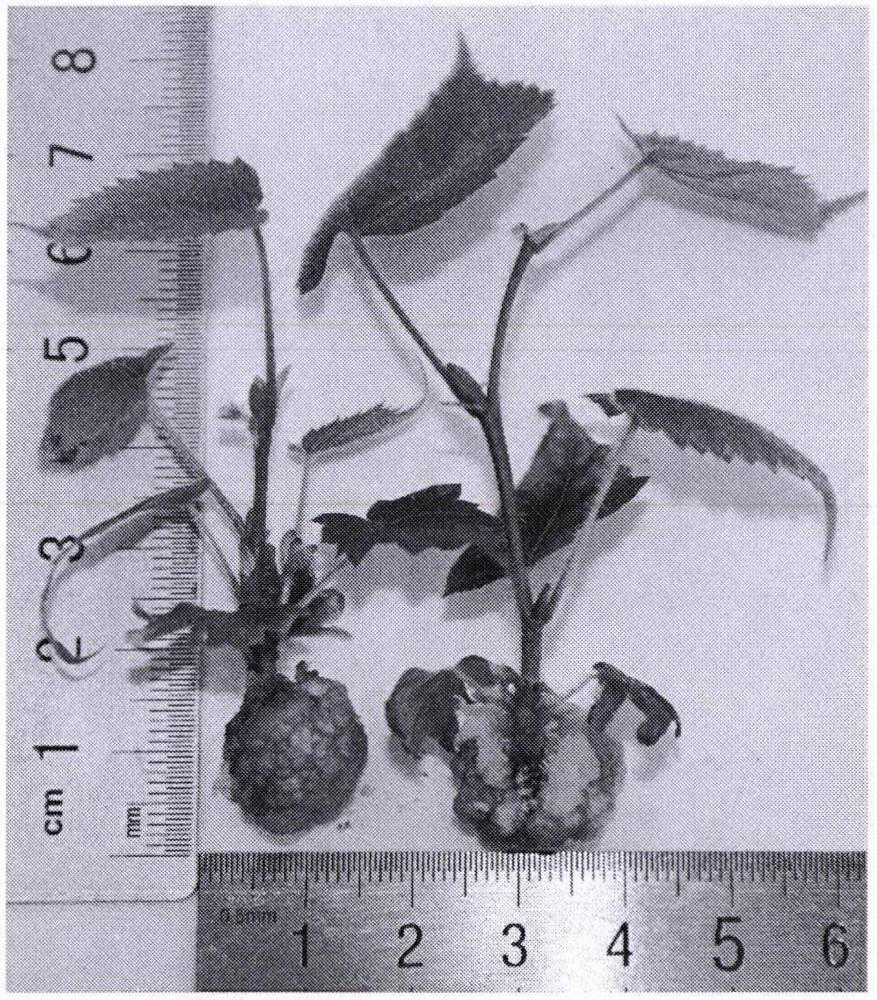

Tilia miqueiana green branch cuttage method with nutrition pot substrates

The invention discloses a tilia miqueiana green branch cuttage method with nutrition pot substrates. The tilia miqueiana green branch cuttage method with nutrition pot substrates comprises the steps of placing nutrition pots loaded with mixed substrates of turf and garden soil in the volume ratio being (2:1) to (3:1) on a cuttage bed, and building a film covering arched shed and a shading shed frame; in the middle ten days of April to the last ten days of June, collecting annual tender twigs as cuttings, under moisture keeping and fresh keeping condition, performing cutting to obtain half-lignified cutting slips of which the length is 10-12cm, reserving one leaf at each top end, and performing cutting off treatment on basal parts; and performing macerating treatment on the cutting slips inrooting liquid, inserting the cutting slips after the macerating treatment in the mixed substrates of the nutrition pots, sequentially spraying mist for replenishing water, spraying sterilizing pesticides, and performing covering with films and shading nets. Through the adoption of the cuttage method provided by the invention, the highest cuttage rooting rate of tilia miqueiana green branches canreach 90%, and root systems of cuttage plantlets are developed; later-stage seedling hardening and transplanting links are simplified, operations are convenient, root systems are not damaged, and transplanting survival and seedling growth are facilitated; and the cuttage bed is arranged without limit by land parcel conditions, the production cost is low, and quick reproduction and production application of tilia miqueiana nursery stocks are facilitated.

Owner:SUZHOU GARDEN DEV +1

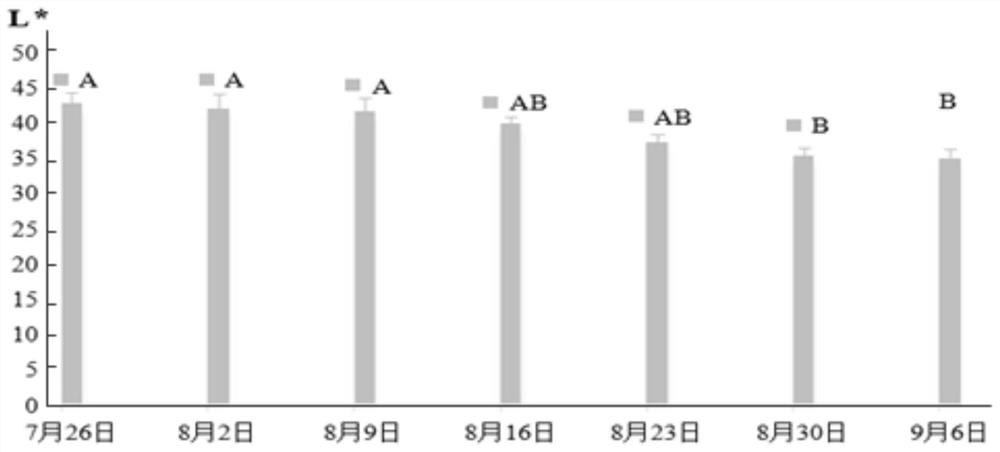

Processing method for improving tilia bast fiber knitting property

The invention belongs to the technical field of tilia bast fiber processing and particularly relates to a processing method for improving tilia bast fiber knitting property. The processing method comprises the following specific methodssteps: performing boiling, freezing and steam and treating fluid dipping treatment on tilia bast fiber and performing temperature-change drying, ultrasonic, variable pressure and constant-temperature drying treatment. In the step of performing boiling, freezing and steam and treating fluid dipping treatment on tilia bast fiber, degradation of hemicelluloses in the tilia bast fiber is effectively inhibited; as the hemicelluloses has an adhesion effect in cell walls, the bonding strength among the tilia bast fiber is enhanced, and the toughness and the breaking resistance of the tilia bast fiber are improved; furthermore, a the color and luster degree of the tilia bast fiber is effectively improved, and sun resistance of the tilia bast fiber is enhanced. In the step of performing temperature-change drying, ultrasonic, variable pressure and constant-temperature drying treatment, conduction resistance of moisture in the tilia bast fiber is reduced, permeability of the tilia bast fiber is improved, the combining capacity between components of the treating fluid and tilia bast fiber cellulose molecules is enhanced, hygroscopicity of the tilia bast fiber is reduced, and dimensional stability of the tilia bast fiber is improved; furthermore, breeding of mould and putrefying bacteria is effectively inhibited, service life of the tilia bast fiber is prolonged, and use quality of the tilia bast fiber is improved.

