A kind of preparation method of high flux reverse osmosis membrane and obtained high flux reverse osmosis membrane

A reverse osmosis membrane, high-flux technology, applied in osmosis/dialysis water/sewage treatment, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of the limited flux-enhancing capacity of reverse osmosis membranes and the difficulty of industrialized production. , the preparation method is cumbersome and other problems, to achieve the effect of reducing water conduction resistance, conducive to adsorption, and improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

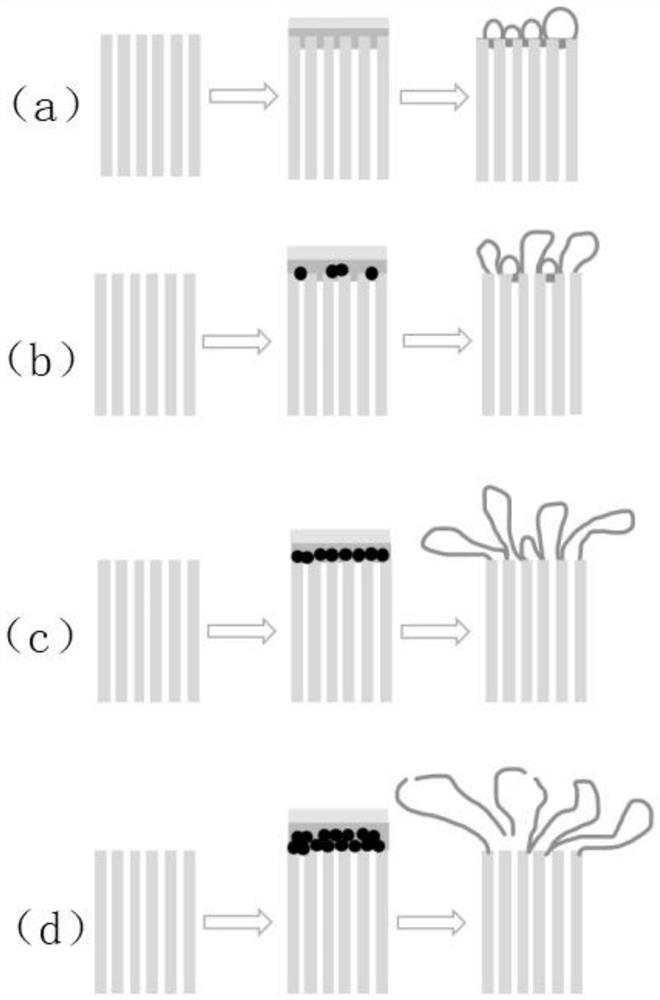

Method used

Image

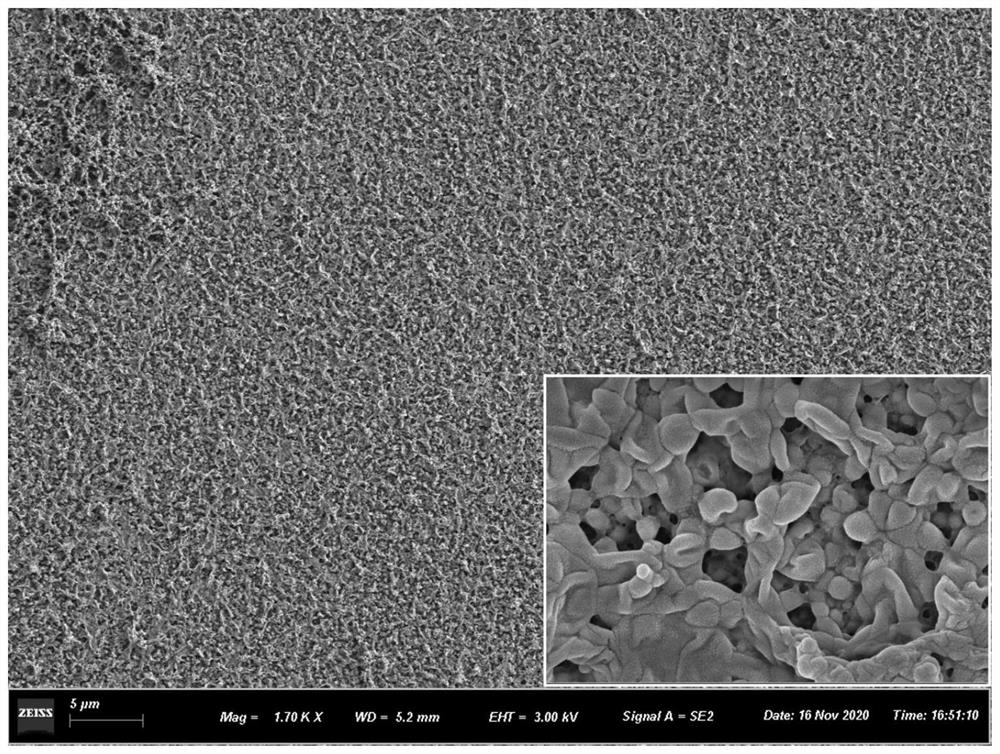

Examples

Embodiment 1

[0032] A preparation method of a reverse osmosis membrane, the reverse osmosis membrane is a high flux reverse osmosis membrane, specifically comprising the following steps:

[0033]Step 1. Preparation of support structure: prepare 18wt% polysulfone solution, filter to remove undissolved impurities, and after vacuum degassing, use a scraper to evenly coat the polymer solution