Large-capacity nickel-hydrogen square battery with low internal resistance

A square battery, low internal resistance technology, used in alkaline batteries, battery pack components, alkaline battery electrodes, etc., can solve the problem that deep active substances cannot participate in chemical reactions in time, the charge diffusion resistance is large, and gas evolution is easy to occur. problems, to achieve the effect of reducing conduction resistance, improving current charging rate and life, and reducing gassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

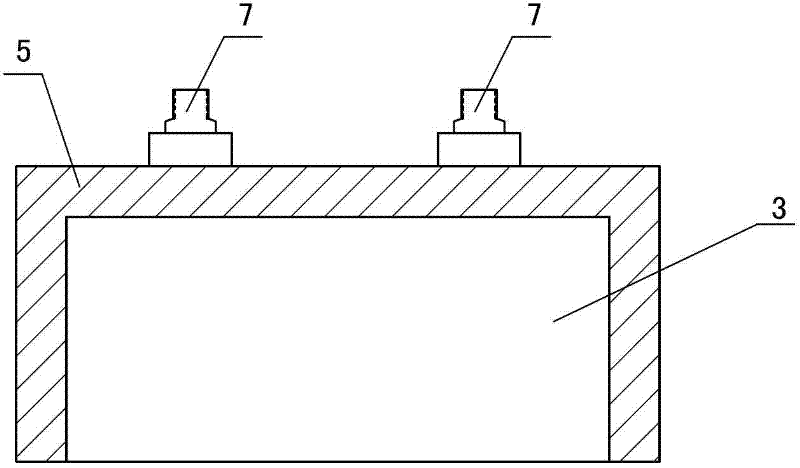

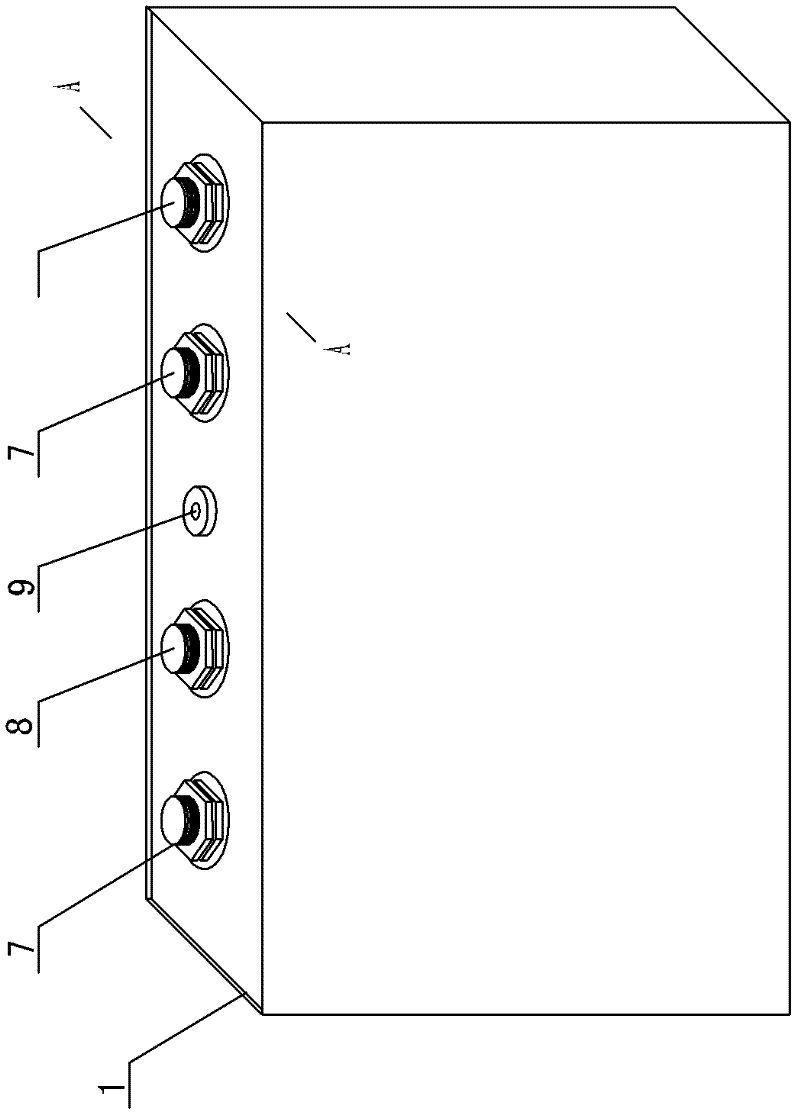

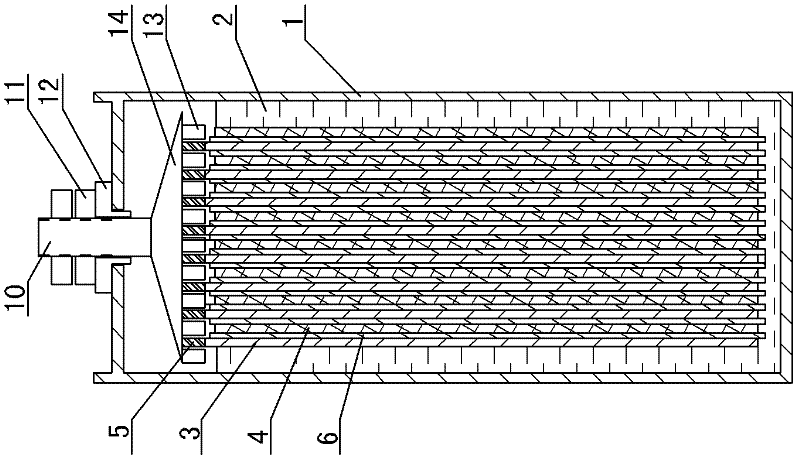

[0020] exist Figure 1-3 In the shown embodiment: it includes a housing 1 filled with electrolyte solution 2, and a plurality of positive plates 3 and a plurality of negative plates 4 soaked in electrolyte 2, wherein each positive plate 3 and each negative plate 4 A guide body 5 is provided on the outer edge of each pole, the positive plate 3 and the negative plate 4 are arranged at intervals, and an insulating diaphragm 6 is used between adjacent plates, and the guide body 5 on the positive plate 3 is connected to the positive column assembly 7 , the guide body 5 on the negative plate 4 is connected to the negative pole assembly 8, the thickness of each positive plate 3 is less than 0.4 mm, the thickness of each negative plate 4 is less than 0.25 mm, and the guide body 5 is arranged on each positive plate 3 and On one long side of each negative plate 4, there are 1 to 3 positive pole assemblies 7 and negative pole assemblies 8 equal to each other. Each positive pole assembly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com