Owner:阜南县宏达工艺品厂

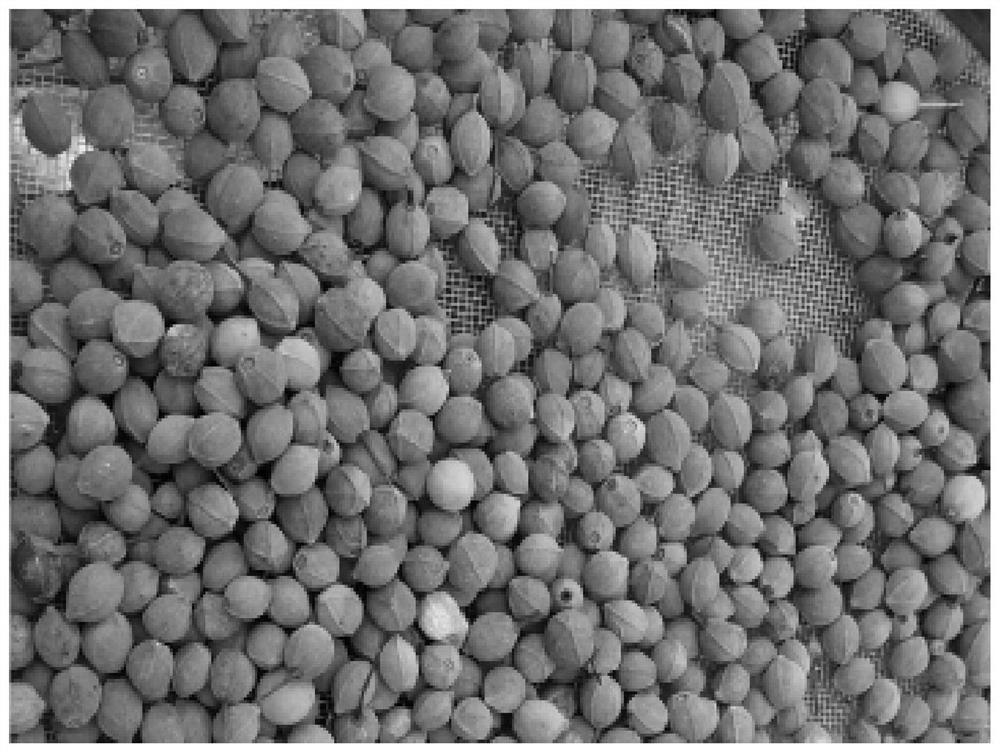

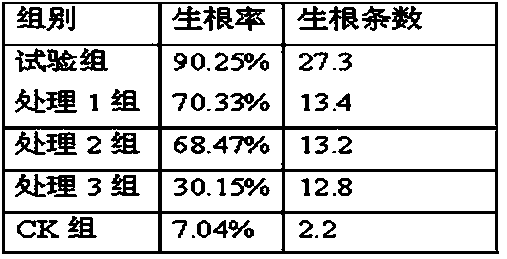

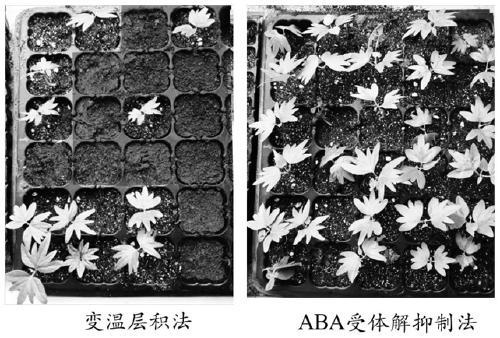

Large-scale breeding method for tilia amurensis

ActiveCN111670745AImprove germination rateThe uniformity of germination is improvedSeed and root treatmentHarvestersBiotechnologyTilia amurensis

The invention relates to the technical field of large-scale breeding of plants and particularly discloses a large-scale breeding method for tilia amurensis. The method comprises the following steps: (1) accurate seed acquisition under quantified detection monitoring; (2) variable-temperature stratification and gibberellin combined seed germination hastening treatment; and (3) plug-tray-plug sowingindustrialized seedling culture. According to the method, a seed collecting occasion is accurately controlled by using correlation between tilia fruit color changes and endogenouse hormone abscisic acid content fluctuations, and the rate of germination and uniformity of seedling emergence of deep-dormant tilia seeds are remarkably improved through a hormone and variable temperature tilia seed treatment mode; and meanwhile, a practical and feasible technical process is provided for large-scale industrialized tilia seedling production.

Owner:BEIJING FORESTRY UNIVERSITY

Dried-ivy mosses nutritive cordial and preparation method thereof

InactiveCN103555490AImprove actual functionsTaste is sweet and palatableAlcoholic beverage preparationChinese liquorHigh fructose

The invention discloses a dried-ivy mosses nutritive cordial and a preparation method thereof. The dried-ivy mosses nutritive cordial is prepared from the following raw materials in parts by weight: 50-90 parts of dried ivy mosses, 15-25 parts of undaria pinnatifida, 10-15 parts of white hyacinth bean, 8-13 parts of euryale ferox, 8-12 parts of spirulina, 20-40 parts of Chinese liquor, 3-4 parts of matrimony vine, 1-2 parts of polygonatum sibiricum, 2-3 parts of galium aparine, 1-3 parts of radix astragali, 2-3 parts of sargentodoxa cuneata, 1-2 parts of herba artemisiae scopariae, 1-2 parts of angelica dahurica, 5-9 parts of tilia honey, 0.02-0.25 part of high fructose syrup, 0.05-0.35 part of rose pure syrup and proper amount of water. The dried-ivy mosses nutritive cordial is abundant in nutrition and health components of dried ivy mosses, is refreshing, fragrant, sweet and palatable; by adding components such as undaria pinnatifida, spirulina and the like into the formula, the nutrition and health functions are increased; and by adding components such as radix astragali, polygonatum sibiricum and the like which have the effects of resisting fatigue and resisting aging, the dried-ivy mosses nutritive cordial is capable of effectively improving human body functions, building up body and helping to keep full energy.