on the non-woven fabric, and then place it in a pure water coagulation bath at 15°C Transform into a membrane after 1 minute in the middle, and obtain a porous support membrane after washing;

[0034] Step 2, in-situ deposition of nano-calcium carbonate: soak the support structure prepared in step 1 in CaCl with a concentration of 0.1mol / L 2 After a period of time in the aqueous solution (specifically 3min), it was transferred to 0.1mo / L Na 2 CO 3 In the aqueous solution, after washing three times with pure water, the support structure with nano-calcium carbonate deposited in situ was obtained;

[0035...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is: in the step 2, CaCl 2 and Na 2 CO 3 The concentrations of the aqueous solutions are all 0.05mol / L, and the others remain unchanged.

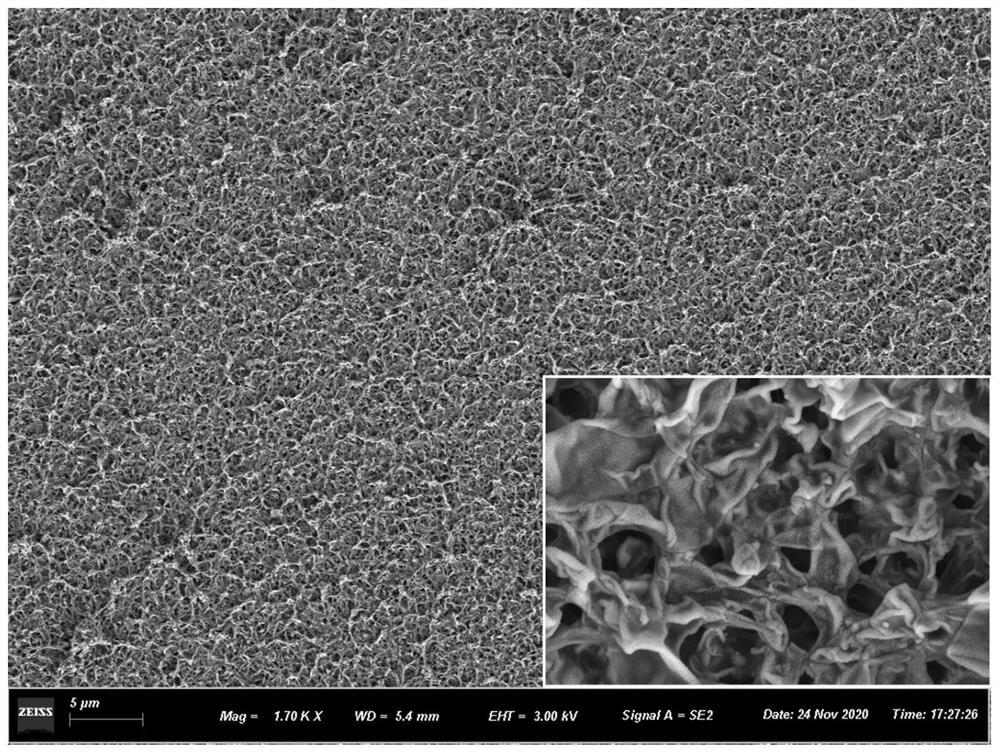

Embodiment 3

[0043] The difference between embodiment 3 and embodiment 1 is: in the step 2, CaCl 2 and Na 2 CO 3 The concentrations of the aqueous solutions are all 0.6mol / L, and the others remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com