Schottky part and semiconductor making process for making same

A technology for semiconductors and components, which is applied in the field of semiconductor manufacturing of Schottky components, can solve the problems of reduced ion concentration, increased conduction resistance, and increased cost, and achieves the effect of reducing cost and reducing conduction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

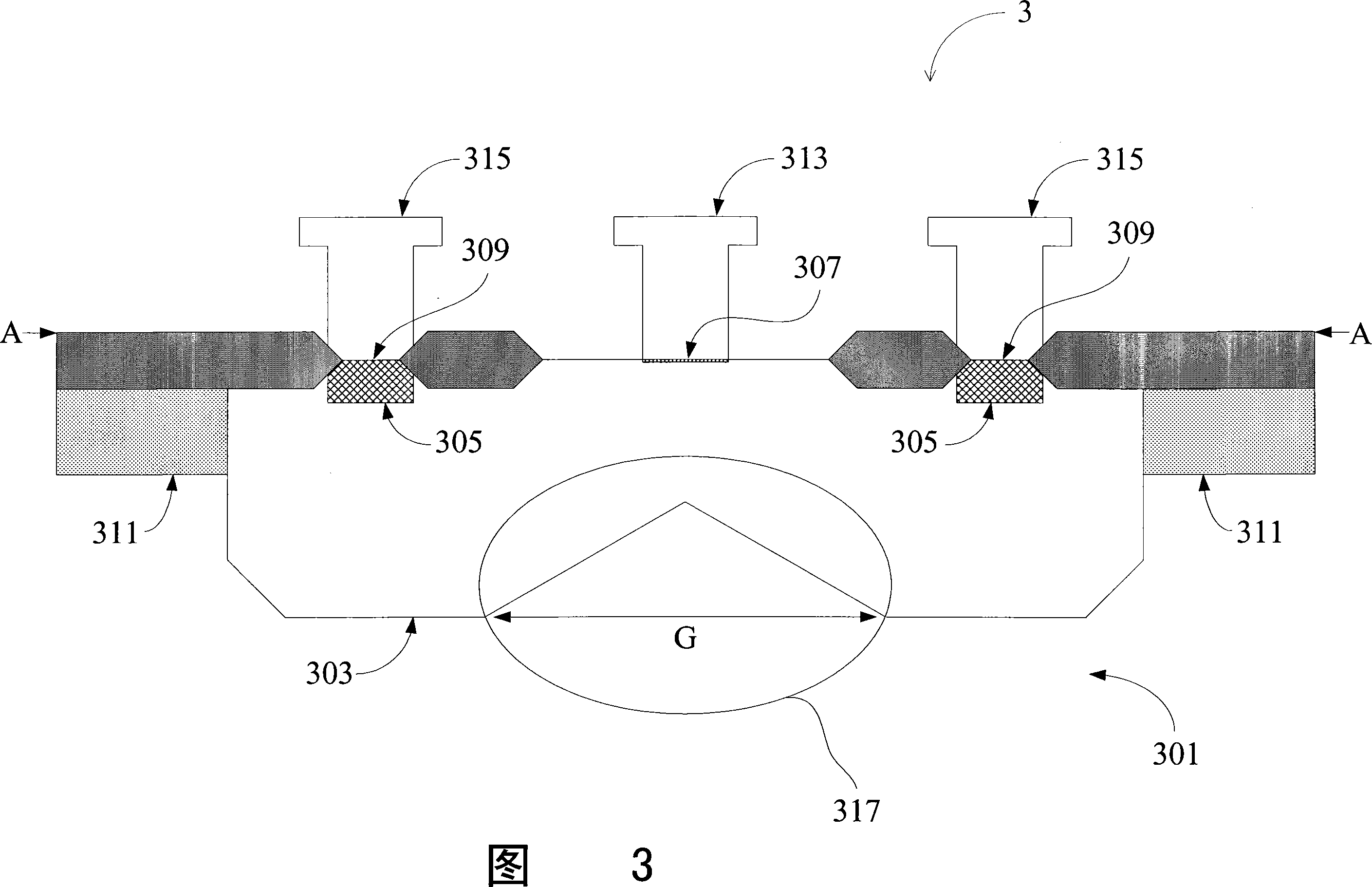

[0016] According to the first embodiment, the P-type substrate 301 is doped with P-type ions, and the N-type deep well region 303 is doped with N-type ions and formed on the P-type substrate 301 . The heavily doped region 305 is heavily doped with N-type ions and formed in the N-type deep well region 303 . The Schottky junction 307 contacts the Schottky electrode 313 with the N-type deep well region 303 . Ohmic junction 309 contacts ohmic electrode 315 with heavily doped region 305 . And the N-type deep well region 303 also has a geometric notch formed in a notch region 317 and has a lateral dimension G. As shown in FIG. The geometric notch region 317 is formed under the Schottky junction 307 , and the lateral dimension G can be used to adjust the breakdown voltage of the Schottky device 3 .

[0017] The second embodiment of the present invention is another Schottky device 4 shown in FIG. 4 and FIG. 5 . FIG. 4 is a top view showing the Schottky device 4 , and FIG. 5 is a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com