Owner:BENGBU KUNPENG FOOD & BEVERAGE

Tilia americana cuttage technology capable of air purification

InactiveCN107333539AHigh rooting rateImproved callus initiationBiocidePlant growth regulatorsAir purificationBiology

The invention discloses a Tilia americana cuttage technology capable of air purification, wherein detailed instructions are given to material section, architecture of a cuttage bed, selection of a cuttage medium and management after cuttage. The method has the advantages that the rooting rate reaches 33%-60%; the curing starting period is increased by 4-6 days; the cut curing period is increased by 7-10 days; and the rooting period is increased by 6-12 days.

Owner:合肥同创园林科技有限公司

A kind of facility cutting method of Nanjing Linden

ActiveCN107018896BAddress resource shortagesRemoved in timePlant tissue cultureHorticulture methodsObserved SurvivalSurvival rate

The invention belongs to the technical field of plant seedling propagation, and discloses a method for installation efficiently cutting tilia miqucliana. The method comprises the following steps of A, selecting and cultivating a female parent; B, building a cutting cultivation room; C, selecting and treating a cutting medium; D, selecting and treating cutting slips; E, cutting; F, transplanting, fertilizing and managing cutting seedlings. According to the method for installation efficiently cutting the tilia miqucliana provided by the invention, the rootage duration of the tilia miqucliana can be greatly shortened to 15d, the survival rate of cutting is 95 percent or more, and 12 times of cutting can be carried out one year, so that the problem of market resource vacancy of the tilia miqucliana is effectively solved, and the application prospect is wide.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Herbal extract composition

InactiveUS20110123649A1Pleasant tasteSimple compositionBiocideDispersion deliveryMedicineFireberry hawthorn

The present invention relates to the field of herbal compositions. In particular, the present invention is directed to an Improved Herbal Extract Composition comprising a Melissa species extract, an Avena species extract, a Tilia species extract and a unique blend of citrus components. The composition can further comprise at least one additional extract of a plant such as Citrus species, Crataegus species, Panax species, and Lavendula species. The herbal extract composition is useful in numerous ingestible forms including an extract concentrate for food and beverage preparation, additive or enhancer for existing foods and beverages and particularly in the form of a pleasant tasting and soothing beverage.

Owner:DAVID MICHAEL & CO INC +1

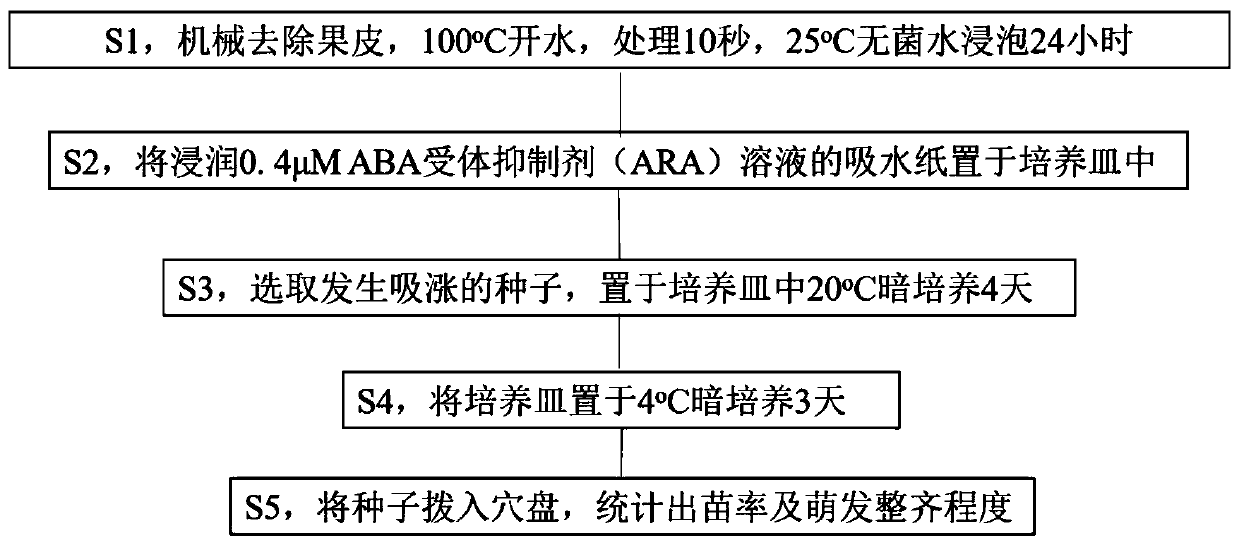

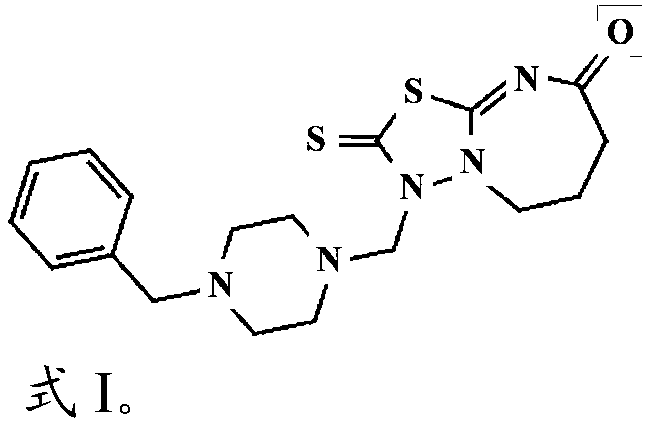

Rapid germination method of tilia tuan seeds

InactiveCN111386787AGerminate fastPromote germinationPlant growth regulatorsBiocideBiotechnologyGermplasm

The present invention relates to a rapid germination method of tilia tuan seeds and belongs to the technical field of forest tree genetic breeding. The germination method comprises the following steps: 1) treating tilia tuan seeds at 90-100 DEG C for 2-10 s and soaking the tilia tuan seeds in water at 24-26 DEG C for 24-48 h; 2) conducting a first dark culture of the swollen seeds in an abscisic acid acceptor inhibitor; 3) conducting a second dark culture of the tilia tuan seeds after the first dark culture; and 4) transferring the seeds after the second dark culture to a substrate for cultivation. The germination method can complete germination of the tilia tuan seeds at low cost, quickly and efficiently, and provides a strong technical support for preservation of tilia tuan germplasm resources and selection and breeding of excellent new varieties.

