Bridging multi-chip packaging structure

A multi-chip packaging and chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of poor characteristic impedance matching, signal attenuation, poor power supply and grounding effect, etc. Signal attenuation, to avoid the effect of impedance mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

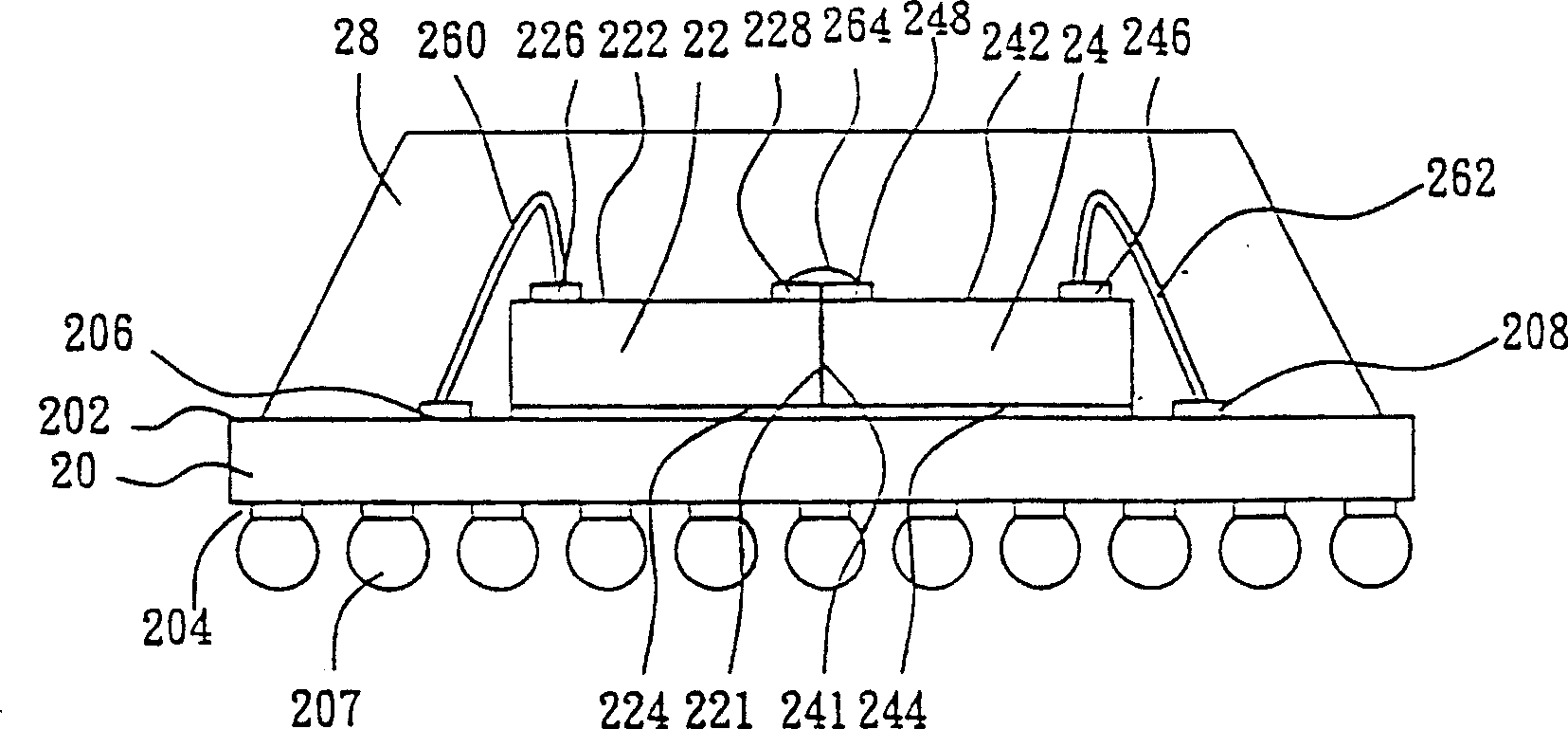

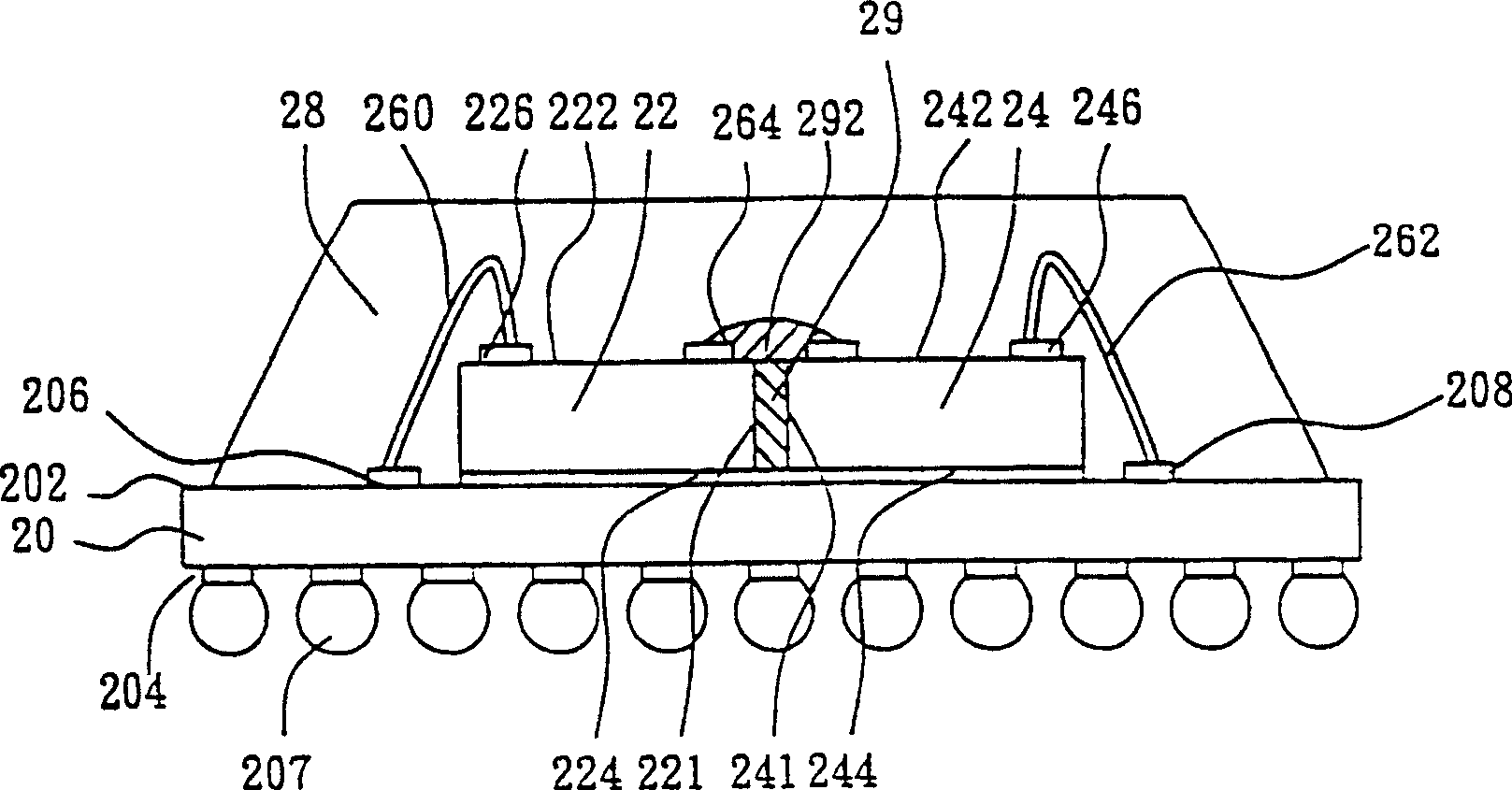

[0066] figure 2 A bridged multi-chip package structure according to the first preferred embodiment of the present invention is disclosed, which mainly includes a carrier 20 , a first chip 22 , a second chip 24 and a conductive bump 264 . The carrier board 20 has an upper surface 202 and a corresponding lower surface 204 , and a plurality of carrier board contacts 206 , 208 are located on the upper surface of the carrier board 20 . The first chip 22 has a first active surface 222 , and the first chip 22 also has at least one first contact 226 disposed on the first active surface 222 of the first chip 22 . Likewise, the second chip 24 has a second active surface 242 , and the second chip 24 also has at least one second contact 246 disposed on the second active surface 242 of the second chip 24 . Wherein, the first chip 22 is arranged on the carrier 20 with its back side (the first back side 224) and through an adhesive material (such as silver glue); An adhesive material (suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com