Owner:BEIJING FORESTRY UNIVERSITY

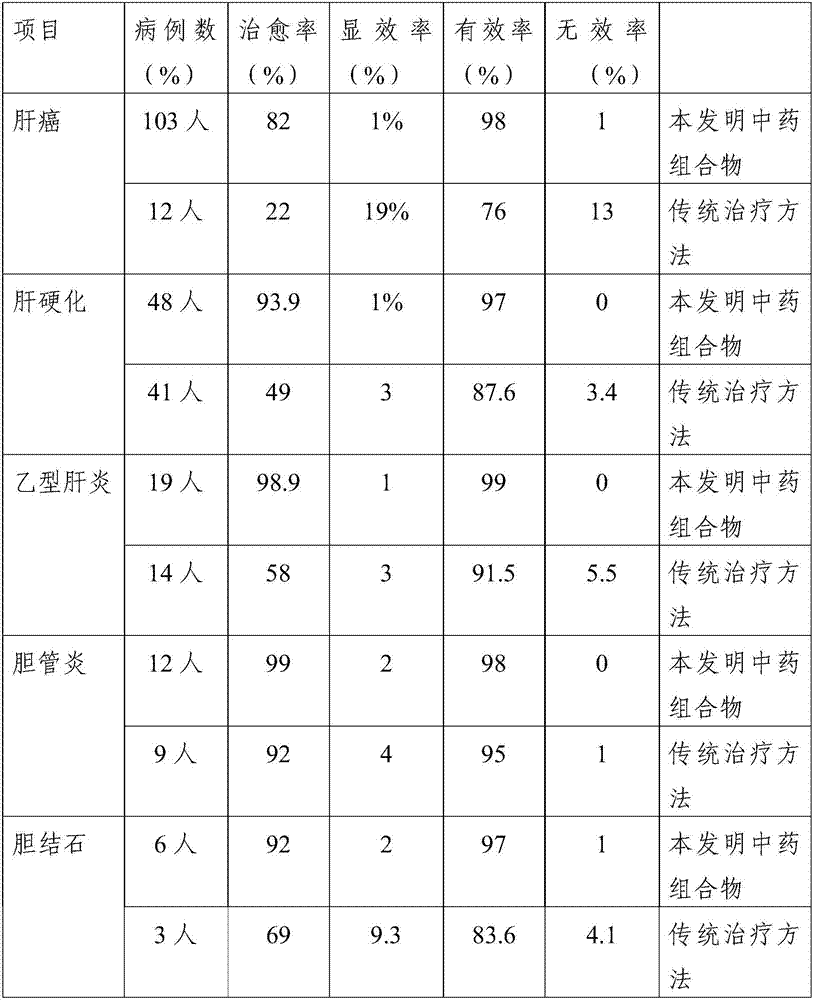

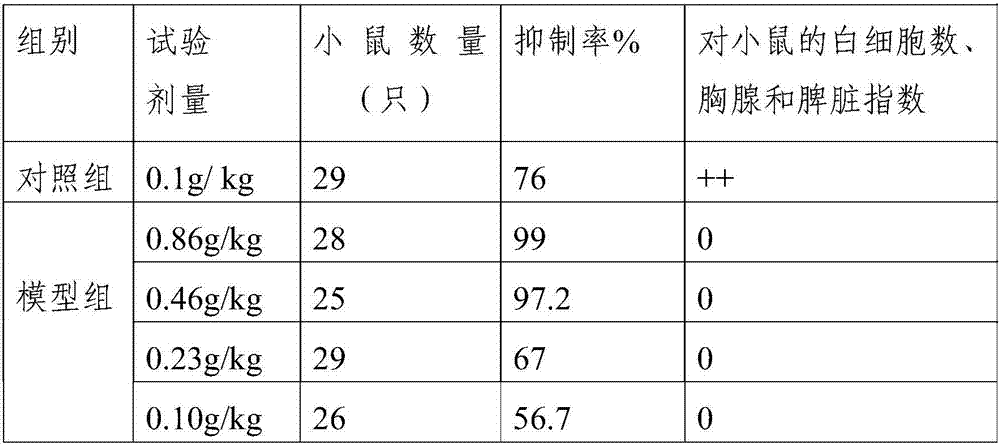

Traditional Chinese medicine combination for treating hepatobiliary diseases and preparation method thereof

InactiveCN107397776AHas an immunomodulatory effectRegulate hormonesOrganic active ingredientsDigestive systemHepatobiliary diseaseGanoderma lucidum

The invention discloses a traditional Chinese medicine combination for treating hepatobiliary diseases and a preparation method thereof. The traditional Chinese medicine combination is composed of the following raw materials, by weight, of 200-300 parts of ganoderma lucidum soak solutions, 30-60 parts of antrodia camphorata polysaccharide, 70-100 parts of selenium-enriched pleurotus ostreatus fruiting body powder, 10-20 parts of bear bile powder, 100-200 parts of panax notoginseng powder, 80-120 parts of rock candies and 180-220 parts of tilia honey. The traditional Chinese medicine combination has good curative effect on treating liver cirrhosis, viral hepatitis type B, cholangitis, gallstones, a bile duct cancer and a gallbladder cancer.

Owner:林树芳

Dry extrusion wall-breaking method for pollen

InactiveCN101518304BImprove broken rateImprove hygieneFood preparationPolygonum fagopyrumPine pollen

A dry extrusion wall-breaking method for pollen comprises the following steps of: (1) soaking pollen in pure water for 30 minutes and filtering the pollen to remove dust and impurities; (2) adding the pollen obtained in step (1) into a food screw extruder to extrude the pollen at a cavity temperature of between 40 and 65 DEG C, a pressure of between 2 and 12 MPa, a rotation speed of 14 to 60 R / minpollen obtained in step (1) into a food screw extruder to extrude the pollen at a cavity temperature of between 40 and 65 DEG C, a pressure of between 2 and 12 MPa, a rotation speed of 14 to 60 R / minand a stroke of 80 to 150 centimeters, and injecting out the pollen at a high speed from a die opening with a 2 to 6 millimeter diameter for wall breaking; and (3) drying the pollen for 1 to 2 hoursunder reduced pressure and filling the pollen in bags for package to obtain the product. The pollen can be pure pollen or a mixture of any several kinds of the pollen. The pollen is selected from hawthorn pollen, rape pollen, thyme pollen, buckwheat pollen, silymarin pollen, chestnut pollen, chrysanthemum pollen, orange pollen, dandelion pollen, tilia europea, pine pollen, acacia pollen, maize polhorn pollen, rape pollen, thyme pollen, buckwheat pollen, silymarin pollen, chestnut pollen, chrysanthemum pollen, orange pollen, dandelion pollen, tilia europea, pine pollen, acacia pollen, maize pollen, sunflower pollen, astragalus sinicus pollen and the like. The pollen wall-breaking efficiency of the method is up to 99 percent. The sanitation, safety and stability of the pollen product are improved. The method is simple in process, can be operated continuously and is high in yield.

Owner:NANJING NORMAL UNIVERSITY +1

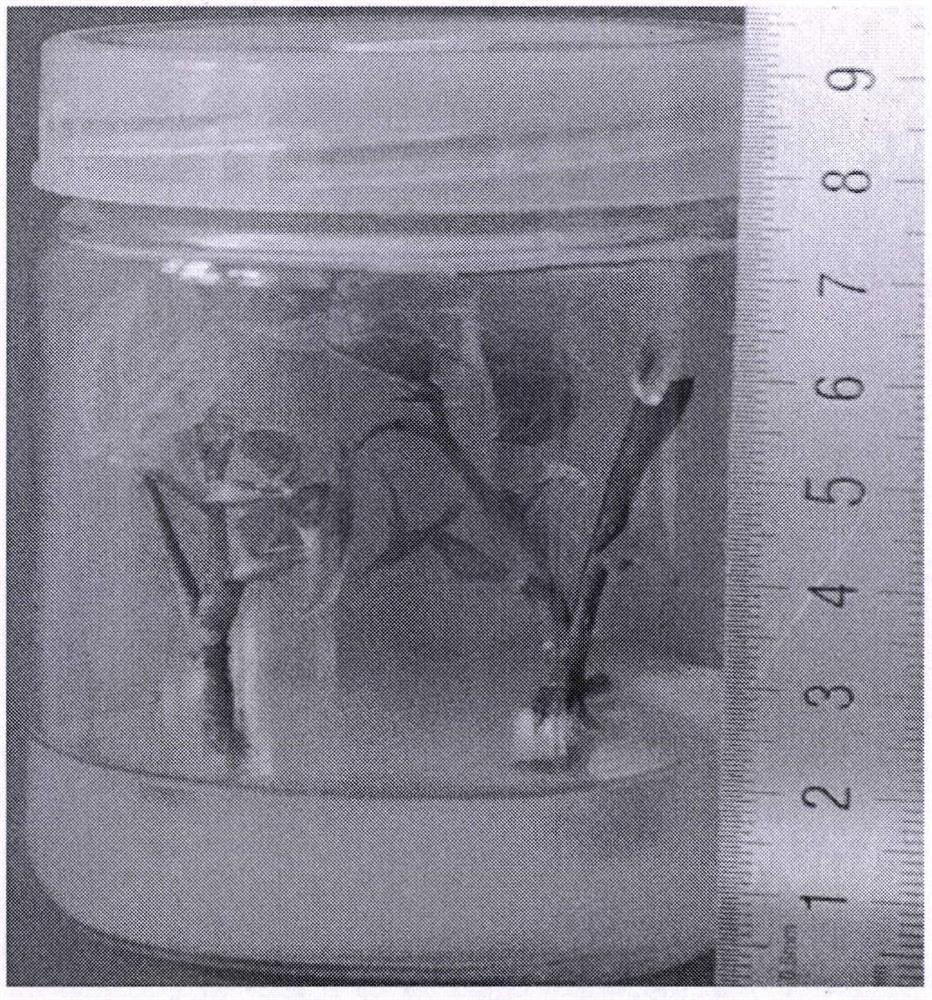

A Simplified Tissue Culture Method of Tilia microphylla

ActiveCN113057099BInduced efficiency dropIncrease success rateHorticulture methodsPlant tissue cultureAxillary budTilia × europaea

The invention discloses a simplified Tilia microphylla tissue culture method, which belongs to the technical field of plant tissue culture. The present invention comprises the following steps: 1) Collect the bud strips with axillary buds on healthy plants 20-40 days after the spring buds germinate, and after surface disinfection, intercept the stems with buds and inoculate them in induction medium for cultivation; 2) cut Remove the axillary bud bud strips in step 1), intercept the stem section with 1 bud, and inoculate it in the induction medium; 3) subculture the adventitious buds obtained in step 2); 4) grow the adventitious buds in step 3) to 2.0-3.0cm adventitious buds were transferred to the rooting medium to obtain aseptic seedlings; 5) Transfer the aseptic seedlings obtained in step 4 into the plug matrix, and cultivate the seedlings in the artificial greenhouse. The invention has strong versatility, simple operation steps, and can effectively realize the germplasm preservation and rapid propagation of different varieties of Tilia microphylla.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

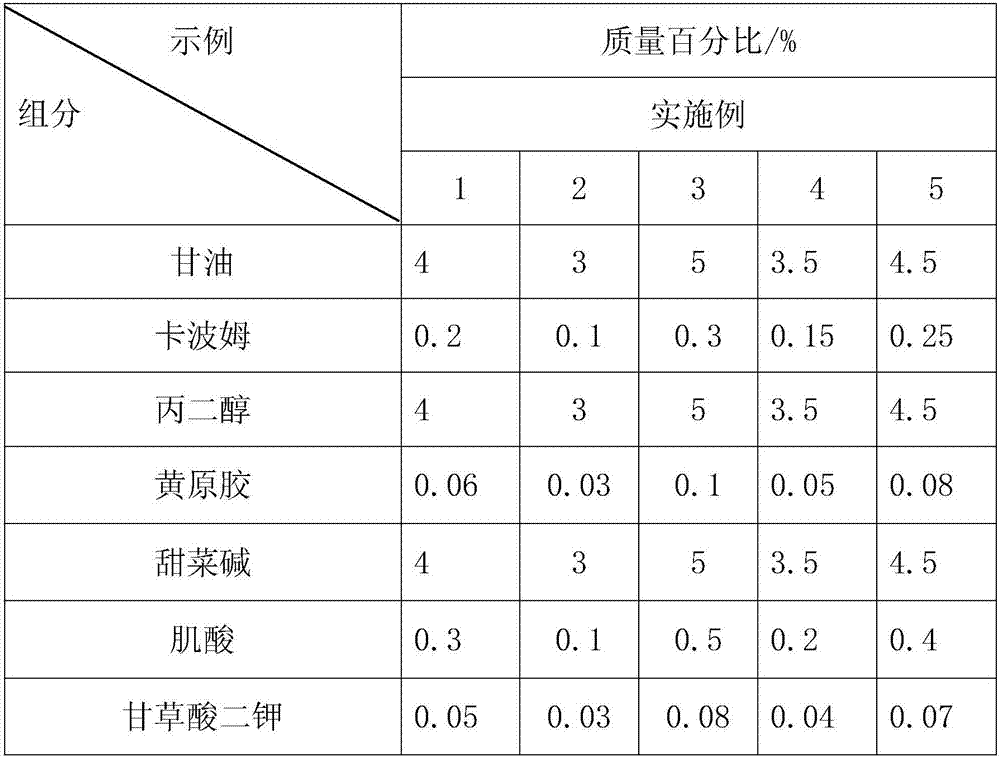

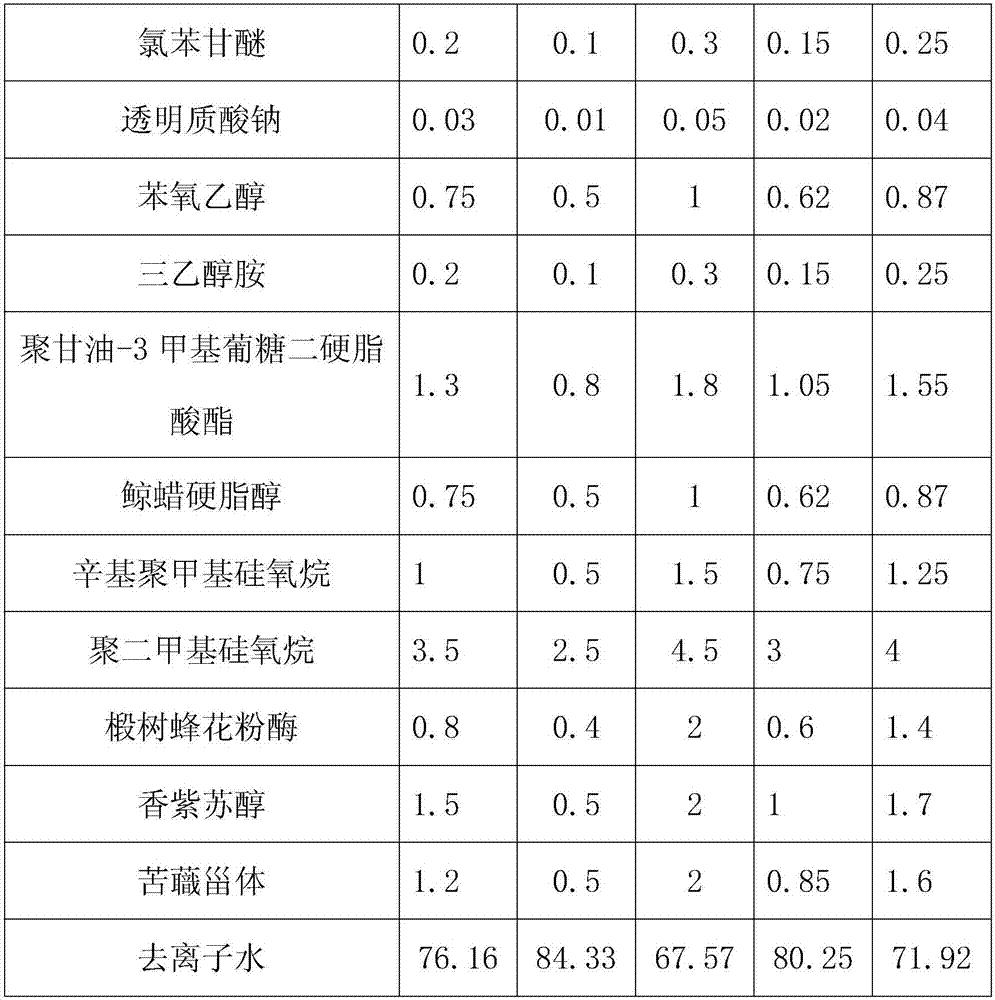

Anti-acne and freckle-removing mask

InactiveCN107496193AImprove permeabilityTo promote metabolismCosmetic preparationsToilet preparationsBetaineIrritation

The invention discloses an anti-acne and freckle-removing facial mask, which comprises components such as linden bee pollen enzyme, sclareol, picrosteroid, glycerin, propylene glycol, betaine, sodium hyaluronate and the like. In the present invention, the compound use of linden bee pollen enzyme, sclareol and picrosteroid can exert the best skin care effect: linden tree bee pollen enzyme can promote cell metabolism and accumulate harmful substances, thereby reducing cell damage and pigmentation deposition; bitter steroids can scavenge free radicals and reduce cell structure damage caused by lipid peroxidation; sclareol can further inhibit microbial reproduction. The ingredients act synergistically to achieve good anti-acne and anti-pigmentation effects; and can improve facial microcirculation, promote skin repair, and maintain skin health: the mask of the present invention is high in safety, mild and non-irritating, and has a good Permeable, can deeply replenish and lock water, and deeply nourish the skin.

Owner:FOSHAN SANSHUI DISTRICT JIAHUA CHEM RES INST GENERAL PARTNERSHIP

A kind of medium and culture method for improving tilia callus induction rate

ActiveCN113179952BHigh induction rateHigh speedAfforestationHorticulture methodsBiotechnologyTyrosine

Owner:JILIN CITY ACADEMY OF FORESTRY

Method for making brassica juncea oil

InactiveCN106701305AGolden colorMellow fragranceDigestive systemDermatological disorderWater vaporImpurity

The invention relates to a method for making brassica juncea oil. The method comprises the following steps of: selecting brassica juncea granules which are free of impurity and full in granule; (2) frying, namely, turning and frying the selected brassica juncea granules in a large iron pot, heating the large iron pot with strong fire and soft fire in sequence, wherein the temperature is within 150 DEG C; (3) grinding, namely, grinding the fried brassica juncea granules into powder by using a stone mill; (4) softening, namely, softening the grinded brassica juncea granules for 24 hours in a softening chamber, and controlling the temperature of the softening chamber to be 32-46 DEG C; (5) steaming, namely, steaming the softened brassica juncea granules in a large cage with vapor for 1-2 hours at 95-100 DEG C; (6) wrapping stacks, and settling the stacks, namely, wrapping the steamed brassica juncea granules into blank cakes by using tilia barks, and stacking together; and (7) squeezing, namely, squeezing the cakes, thereby obtaining the brassica juncea oil. By adopting the method, raw material production, squeezing processing and product sale are all independently implemented and managed, so that the product purity can be ensured; in addition, the produced brassica juncea oil is golden yellow in color, mellow in fragrance, long-lasting in aftertaste and thick and bright in oil texture.

Owner:李建明

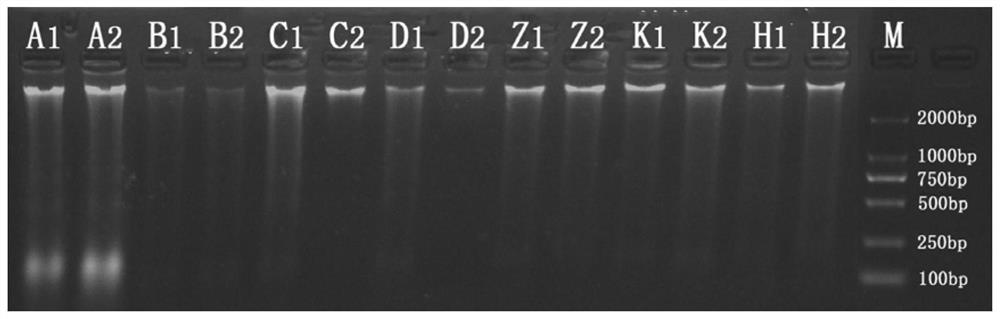

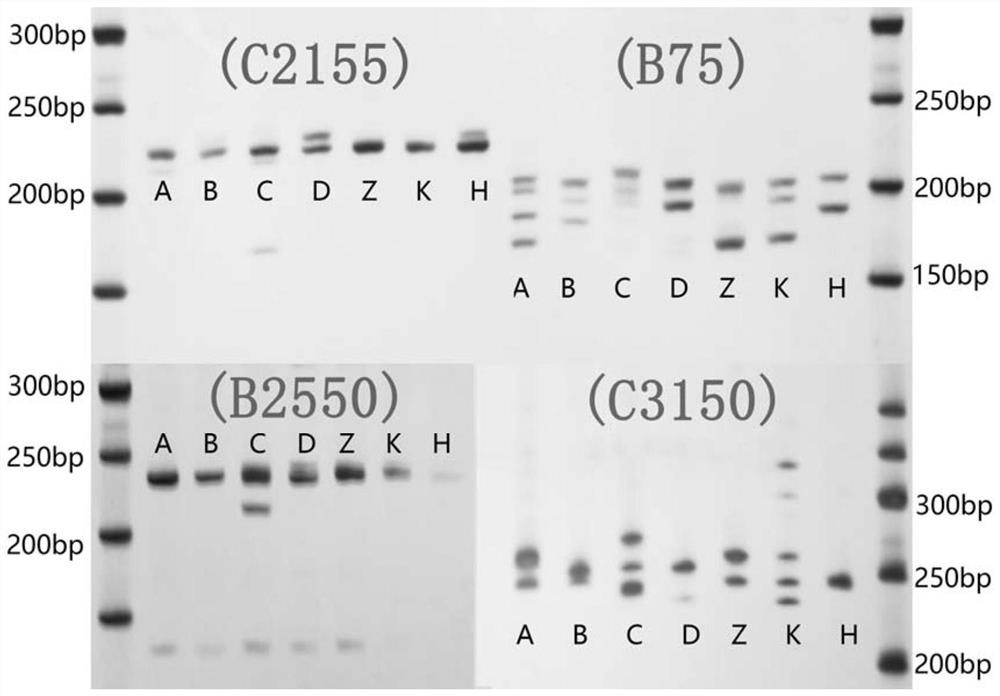

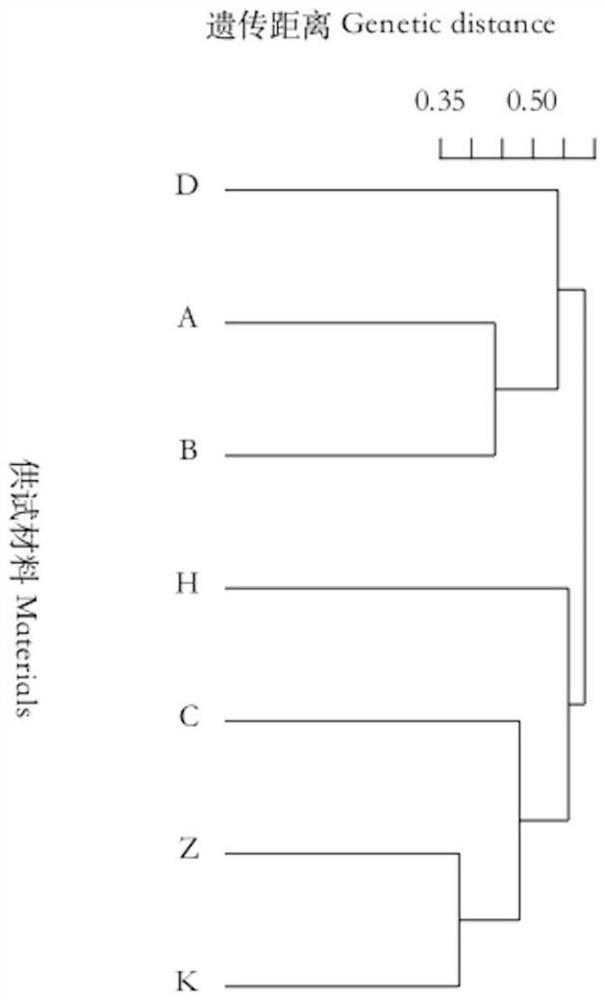

Transcriptome-based Tilia est-ssr primers and their screening methods and applications

ActiveCN110951911BConvenient researchPromote application developmentMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyGerm plasm

The invention discloses a set of EST-SSR molecular markers developed based on a full-length transcriptome sequence of tilia miqueliana and relates to 27 pairs of primers in all with nucleic acid sequences shown in SEQ ID No. 1-54 of a sequence listing. The 27 pairs of EST-SSR markers disclosed by the invention are SSR amplification primers obtained through screening candidate SSR loci based on thetranscriptome sequence and carrying out designing, are verified as definite SSR markers through taking different species of this tilia as materials and carrying out amplification by selecting genomicDNA and have the advantages of rich polymorphism, stability in amplification, good repeatability, codominance, easiness in detection and the like. This group of markers fill up a blank in codominantmarkers of the tilia, belong to the fields of variety identification, genetic pedigree analysis, germ plasm resource protection, assisted breeding and the like of plants of this tilia and can be usedfor greatly promoting researches and development application of tilia resources.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Procedure and extraction of a regenerative product for vital organs and a by-product for cutaneous use

A procedure and extraction of a regenerative product and a by-product for cutaneous use consisting of an infusion based on one litre of water boiled at between 95° and 100° centigrade and where, for said quantity of water, the following products must be added, quantified by weight:12 g rosemary (Rosmarinus officinalis)6 g eucalypt (Eucaliptus camaldulensis)6 g thyme (Thymus vulgaris)6 g bayleaf (Laurus nobilis)3 g linden flower (Tilia sp.)3 g fresh mint (Mentha ssp)3 g oregano (Origanum vulgare)

Owner:CARBALLO DE SALES MANUEL

Cutting propagation method for tilia hirsutella

PendingCN113973599AReduce manufacturing costShort breeding periodHorticulture methodsVegetative propogationEconomic benefitsDrug treatment

The invention relates to the technical field of cultivation and propagation of tilia hirsutissima, in particular to a cutting propagation method for tilia hirsutissima, which is different from a conventional cutting slip collection method and comprises the following steps: firstly, building a cutting orchard, performing drug treatment on cutting slips and a substrate before cutting, and performing environment controlling on the tilia hirsutissima after cutting. According to the cutting propagation method for the tilia hirsutissima, the tilia hirsutissima cuttage cultivation can be in a manual control range, a large number of seedlings can be propagated in a short period, the seedlings can be transplanted to a field in the current year, and seedlings can be formed in the current year, in general, the cutting propagation method for the tilia hirsutissima has the advantages of being simple in cuttage technology, high in survival rate, rapid in propagation expanding, high in propagation coefficient, short in seedling raising period and the like. The production cost of tilia hirsutella breeding is greatly reduced, and good economic benefits, social benefits and ecological benefits are achieved.

Owner:河南林业职业学院 +1

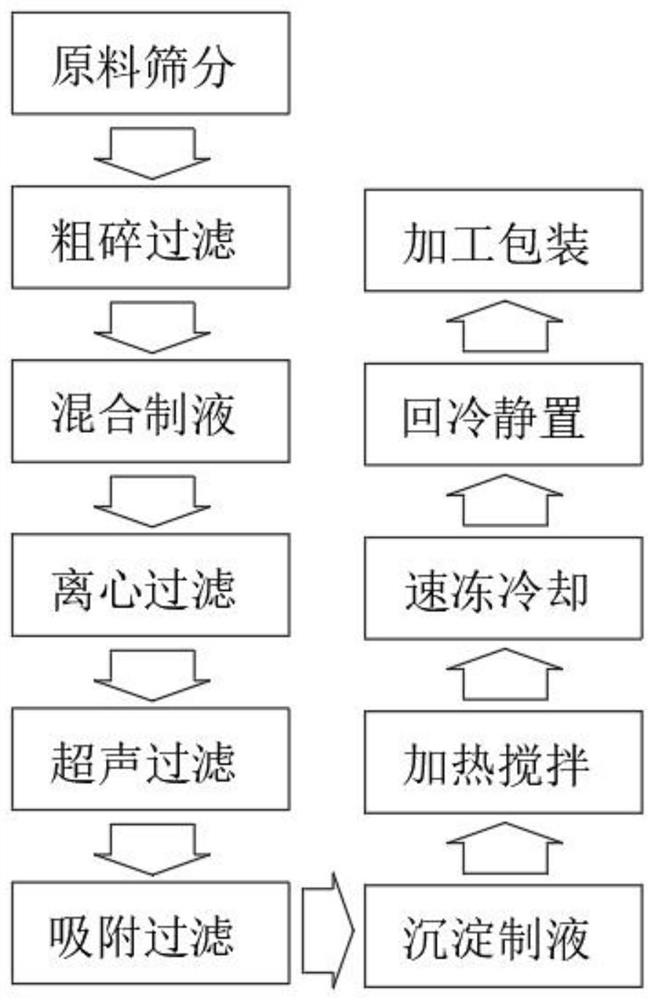

Extraction method of tilia europaea flower essence

InactiveCN112370388AReduce allergiesHigh preparation rateCosmetic preparationsToilet preparationsSkin sensitizationTilia × europaea

The invention discloses an extraction method of tilia europaea flower essence. The extraction method of the tilia europaea flower essence comprises the following steps: selecting fresh tilia europaeaflowers, screening raw materials, performing coarse crushing, performing filtering, performing mixing to prepare liquid, performing centrifugal filtering, performing ultrasonic filtering, performing adsorbing and filtering, performing precipitating and preparing liquid, performing heating and stirring, performing quick freezing and cooling, performing recooling and standing, and performing processing and packaging. According to the extraction method of tilia europaea flower essence provided by the invention, in the preparation process, through multiple times of coarse crushing, precipitating and filtering, allergy source impurities in the essence are effectively reduced, and the skin allergy condition caused by the impurities is reduced; besides, by adding matrix oil, the characteristics of essence preparation liquid mixture smell selection and composite product diversity are improved, the smell loss of the preparation liquid can be effectively reduced through the cold storage packaging mode, and besides, due to the infiltration type packaging mode, the situation that water vapor remains on a bottle wall to influence the quality of prepared liquid finished products i, is avoided.

Owner:深圳市亚森金元科技有限公司

Method of quickly acquiring Tilia plant primary aseptic material

InactiveCN109479711AUnsleepSolve pollutionHorticulture methodsPlant tissue cultureMercury DichlorideGibberellin

The invention provides a method of quickly acquiring a Tilia plant primary aseptic material. The method includes: S1, treating a culture medium, to be specific, disinfecting wet sand to obtain a linden seed culture medium; S2, treating linden seeds, to be specific, using concentrated sulfuric acid, mercury dichloride and gibberellin successively to treat linden seeds; S3, acquiring an aseptic material, to be specific, culturing the linden seeds treated in step S2, in the culture medium of S1. River sand is utilized herein as a culture medium for primary aseptic seedlings; dormancy of linden seeds can be quickly eliminated, production cost can be greatly reduced, the pollution problem in tissue culture can be effectively avoided, seedling yield is high, and the method has a good actual application prospect.

Owner:SHANDONG FOREST SCI RES INST

A method for improving the survival rate of wild Nanjing Tilia transplantation

ActiveCN104082096BImprove transplant survivalRealize artificial domestication and cultivationHorticulture methodsForestryBiotechnologyTilia miqueliana

The invention discloses a method for improving the survival rate of wild Nanjing linden transplantation, which comprises the following steps: (1) arrangement of nursery ground; (2) transplantation of seedlings; (3) treatment of seedlings; (4) watering of rooting promoters; (5) Seedling management. The survival rate of transplanting wild Nanjing Tilia by this method is over 90.0%, which is of great significance for ex situ preservation of Nanjing Tilia germplasm gene resources, preventing the loss of excellent Nanjing Tilia genetic genes, and further research, development and utilization of wild Nanjing Tilia resources.

Owner:中林绿苑江苏生态环境有限公司

Steamed stuffed bun with sugarcane and safflower and preparation method thereof

InactiveCN104207014AFull of nutritionGood for promoting blood circulation and moistening drynessFood preparationMonosodium glutamateAdditive ingredient

The invention discloses a steamed stuffed bun with sugarcane and safflower and a preparation method thereof. The steamed stuffed bun is prepared from following raw materials including, by weight, 600-700 parts of flour, 9-14 parts of a nutritional additive, 20-30 parts of carambola, 4-9 parts of fresh ginger candies, 5-10 parts of clam flesh, 10-30 parts of wax gourd, 0.6-1 part of lactic acid bacteria, 10-20 parts of grapes, 4-5 parts of salt, 2-3 parts of bagasse, 2-10 parts of white sesame seeds, 1-4 parts of jam, 0.5-0.9 parts of cordyceps sobolifera, 1-1.2 parts of safflower seeds, 0.5-1 part of eriophorum comosum, 1-2 parts of tilia omeiensis, 1-2 parts of beautiful millettia roots, 1-2 parts of monosodium glutamate, a proper amount of olive oil, a proper amount of water, and a proper amount of fresh yeast. With the added raw materials, including the carambola, the fresh ginger candies, the clam flesh and the like, the steamed stuffed bun is rich in nutrition. In addition, the steamed stuffed bun contains various Chinese herbal medicine components so that the steamed stuffed bun, when being often eaten, has effects of activating blood and moistening dryness, relieving cough and asthma, and moving qi and freeing collaterals.

Owner:马鞍山市海滨水产品生态养殖专业合作社

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com